Cutting insert for cutting and grooving tools

a cutting insert and tool technology, applied in the direction of cutting inserts, manufacturing tools, shaping cutters, etc., can solve the problems of high production cost, high difficulty, and tangled chips that may wrap around the workpiece or the tool, and achieve the effect of less costly, efficient and safe chips, and less tangled chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

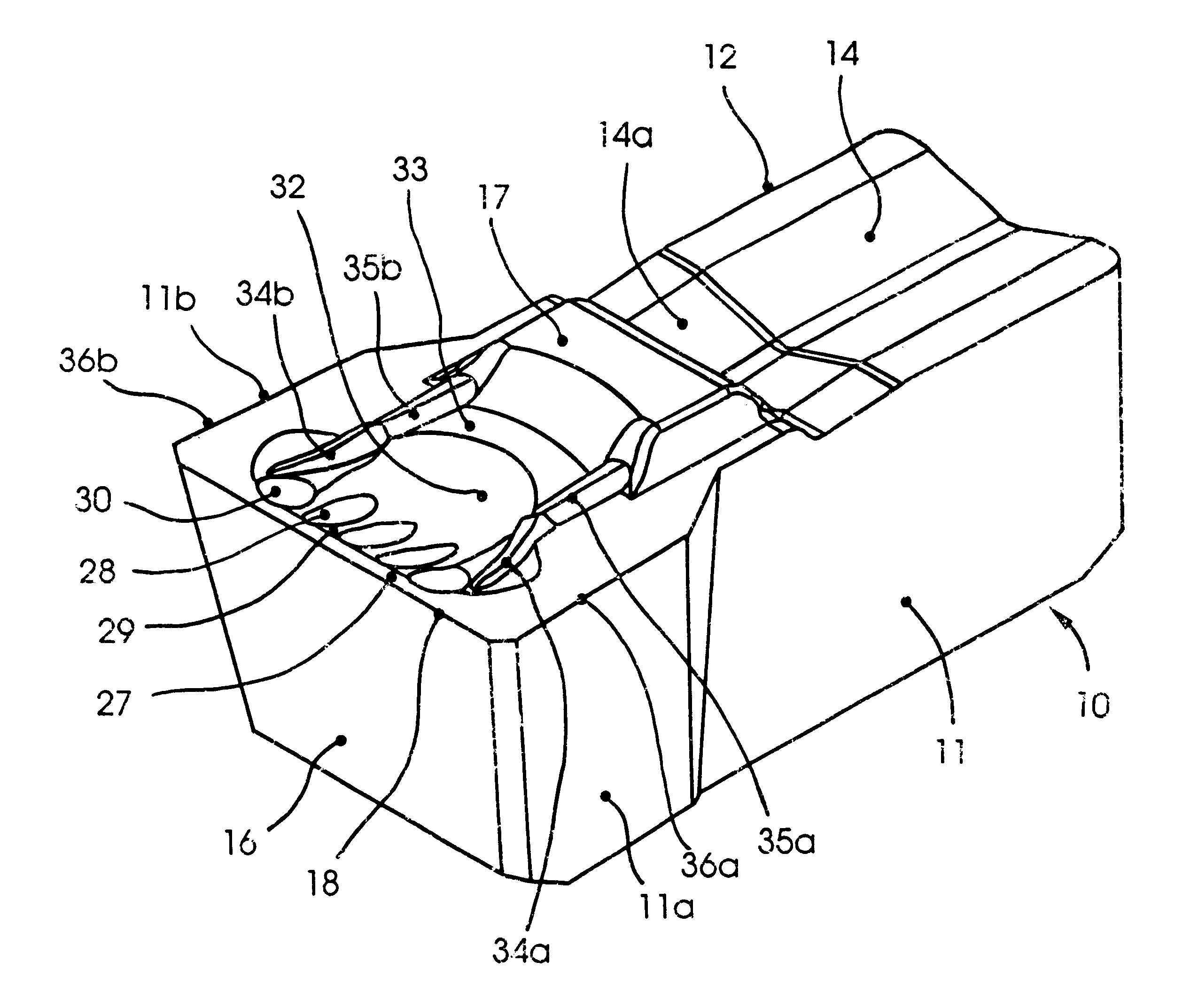

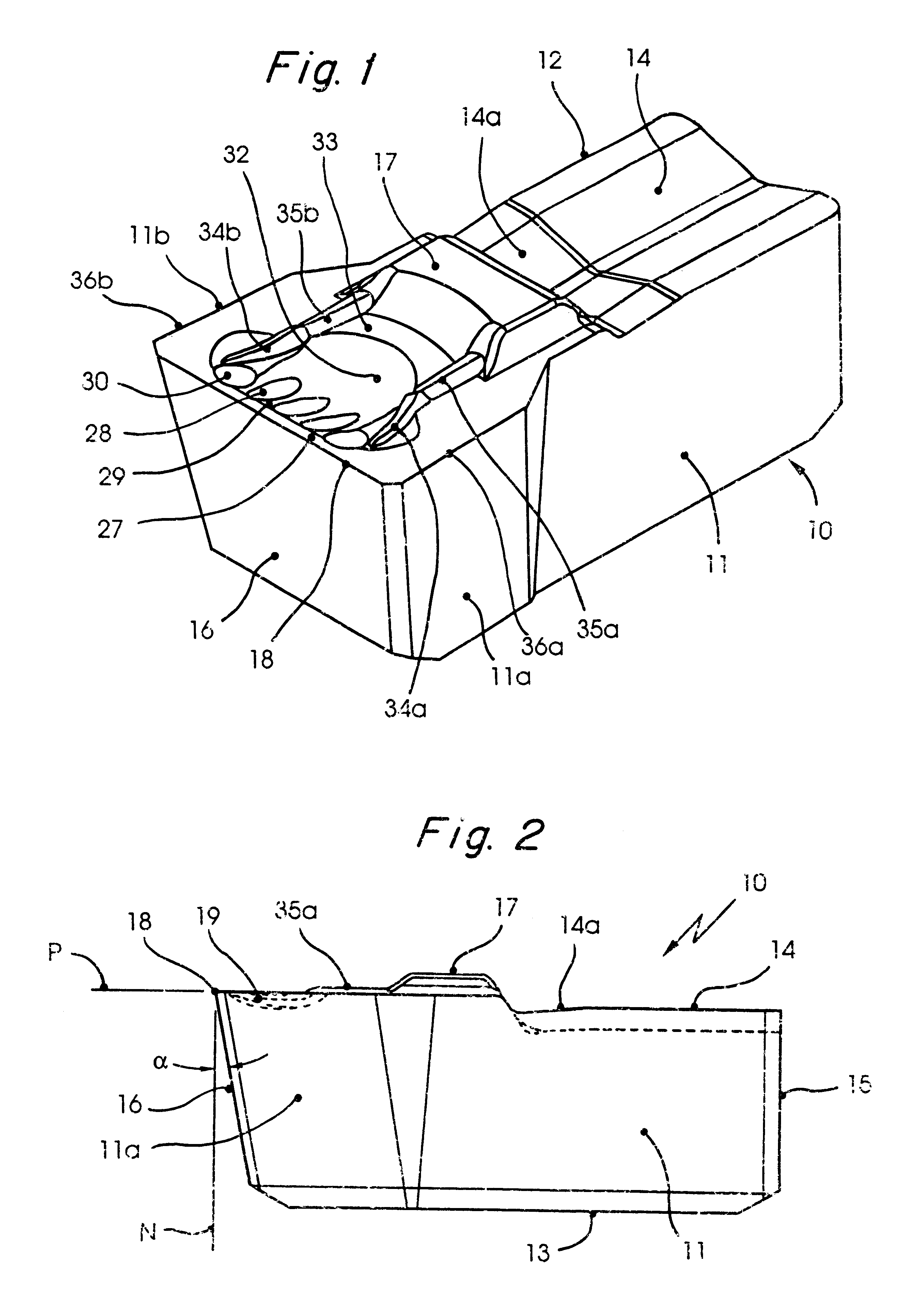

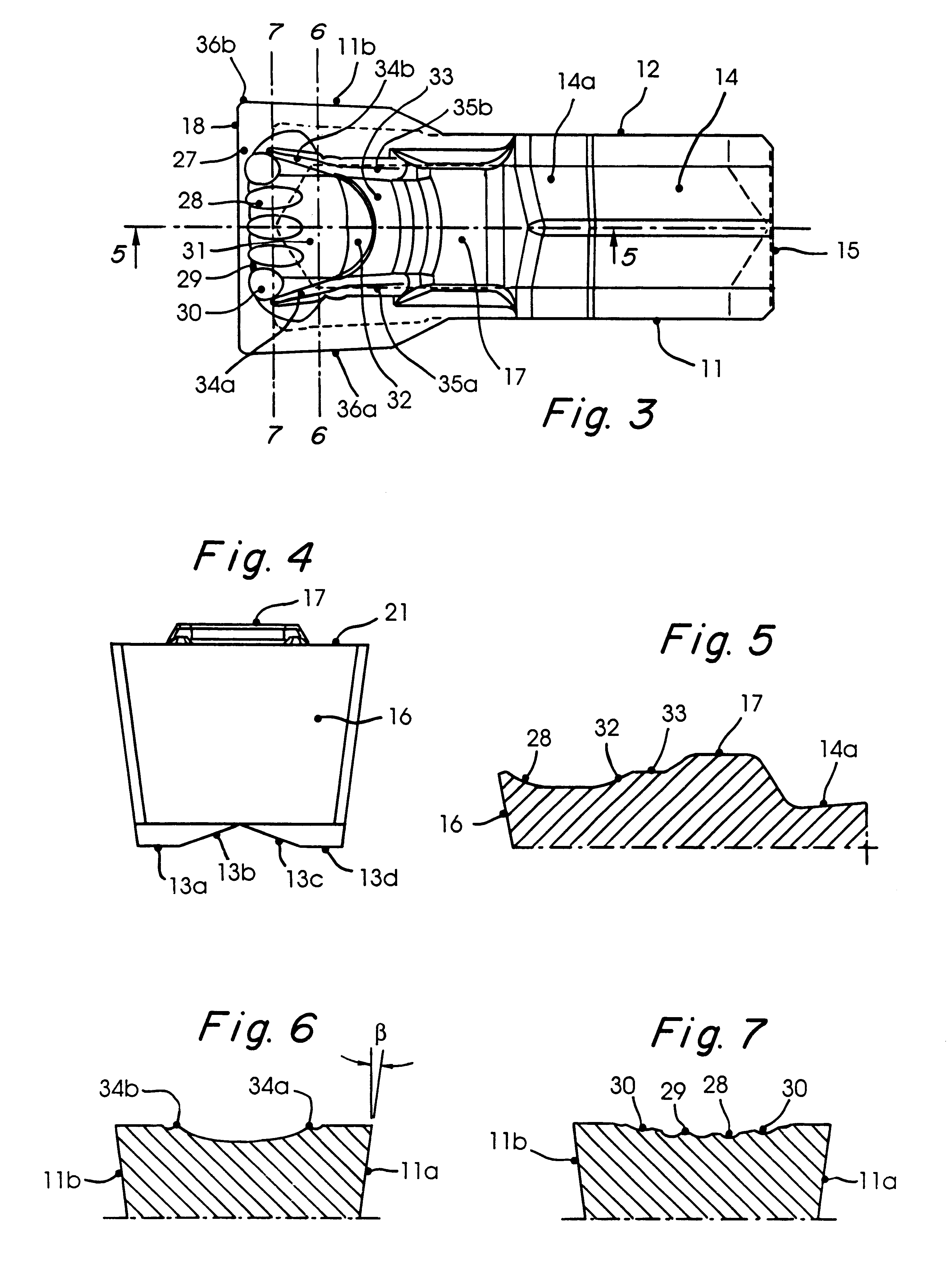

An insert 10 according to the invention is shown in the drawing figures. The insert is in the shape of a polygonal body of generally parallepipedic shape. It comprises two mainly plane-parallel side surfaces 11, 12, opposed top and bottom surfaces 14 and 13, respectively, two end surfaces 15, 16, and a shoulder 17. The front portion of the insert is provided with a main cutting edge 18 and a chip forming area 19. The insert is intended to be secured to a holder body 20 (FIG. 8) provided with an integral clamping arm 21. The top surface 14 is broken at the vicinity of the shoulder 17 so that an upper surface portion 14a forms an acute angle with the remainder of the surface 14.

With reference to FIG. 8, the insert 10 is intended to be removably held in a holder, which includes the holder body 20 having an integral clamping arm 21 in a front portion 22 of the holder body 20 and an insert receiving recess 23 in which the insert 10 is to be located. The insert receiving recess 23 communi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com