Hybrid vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

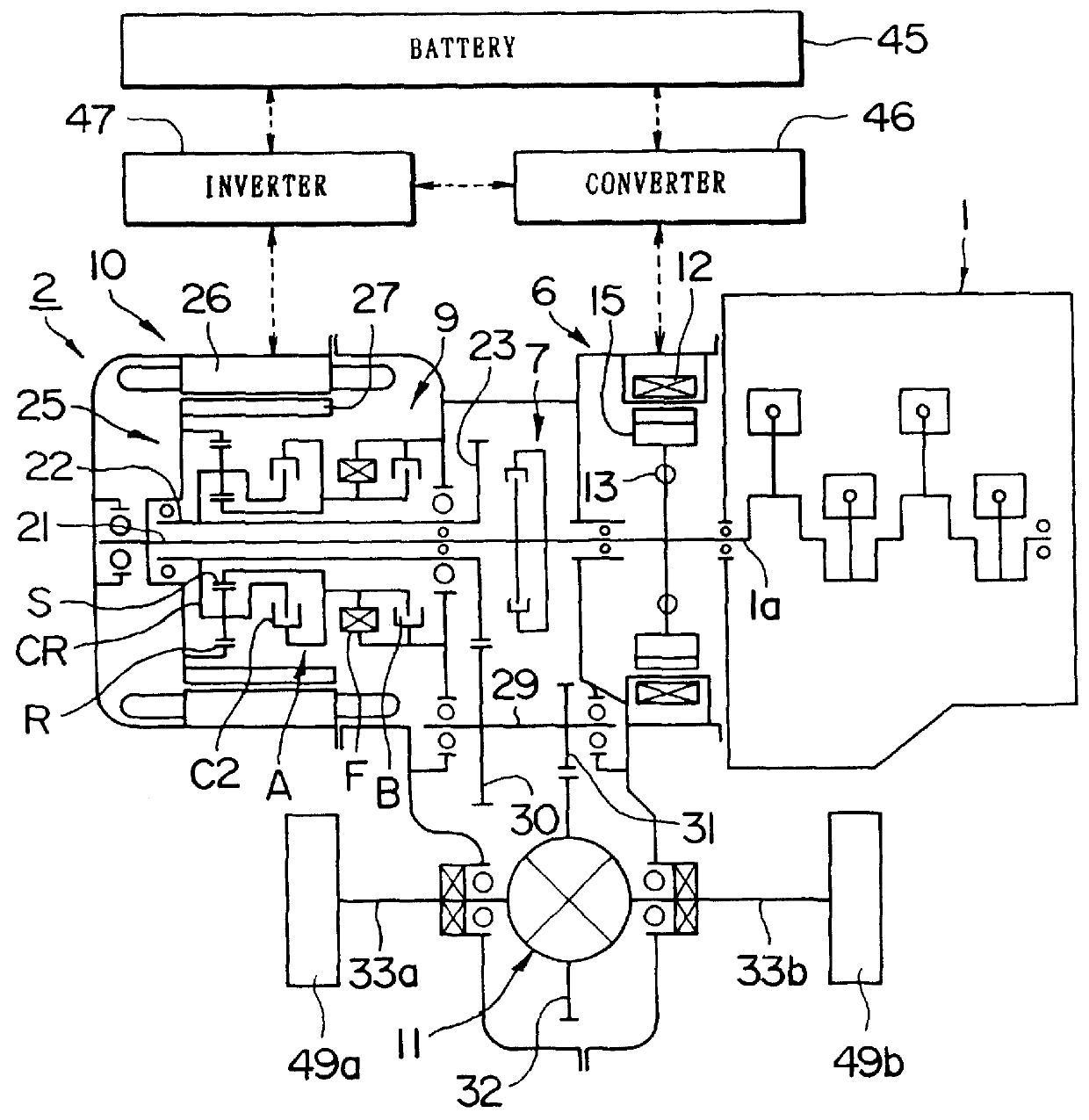

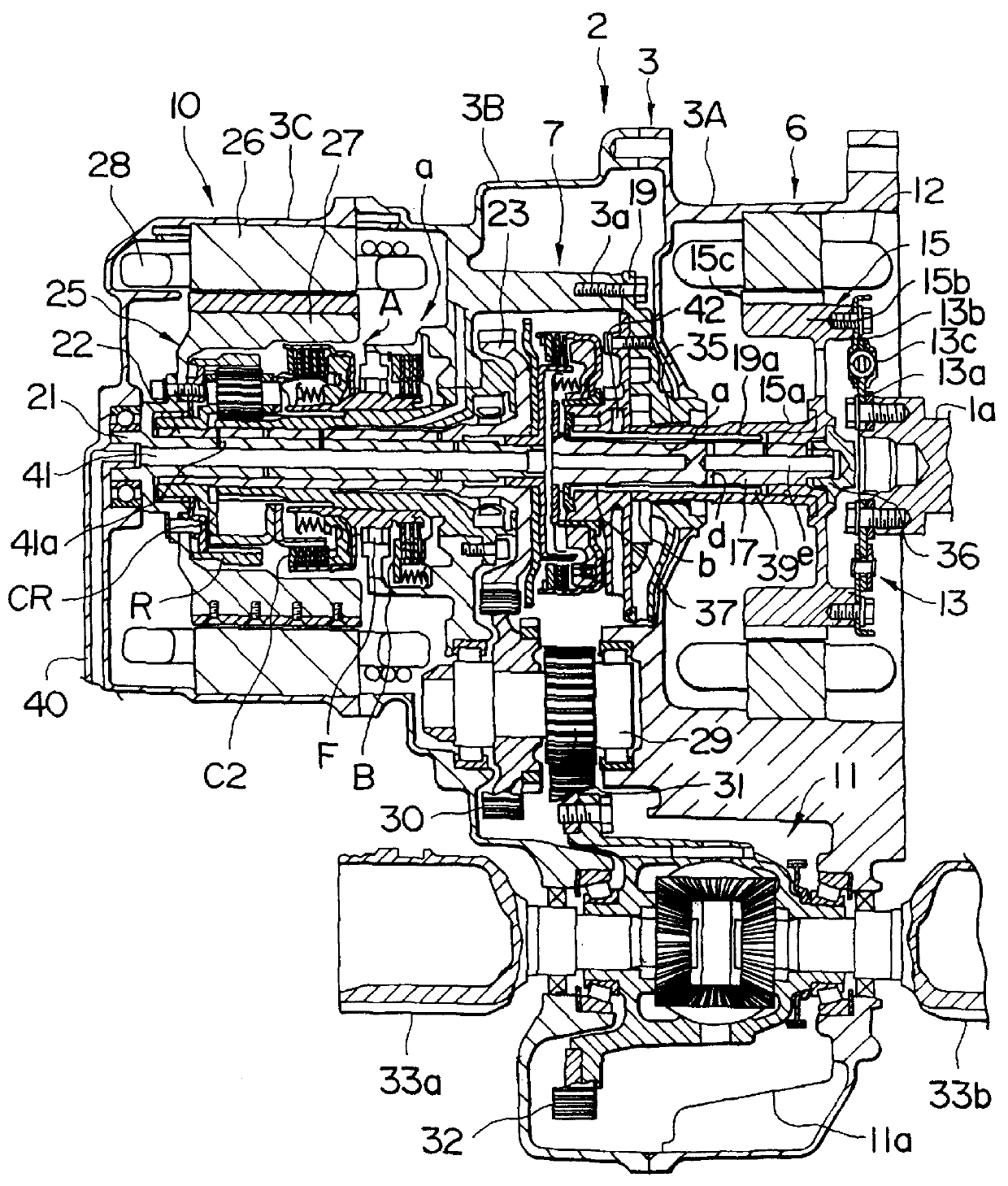

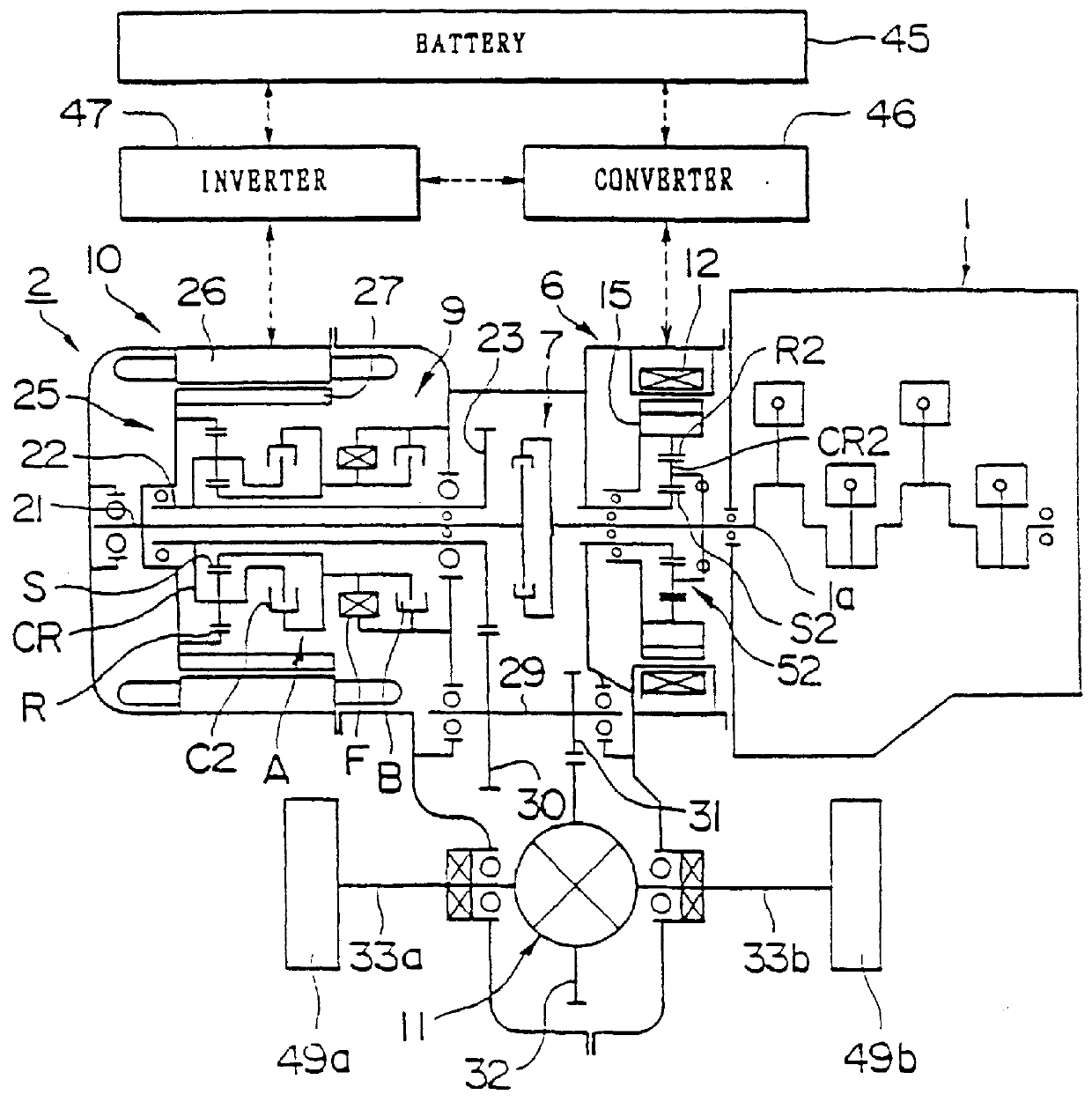

A first preferred embodiment of the present invention will now be described with reference to FIGS. 1 and 2.

An engine compartment provided at a front portion of the vehicle houses an internal combustion engine (hereinafter referred to as "engine") 1, such as a gasoline or diesel engine, which is transversely mounted, and a hybrid unit 2, which replaces a conventional automatic-transmission unit and receives output of the engine 1. The hybrid unit 2 has an integral case 3 which abuts one end of the engine and is defined by three sections (3A, 3B, 3C). Case 3 houses a generator 6, a clutch 7, a two-speed automatic transmission unit 9 and an electric motor in alignment with output shaft la of the engine 1. A differential gear unit 11 is mounted under the case 3.

The generator 6 is provided, in place of the torque converter of the conventional automatic transmission unit, adjacent to the engine 1 in a generator housing 3A forming one section of the integral case 3. The generator 6 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com