Device and method for decontamination, disinfection, and sanitation

a technology of decontamination and disinfection, applied in the direction of disinfection, life-saving devices, chemicals, etc., can solve the problems of flash vaporization, severe scaling limitations, and ineffective production of large quantities of vapors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The following description is intended to provide the reader with a better understanding of the invention. The description is not intended to be limiting with respect to any element not otherwise limited within the claims.

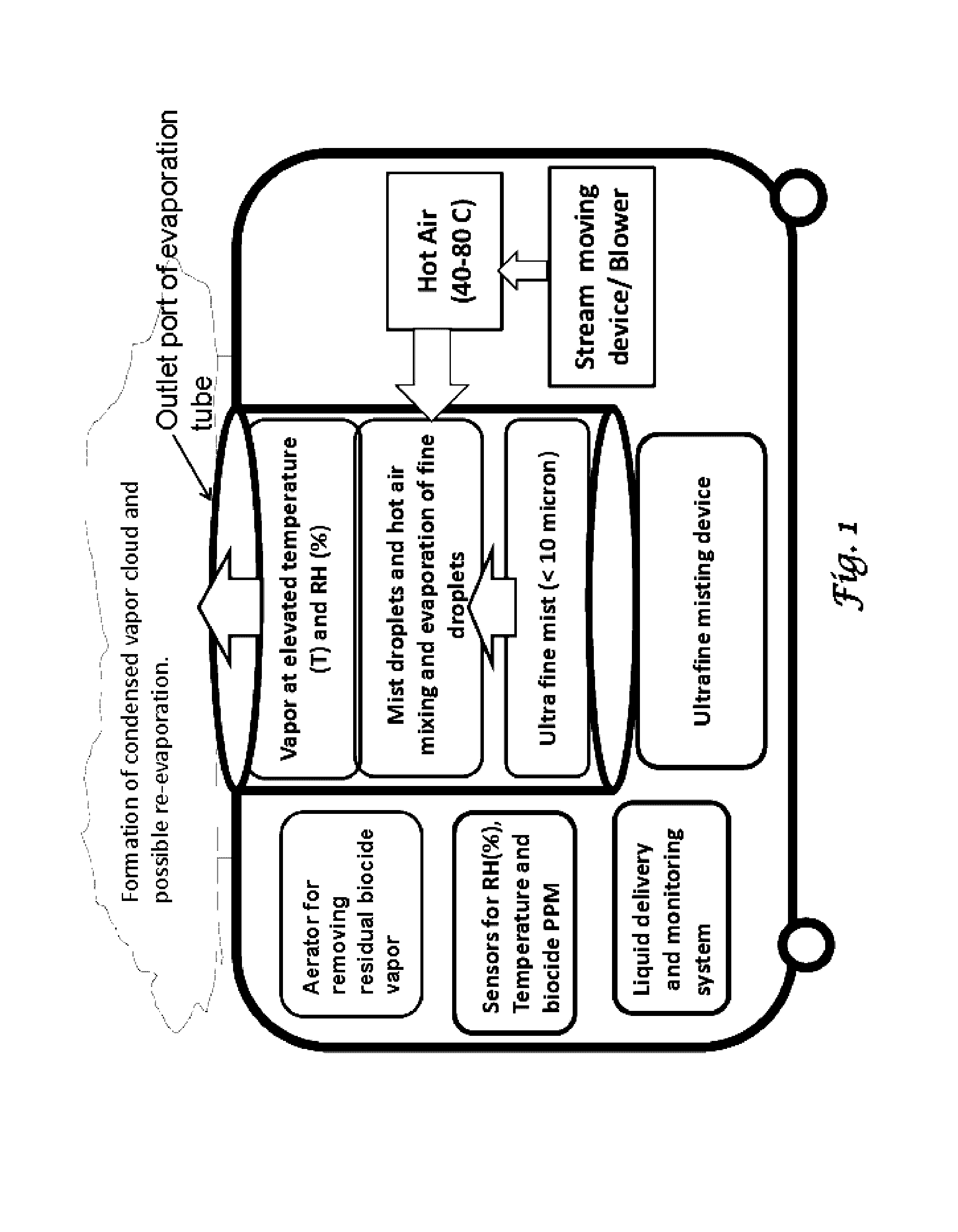

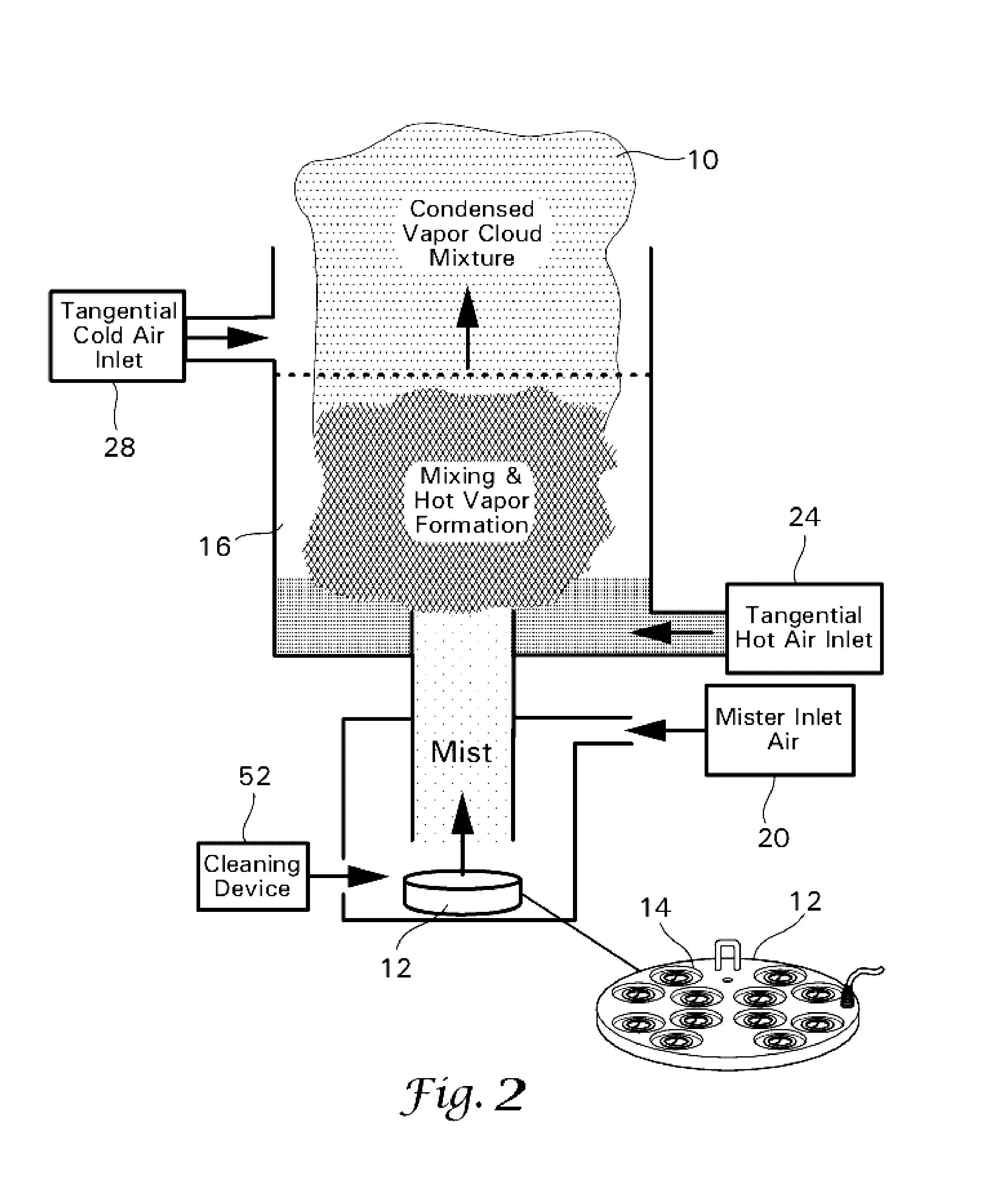

[0050]The present invention discloses a short length evaporation process that focuses on the resultant vapor as a means of producing a desired and optimized output in the form of a condensed vapor cloud discharged into an environment to be decontaminated, preferably a room or an enclosed volume for decontamination, disinfection or sanitation.

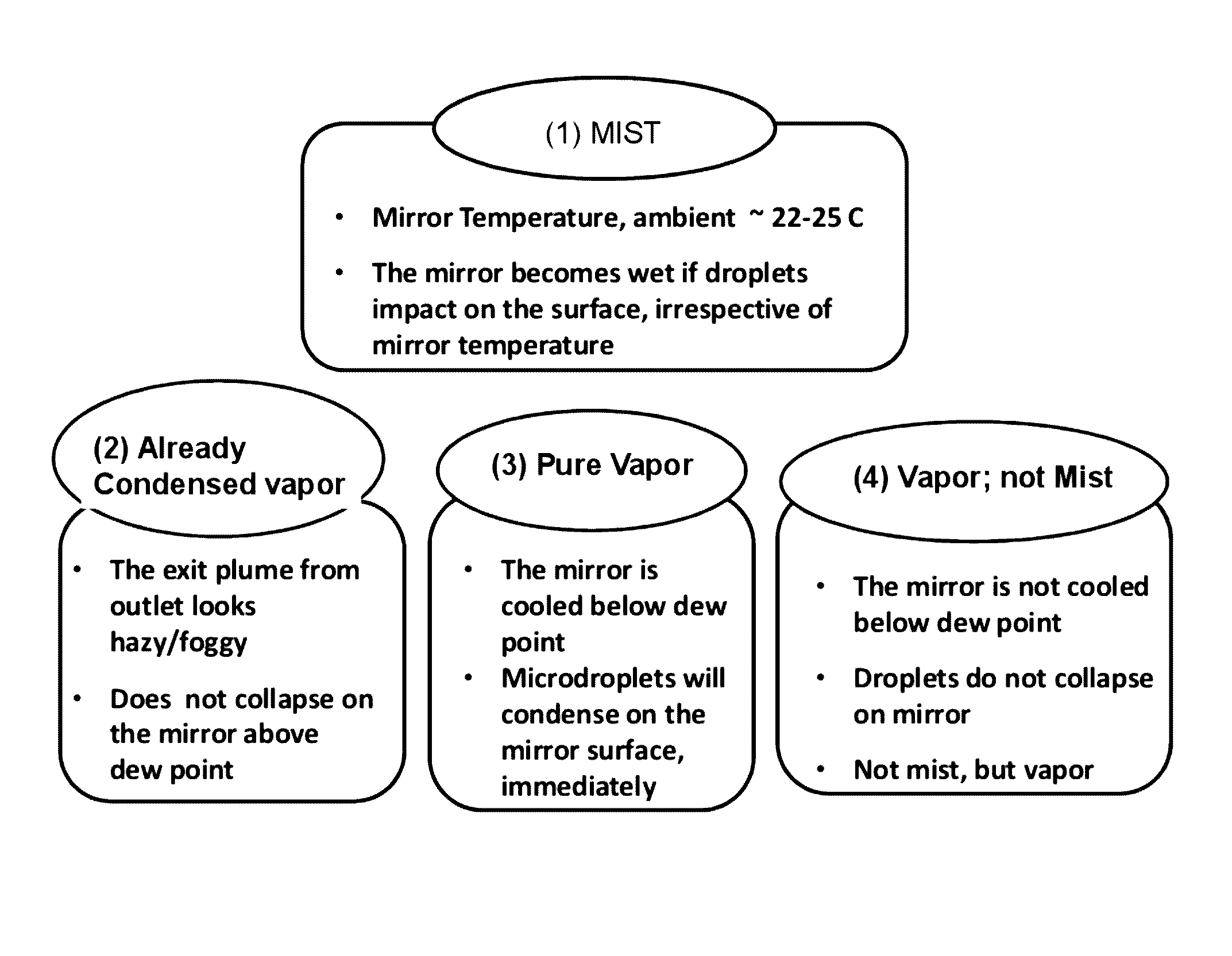

[0051]FIG. 1 shows a flow chart of the present inventive method for producing a condensed vapor cloud for decontamination of a volume and its contents. In a preferred embodiment, monodisperse ultrafine mist of a biocide or other solution is produced using an ultrasonic or suitable atomizer device and carried to the inlet of the evaporator enclosure. Separately, an air movement device is used to transport a gas through a he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass concentration | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

| particle diameters | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com