Leadframe with heat dissipator connected to S-shaped fingers

a technology of heat dissipator and lead frame, which is applied in the direction of solid-state devices, electric devices, basic electric elements, etc., can solve the problems of reducing the life and therefore the reliability of the device, reducing the efficiency of the device, and reducing the life of the device. , to achieve the effect of reducing manufacturing costs and simplifying the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

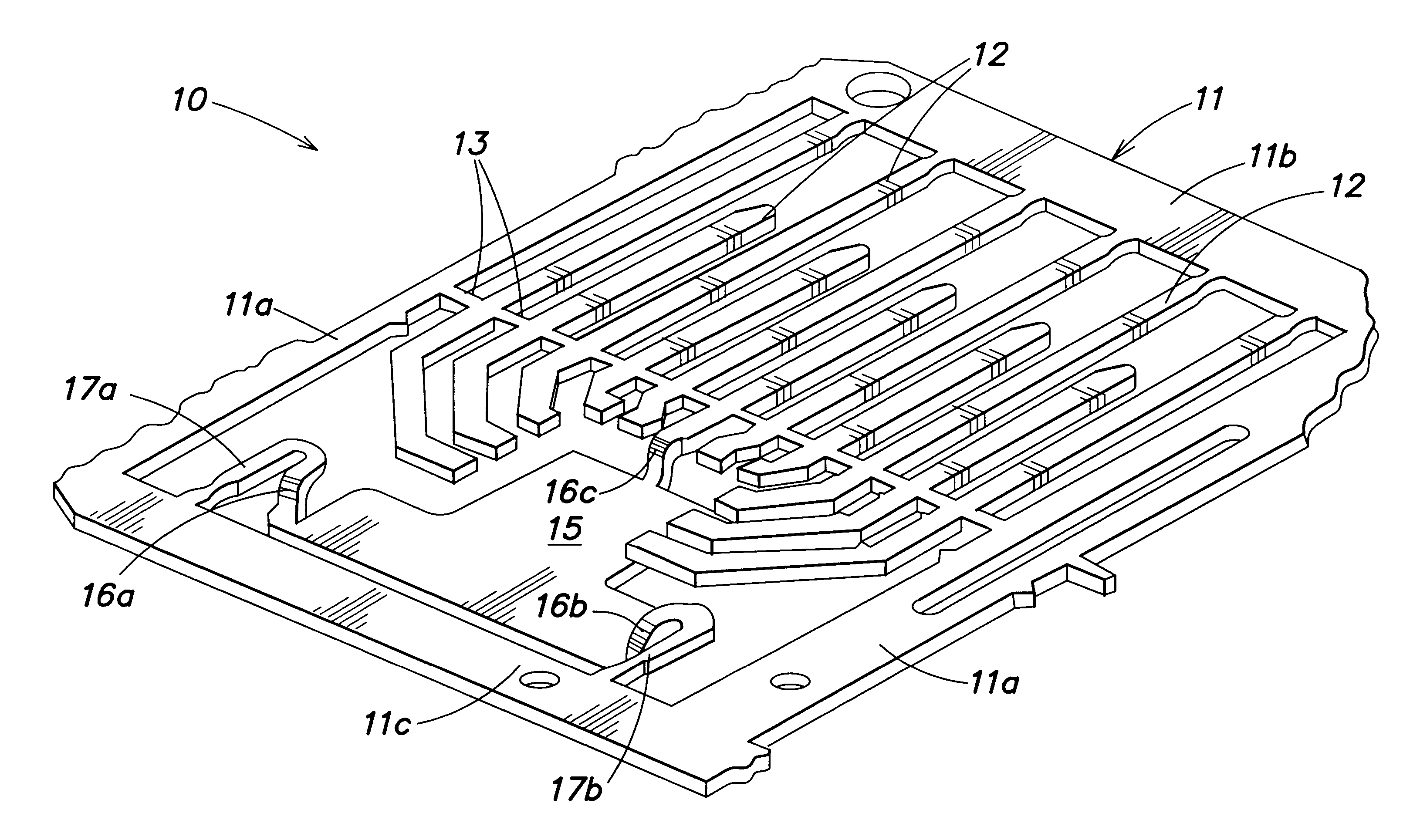

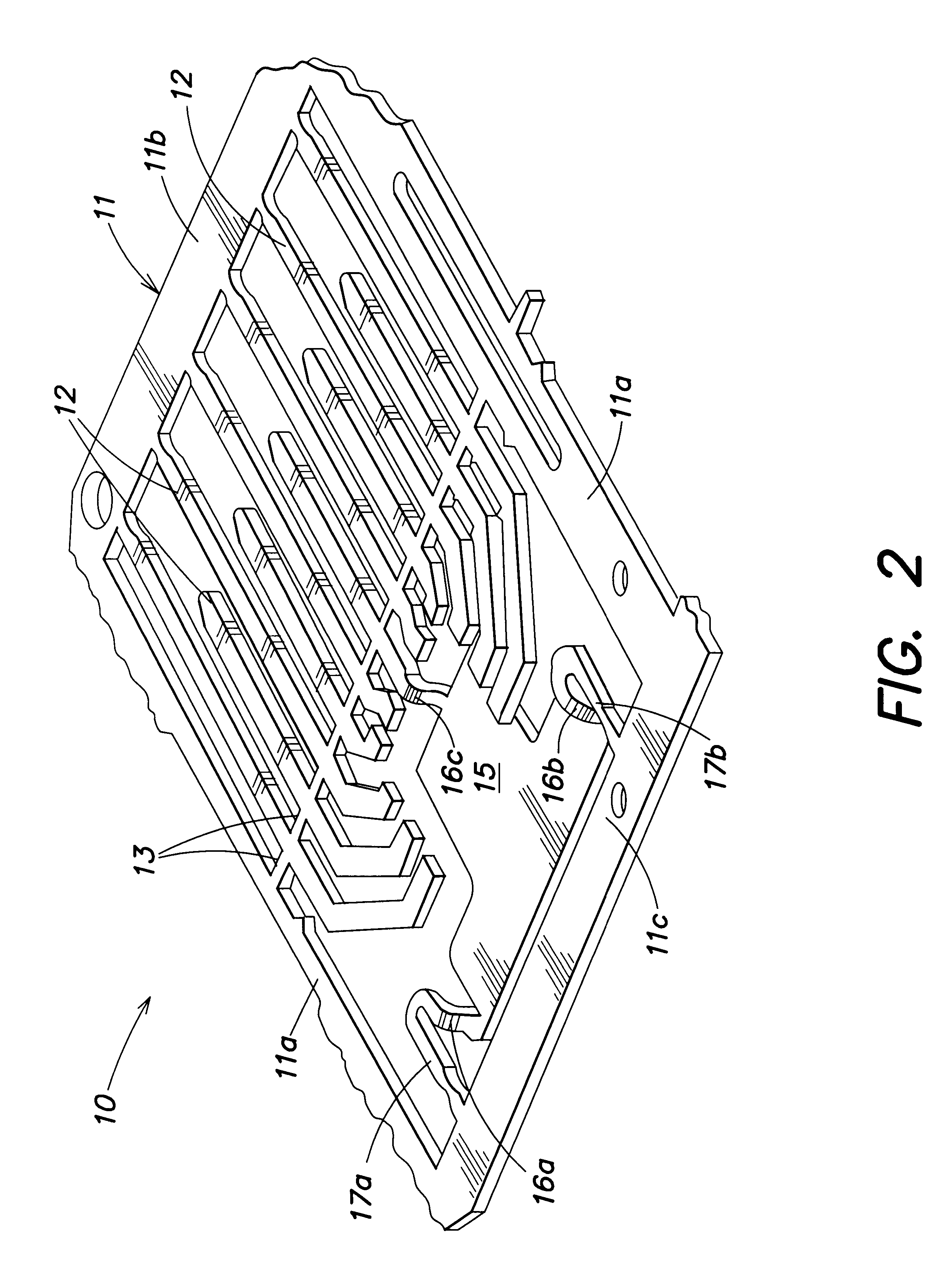

With reference to FIG. 2, the leadframe according to the invention is generally indicated by the reference numeral 10 and is part of a strip which comprises for example ten of said leadframes, all identical and arranged side by side. In detail, the leadframe comprises a frame 11 which, according to the invention, extends along a substantially rectangular closed line which defines the outer perimeter of the leadframe. The sides of the frame indicated by 11a are in common with the adjacent leadframes (not illustrated in the figure) of the same strip. The frame 11 supports the leads 12 (eleven in the illustrated example), some of which are connected to the side 11b of the frame at their tip, whereas all the leads are connected to an intermediate portion of the sides 11a of the frame by means of segments 13 which define an interconnection line. Similarly to the prior art, the lead interconnection segments 13 are intended to be removed, together with the frame 11, after the execution of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com