Vertical cavity surface emitting laser

a laser and vertical cavity technology, applied in semiconductor lasers, laser details, electrical devices, etc., can solve the problem of not easy to obtain high output of fundamental transverse modes, and achieve the effect of lowering the reflectance, and reducing the gain of high-order transverse modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

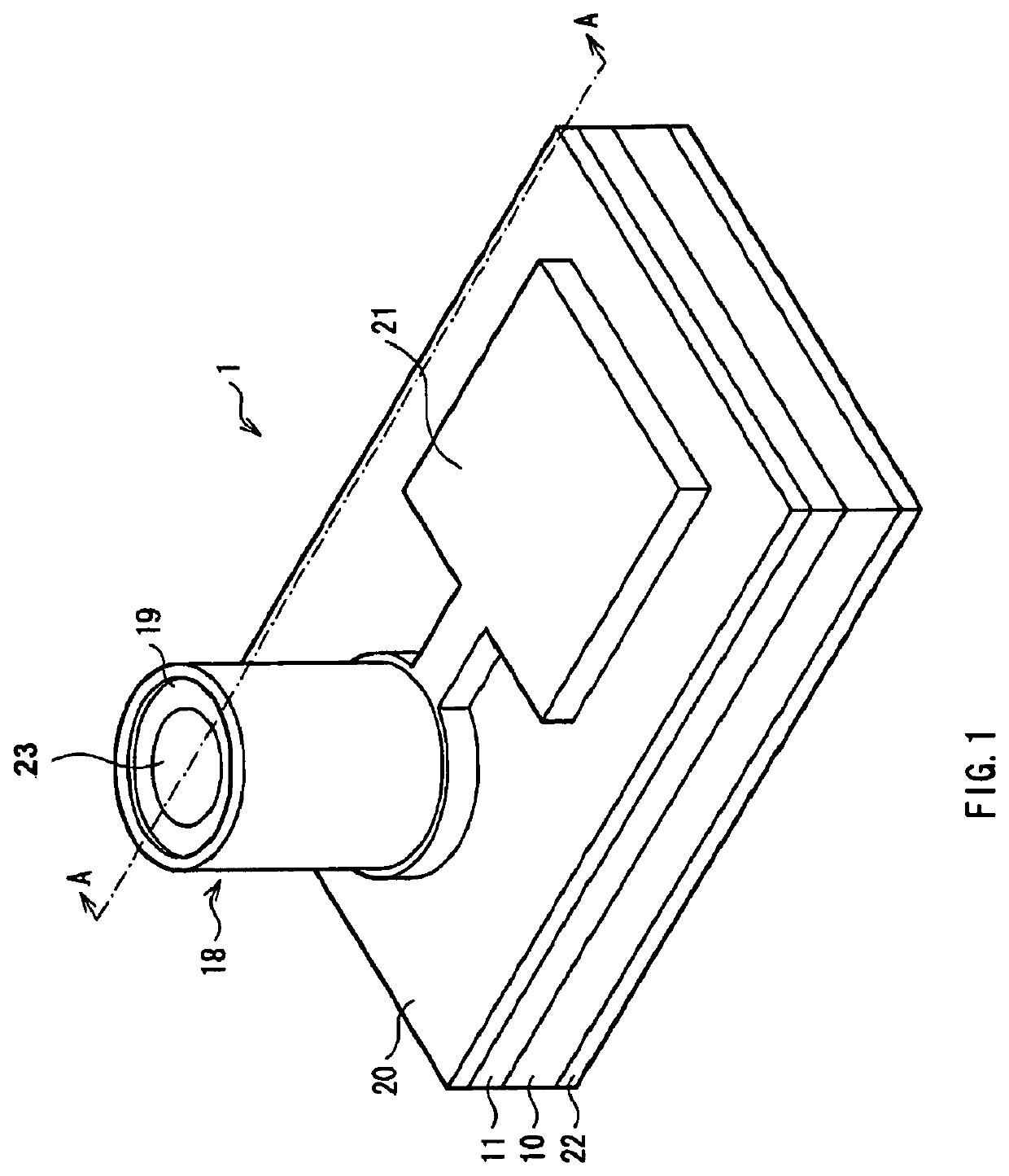

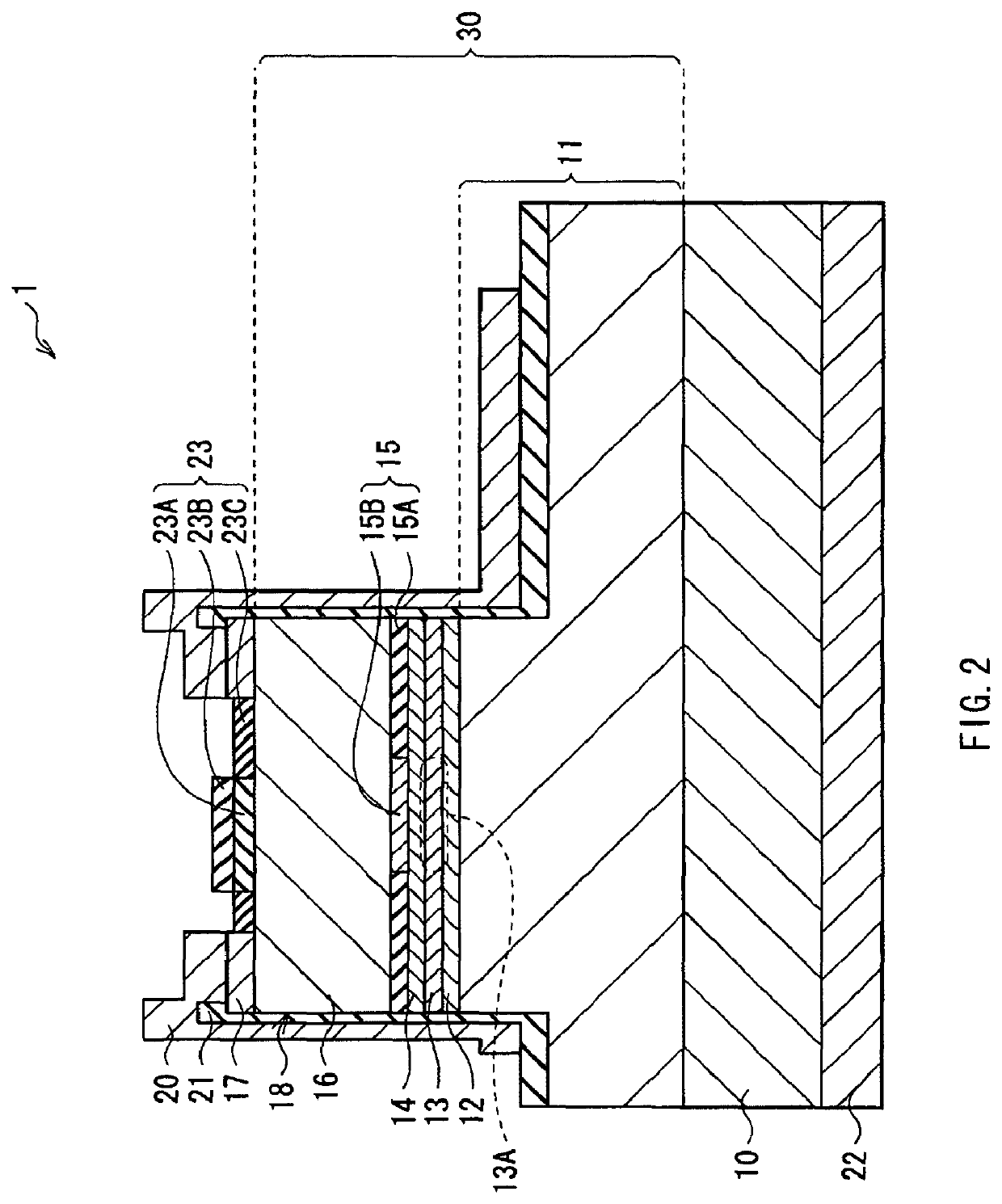

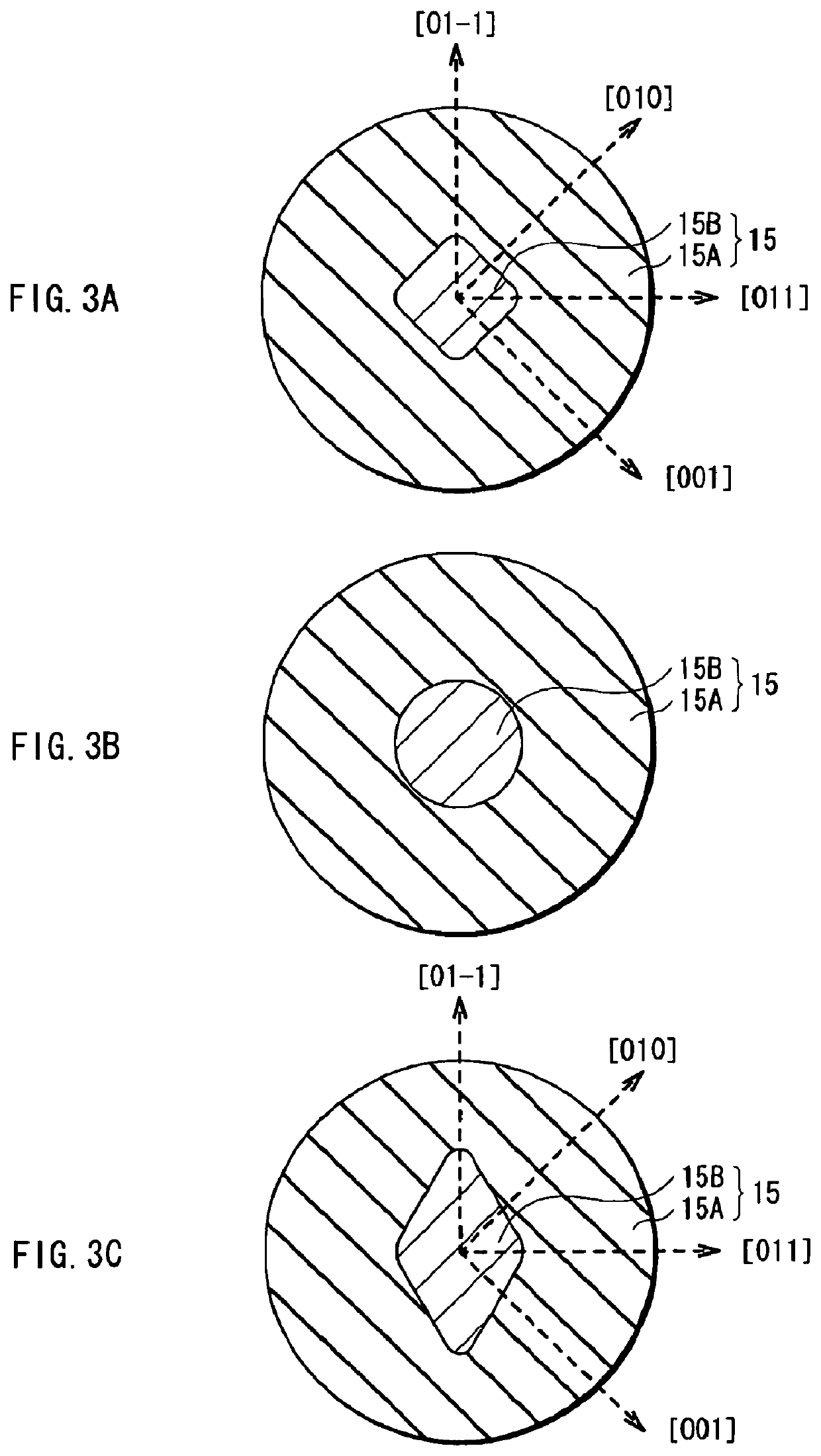

Image

Examples

modified examples

[0077]In the foregoing embodiment, the laminated structure 23D is circular. However, for example, as illustrated in FIGS. 11A to 11C, the laminated structure 23D may be in the shape of a convex protruding toward a region sandwiched between the specific regions 23E. Otherwise, for example, as illustrated in FIGS. 12A to 12C, the laminated structure 23D may be in the shape having double convexes protruding toward two regions sandwiched between the specific regions 23E. Further, for example, as illustrated in FIGS. 13A to 13C, the laminated structure 23D may be in the shape of a cross in the region other than the region corresponding to each peak P of the opposed region opposing to the current injection region 15B.

[0078]For example, if the laminated structure 23D is circular, and the laminated structure 23D is arranged so that the center point C2 of the laminated structure 23D corresponds to the opposed region C1, as illustrated in FIG. 14, output of a simple transverse mode is able to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| refractive index n2 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com