Probe skates for electrical testing of convex pad topologies

a convex pad and topology technology, applied in the direction of electrical testing, measurement devices, instruments, etc., can solve the problems of unusable wafers, unfavorable convex pad topology testing, and non-conductive layer of debris on the pad, so as to improve the tolerance of overdrive motion, prolong the mean time, and improve the control of the skate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]Although the following detailed description contains many specifics for the purposes of illustration, anyone of ordinary skill in the art will readily appreciate that many variations and alterations to the following exemplary details are within the scope of the invention. Accordingly, the following preferred embodiment of the invention is set forth without any loss of generality to, and without imposing limitations upon, the claimed invention.

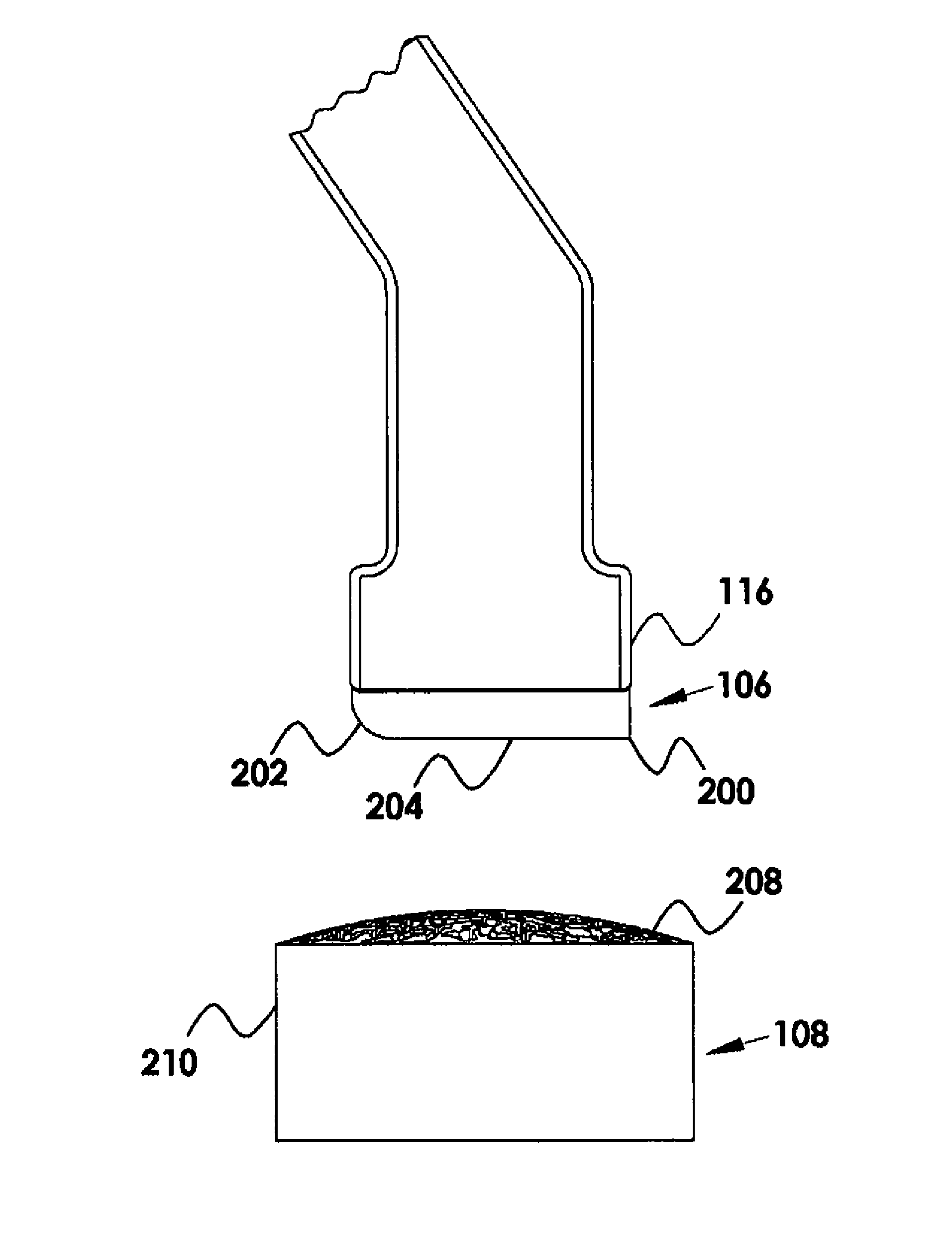

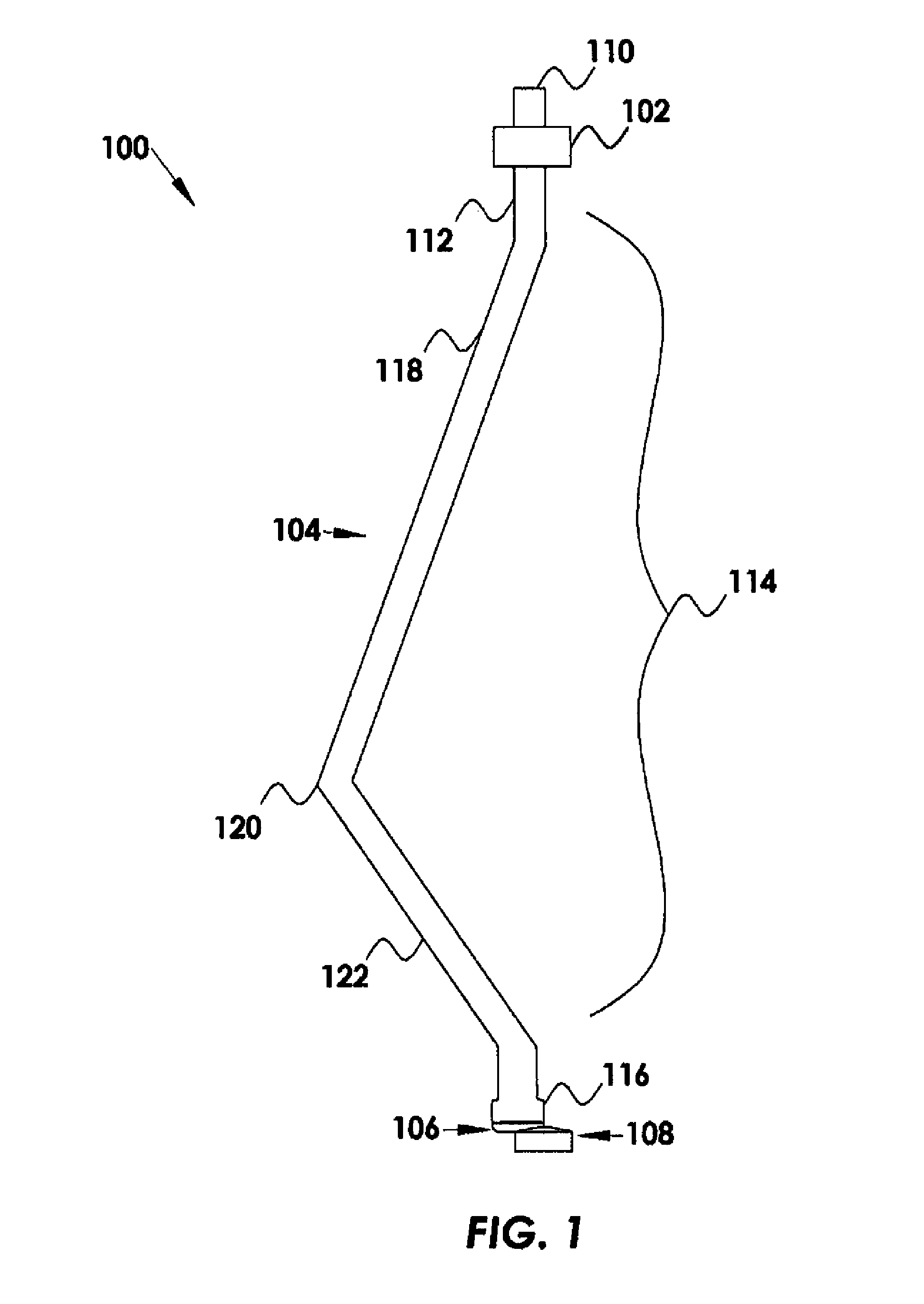

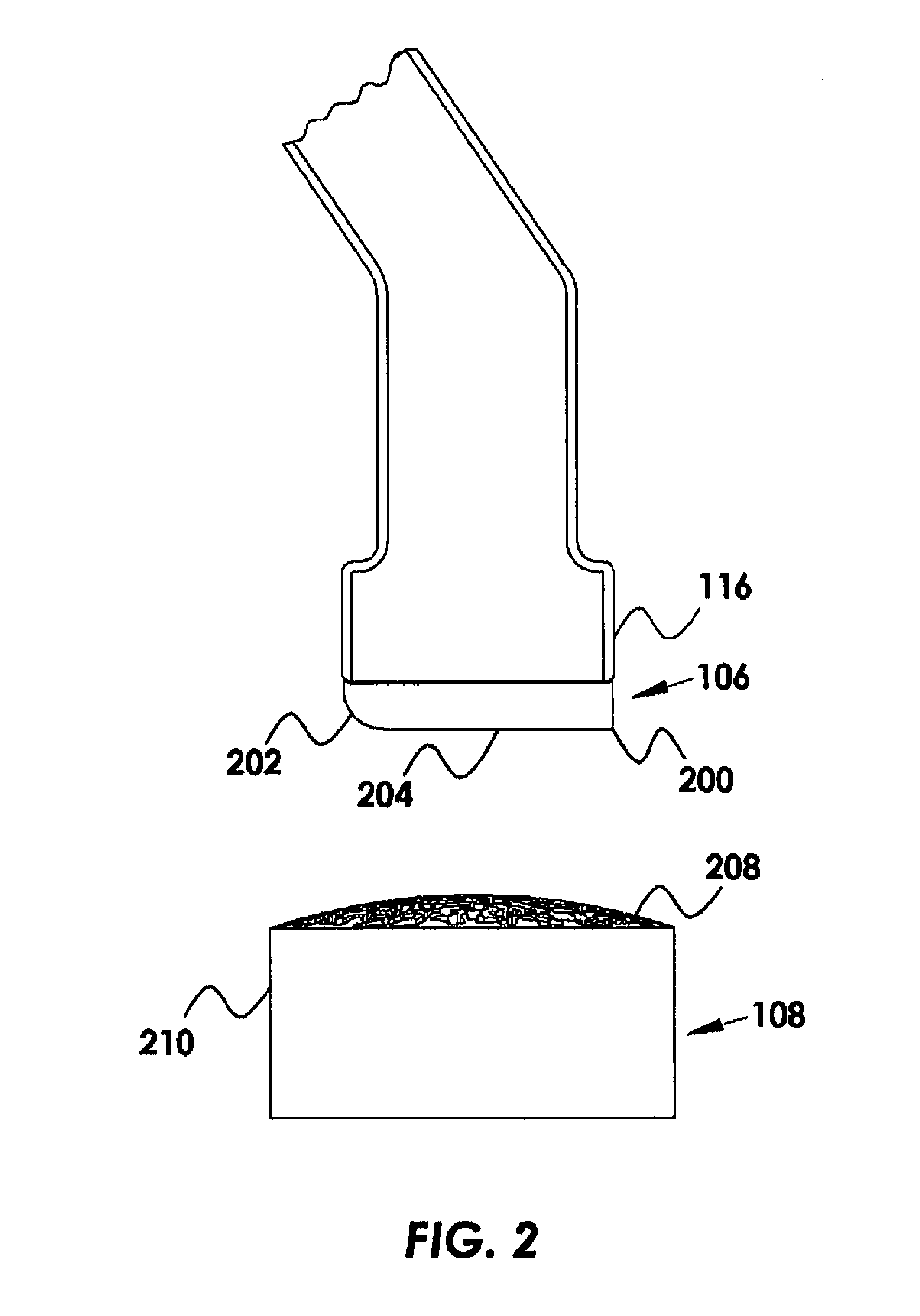

[0031]Semiconductor wafer processing methods and technology have been dynamic fields and continue to be the focus of much research and development. Among the numerous areas of these fields, early verification of process integrity and circuit design is an important step for effective cost control and manufacturing efficiency. As new methods of fabrication and new semiconductor wafer features evolve, testing methods must adapt to these changes. For example, the conductive pad of a semiconductor wafer can be fabricated as a dome-shape, or ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com