Turbocharger compressor inlet flow control

a technology of turbocharger compressor and inlet flow control, which is applied in the direction of machines/engines, mechanical equipment, non-fuel substance addition to fuel, etc., can solve the problems of limiting the flow capacity of high-end compressors, adversely affecting the flow loss of high-end performance compressors, and affecting the flow of high-end performance turbines. , to achieve the effect of increasing the torque/power output density of the engine, increasing the pressure in the intake manifold,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

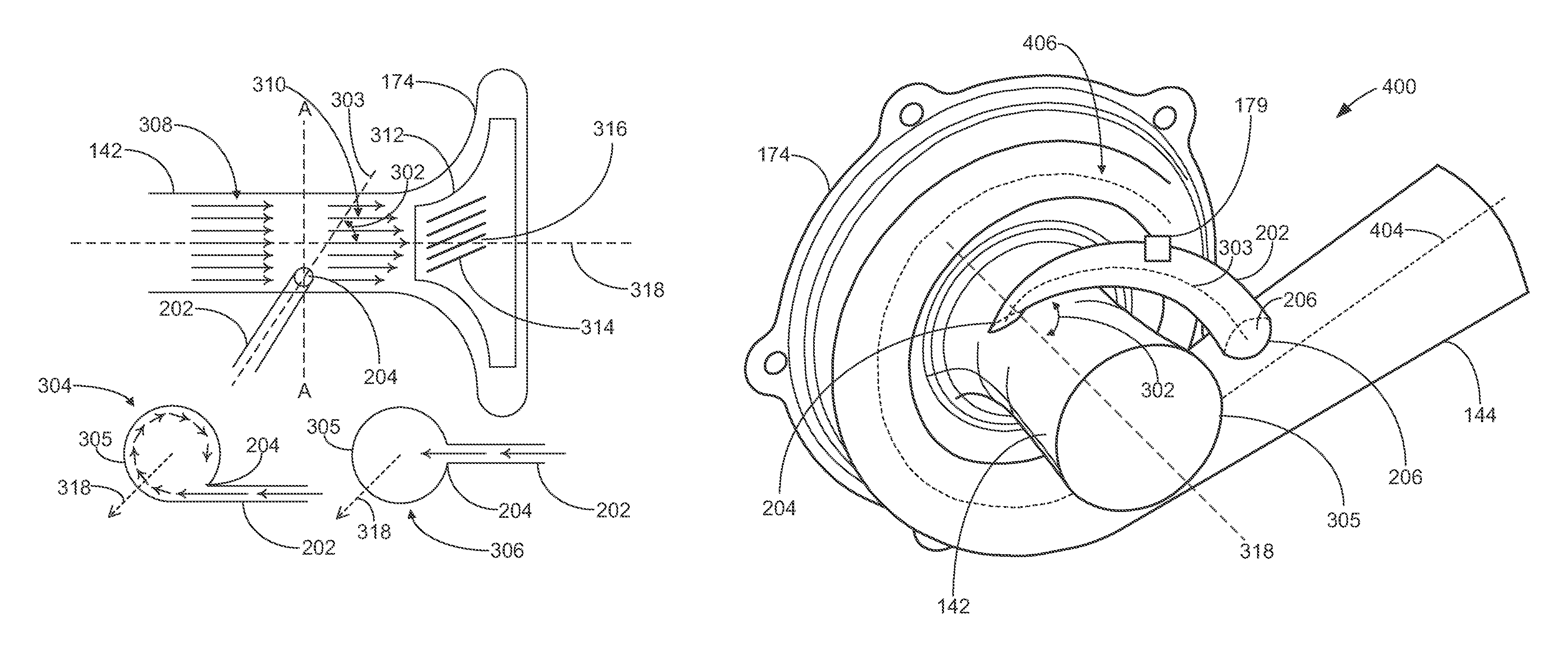

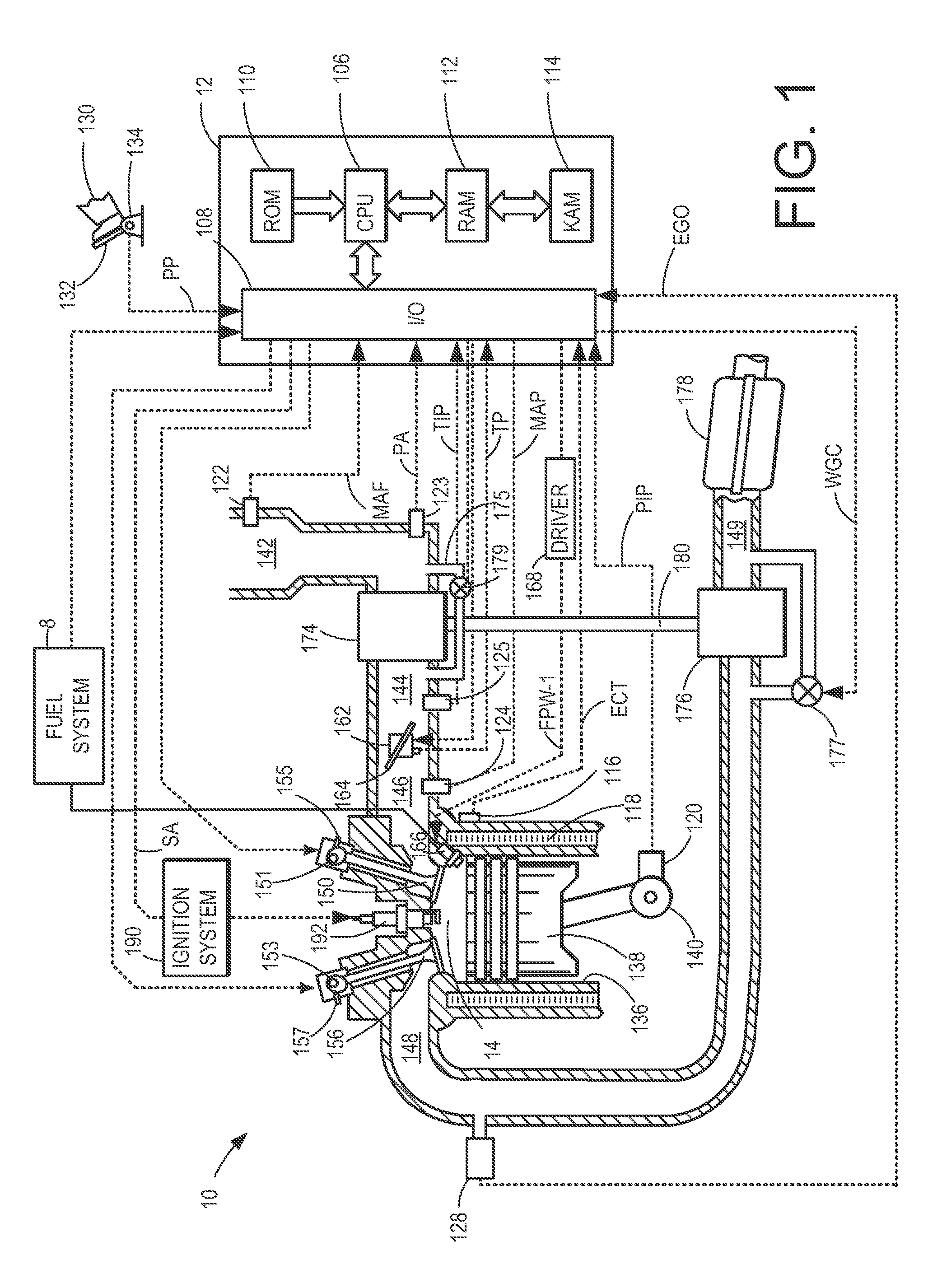

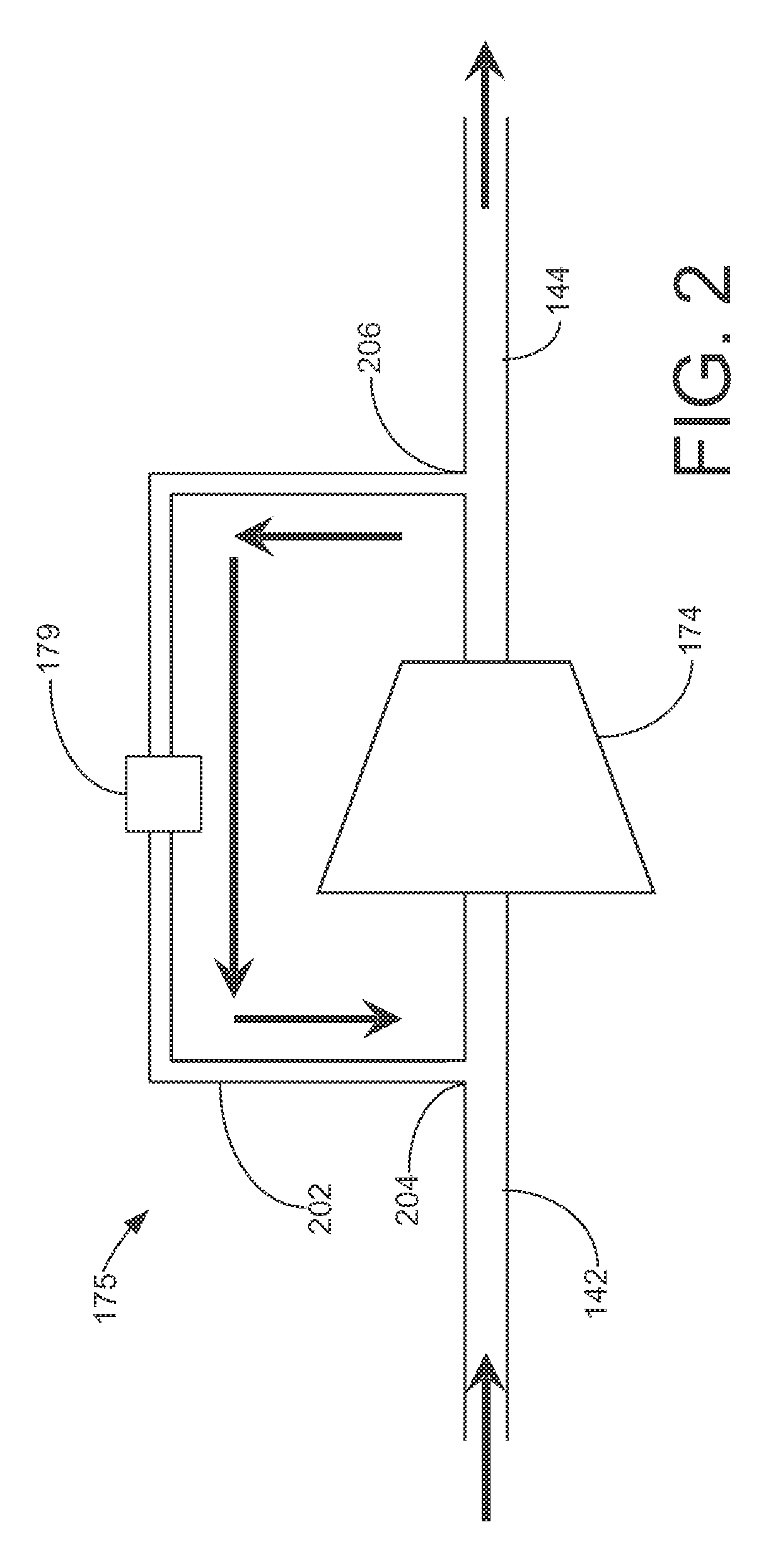

[0012]The following description relates to systems and methods for controlling compressor inlet flow in a turbocharger of an engine, such as the engine shown in FIG. 1. As one example, a compressor bypass conduit, such as shown in FIG. 2, may be used to direct pressurized air from downstream the compressor to the compressor inlet. As another example, a conduit may be used to direct pressurized air from a high pressure source to the compressor inlet, as shown in FIG. 3. The compressor bypass conduit design may be based on various components of the compressor, such as shown in FIG. 3, so that the compressor inlet velocity flow field can be tailored and controlled to increase the efficiency of the compressor rotor, increasing the surge margin of the compressor, reducing low end NVH effects such as tip-in and tip-out whoosh, improving transient response characteristics such as time-to-torque, and minimizing the high end flow loss effects associated intrusive devices, for example.

[0013]F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com