Rapidly convertible hybrid aircraft and manufacturing method

a hybrid aircraft and rapid technology, applied in the field of roadable aircraft, can solve the problems of affecting the operation of the operator's visibility, and affecting the folding and storage of the wings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

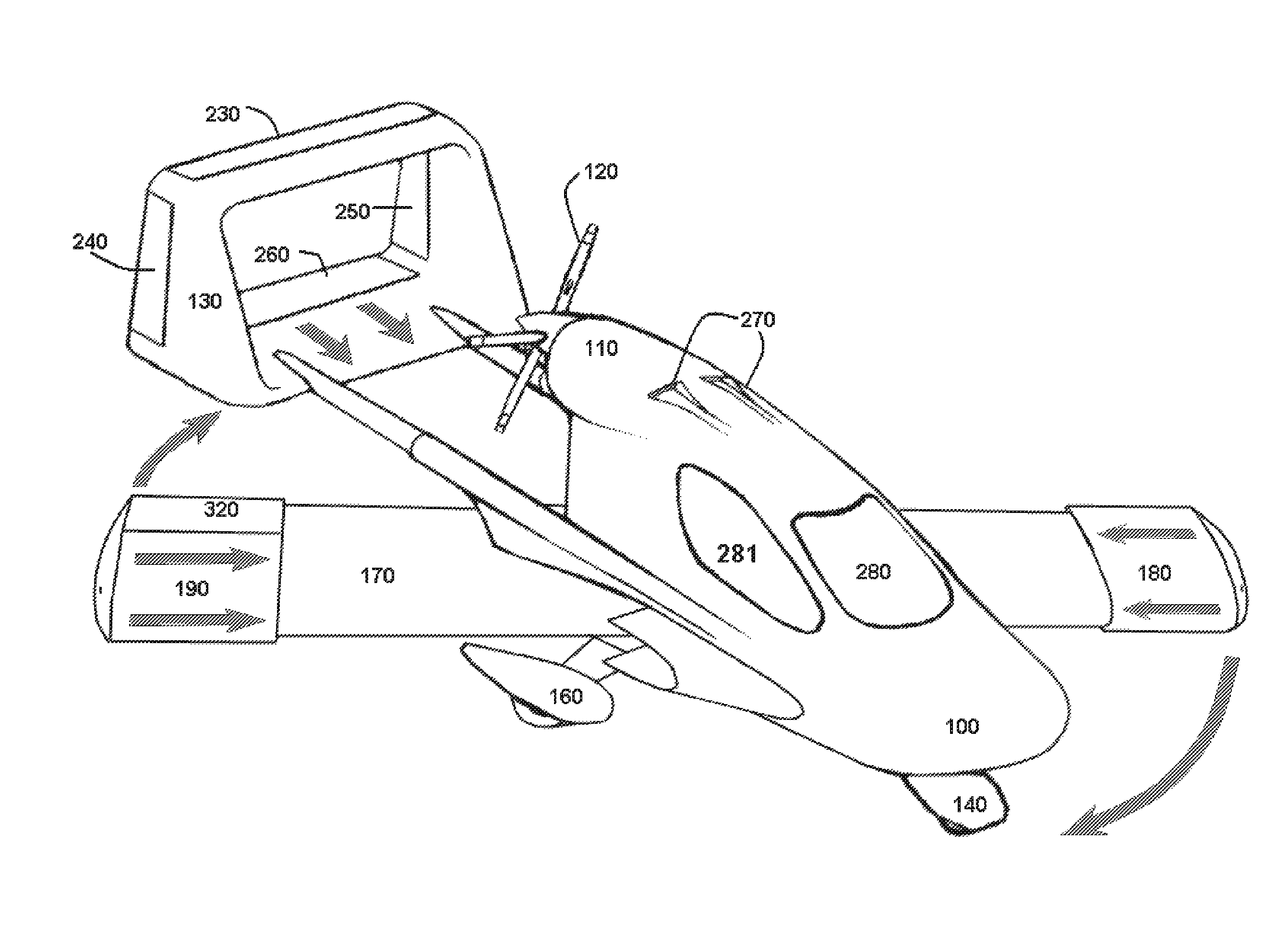

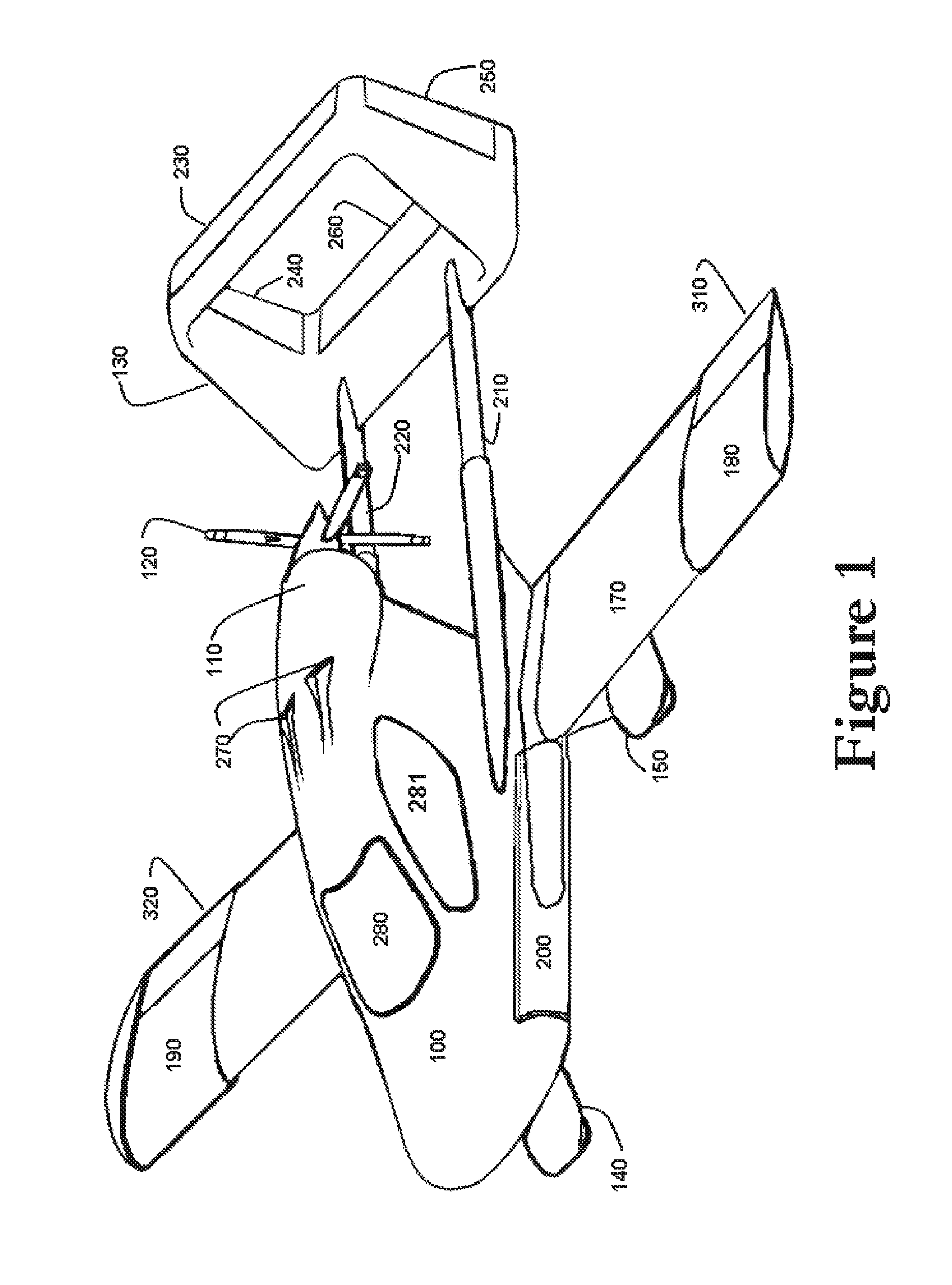

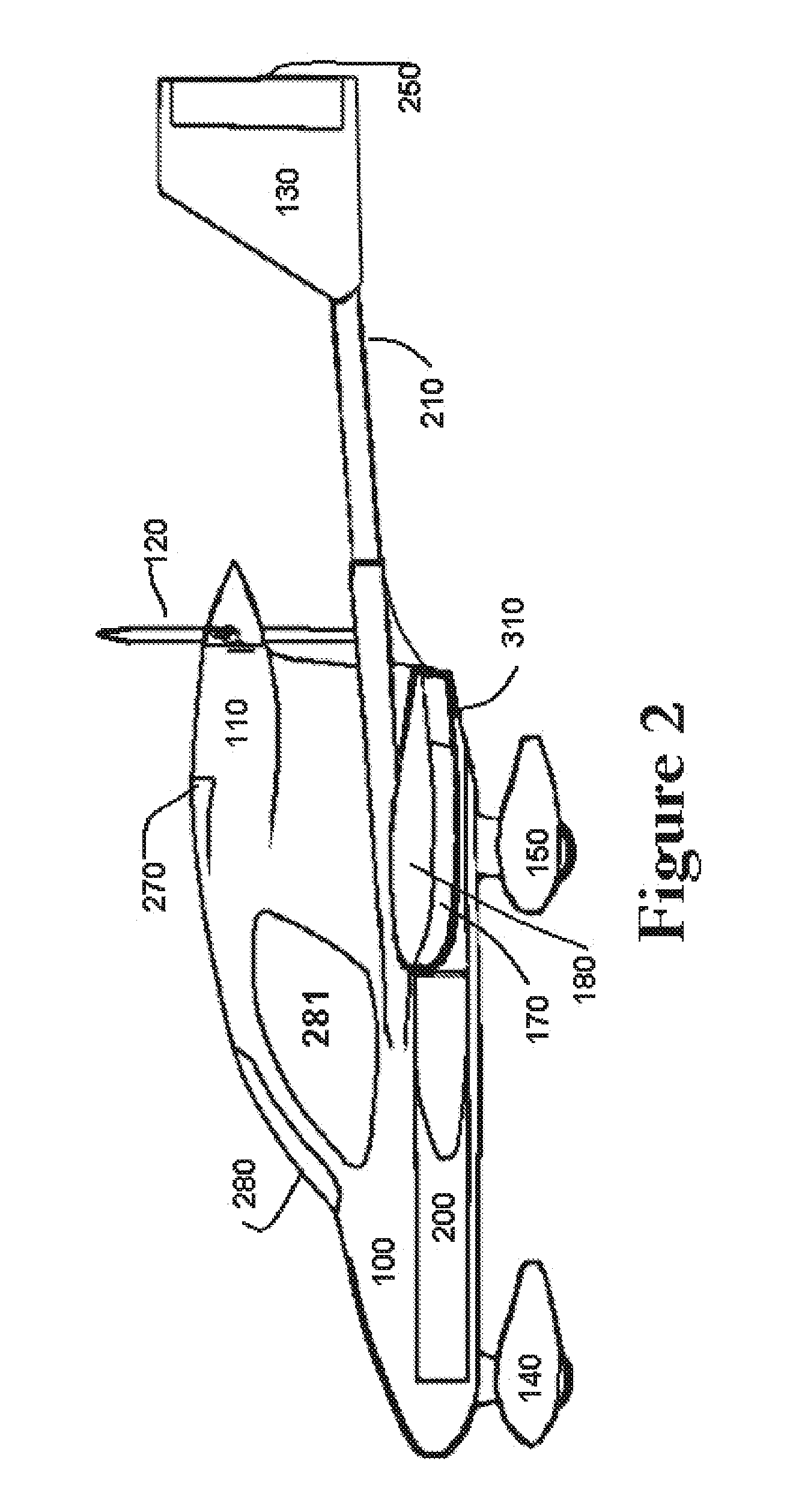

[0047]Referring to FIGS. 1-9, the preferred configuration for roadable aircraft of the present invention is a two-seat aircraft 100 with a pusher propeller 120, twin booms 210 and 220, a box tail 130 and a low wing 170. A preferred configuration is such that the Empty weight is below 1500 pounds so that the vehicle may be licensed in all States as a 3-wheel motorcycle and also possibly as a light sport aircraft if below 1320 pounds. The twin boom configuration 210, 220 keeps the propeller 120 within a well-protected area such that pedestrians cannot easily enter the plane of rotation. The wing 170 in the retract position is located under the propeller 120 to prevents stones and debris from entering the propeller 120 and in combination with the twin booms 210, 220 help to prevent pedestrians from entering the plane of rotation, providing a ground-safe vehicle. The box tail 130 further helps in this area. It is important for the vehicle to have a low wing 170 in order have a low CG. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com