Patents

Literature

41results about How to "Minimizes ink leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of fabricating printhead having hydrophobic ink ejection face

ActiveUS20080225076A1Minimizes ink leakageMinimize actuationRecording apparatusInking apparatusEngineeringPolymer

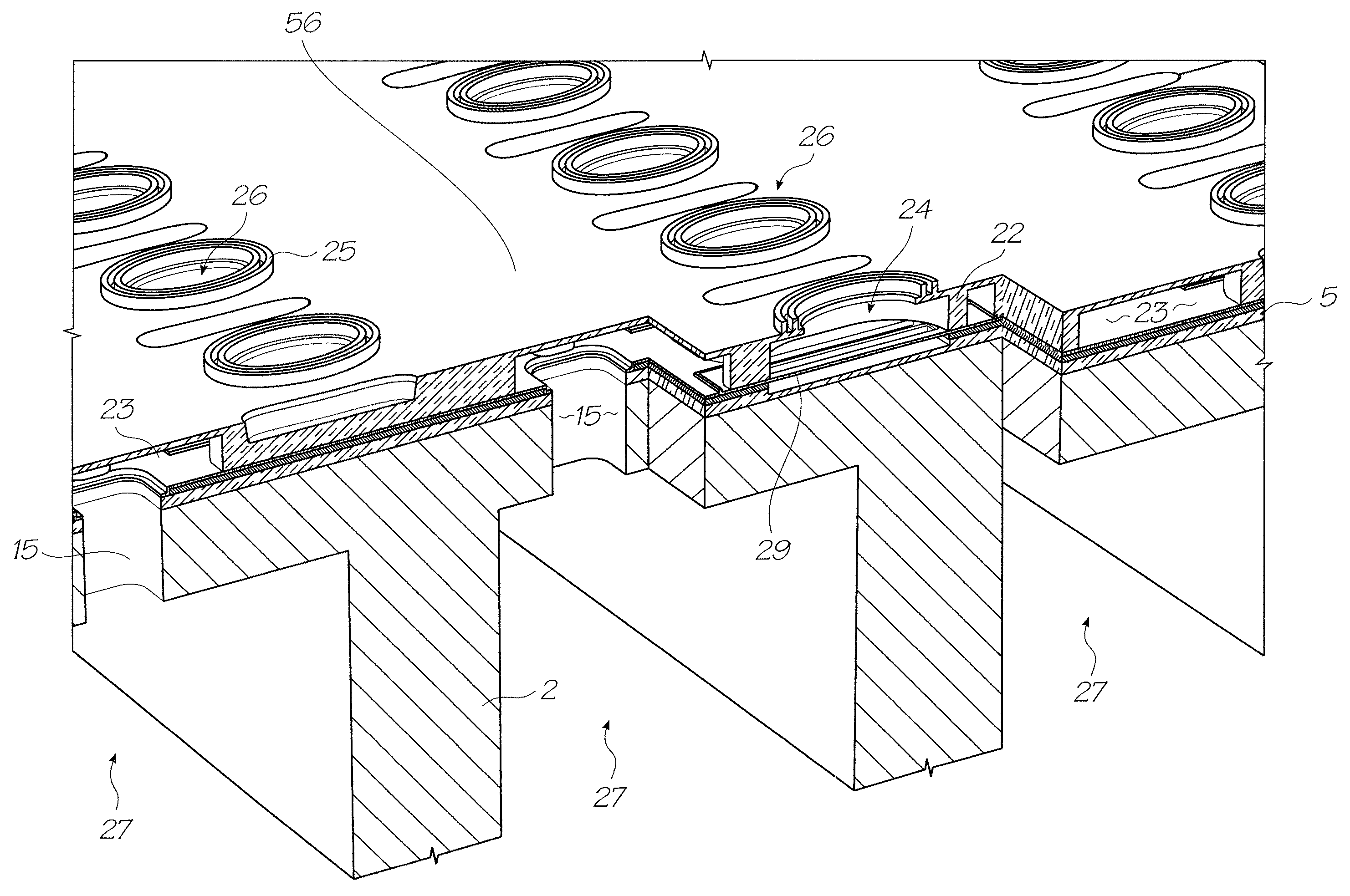

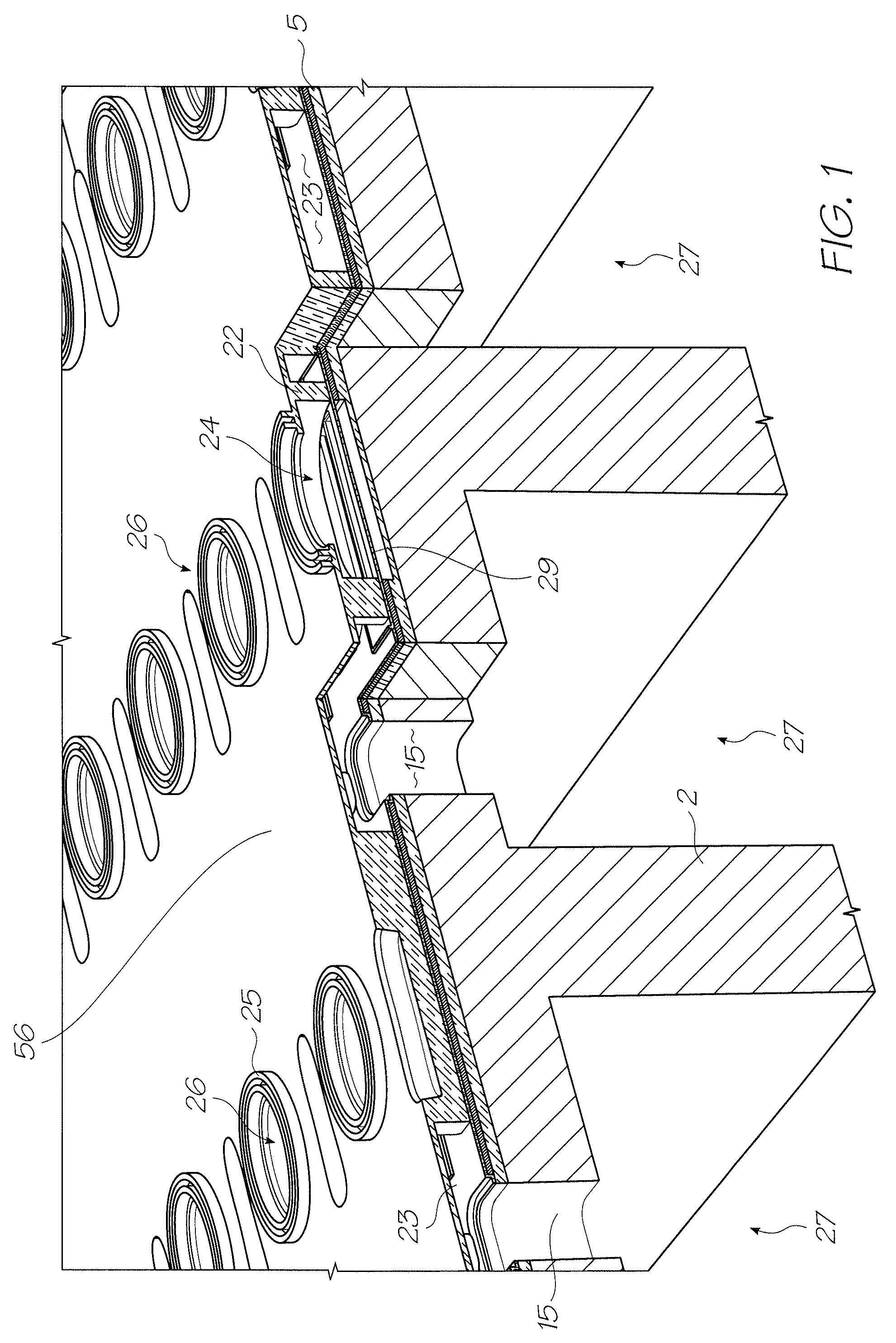

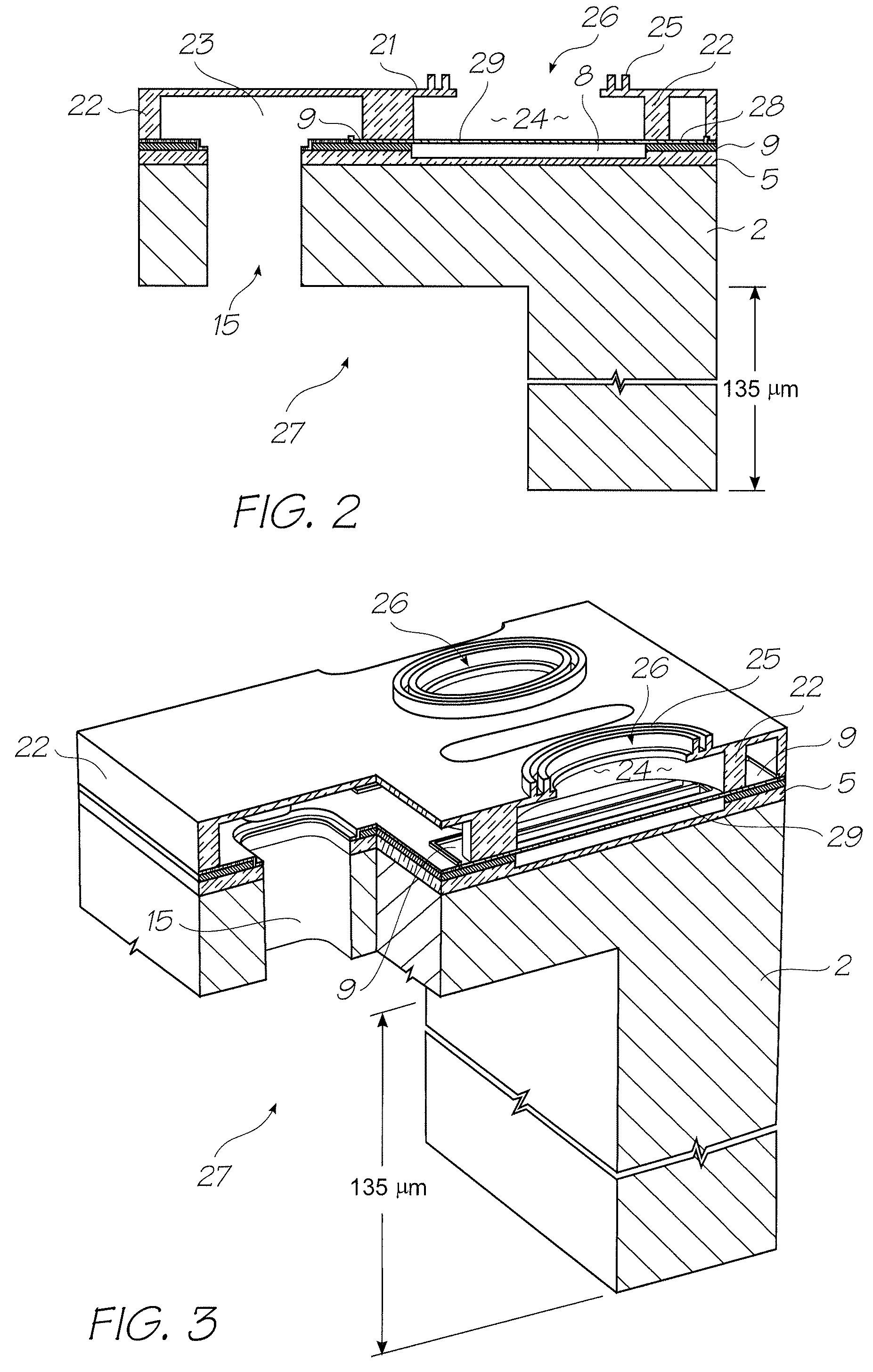

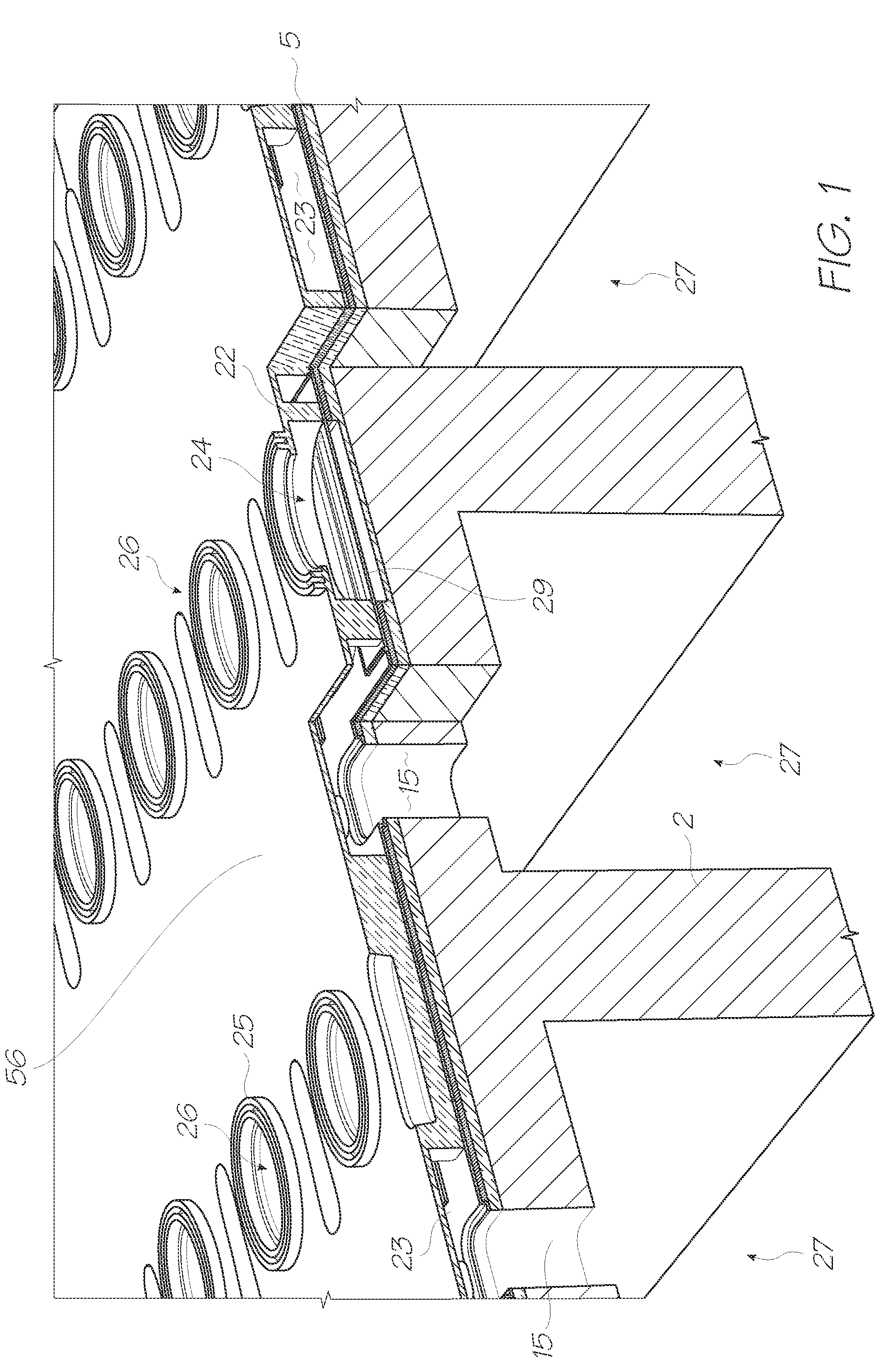

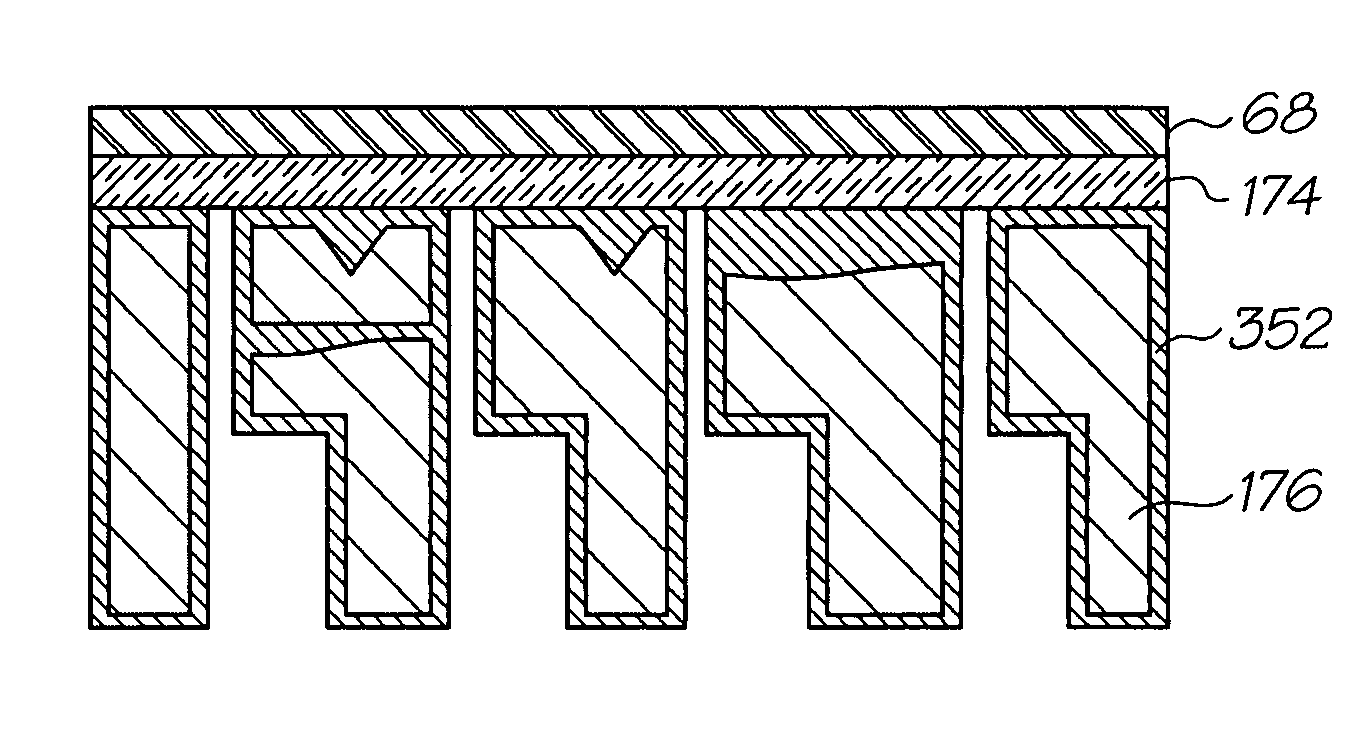

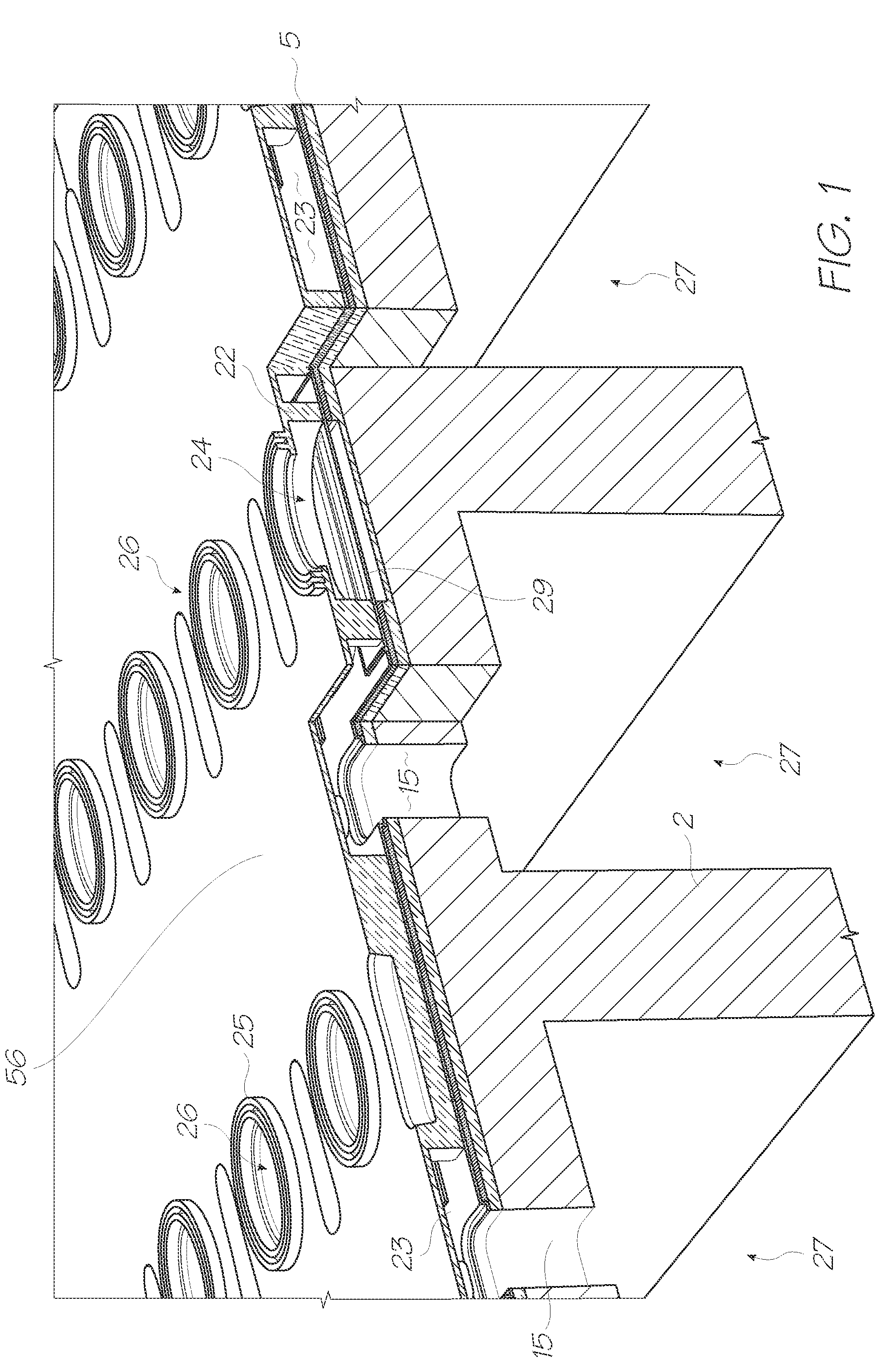

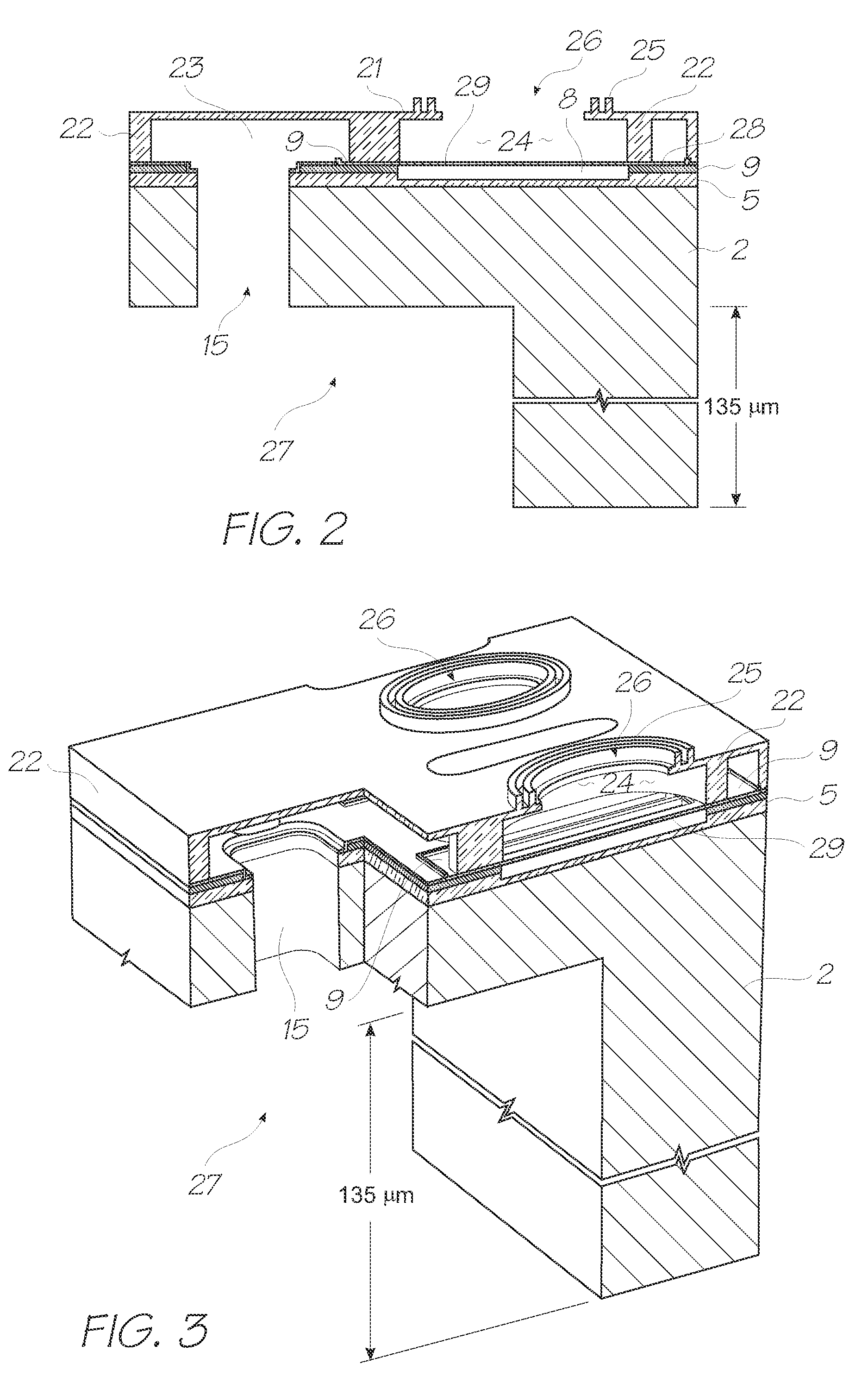

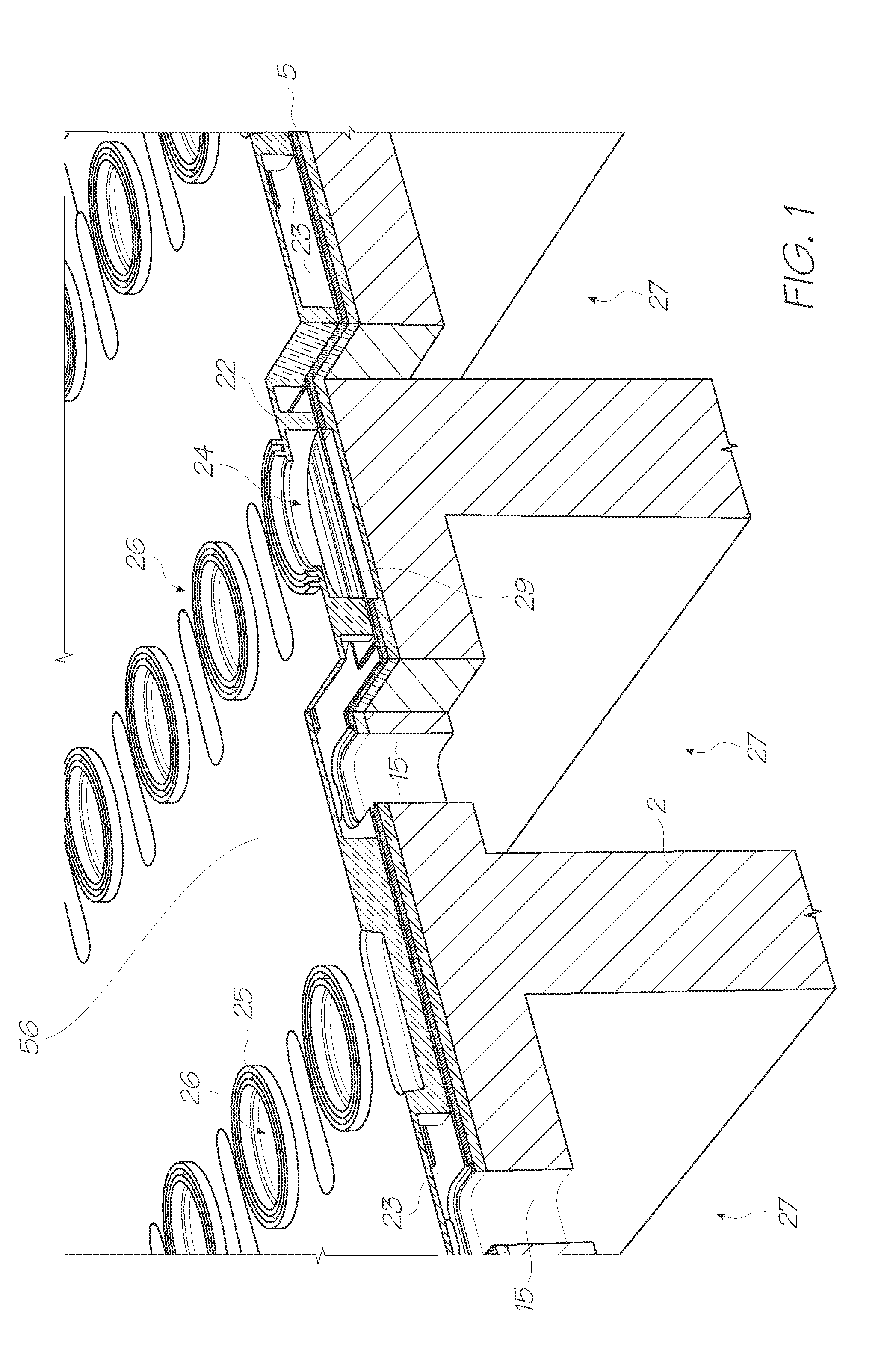

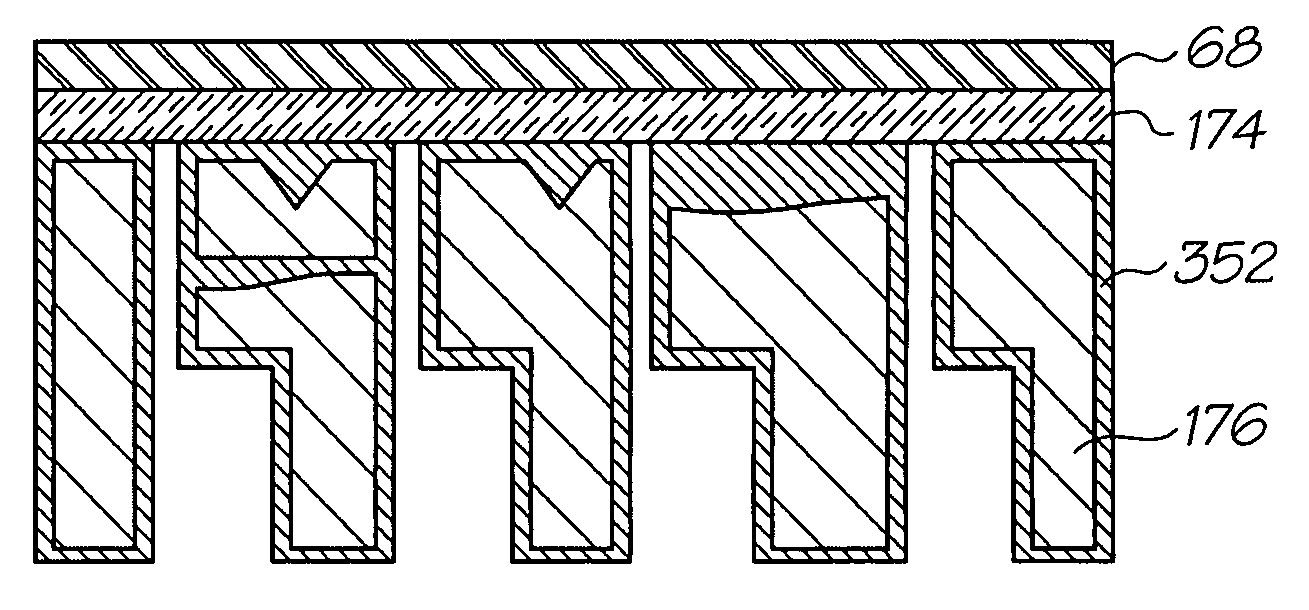

A method of fabricating a printhead having a hydrophobic ink ejection face is provided. The method comprises the steps of: (a) providing a partially-fabricated printhead comprising a plurality of nozzle chambers and a relatively hydrophilic nozzle surface, the nozzle surface at least partially defining the ink ejection face; (b) depositing a layer of relatively hydrophobic polymeric material onto the nozzle surface, the polymeric material being resistant to removal by ashing; and (c) defining a plurality of nozzle openings in the nozzle surface, thereby providing a printhead having a relatively hydrophobic ink ejection face. Steps (b) and (c) may be performed in any order.

Owner:MEMJET TECH LTD +1

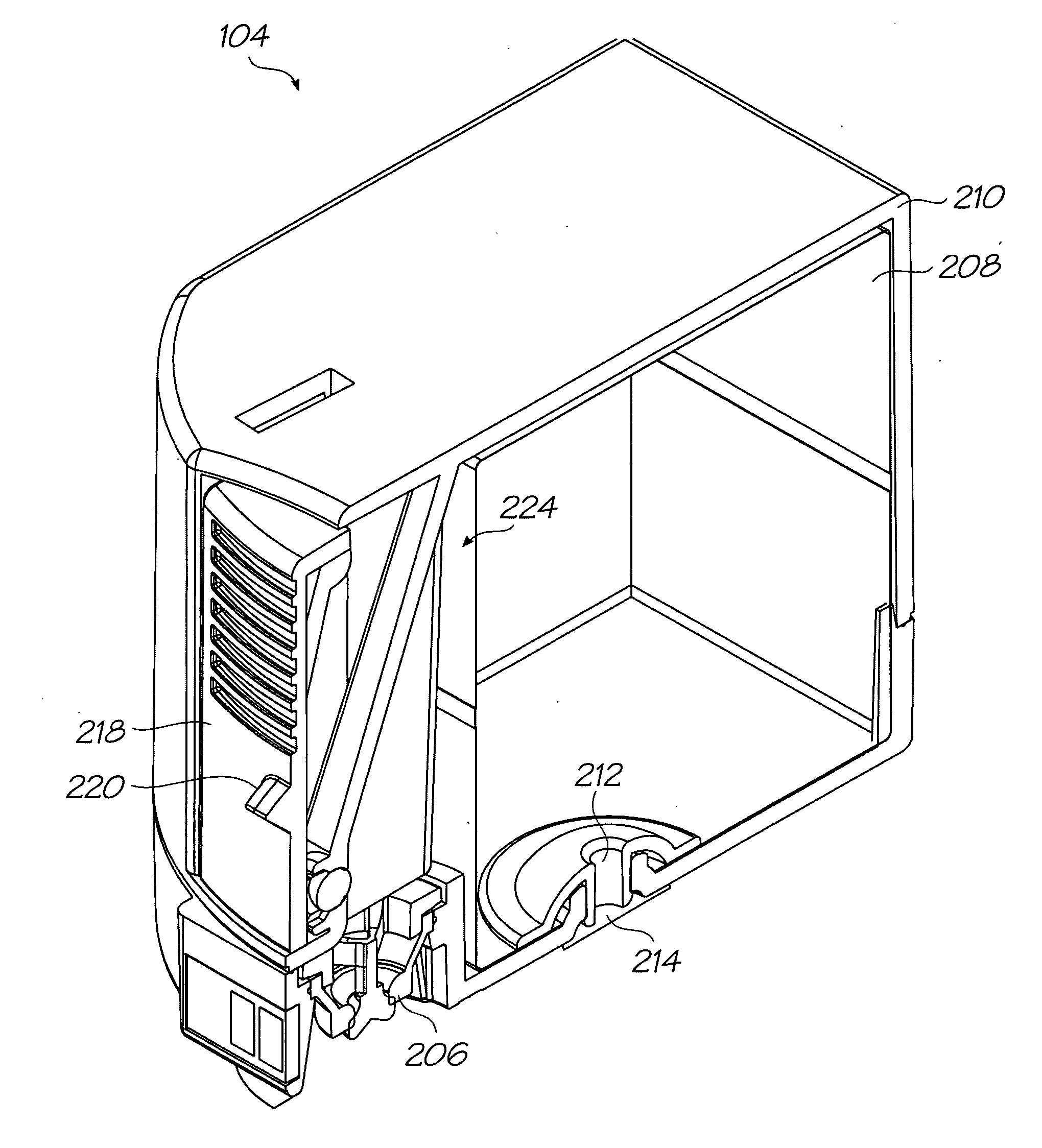

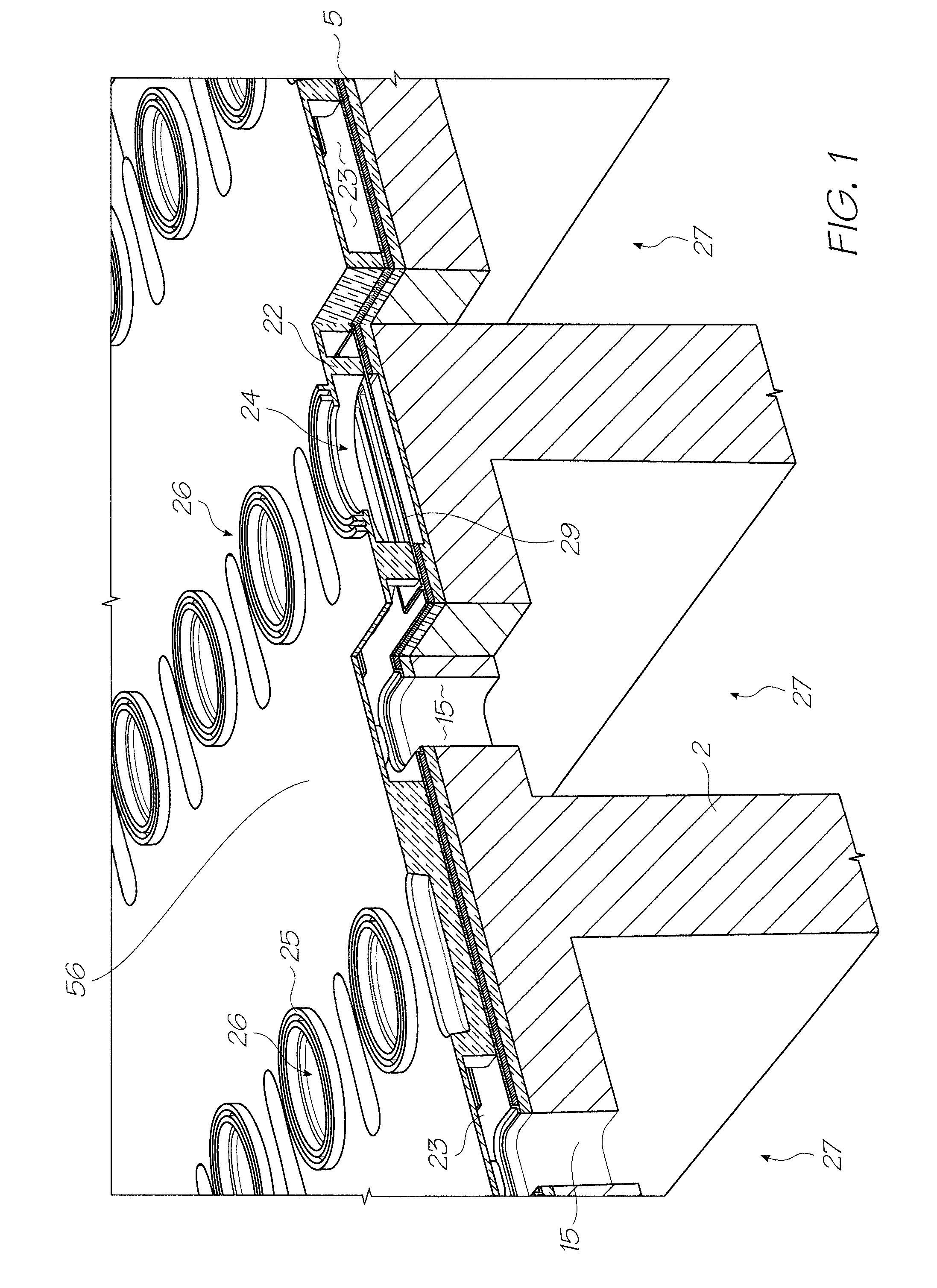

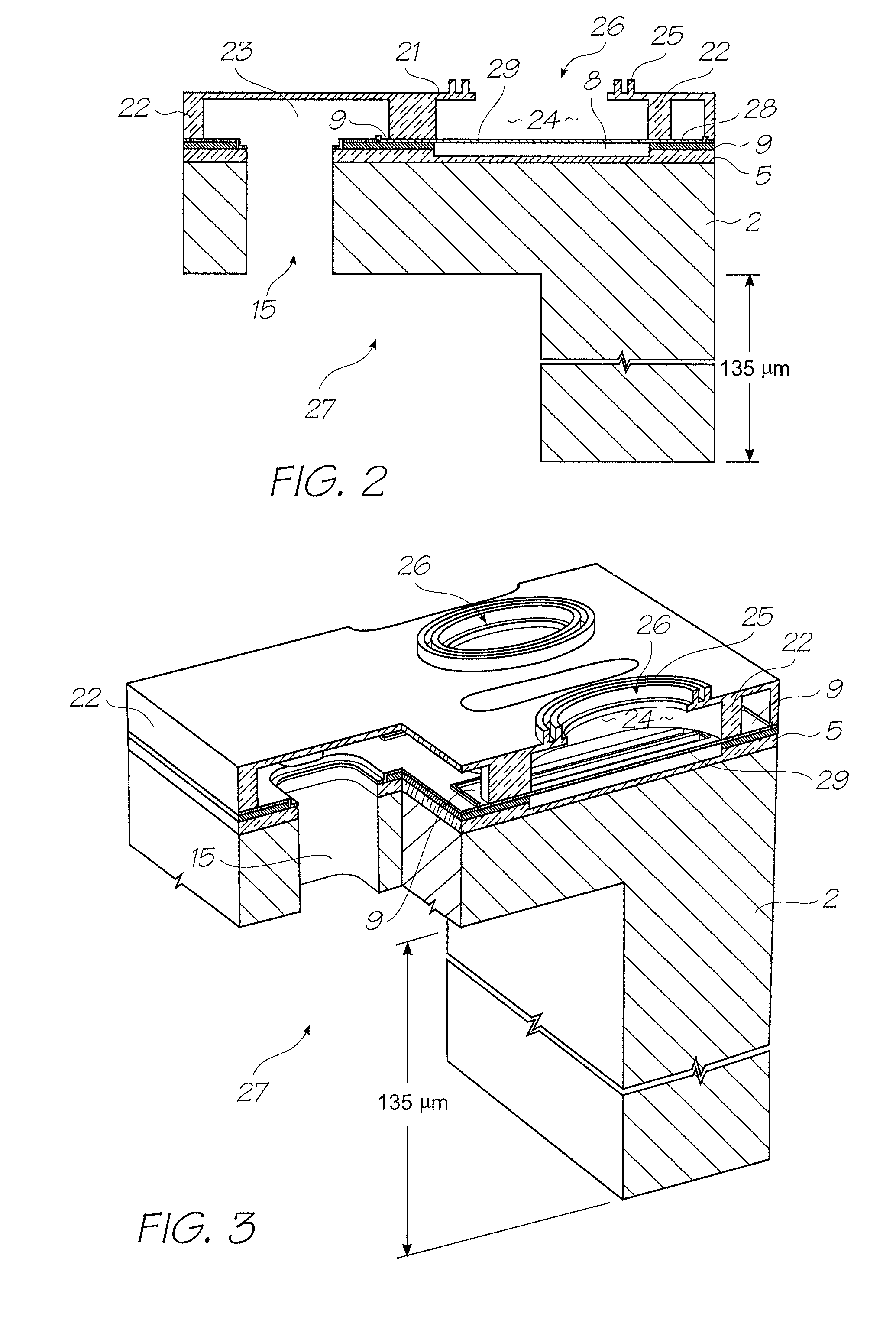

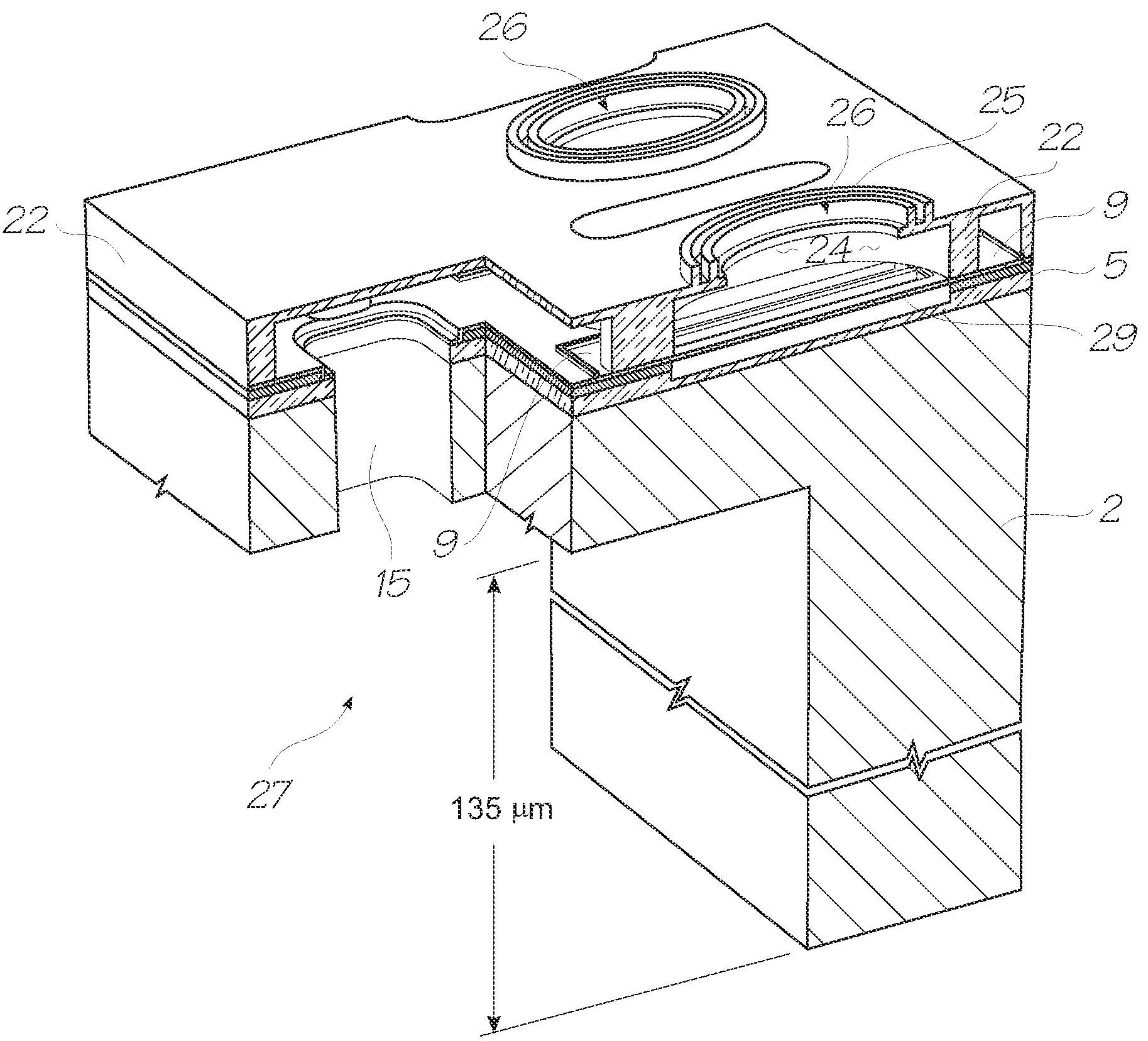

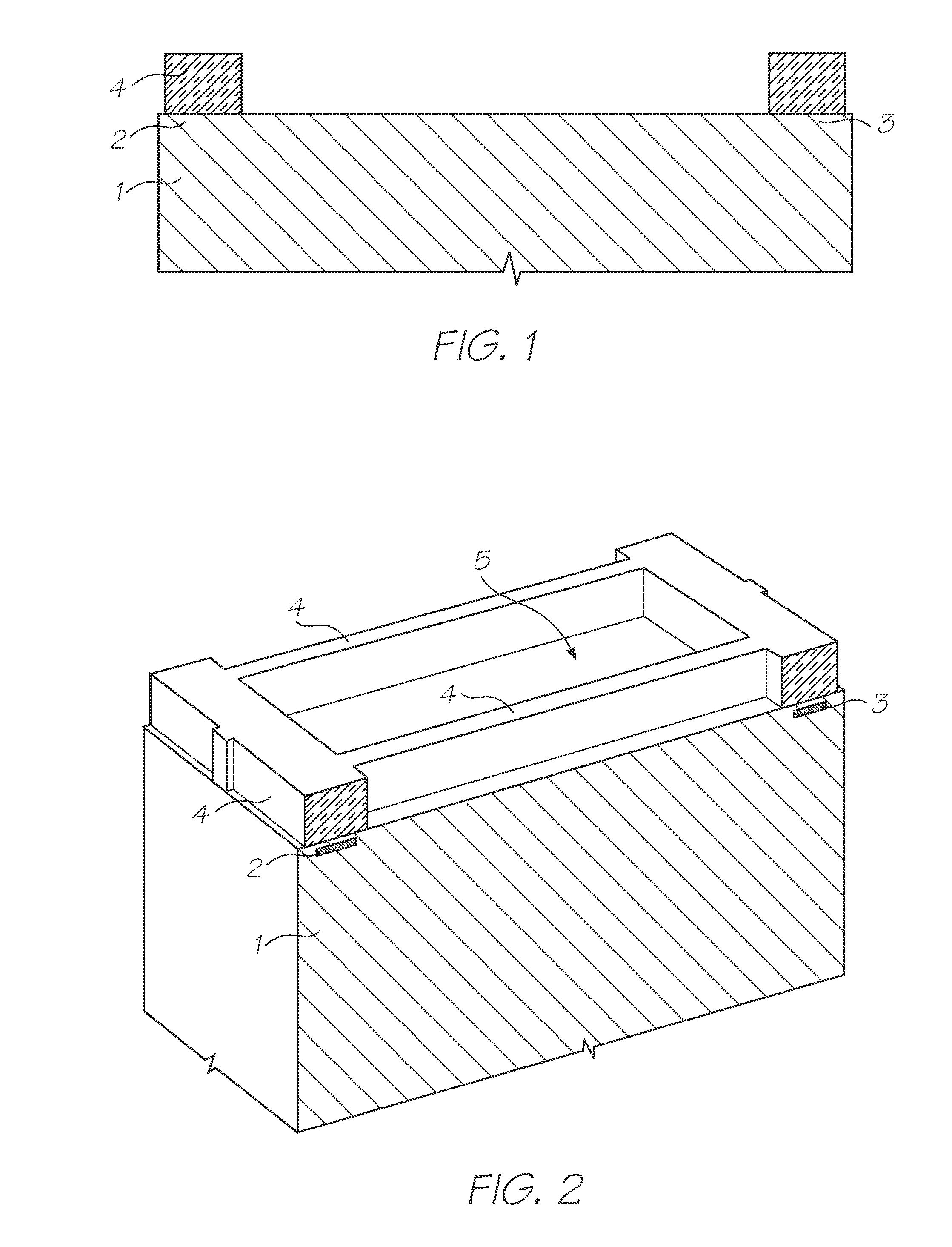

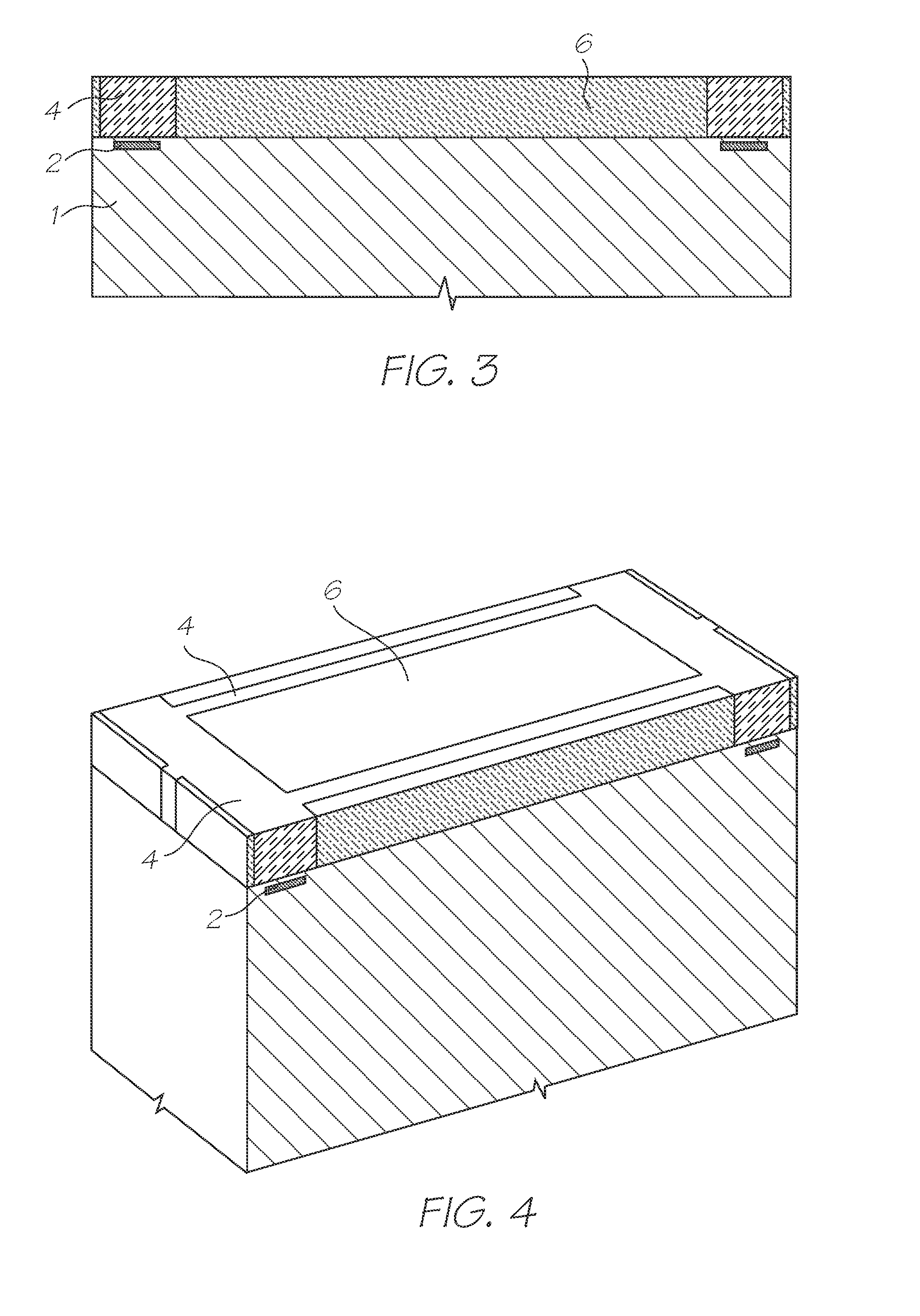

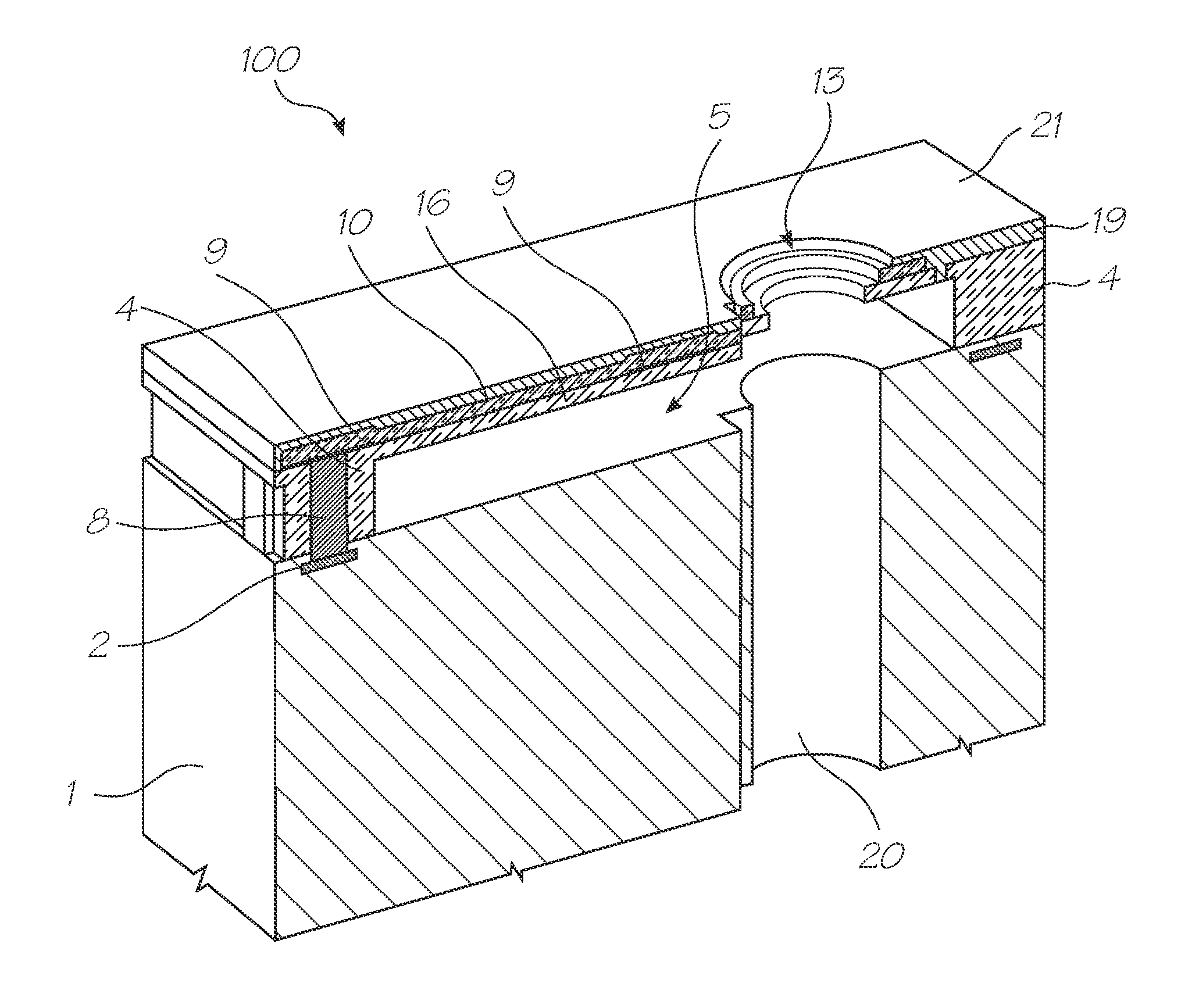

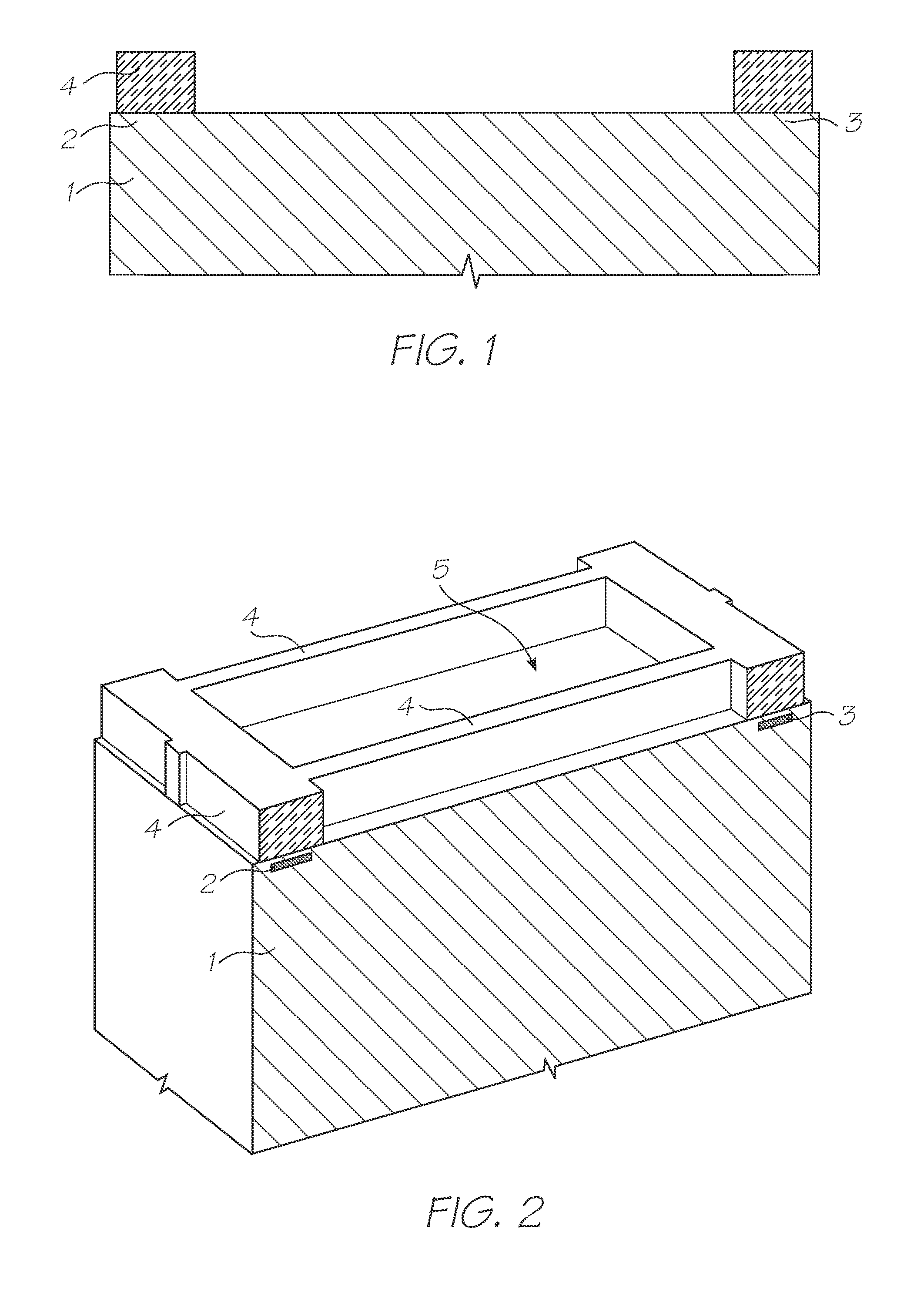

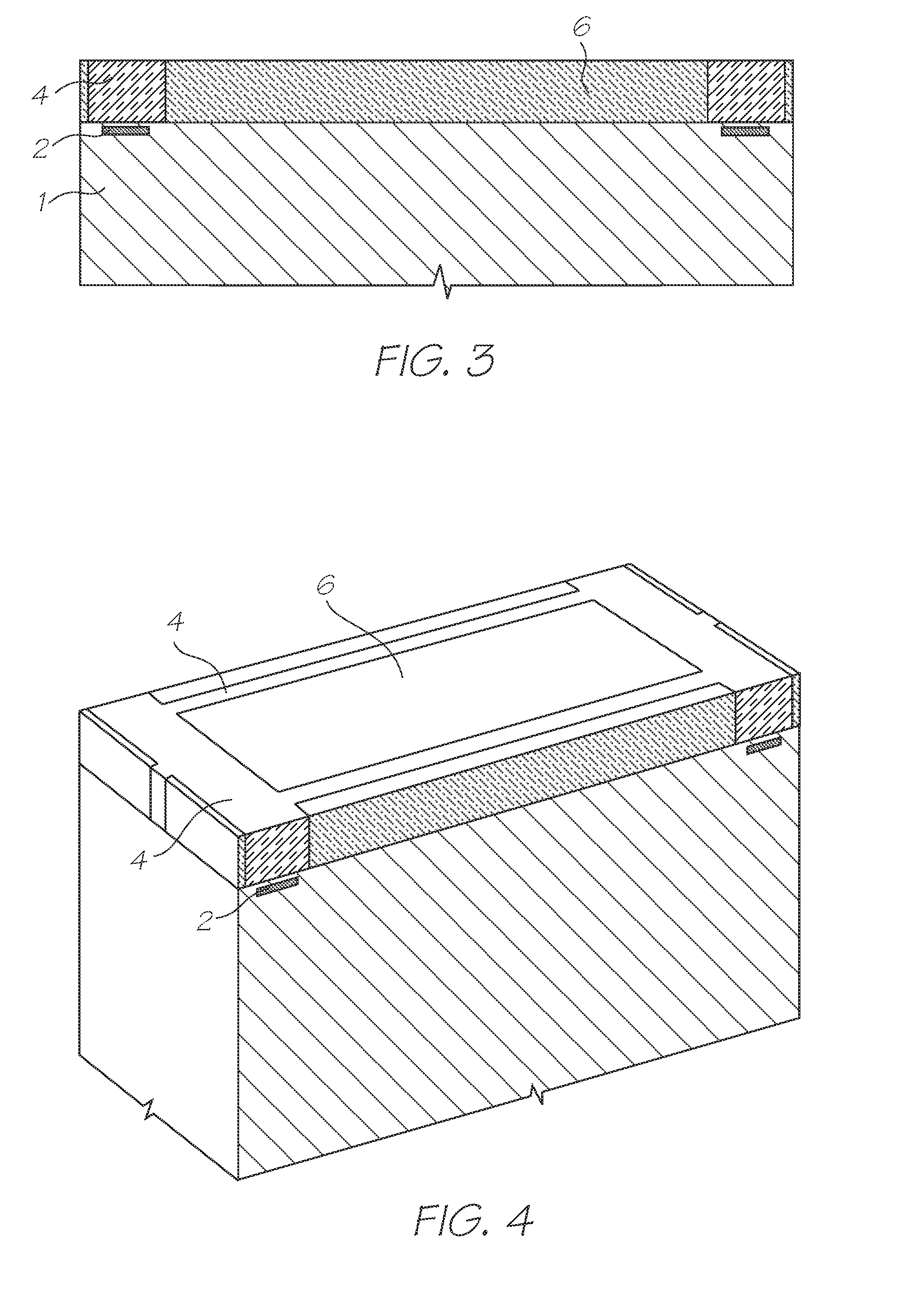

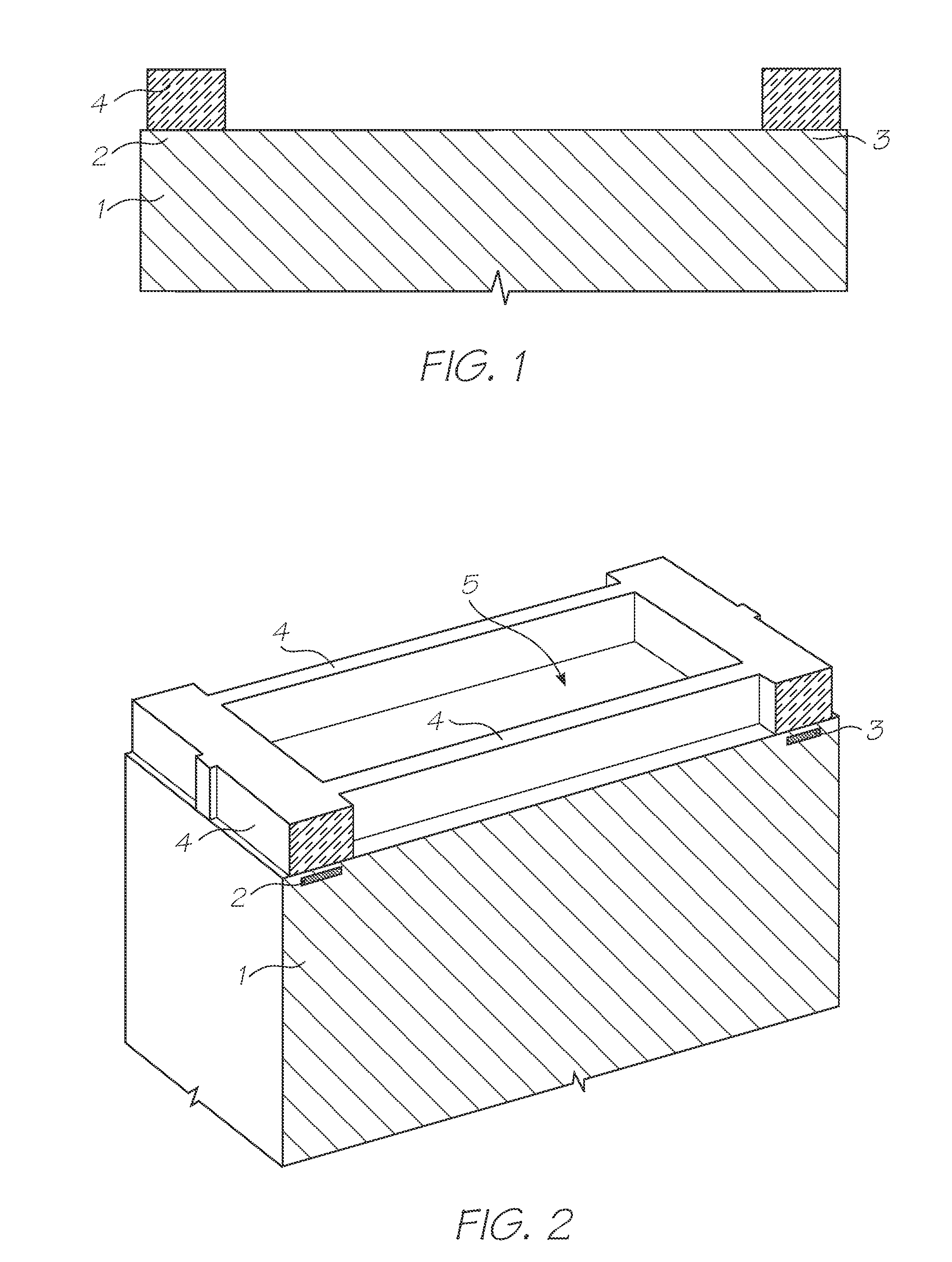

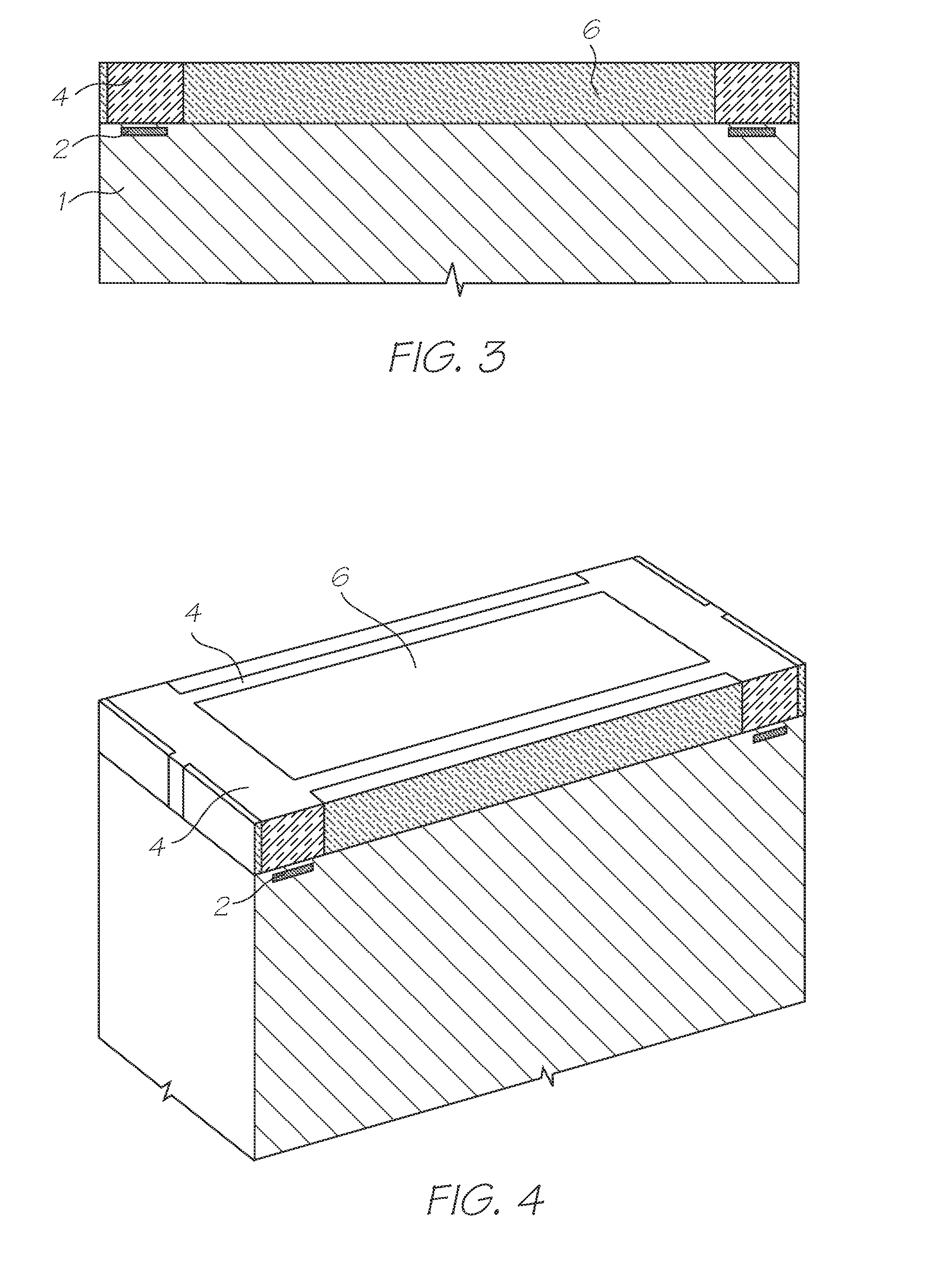

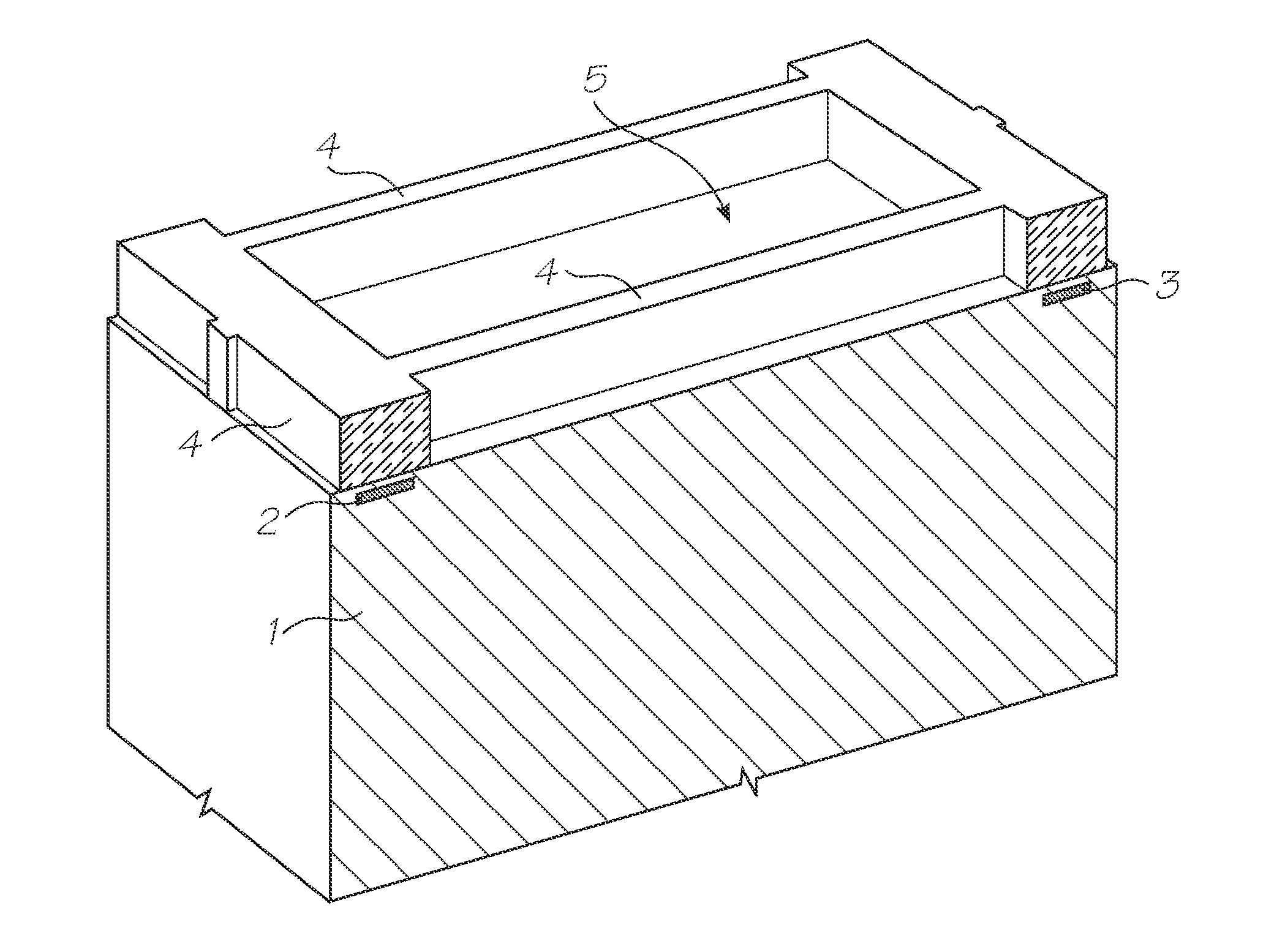

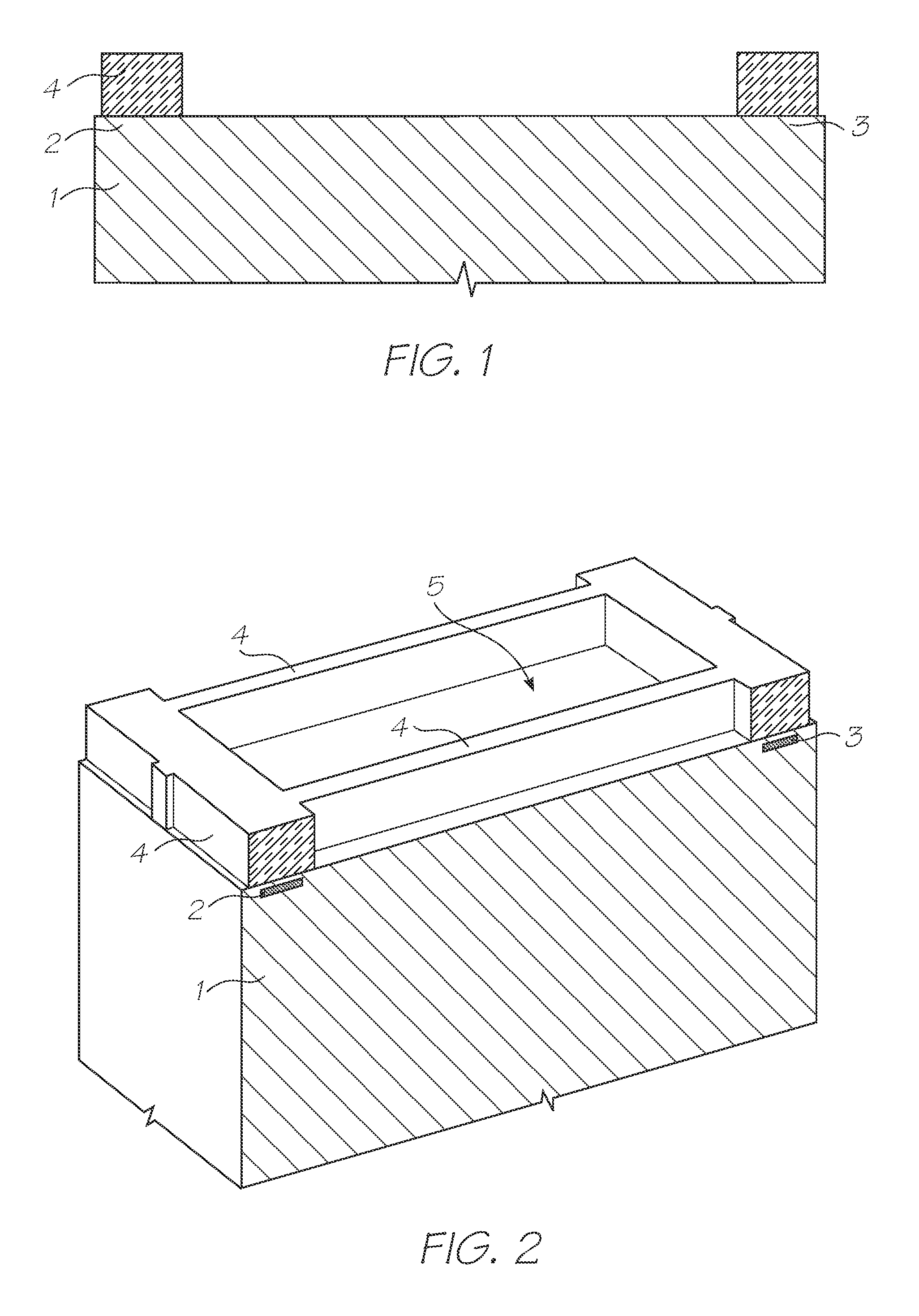

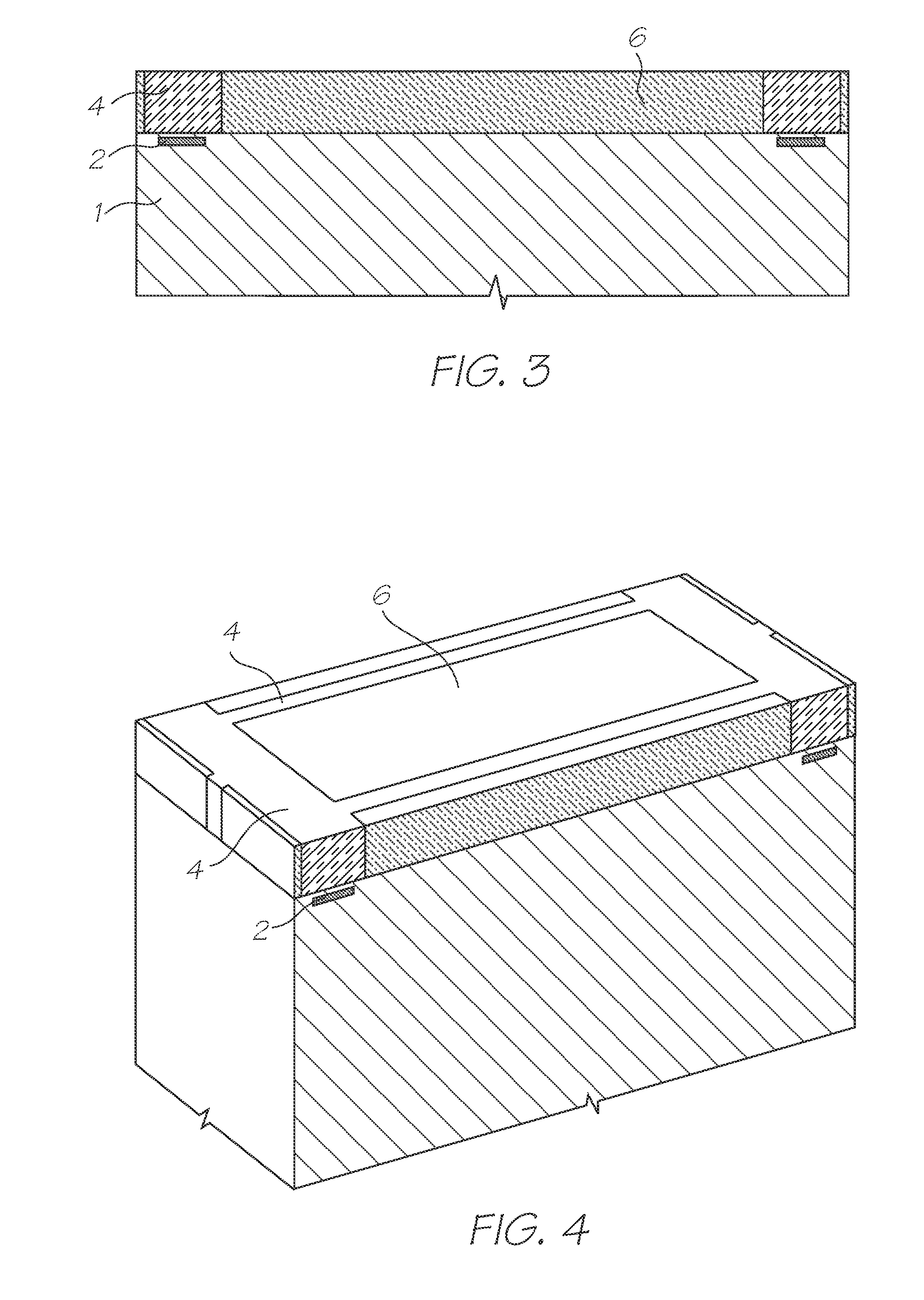

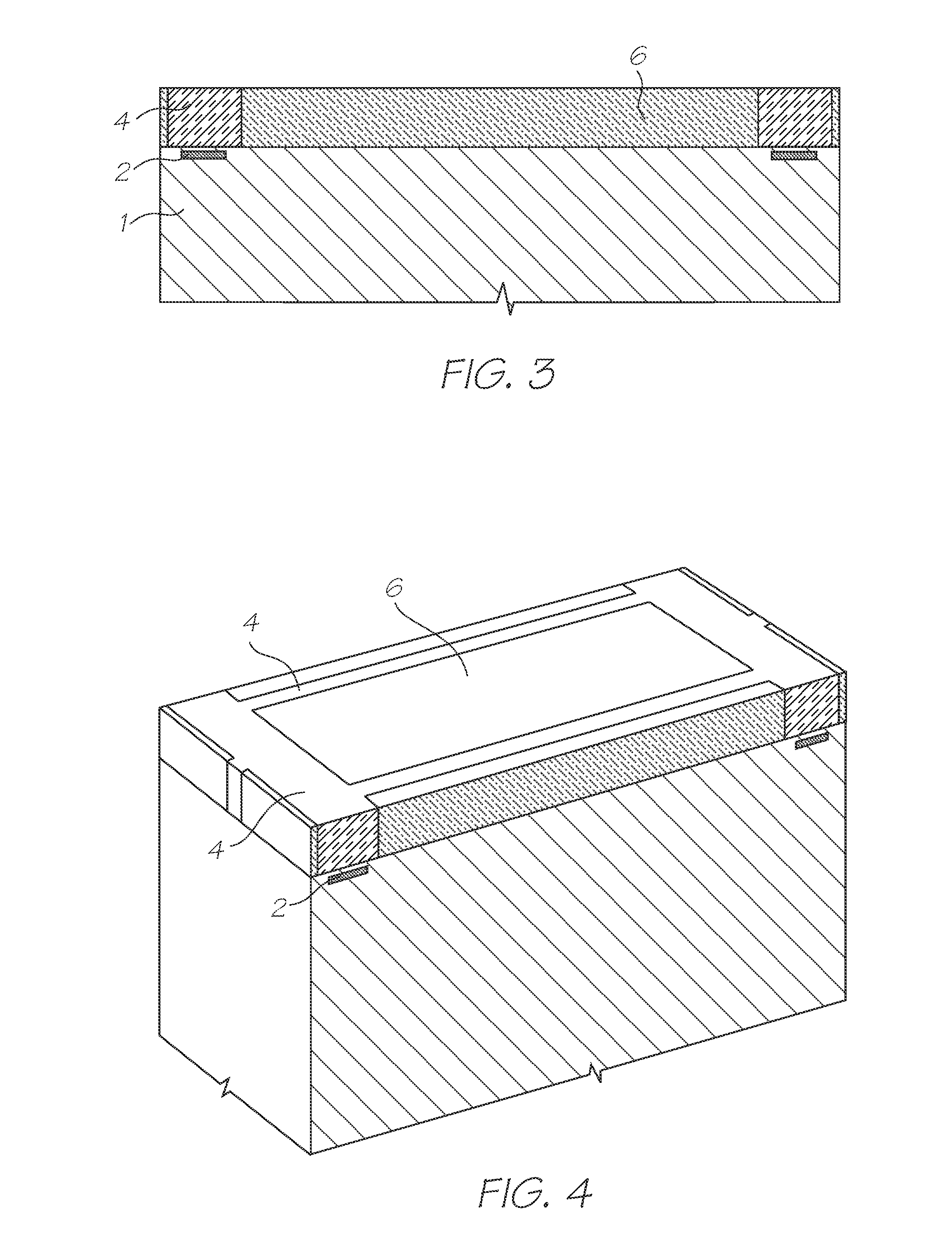

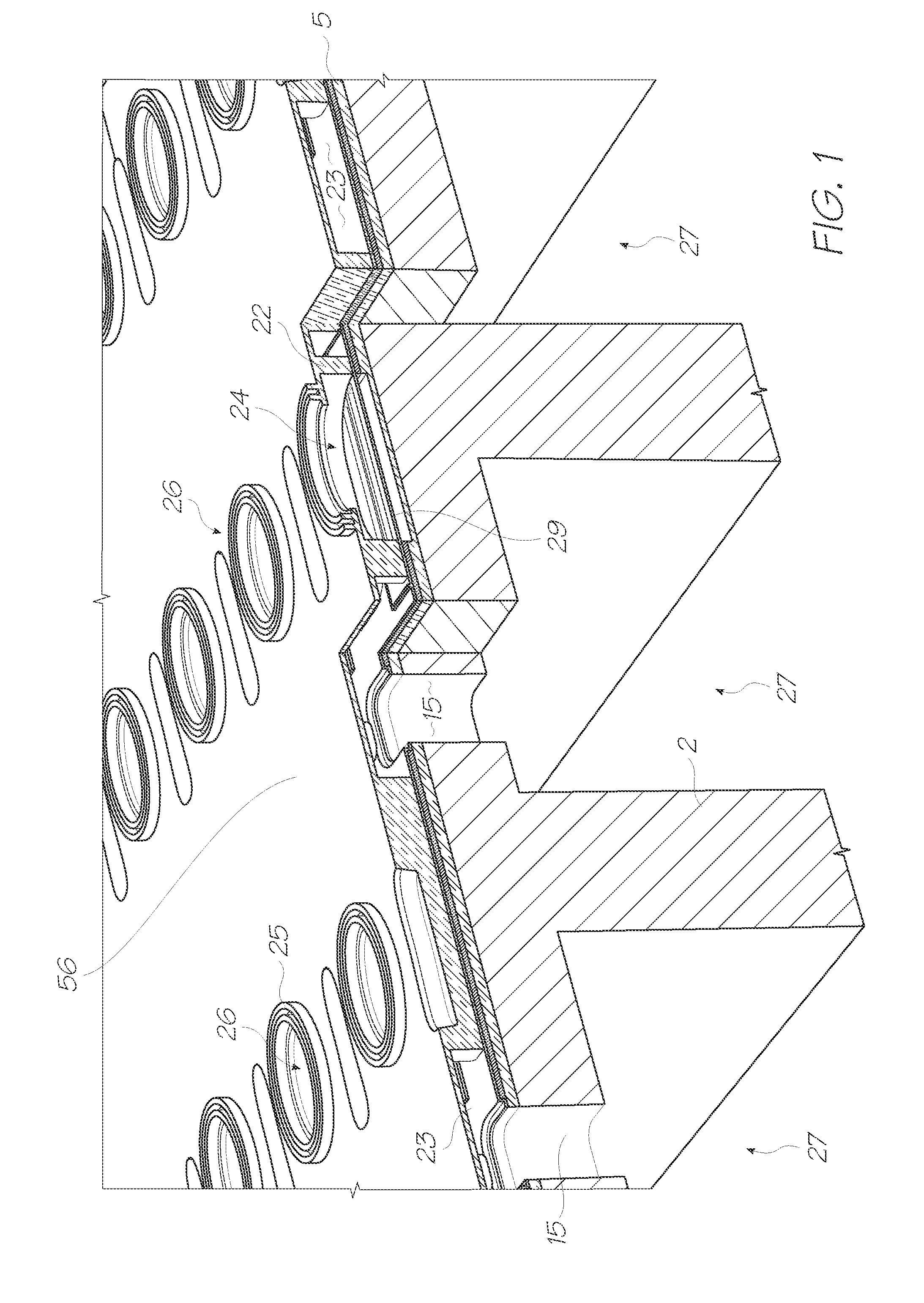

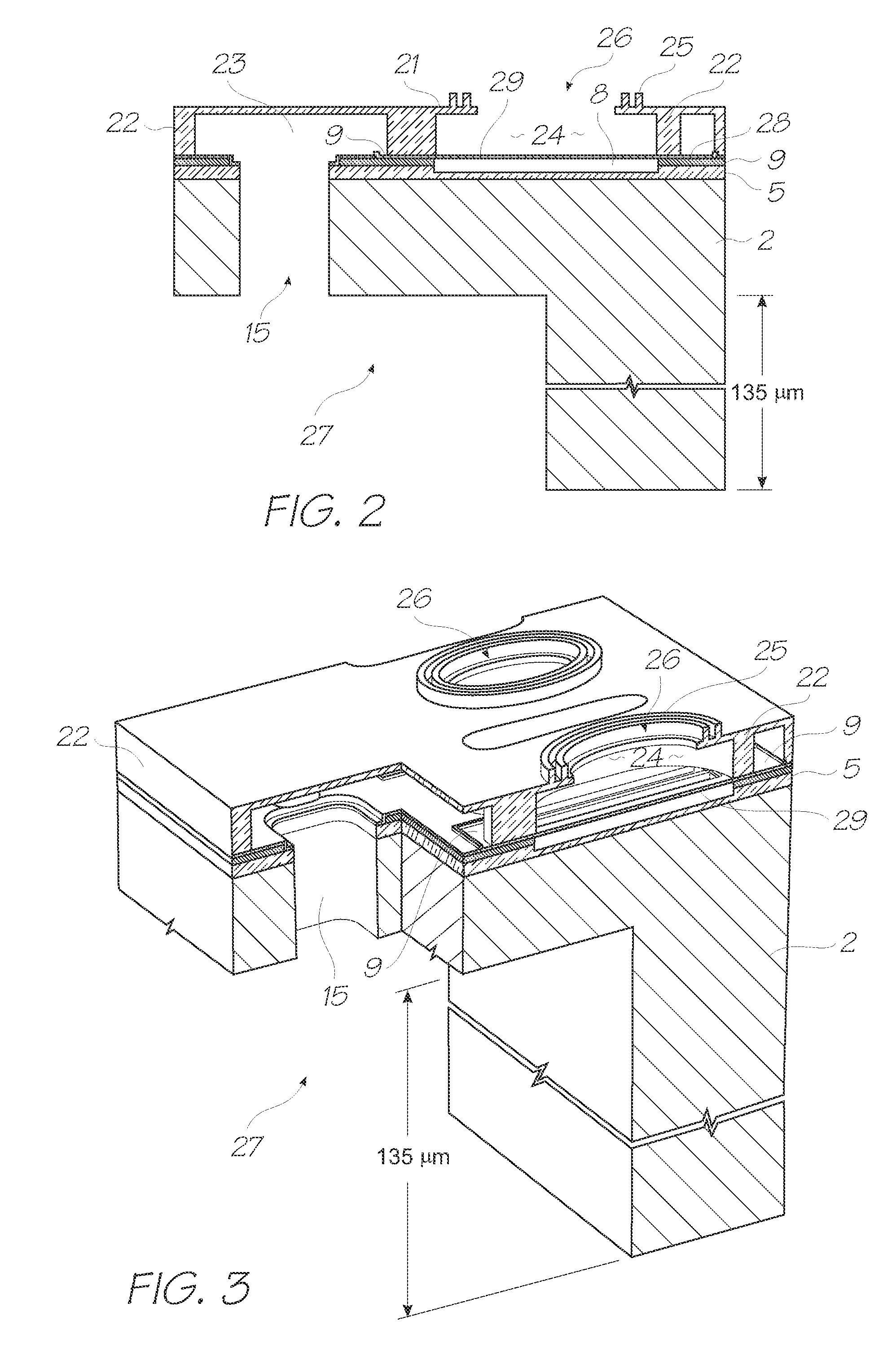

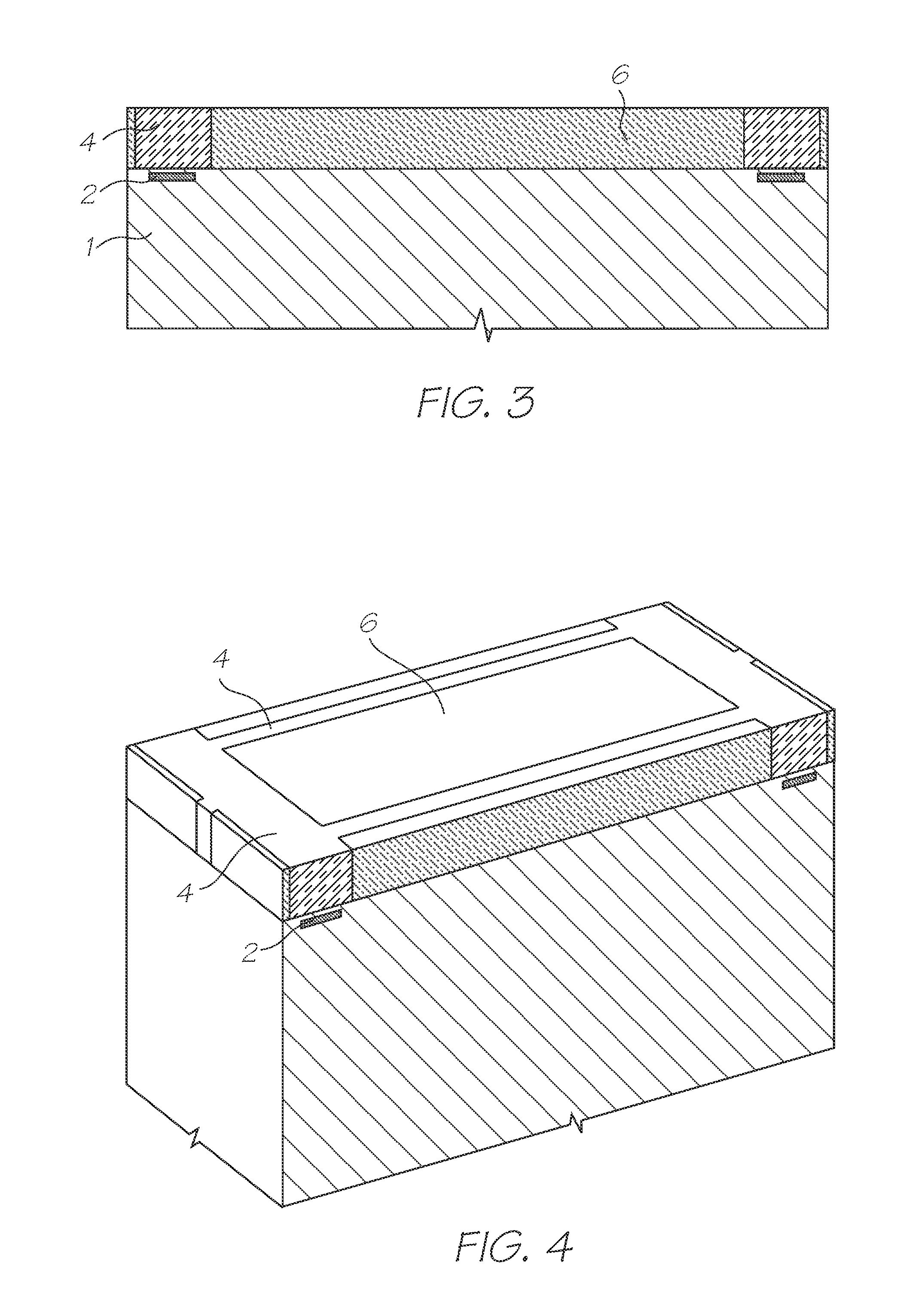

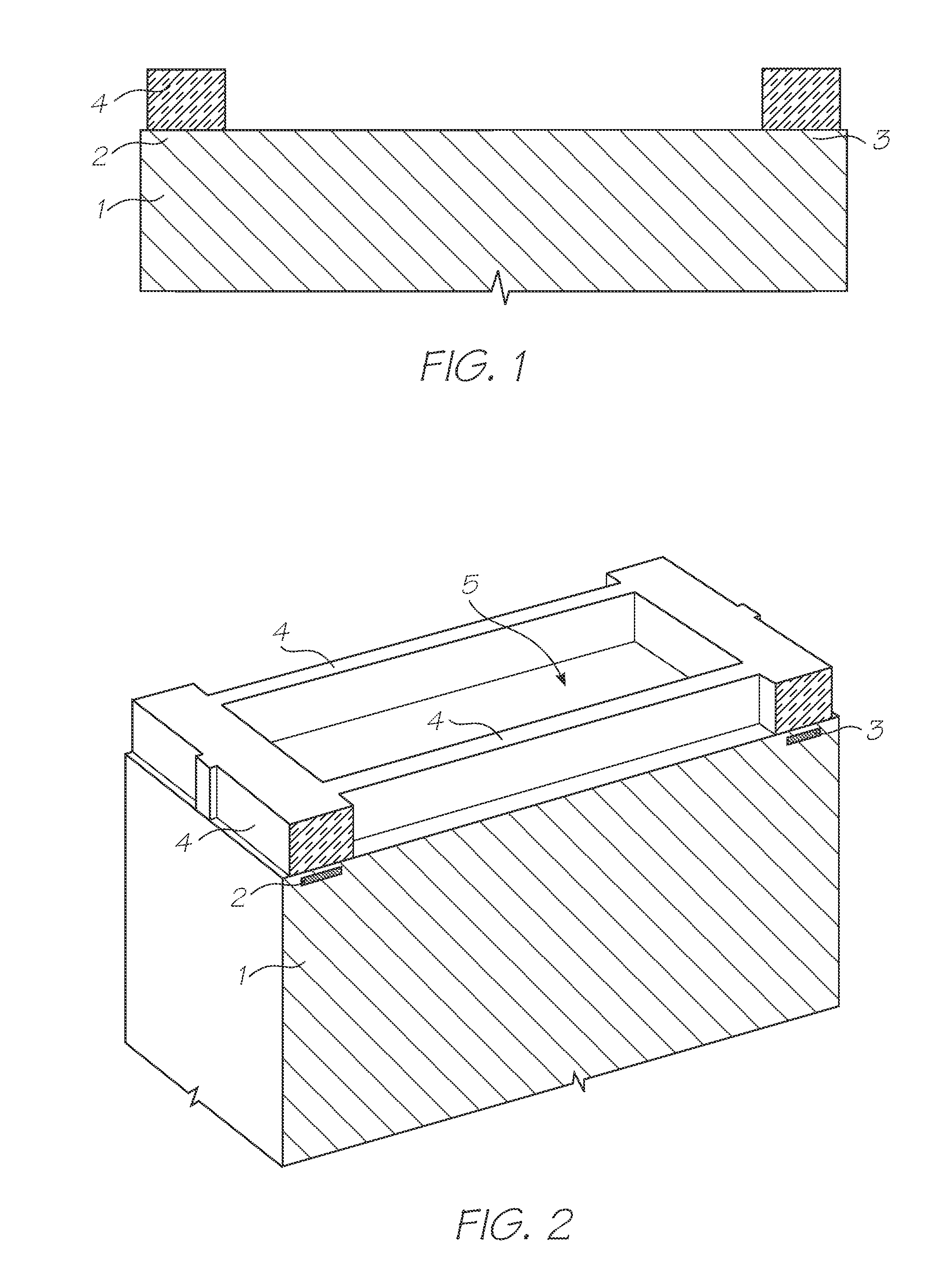

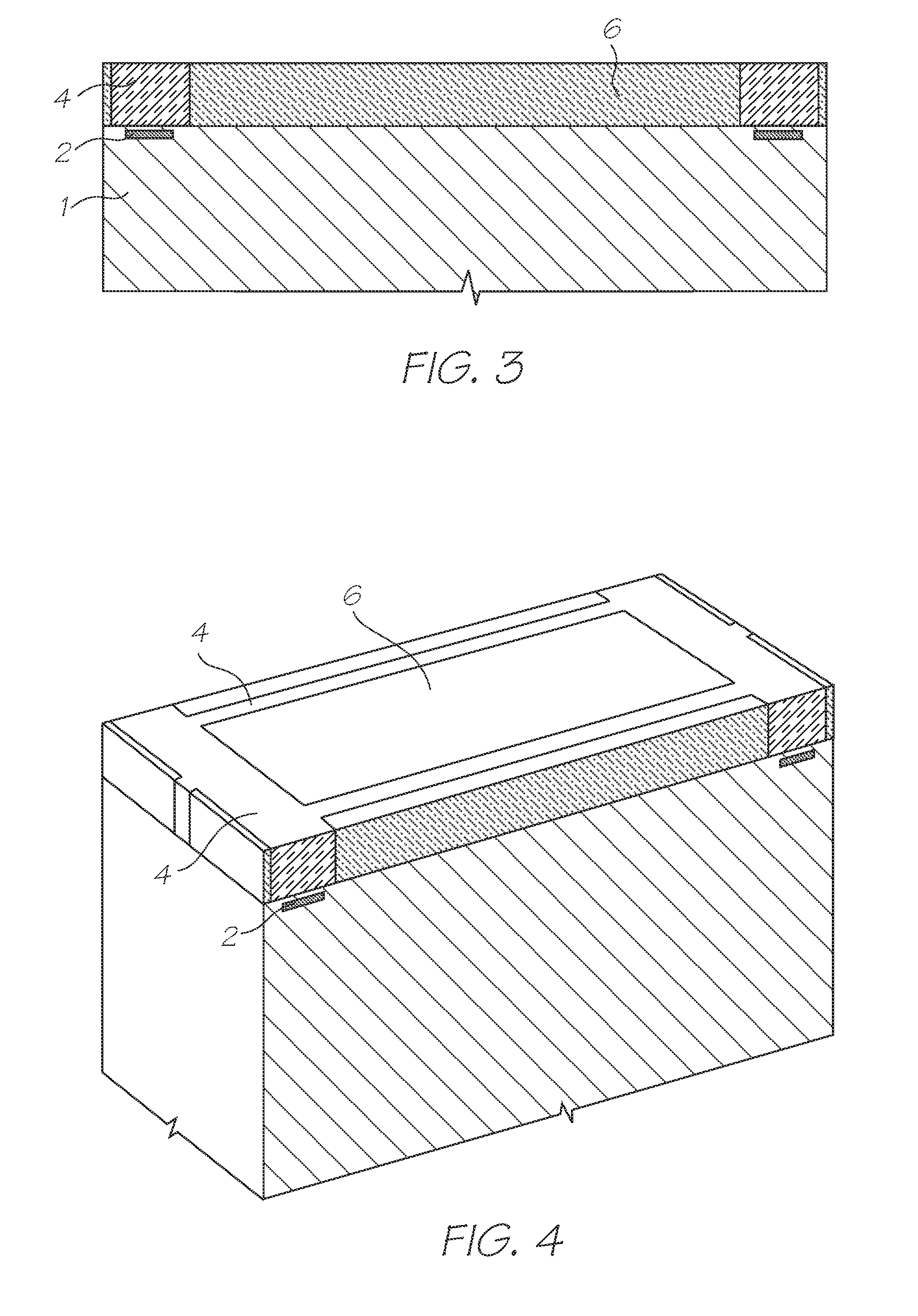

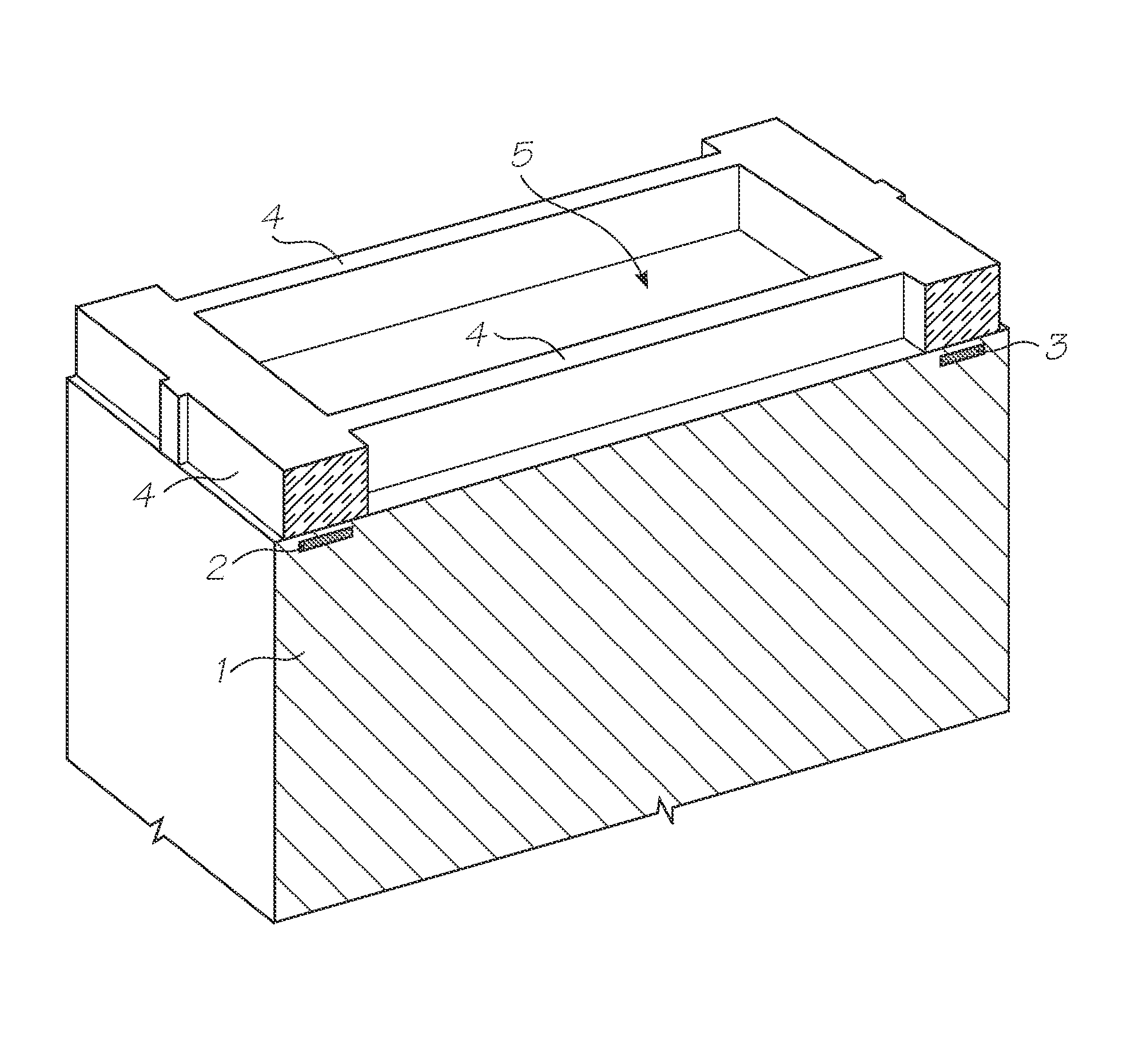

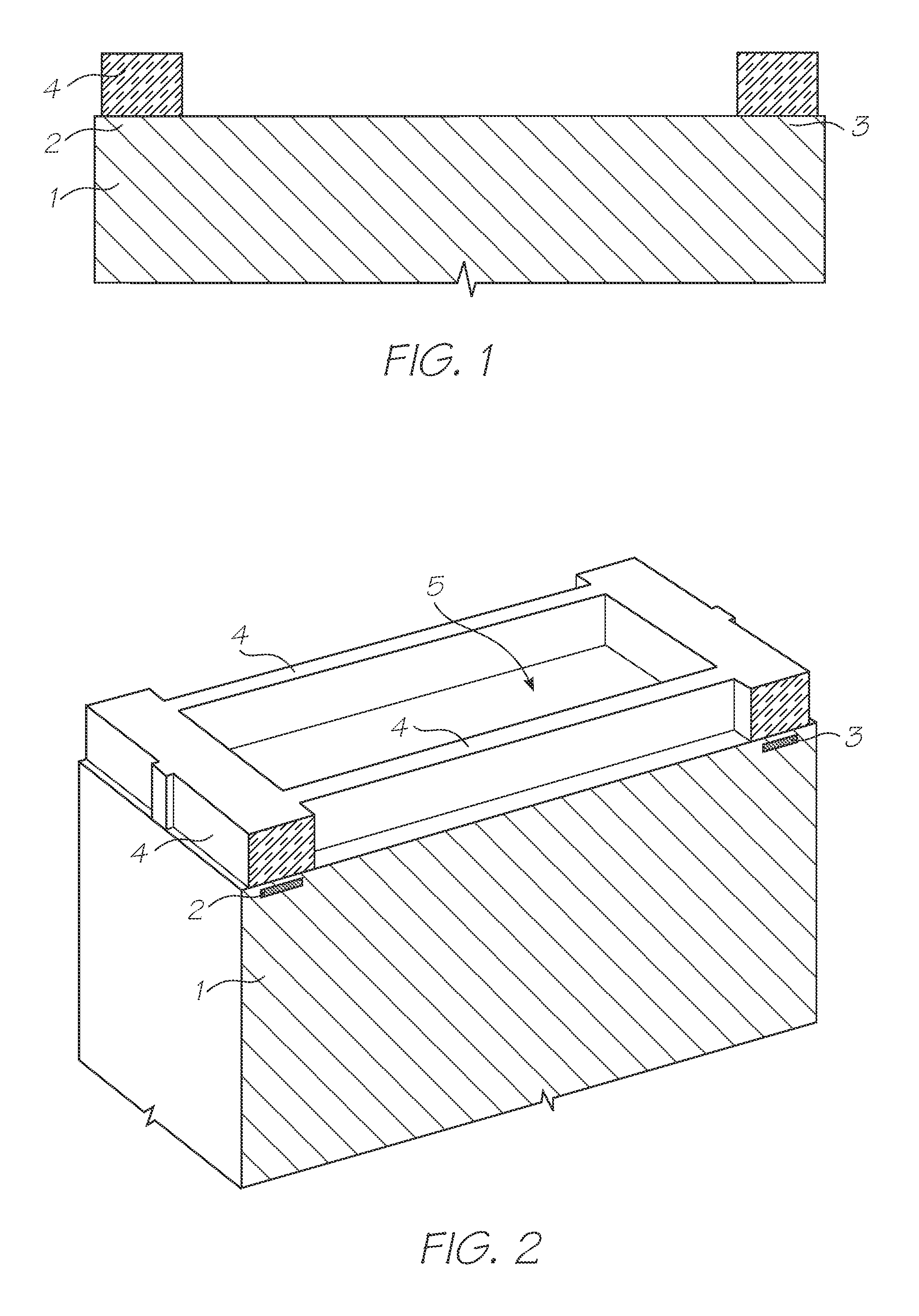

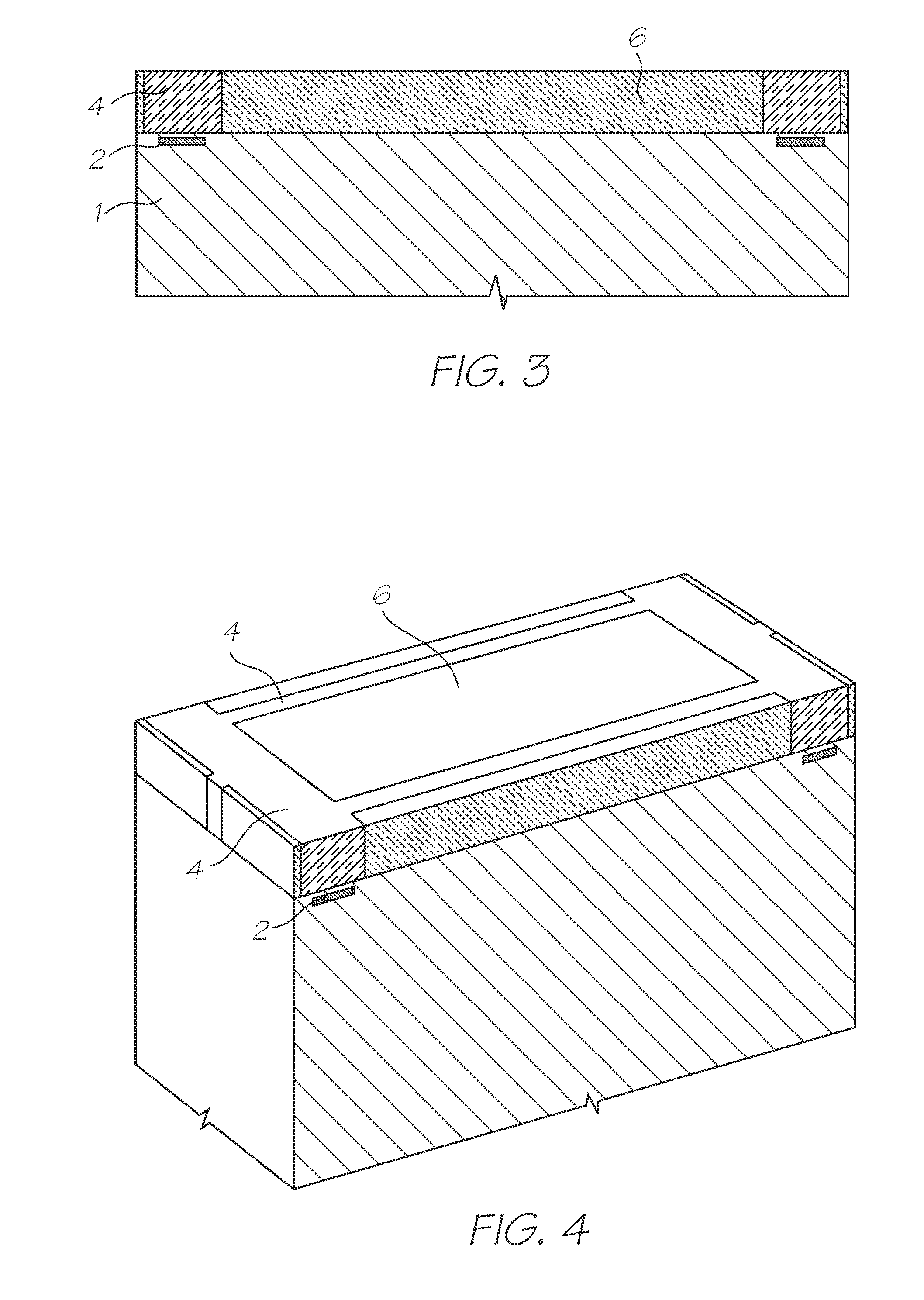

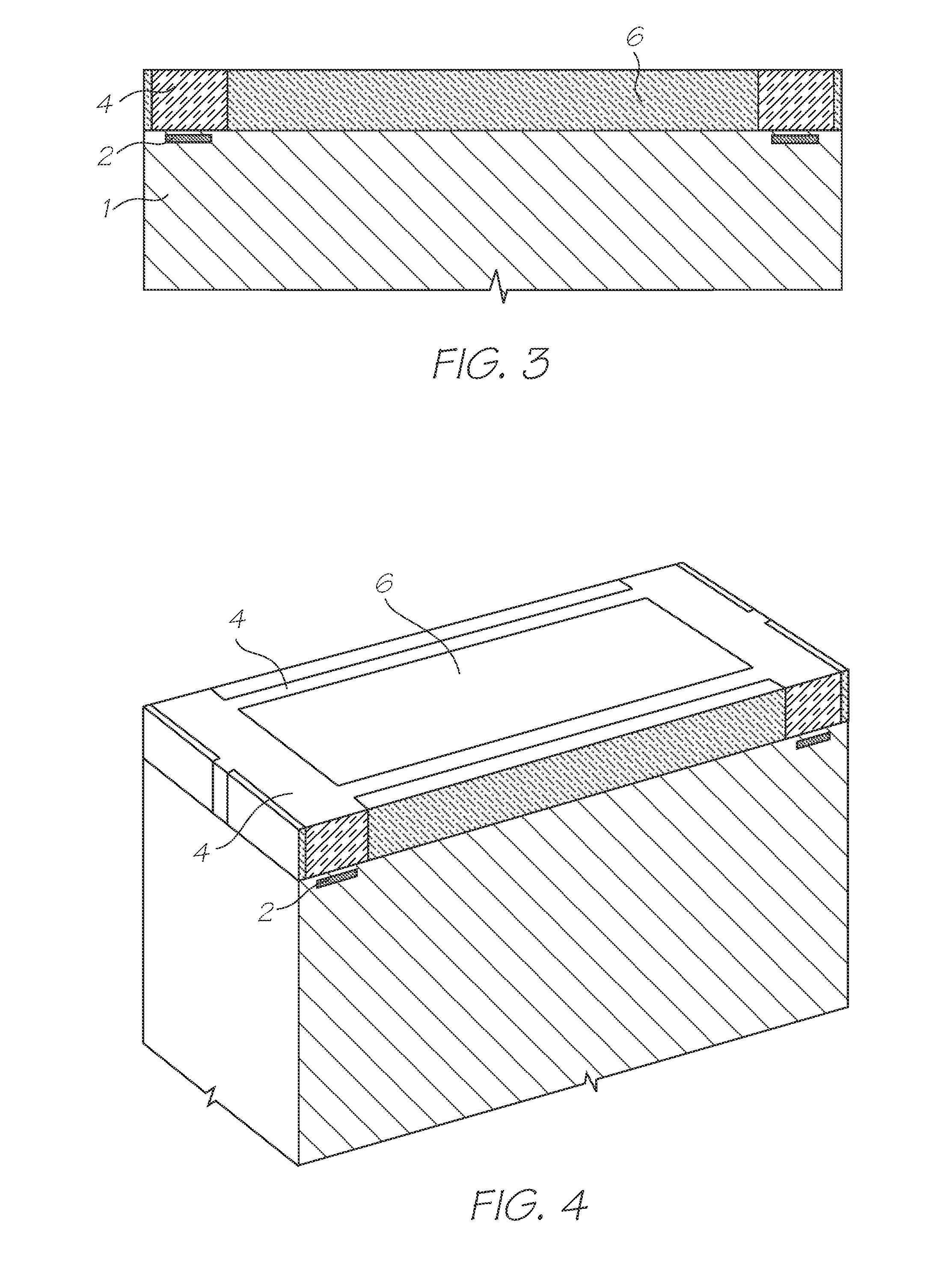

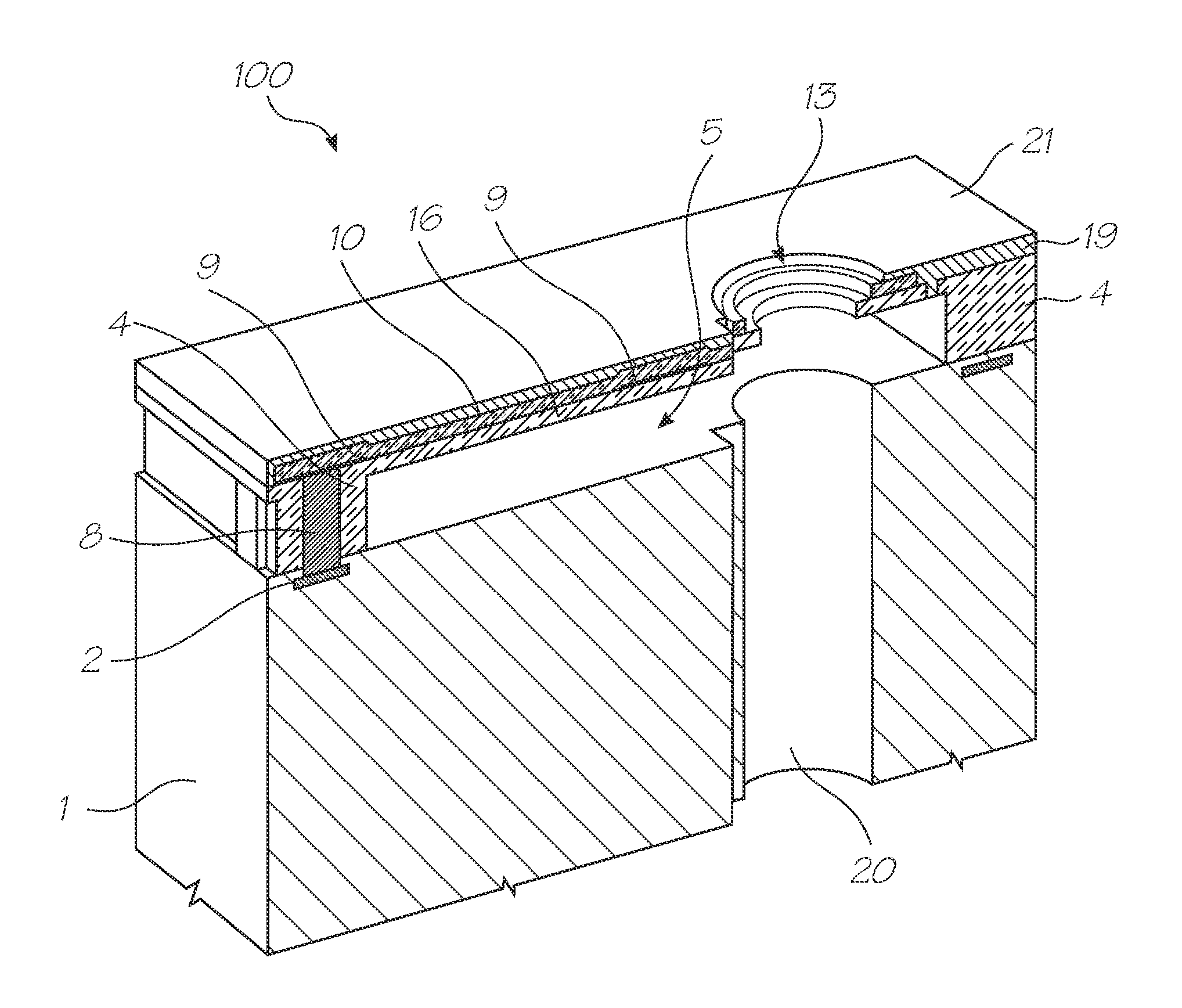

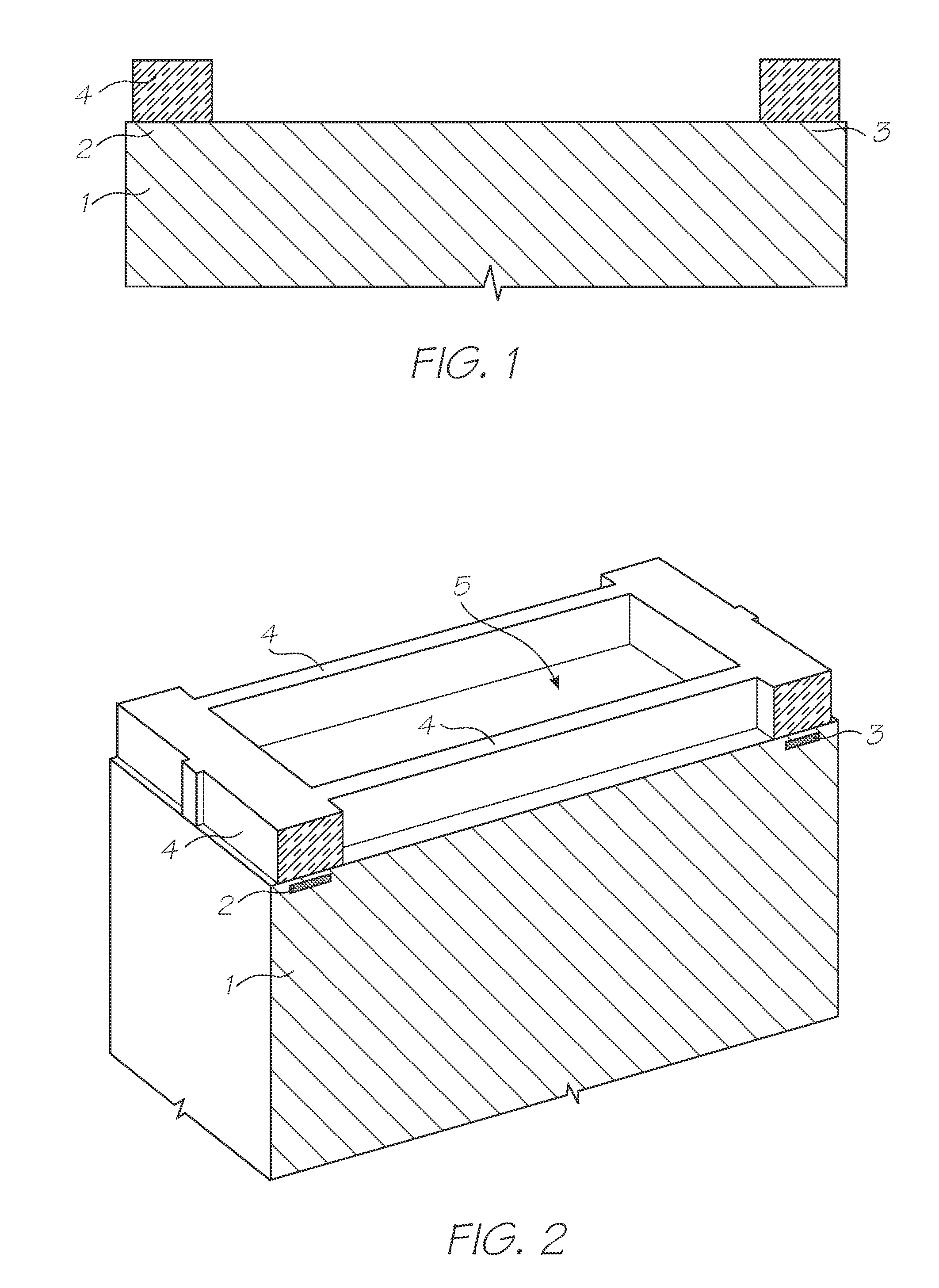

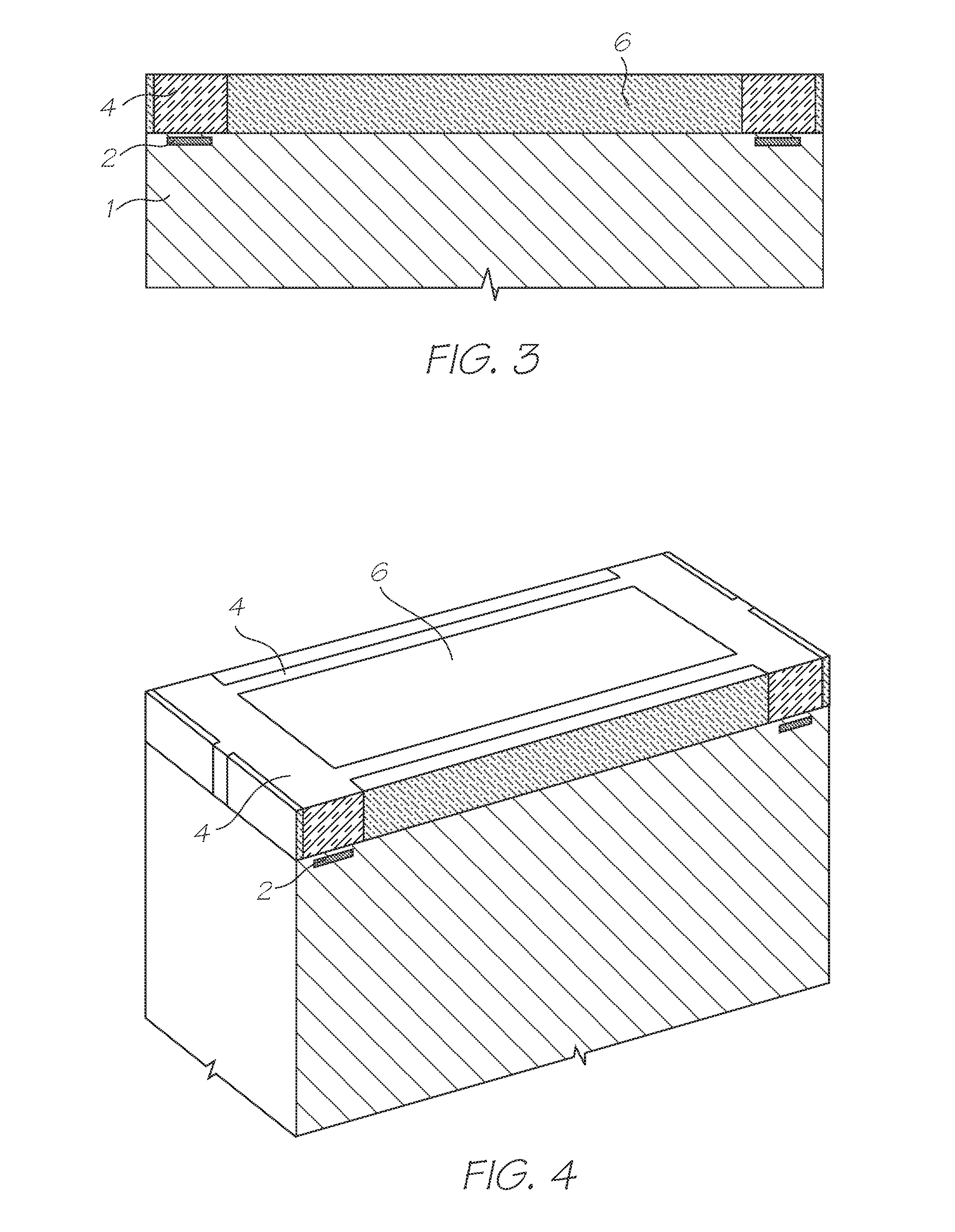

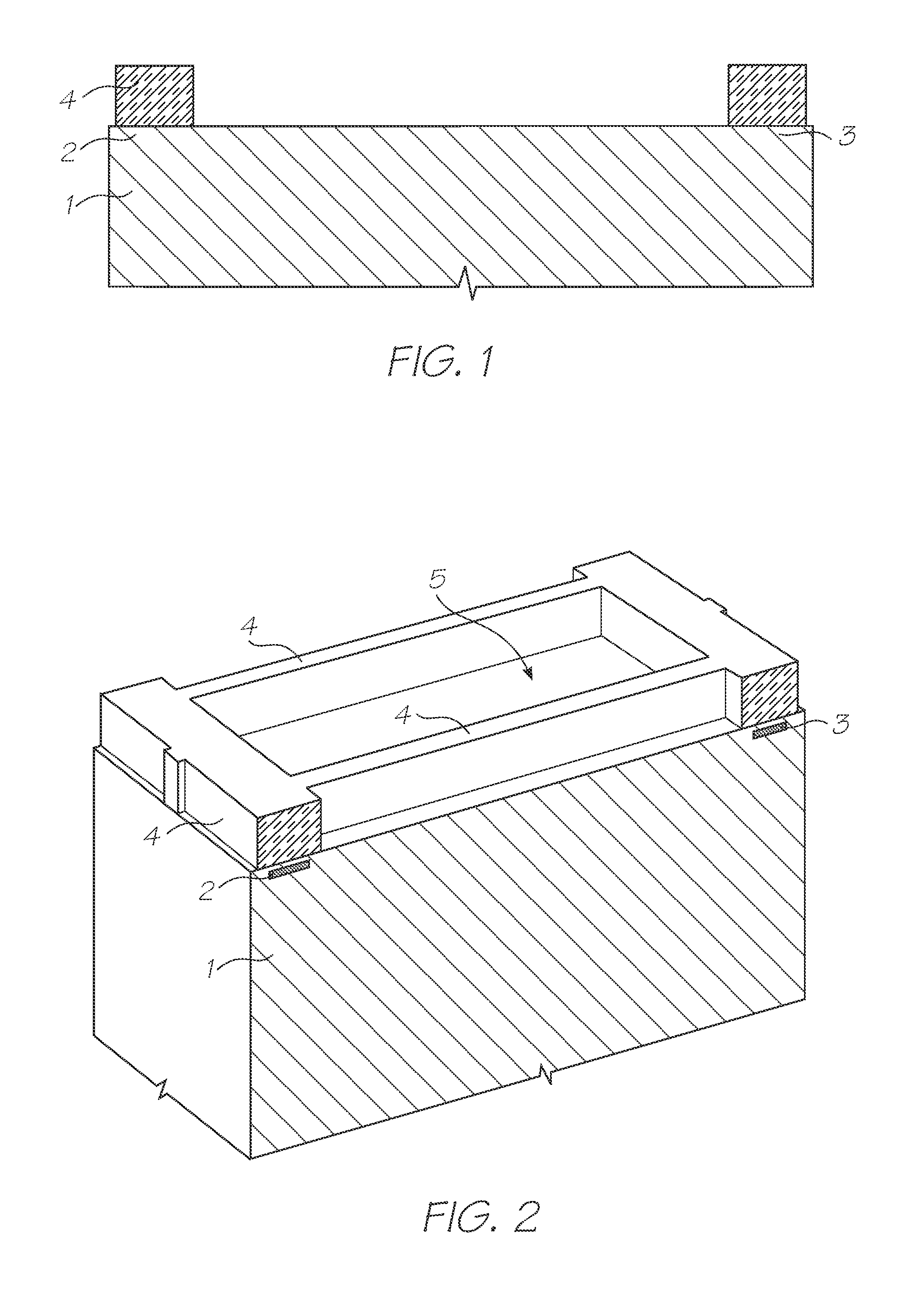

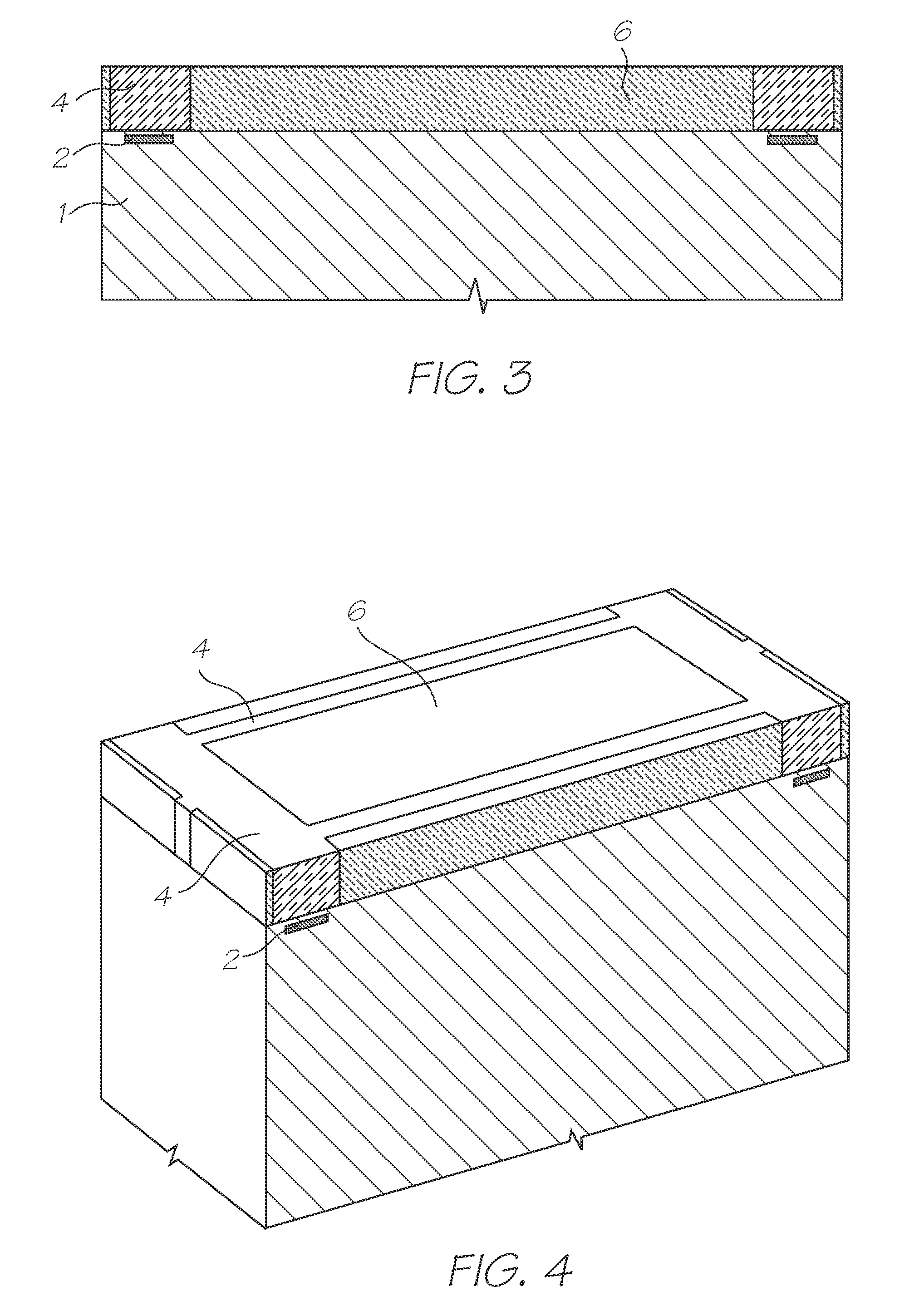

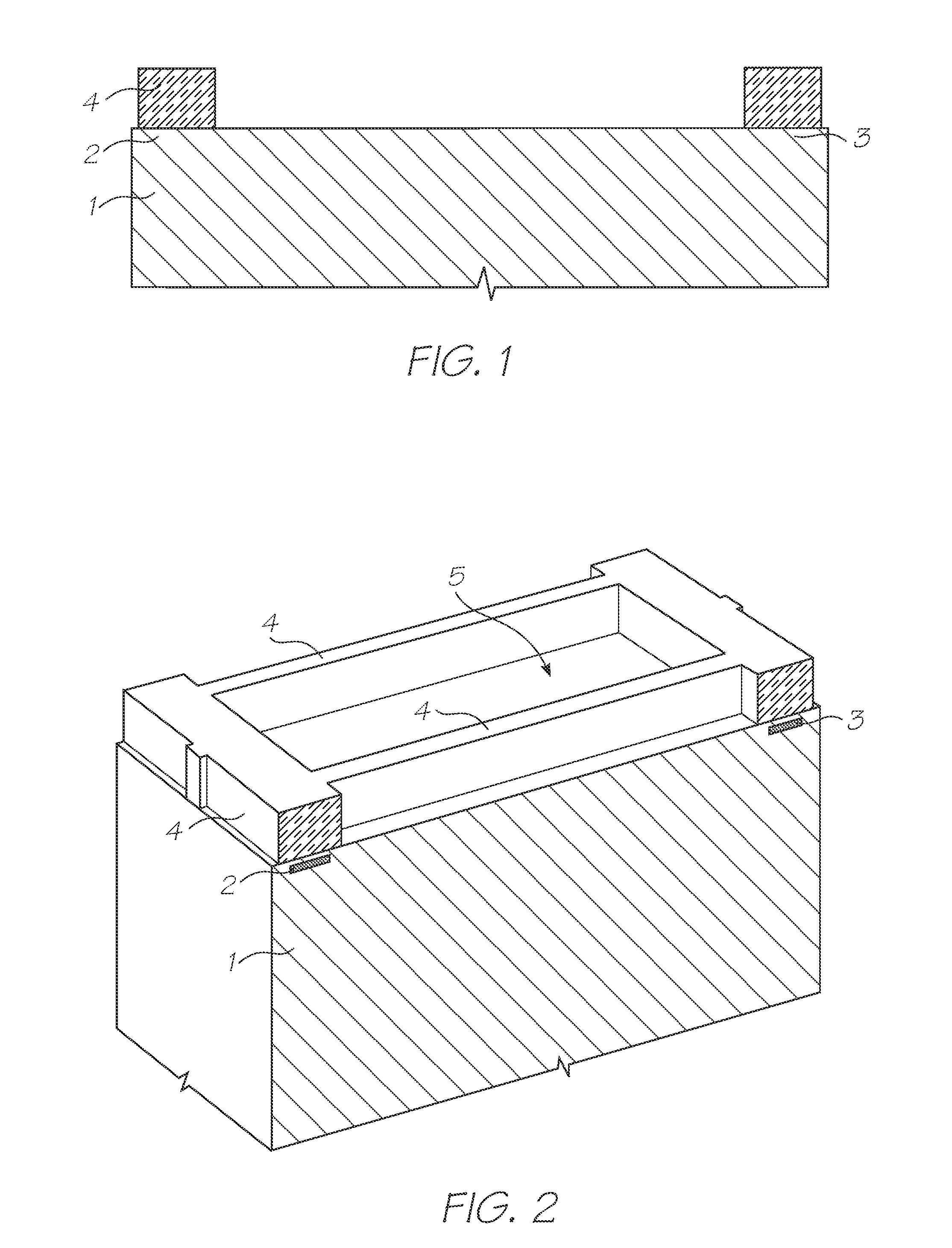

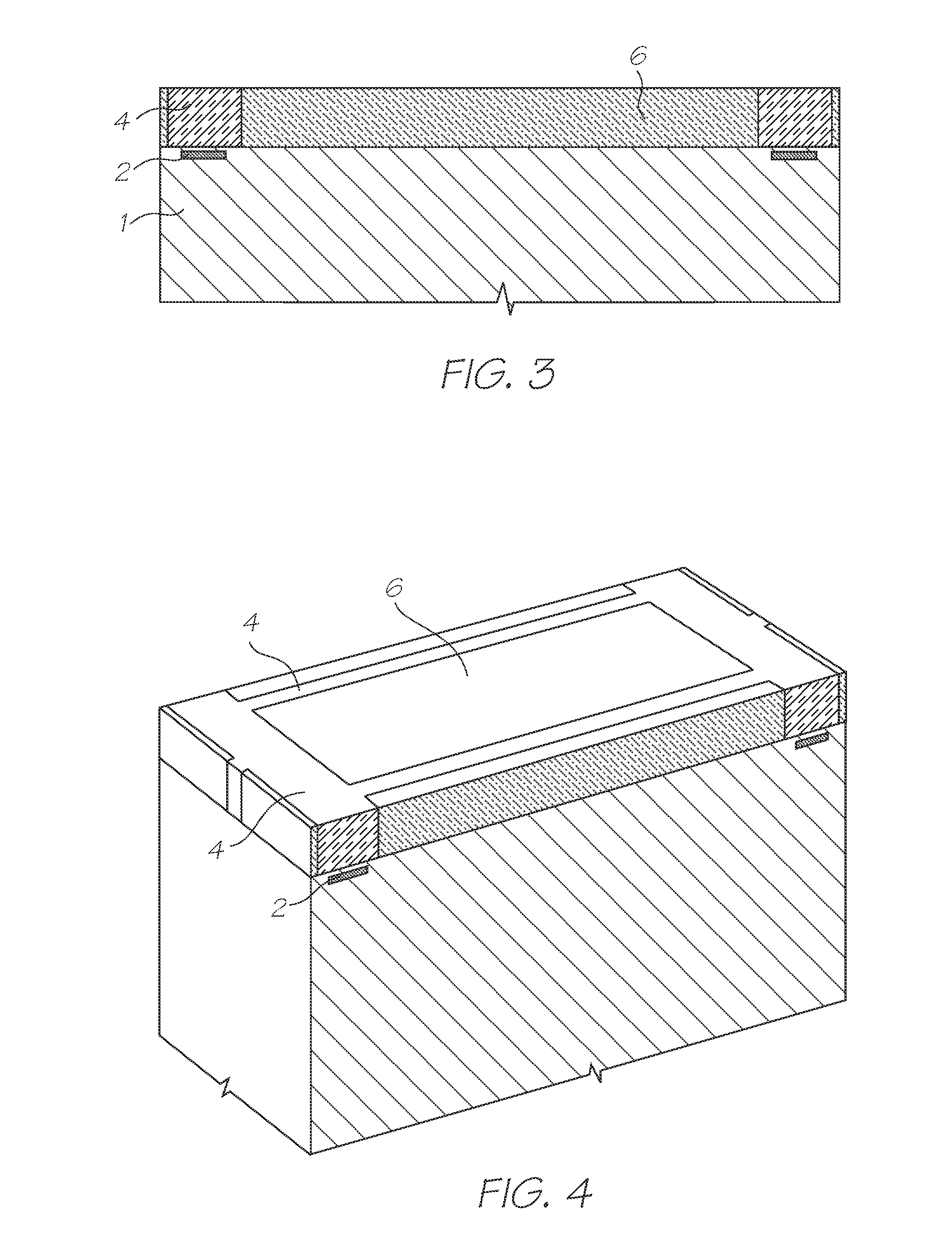

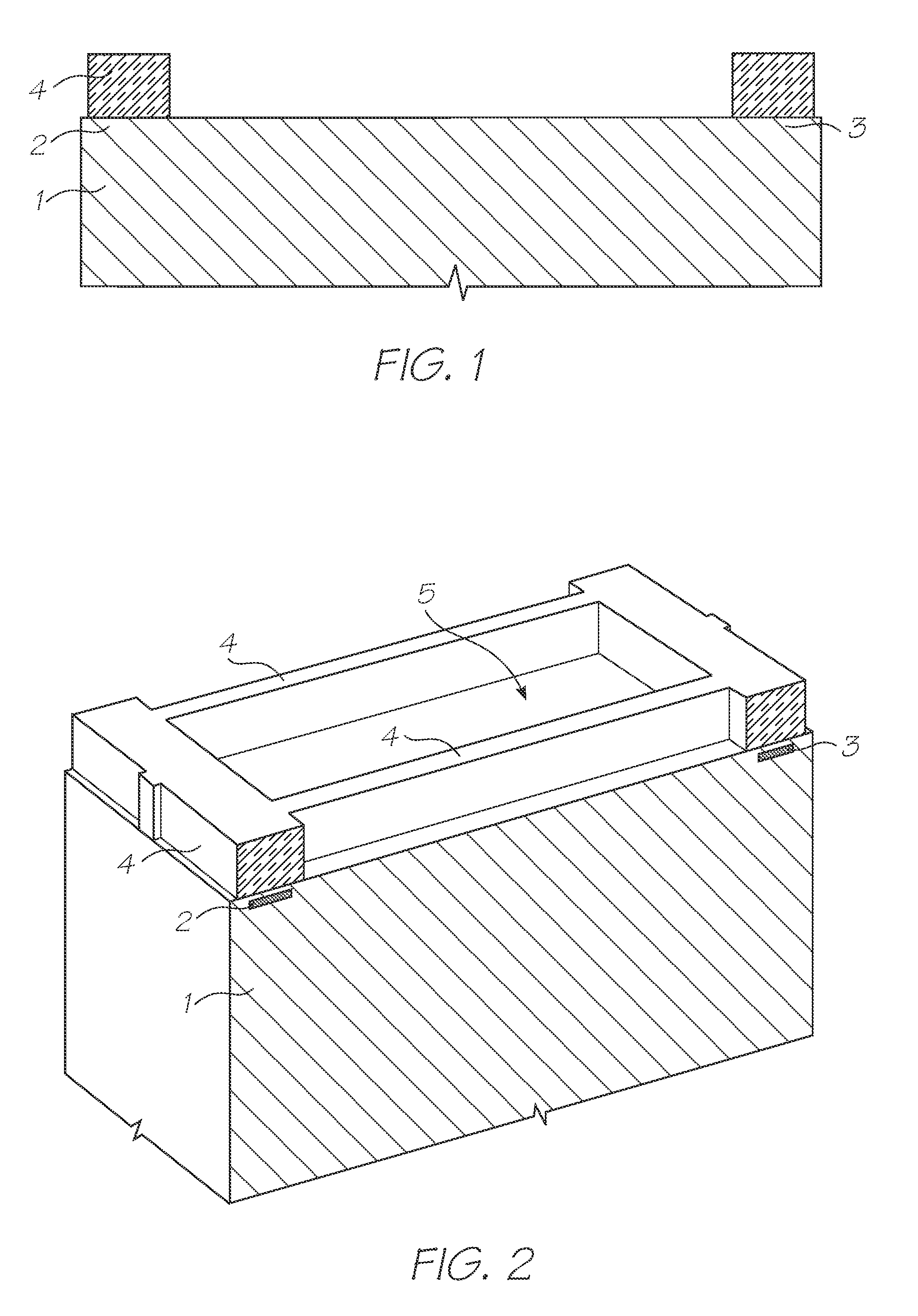

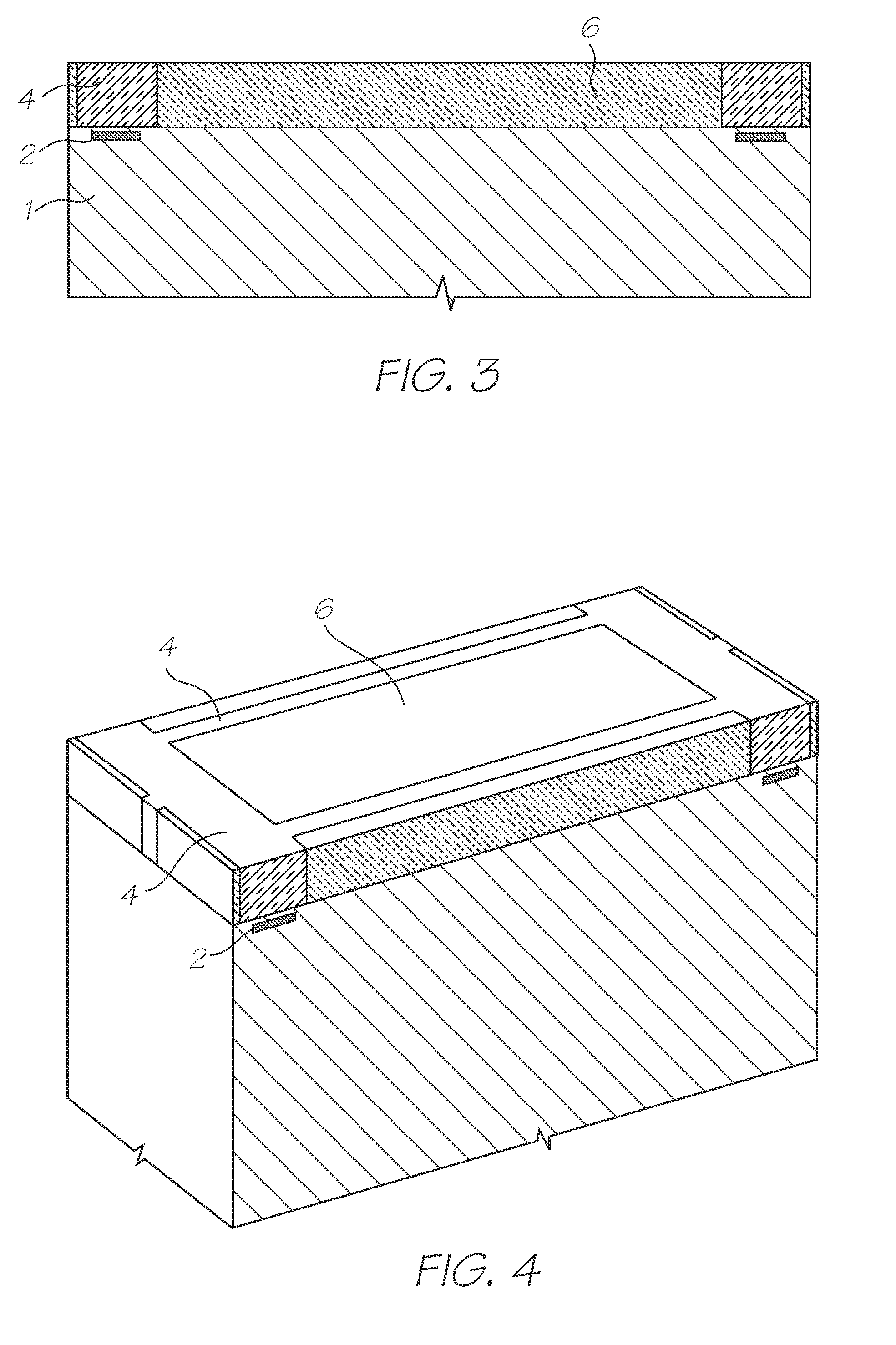

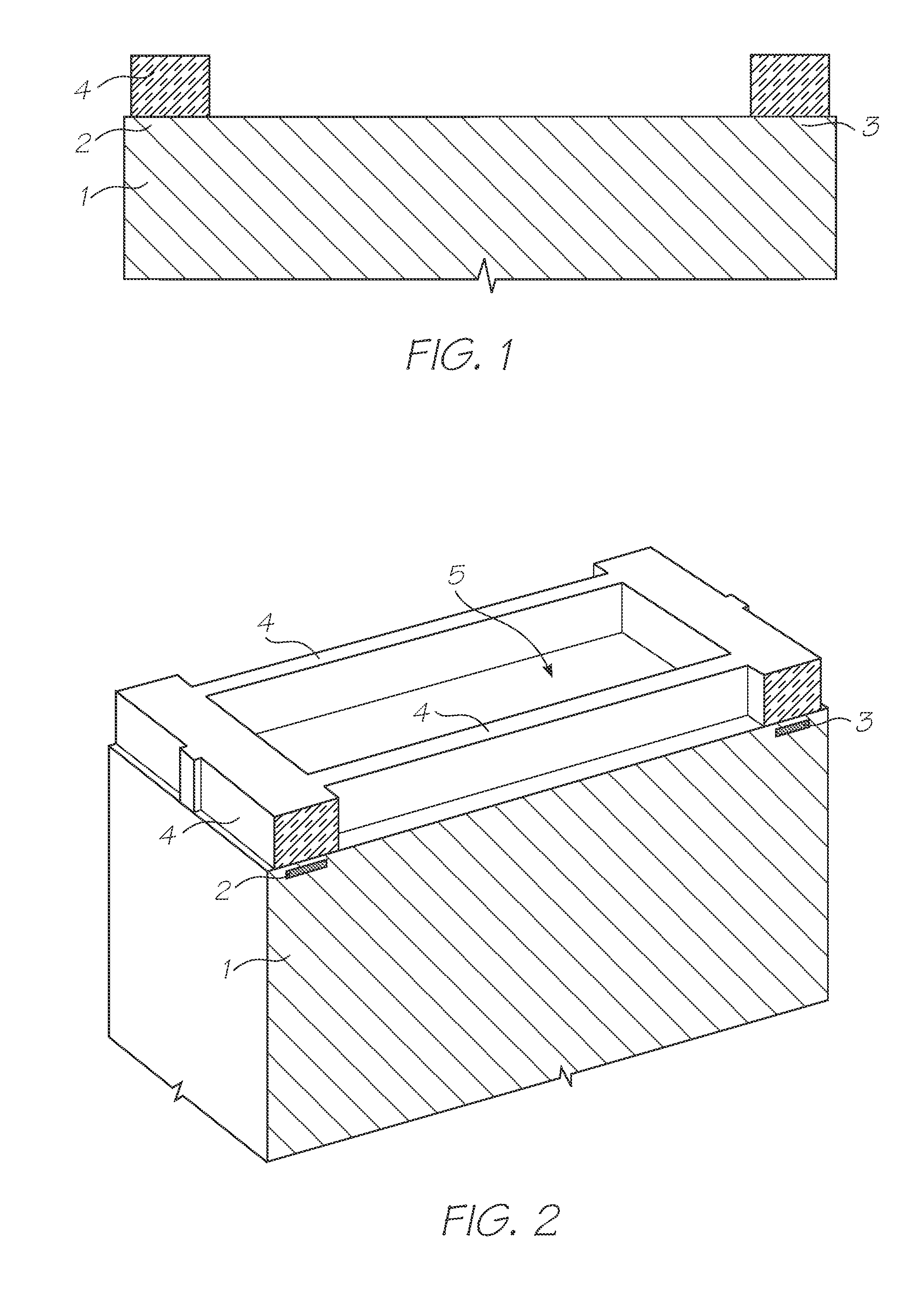

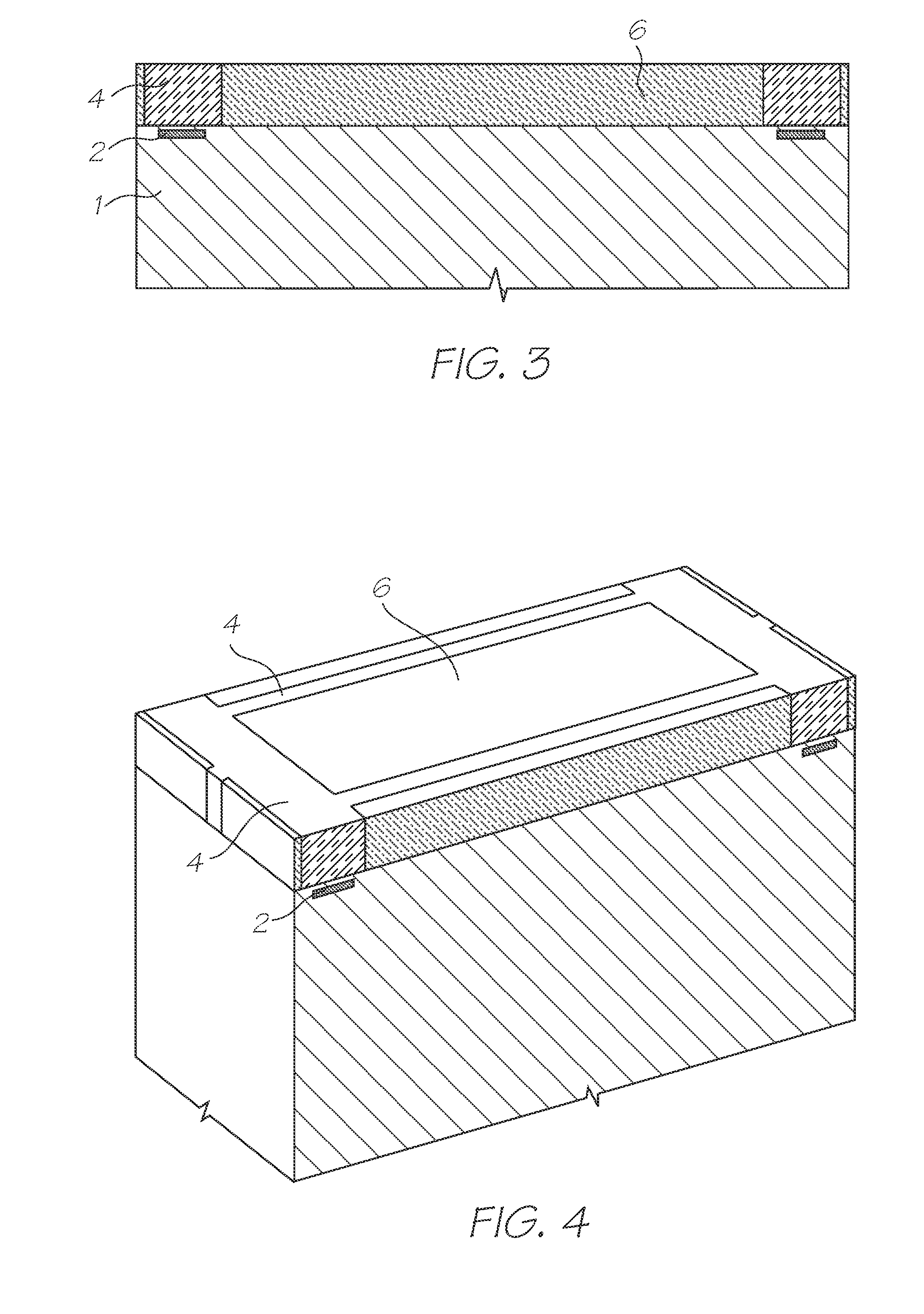

Ink cartridge with sealed air inlet

InactiveUS7527353B2Minimizes ink leakageSimple procedureOther printing apparatusEngineeringMechanical engineering

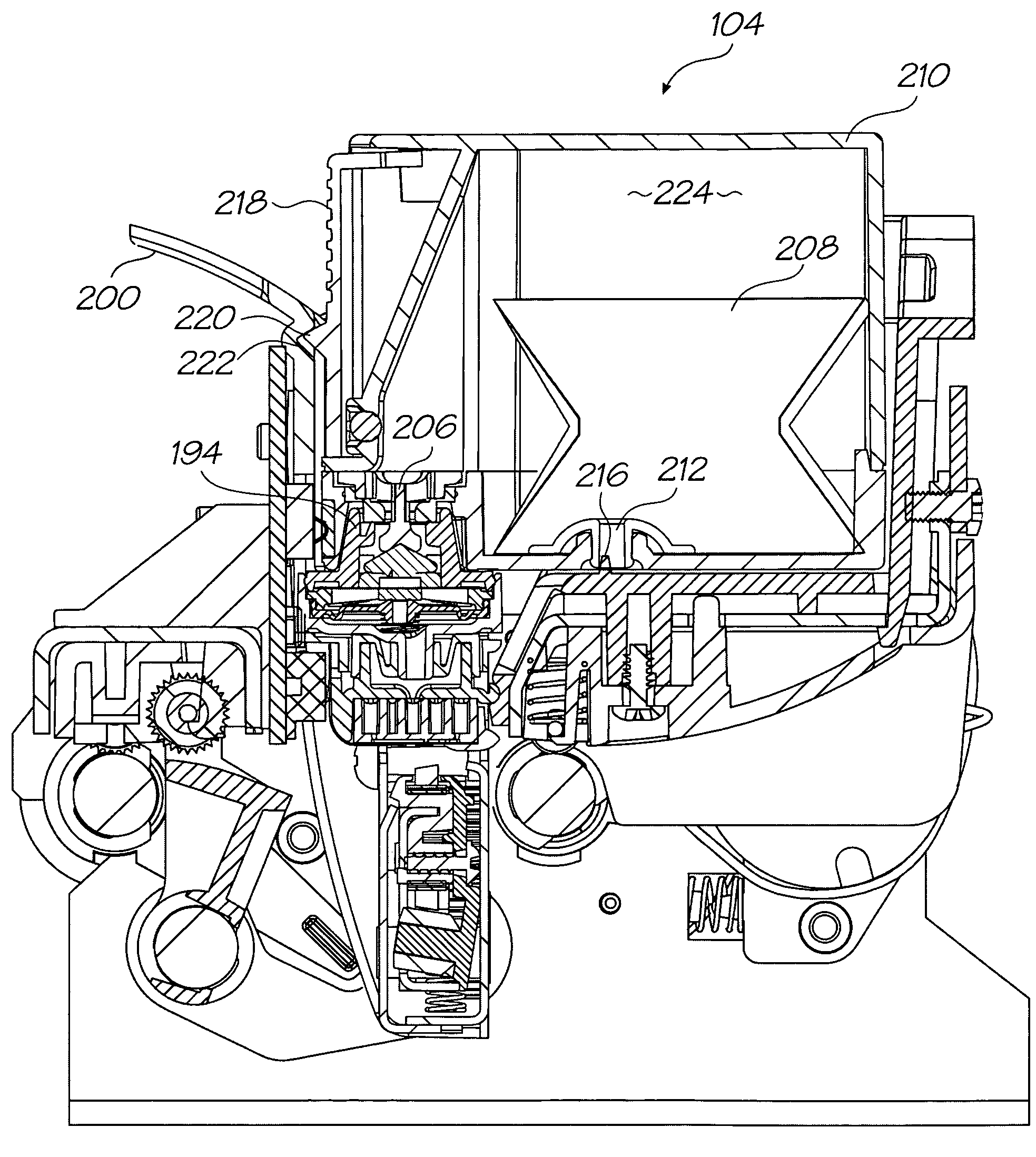

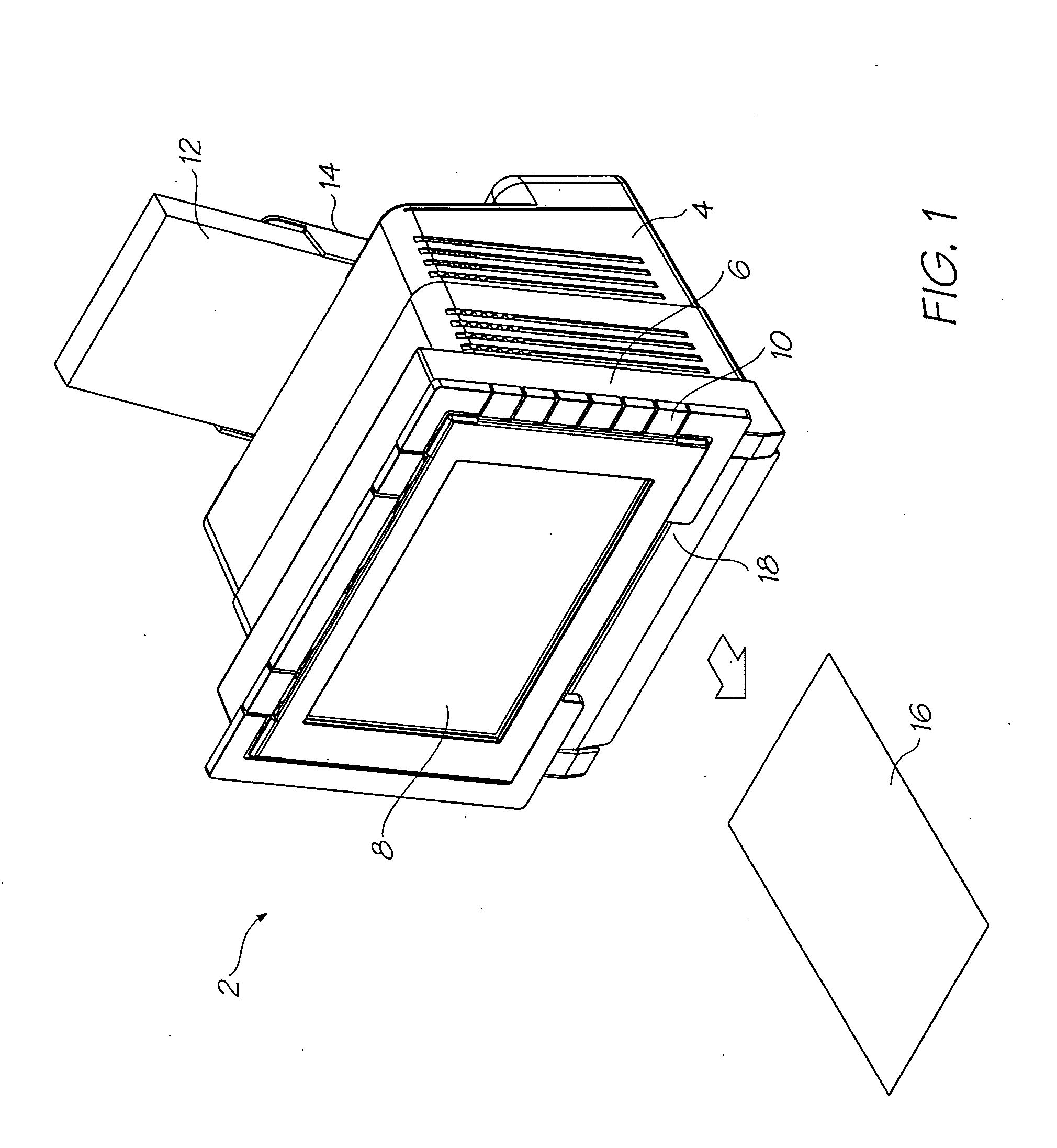

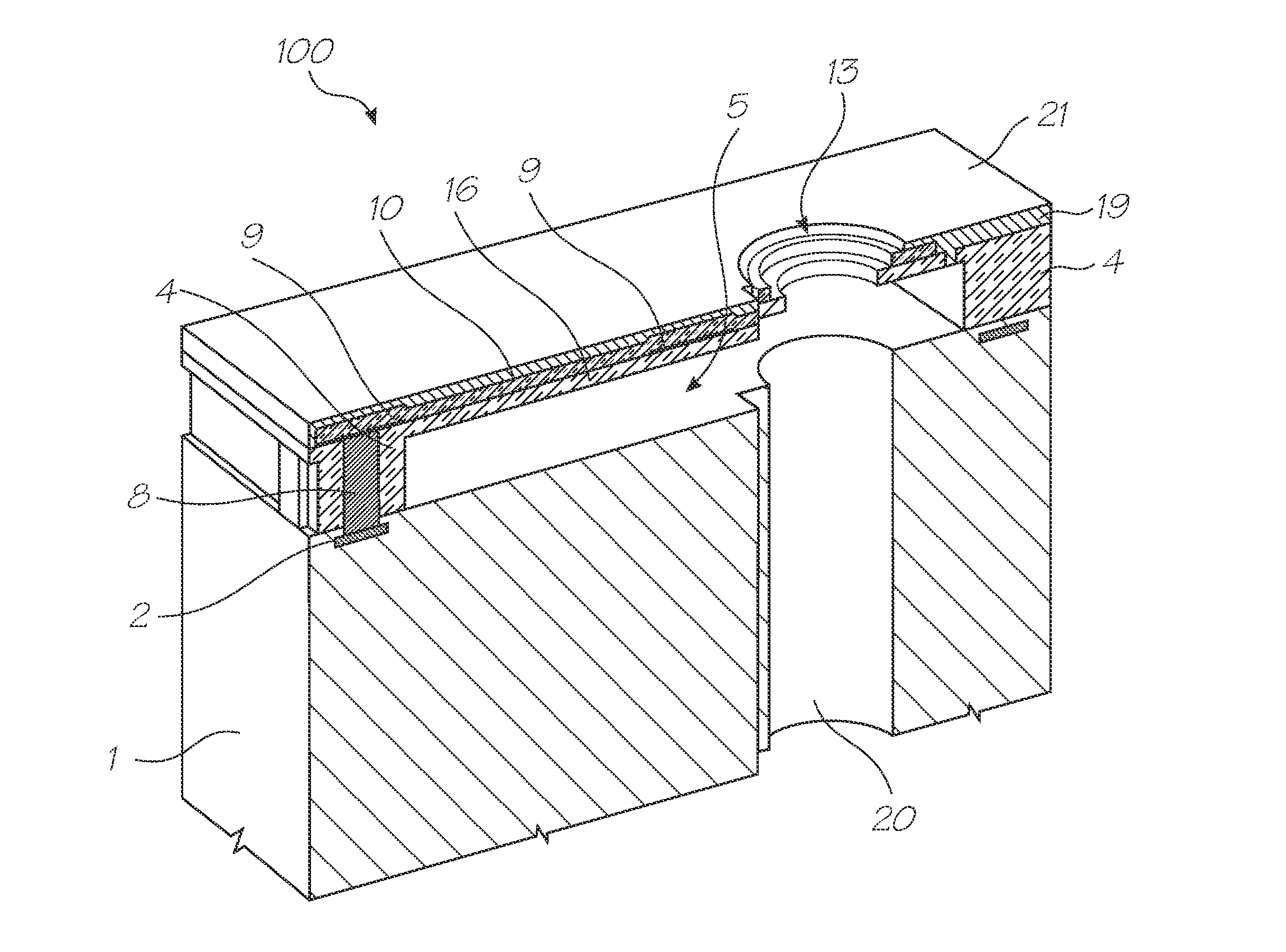

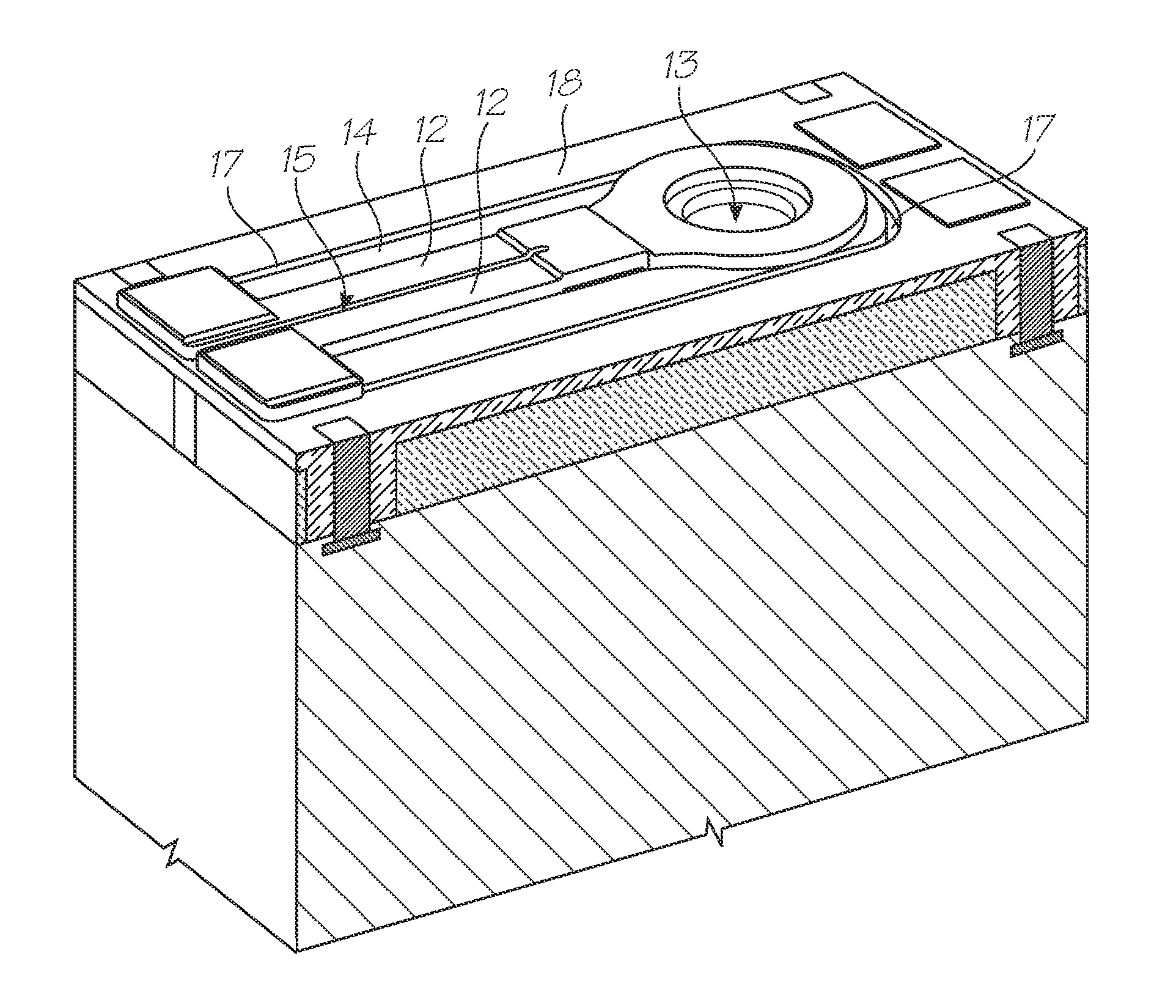

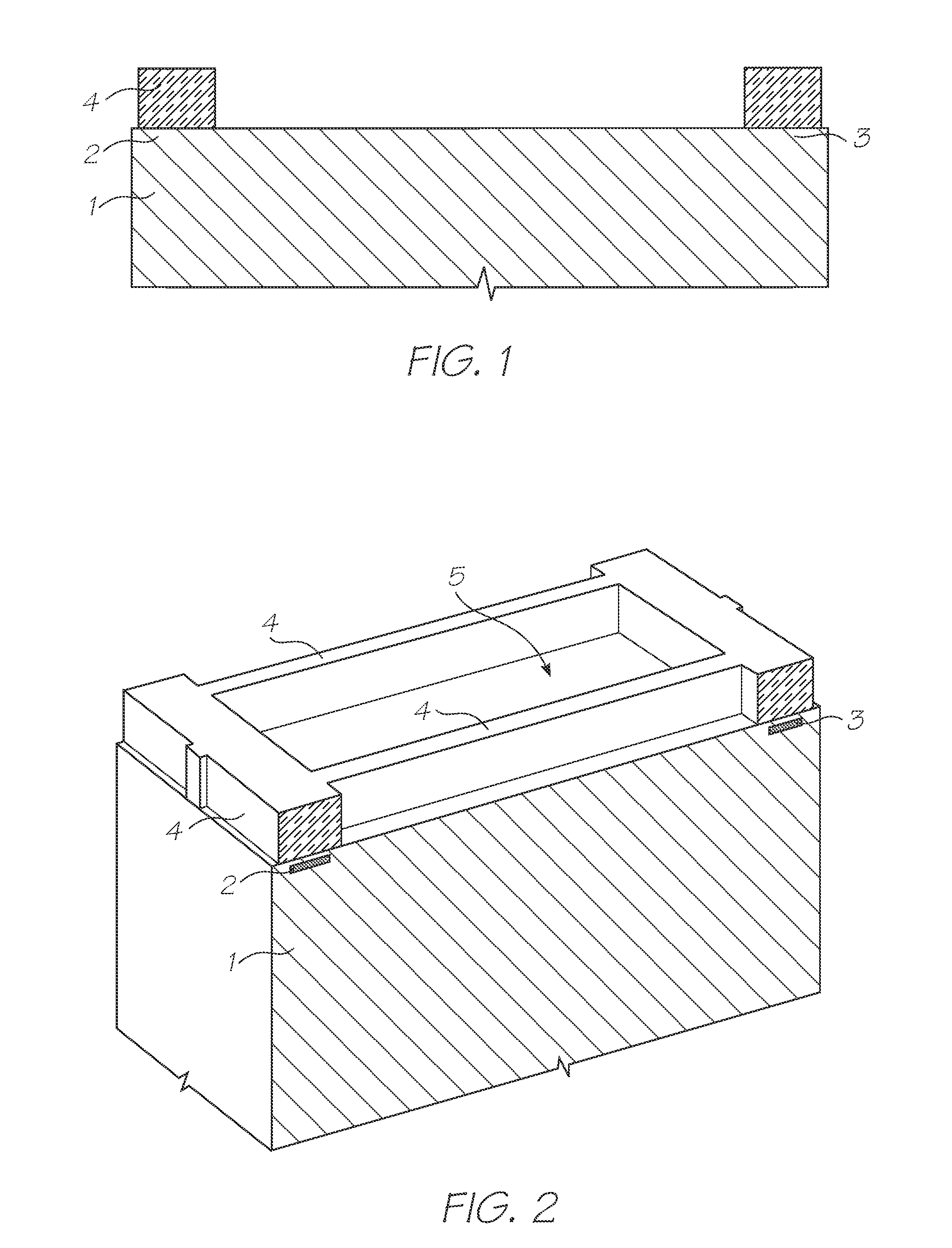

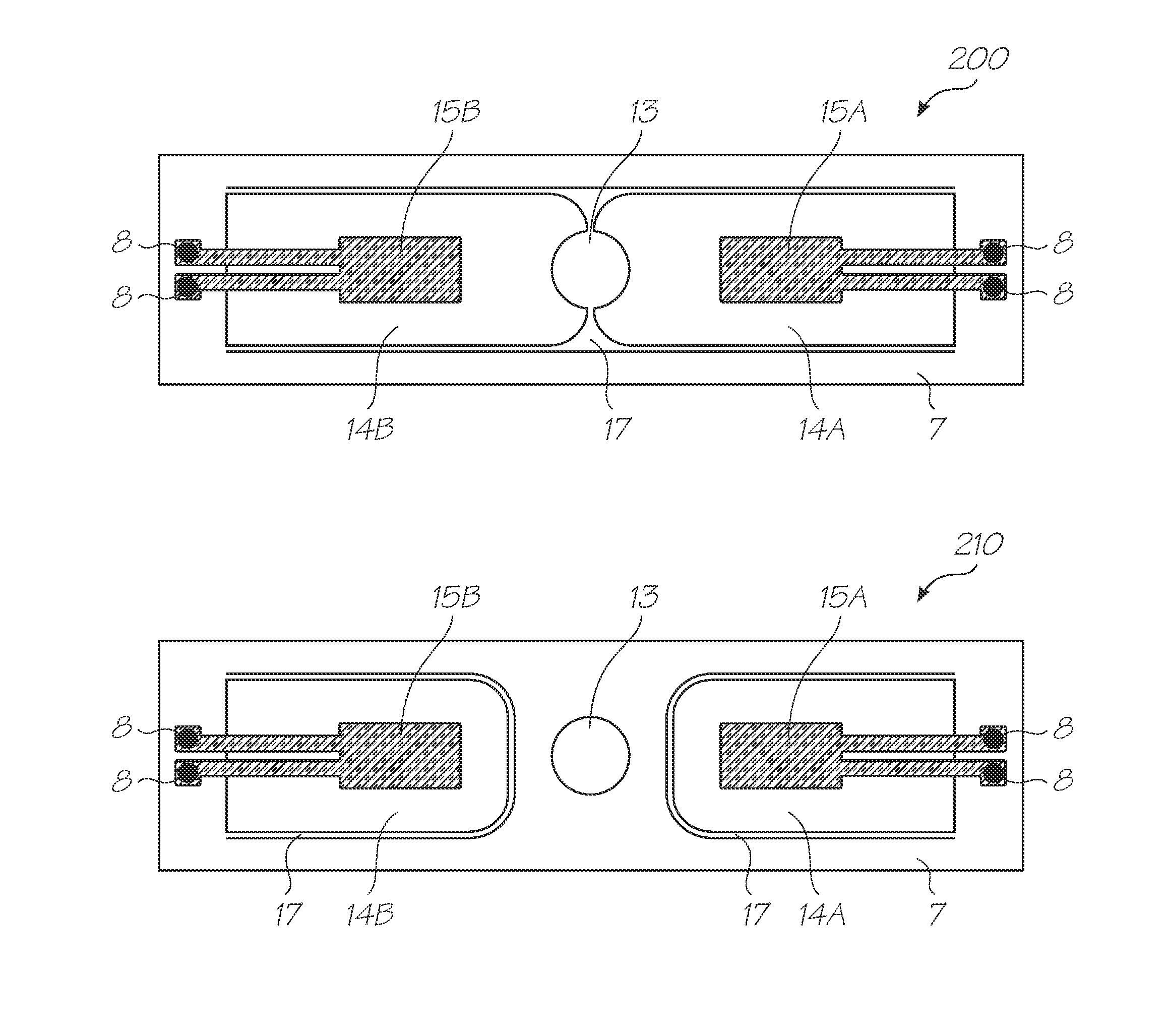

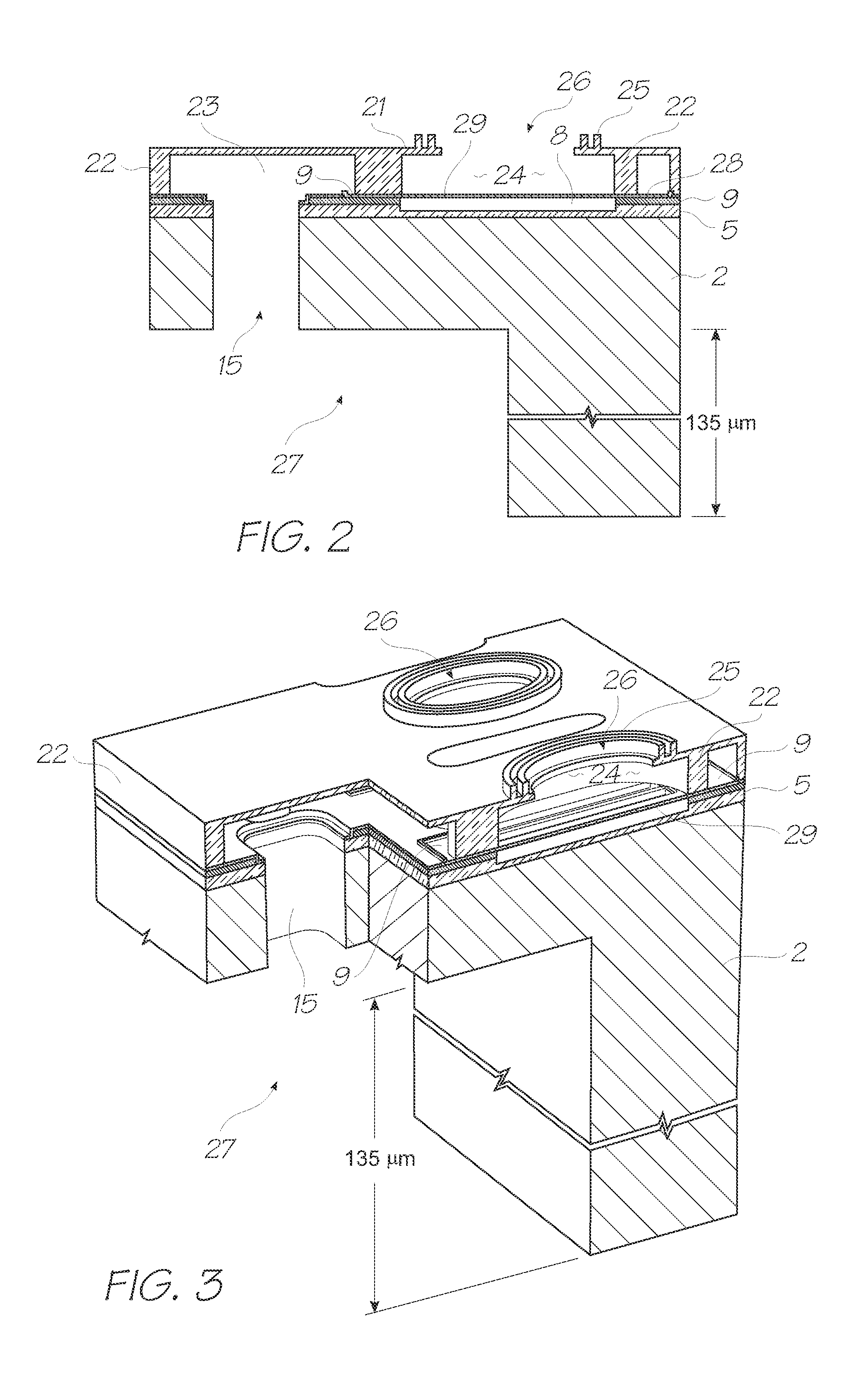

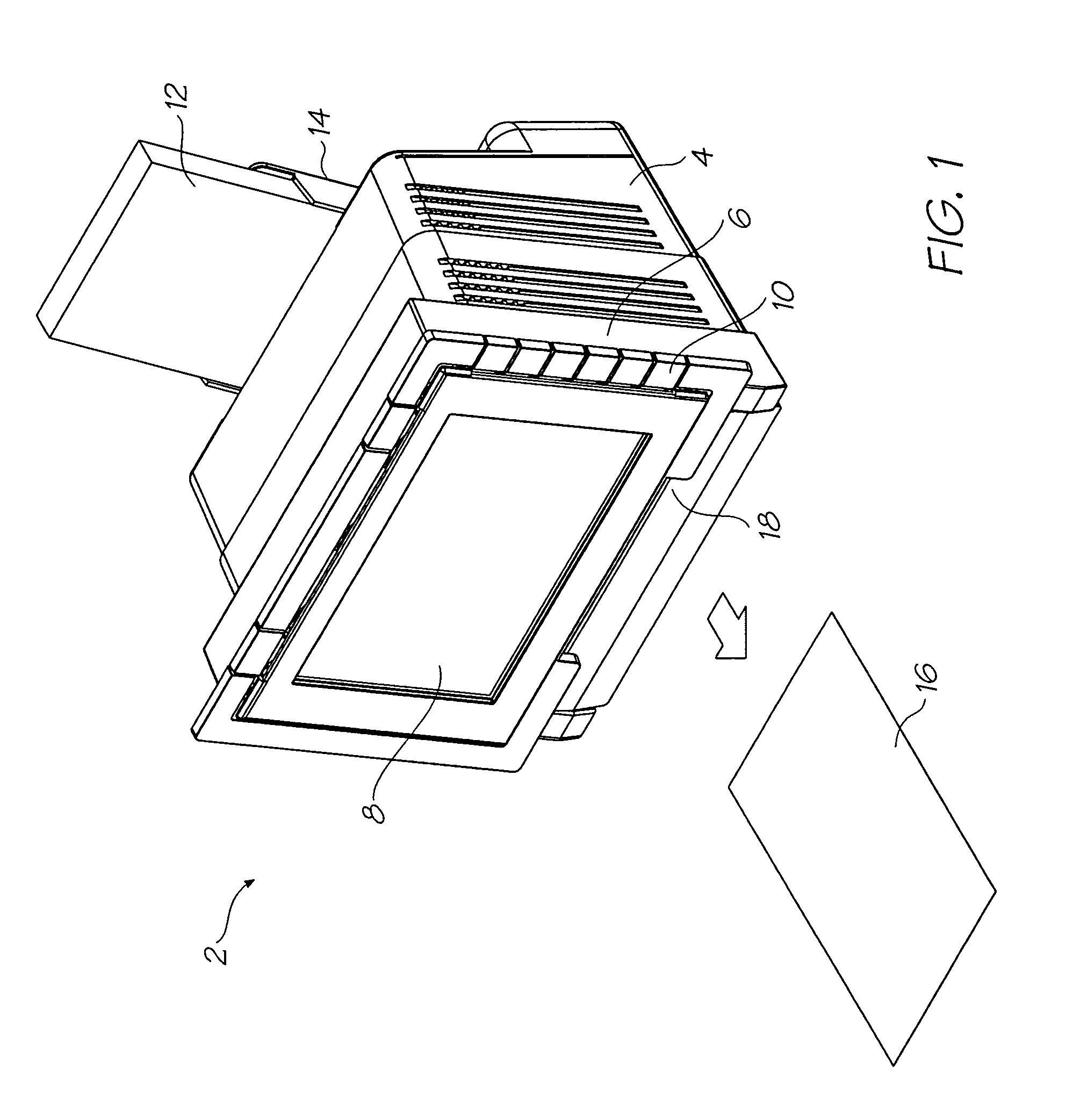

An ink cartridge for a printer with an inkjet printhead, the ink cartridge comprising: an ink storage volume; an outlet valve for fluid communication with the printhead; and, an air inlet spaced from the outlet valve for letting air into the ink storage volume as ink is drawn out through the outlet valve; wherein, the outlet valve and the air inlet are configured for engagement with complementary formations on the printer such that the ink outlet and the air inlet are both opened upon installation of the cartridge in the printer.

Owner:MEMJET TECH LTD +1

Ink cartridge with sealed air inlet

InactiveUS20070126821A1Minimize ink leakageLess flowOther printing apparatusMechanical engineeringEngineering

An ink cartridge for a printer with an inkjet printhead, the ink cartridge comprising: an ink storage volume; an outlet valve for fluid communication with the printhead; and, an air inlet spaced from the outlet valve for letting air into the ink storage volume as ink is drawn out through the outlet valve; wherein, the outlet valve and the air inlet are configured for engagement with complementary formations on the printer such that the ink outlet and the air inlet are both opened upon installation of the cartridge in the printer.

Owner:MEMJET TECH LTD +1

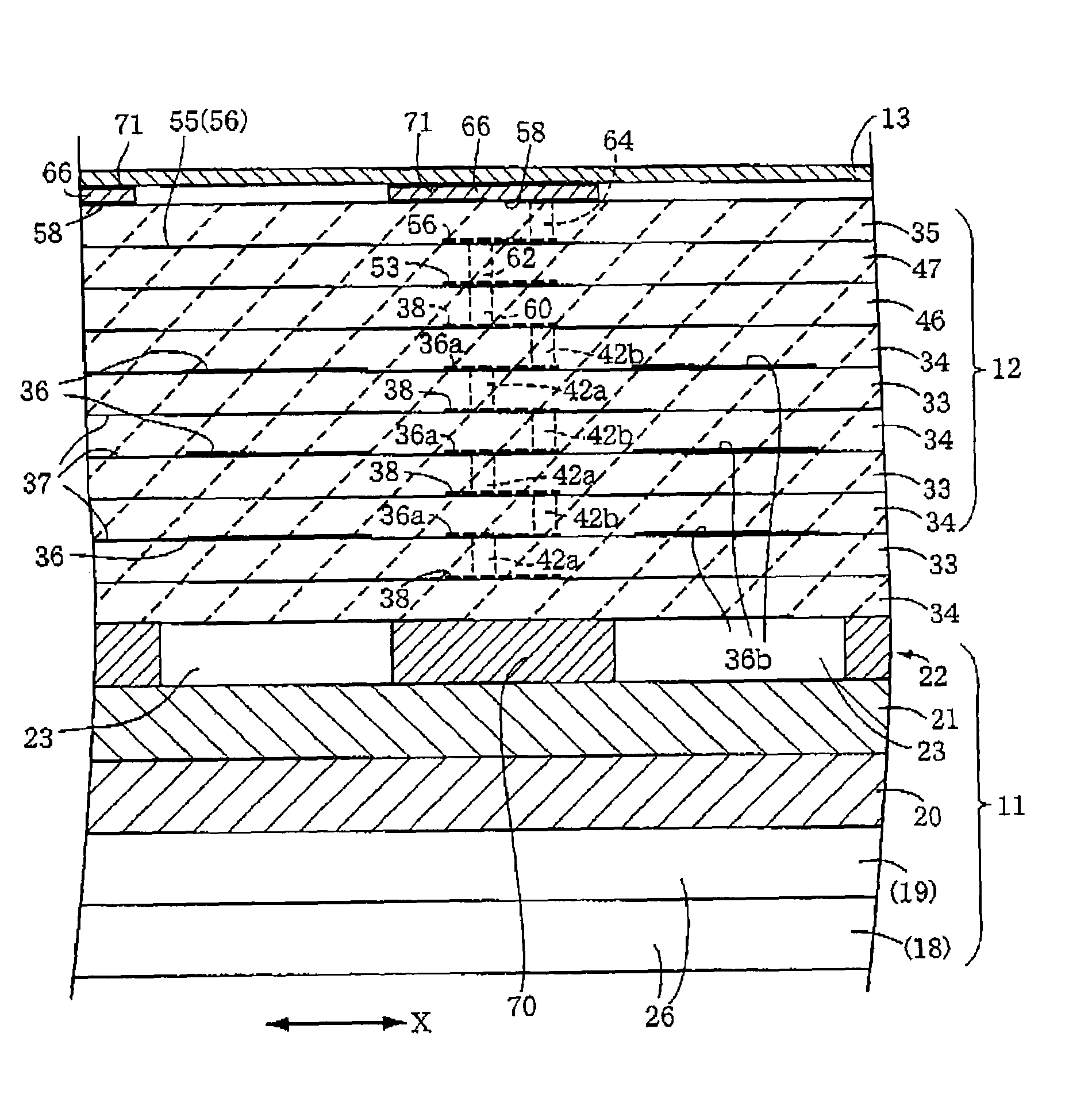

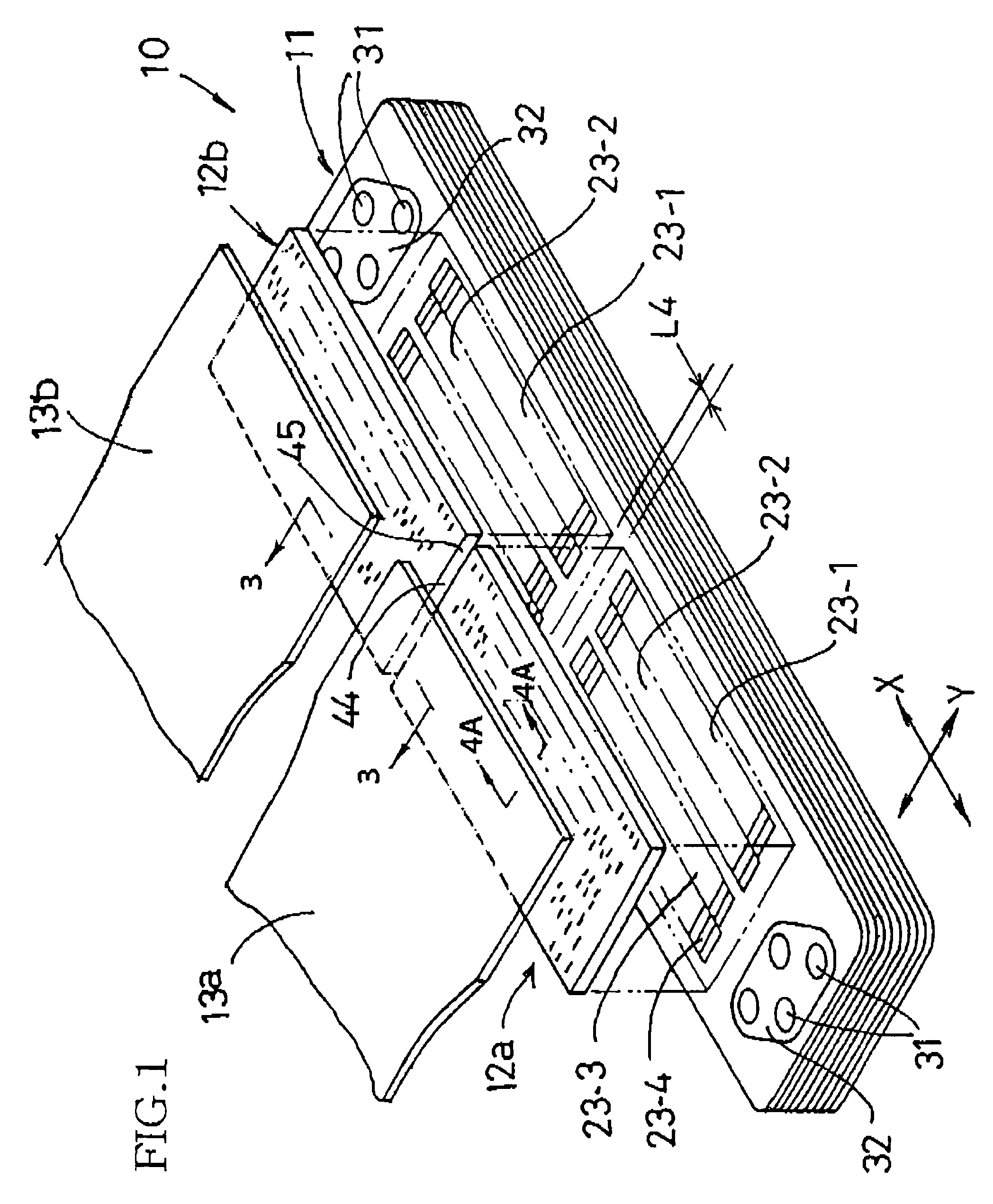

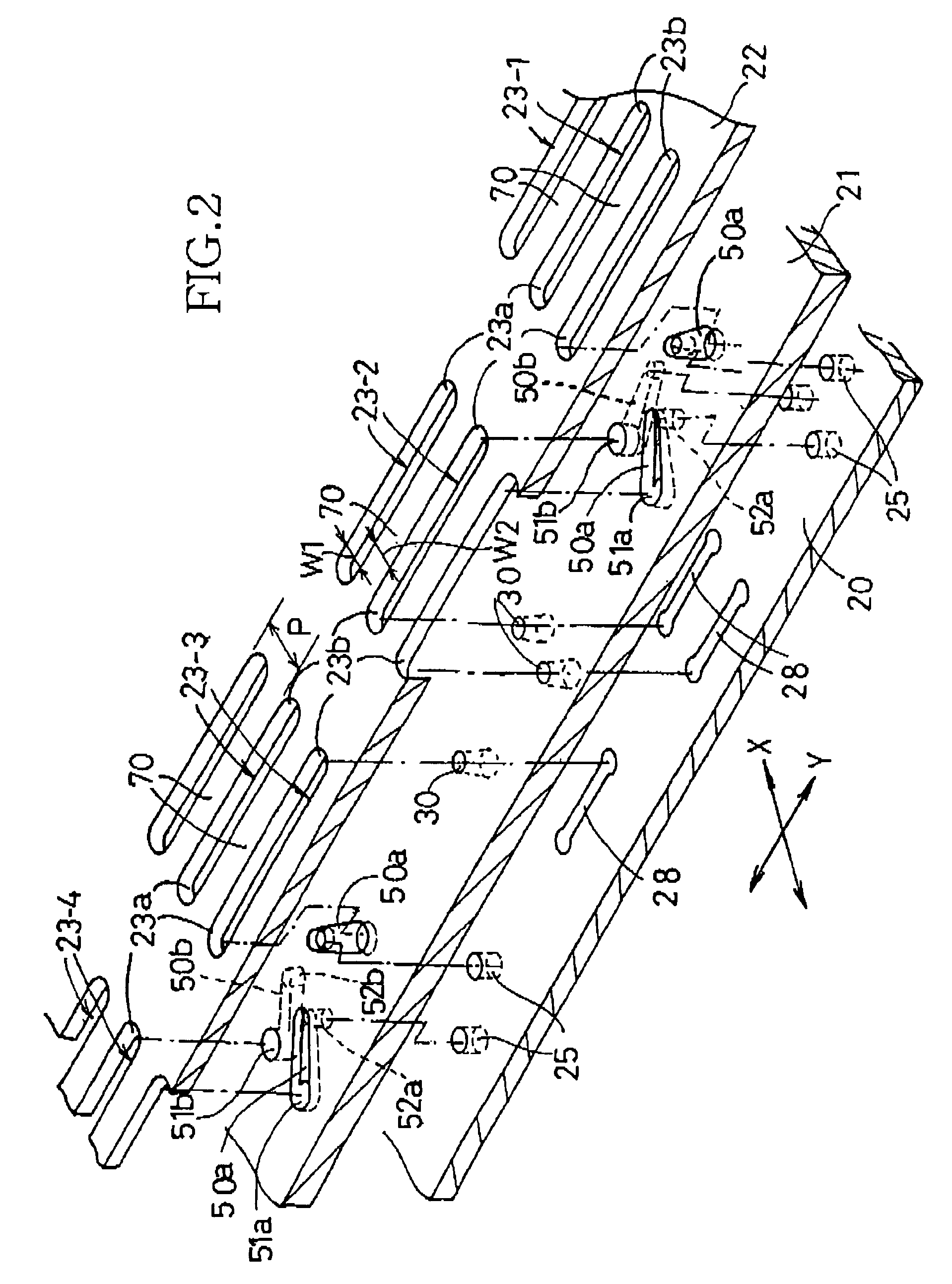

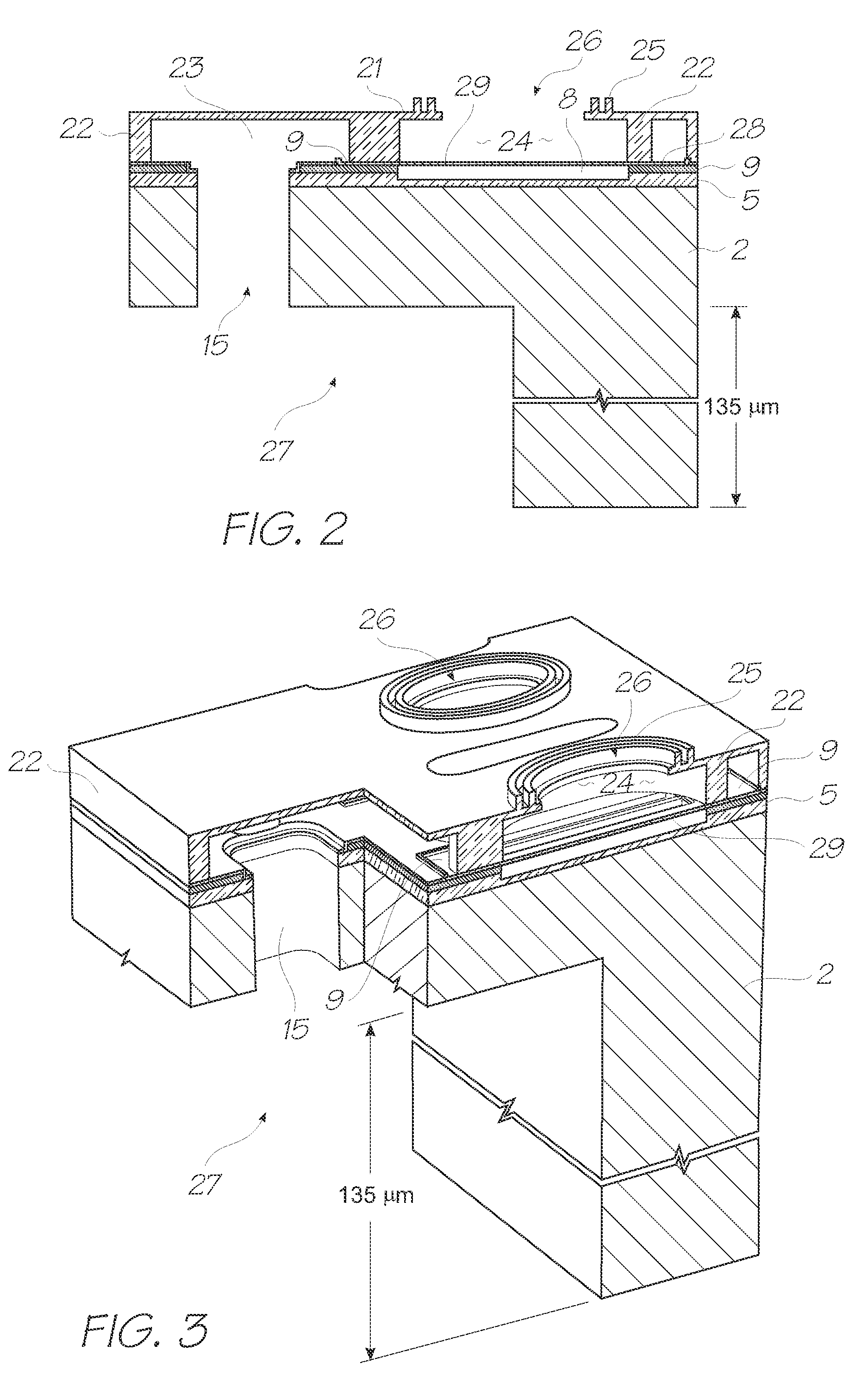

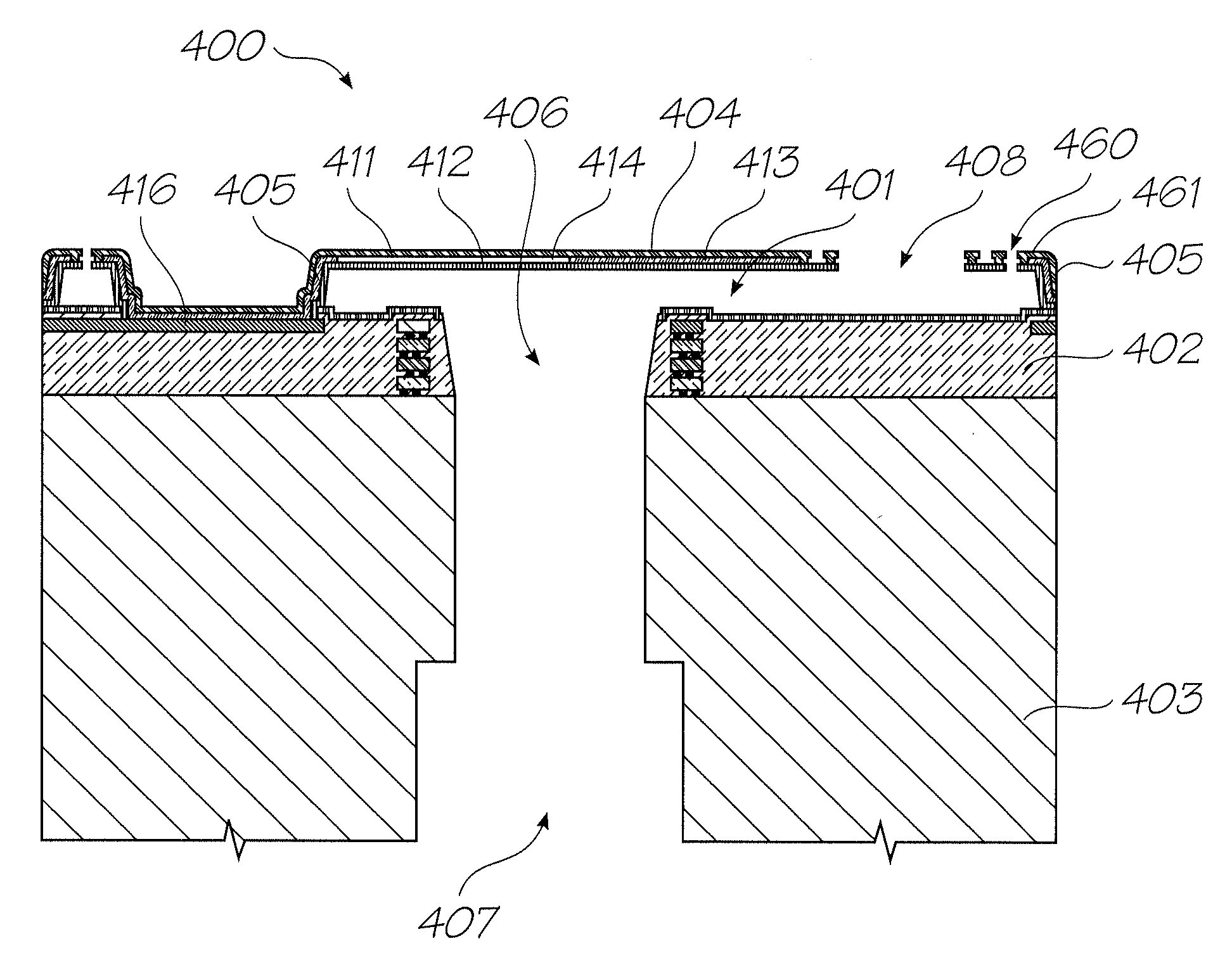

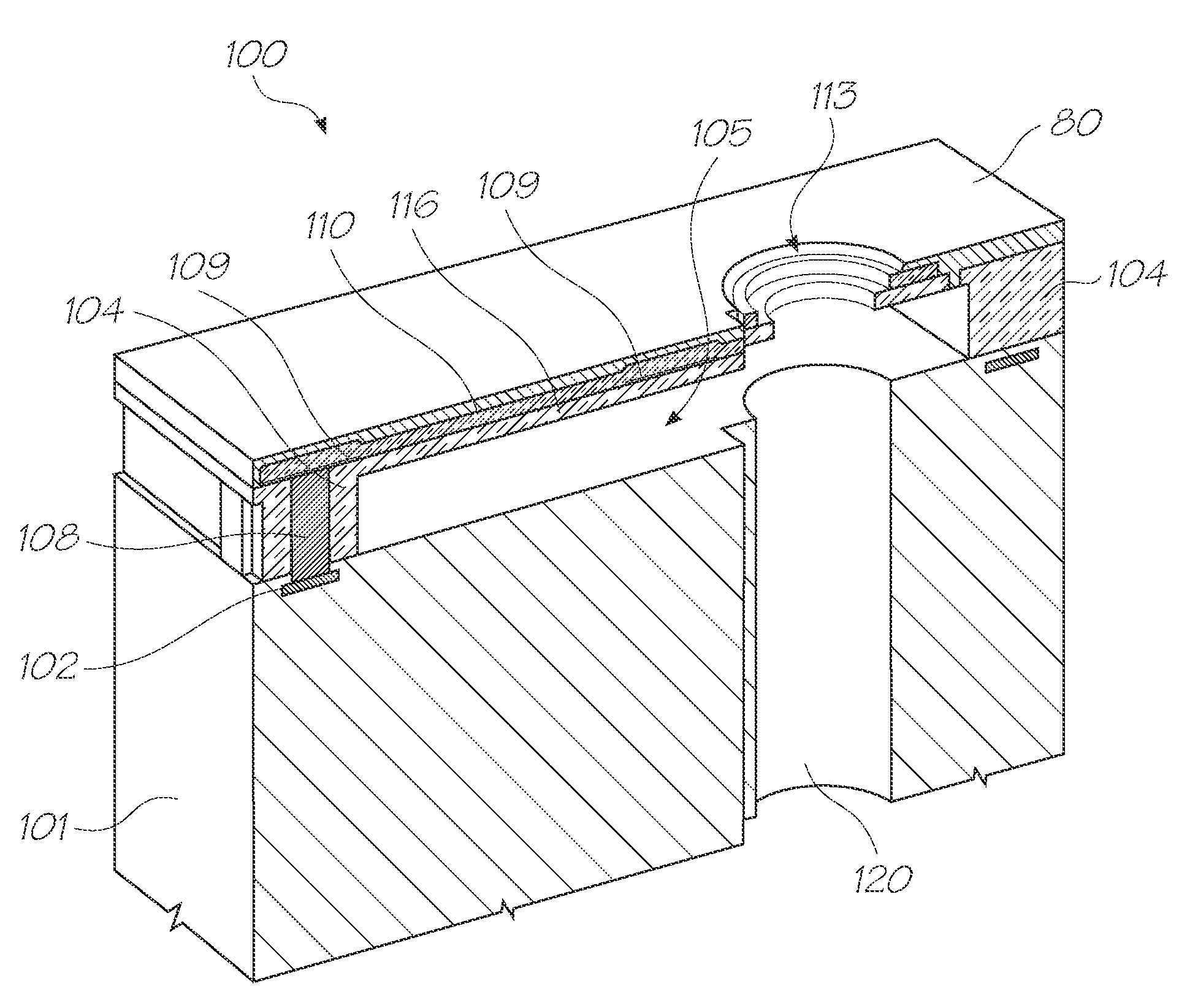

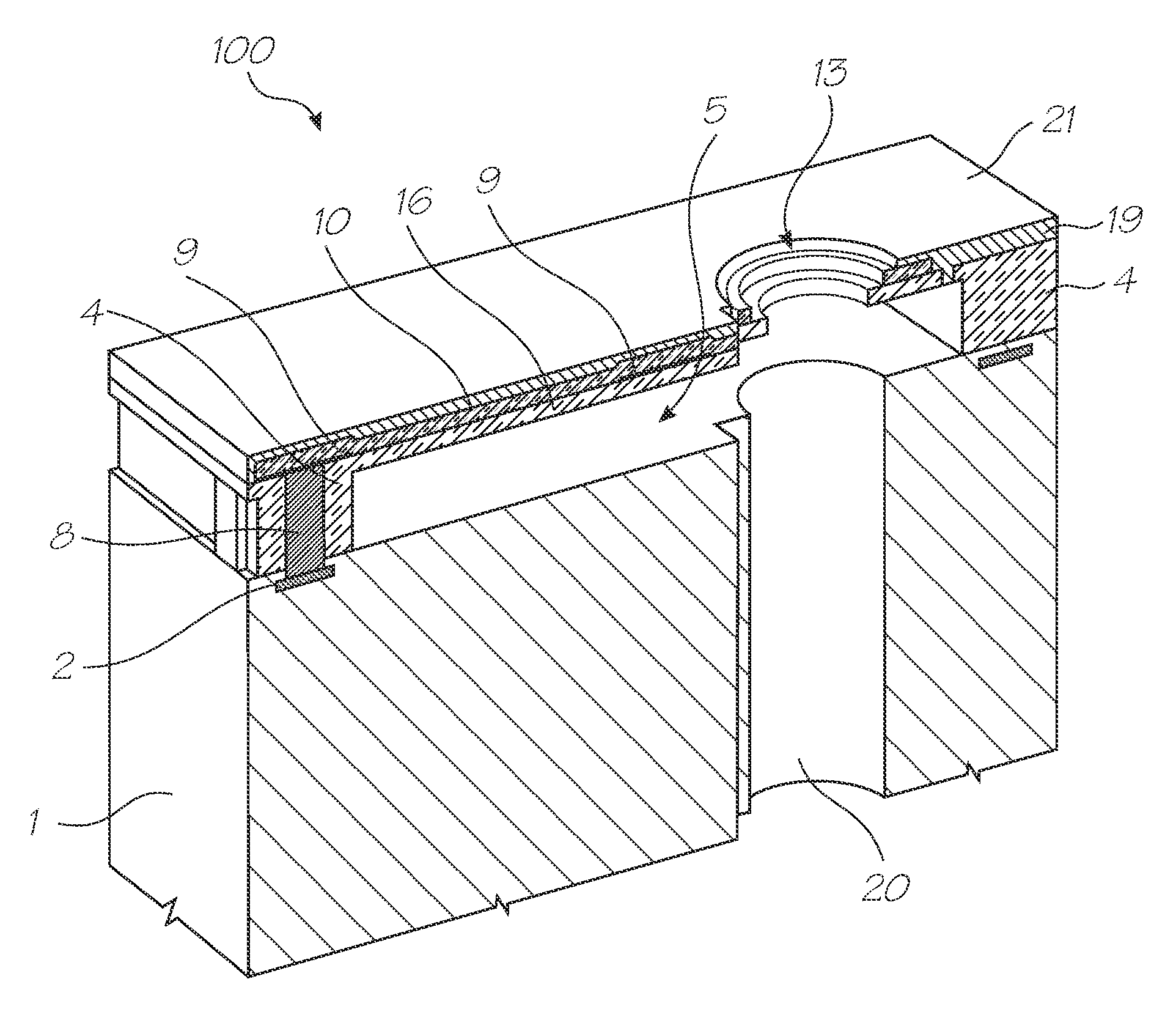

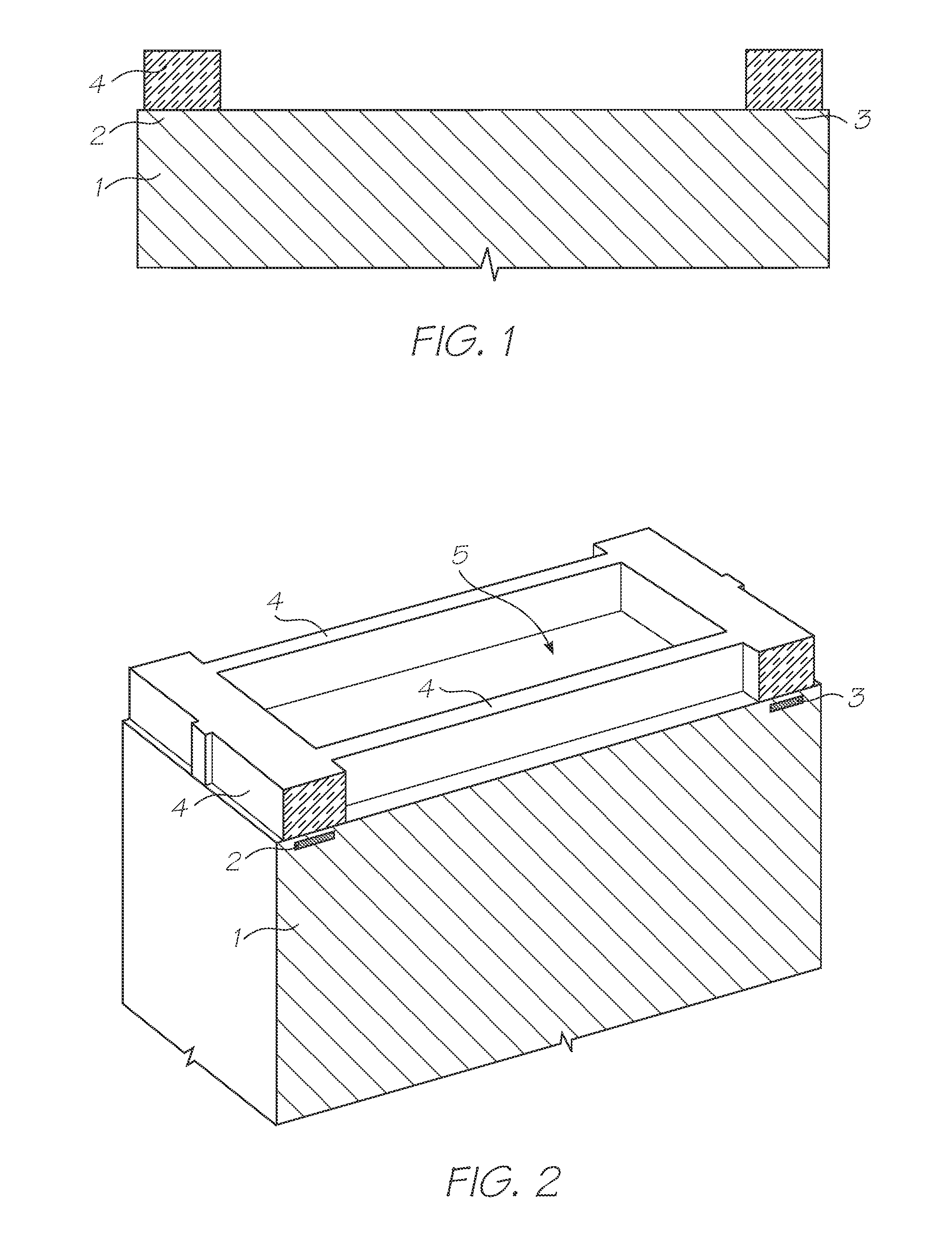

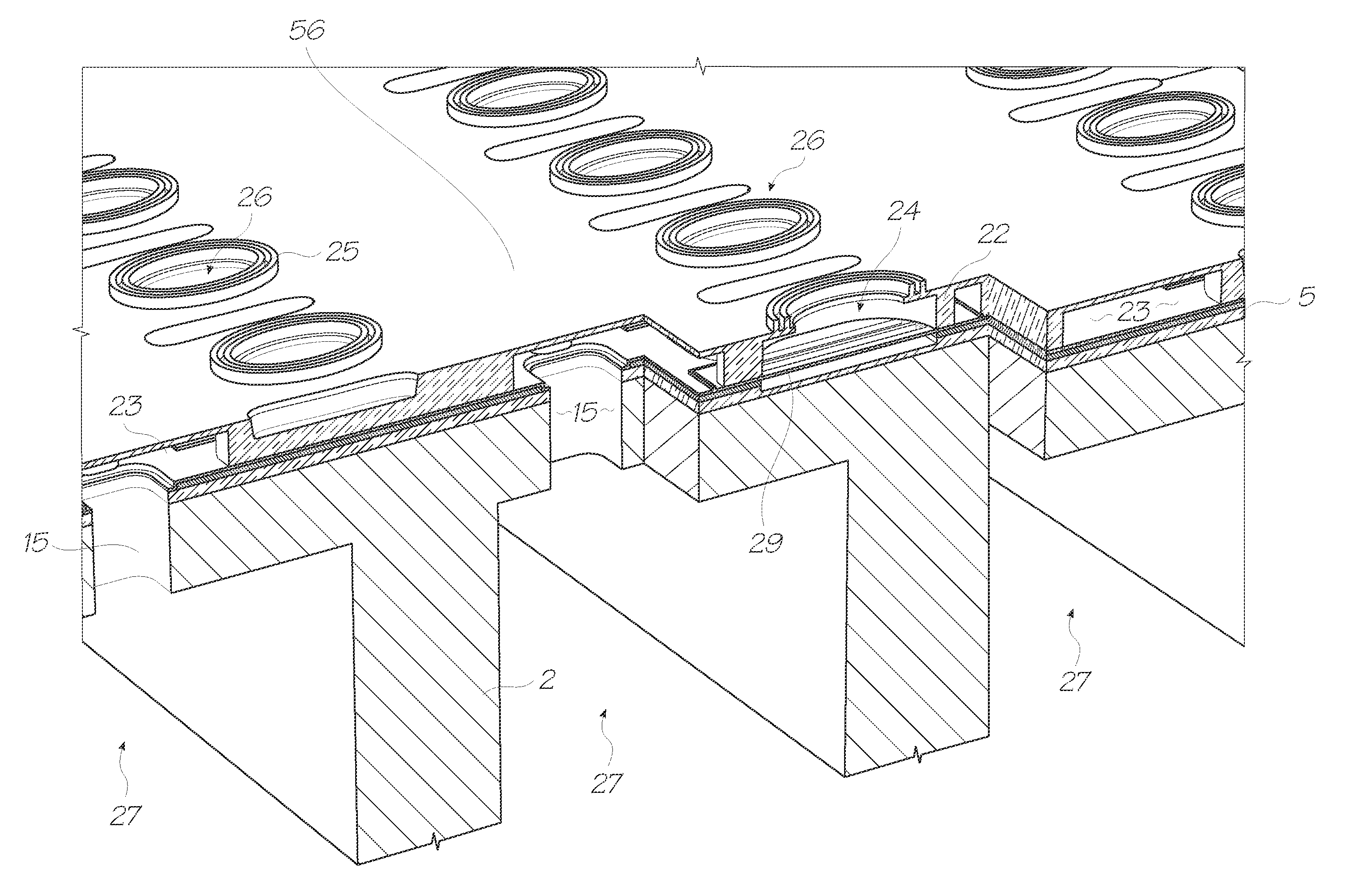

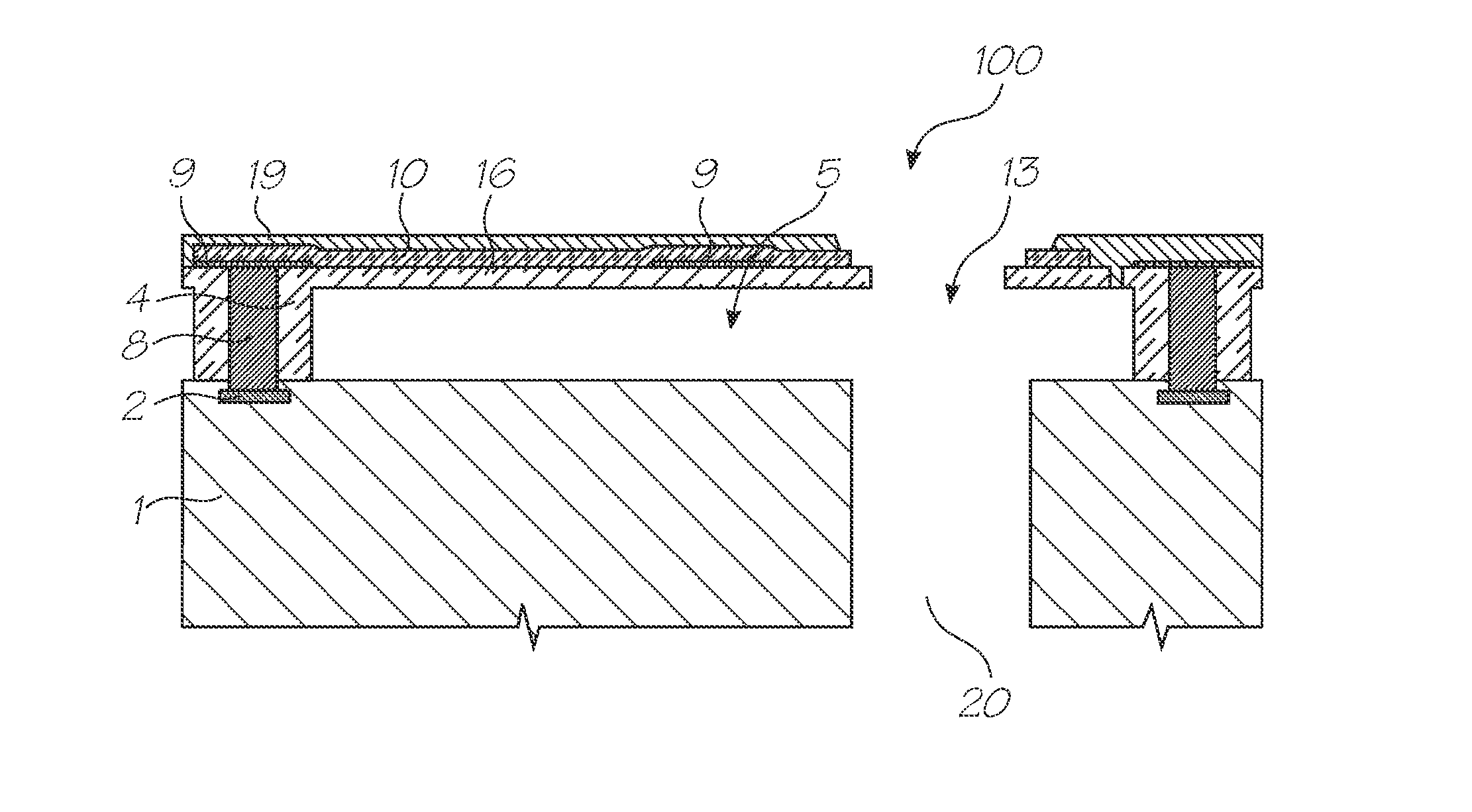

Ink jet printer head

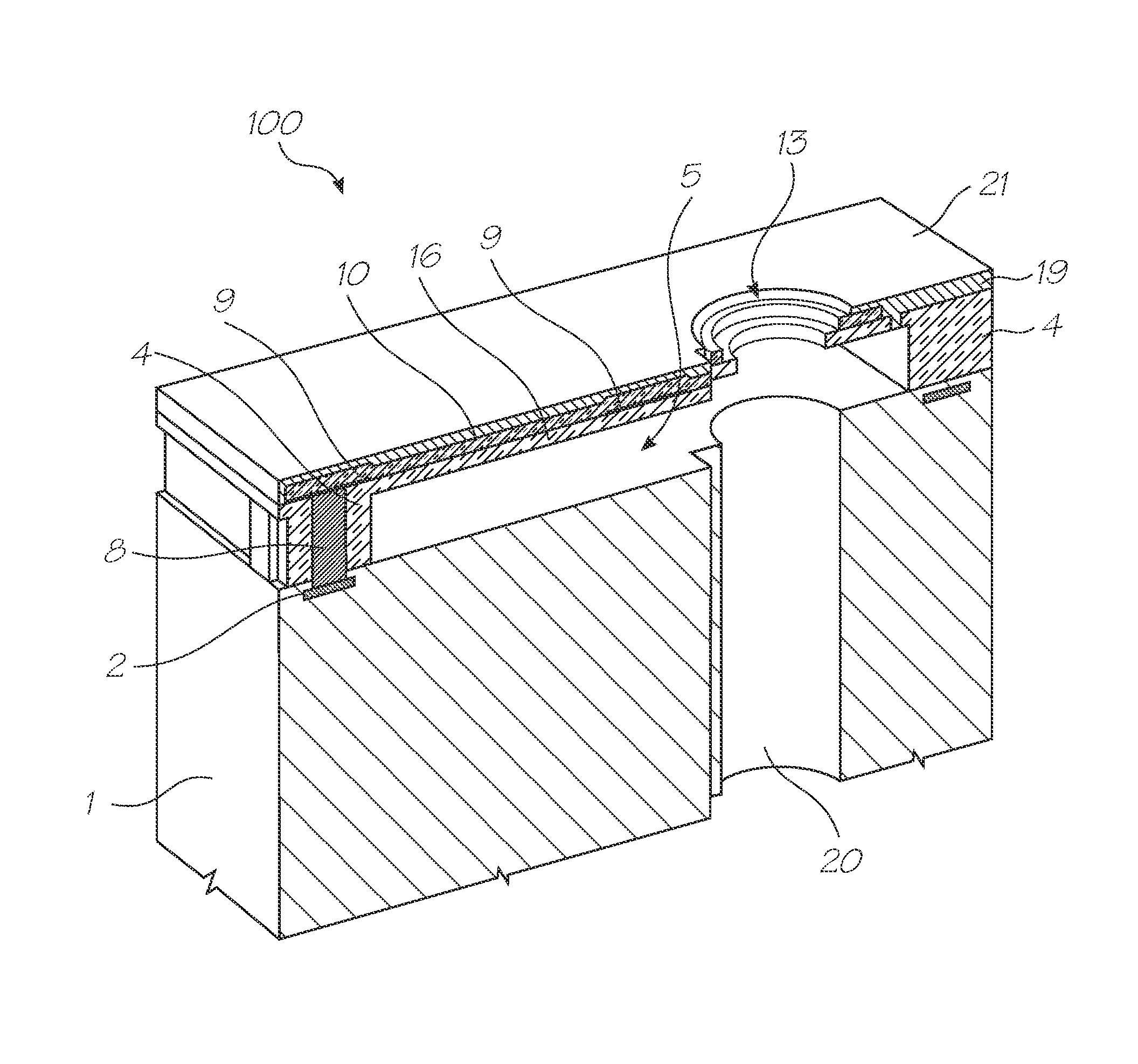

An ink jet printer head includes a cavity unit and a piezoelectric actuator that is bonded to the cavity unit. The piezoelectric actuator includes a top sheet on which external pads are formed in arrays, at an appropriate pitch in each array, in a direction parallel to a direction in which nozzles are formed in arrays in the cavity unit. The external pads are electrically connected to respective individual electrodes via respective internal leads, and also to a flat cable. Each of the external pads is formed at a position right above a partition wall that separates two pressure chambers from each other in the cavity unit. Therefore, when the piezoelectric actuator is bonded to the cavity unit, the external pads of the actuator can be strongly pressed against the partition walls of the cavity unit, so that the actuator can be strongly bonded to the cavity unit and the amount of leakage of ink from the pressure chambers can be minimized. In addition, since the pressing force is not directly applied to the pressure chambers each as a vacant space, the pressure chambers can be prevented from being deformed and the piezoelectric actuator can be prevented from being cracked.

Owner:BROTHER KOGYO KK

Printhead having polymer incorporating nanoparticles coated on ink ejection face

A printhead having an ink ejection face, wherein at least part of the ink ejection face is coated with a polymeric material. The polymeric material is comprised of a polymerized siloxane incorporating nanoparticles. The printhead may be compatible with various printhead maintenance operations, ink characteristics and inkjet nozzle types.

Owner:SILVERBROOK RES PTY LTD

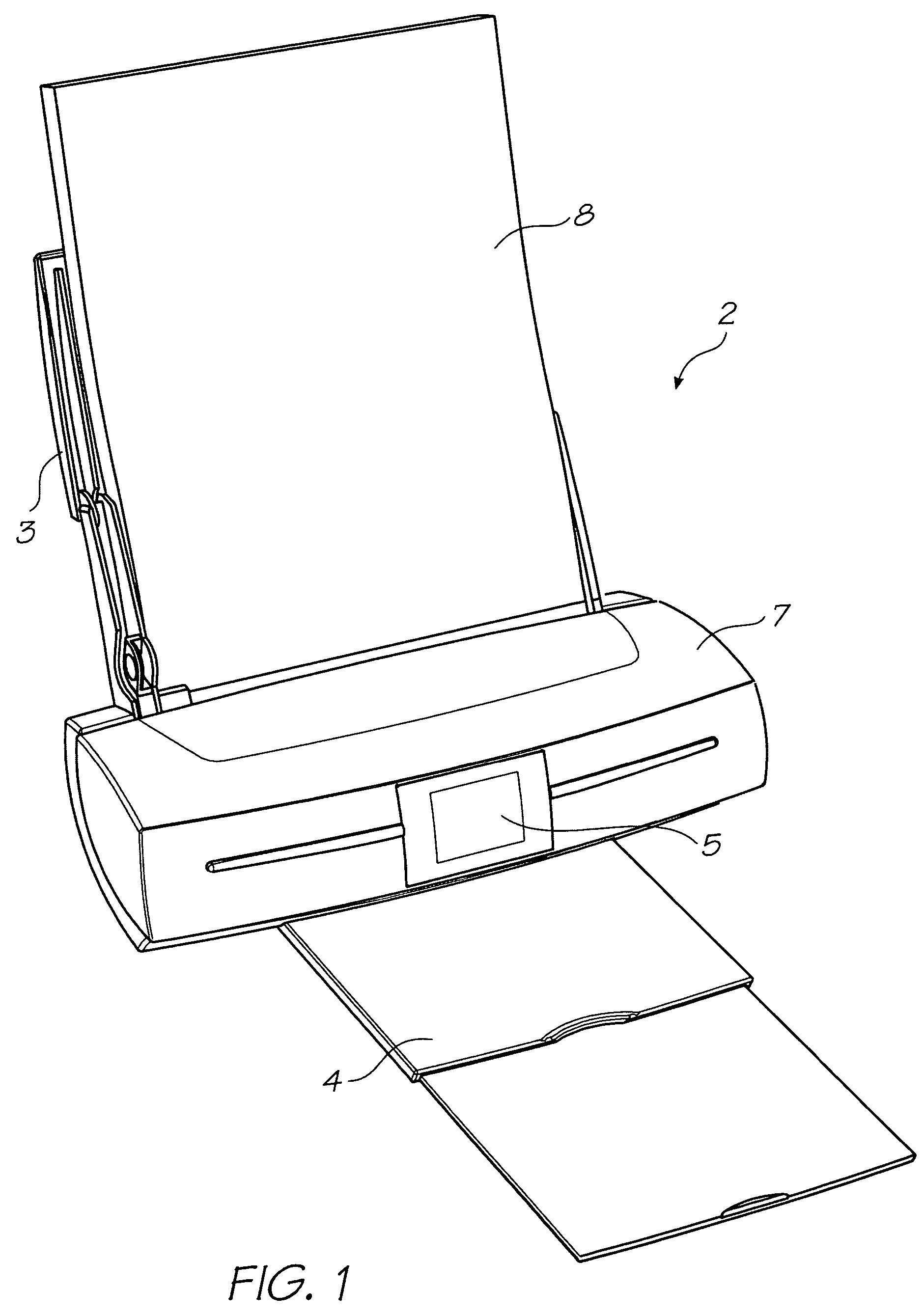

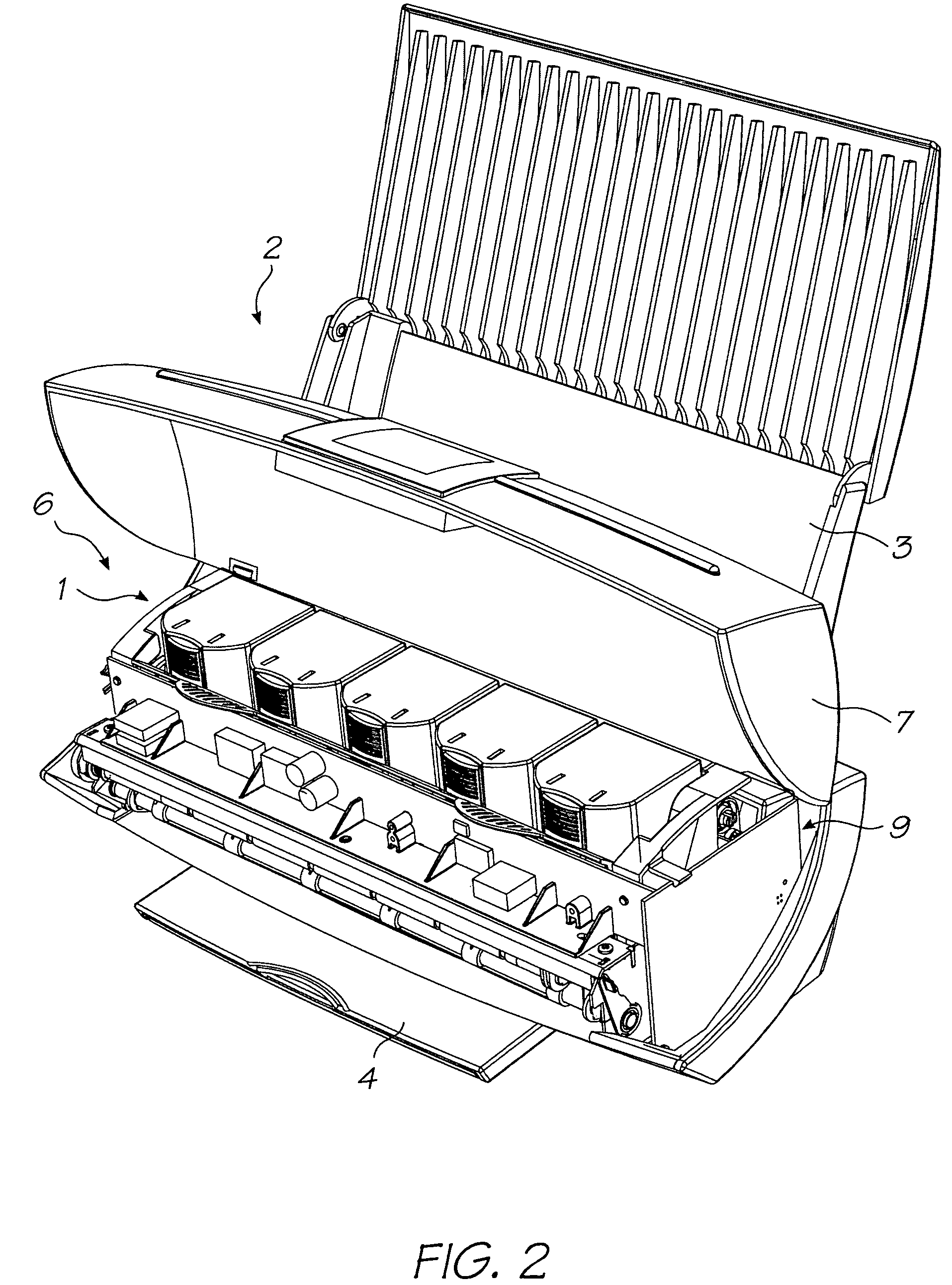

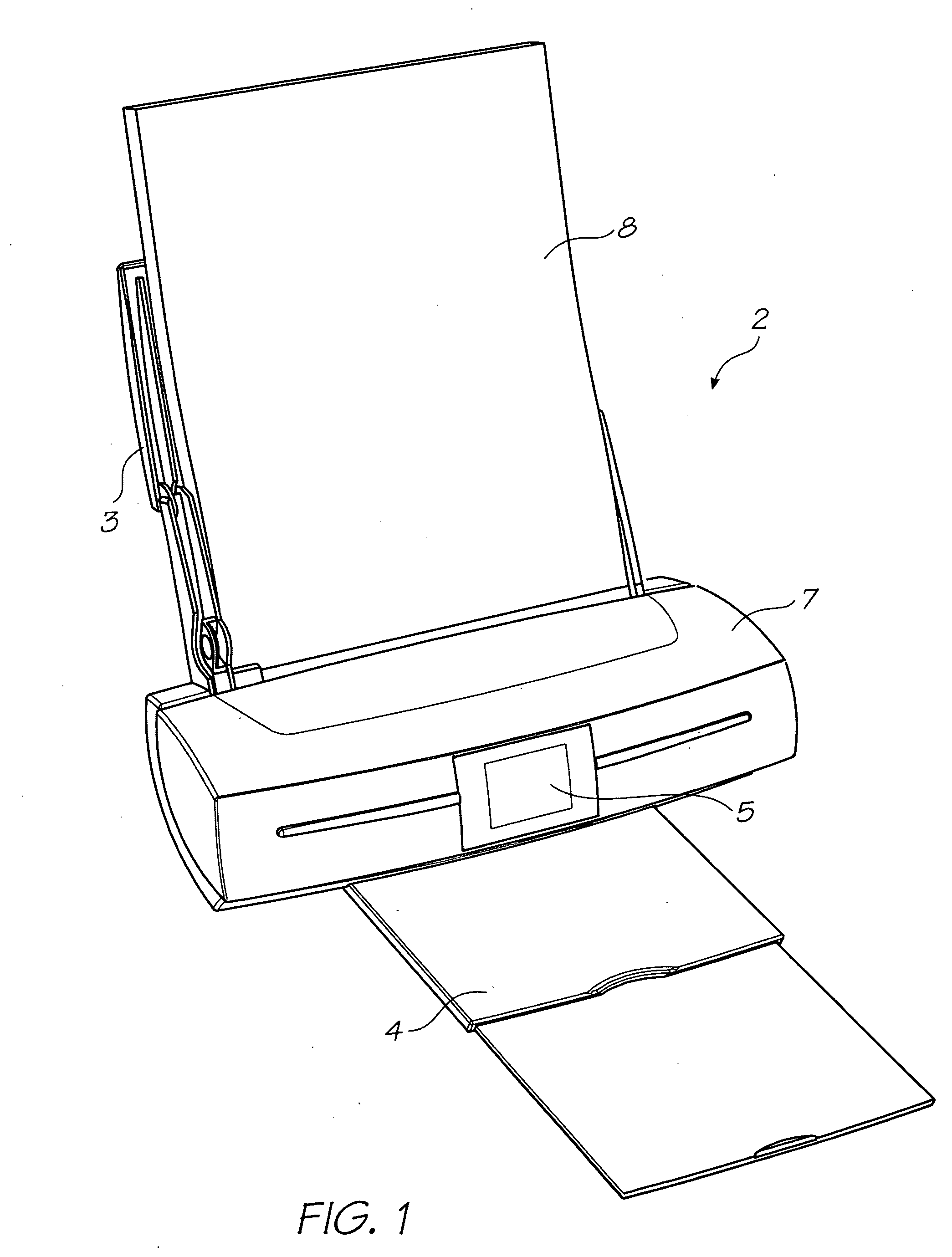

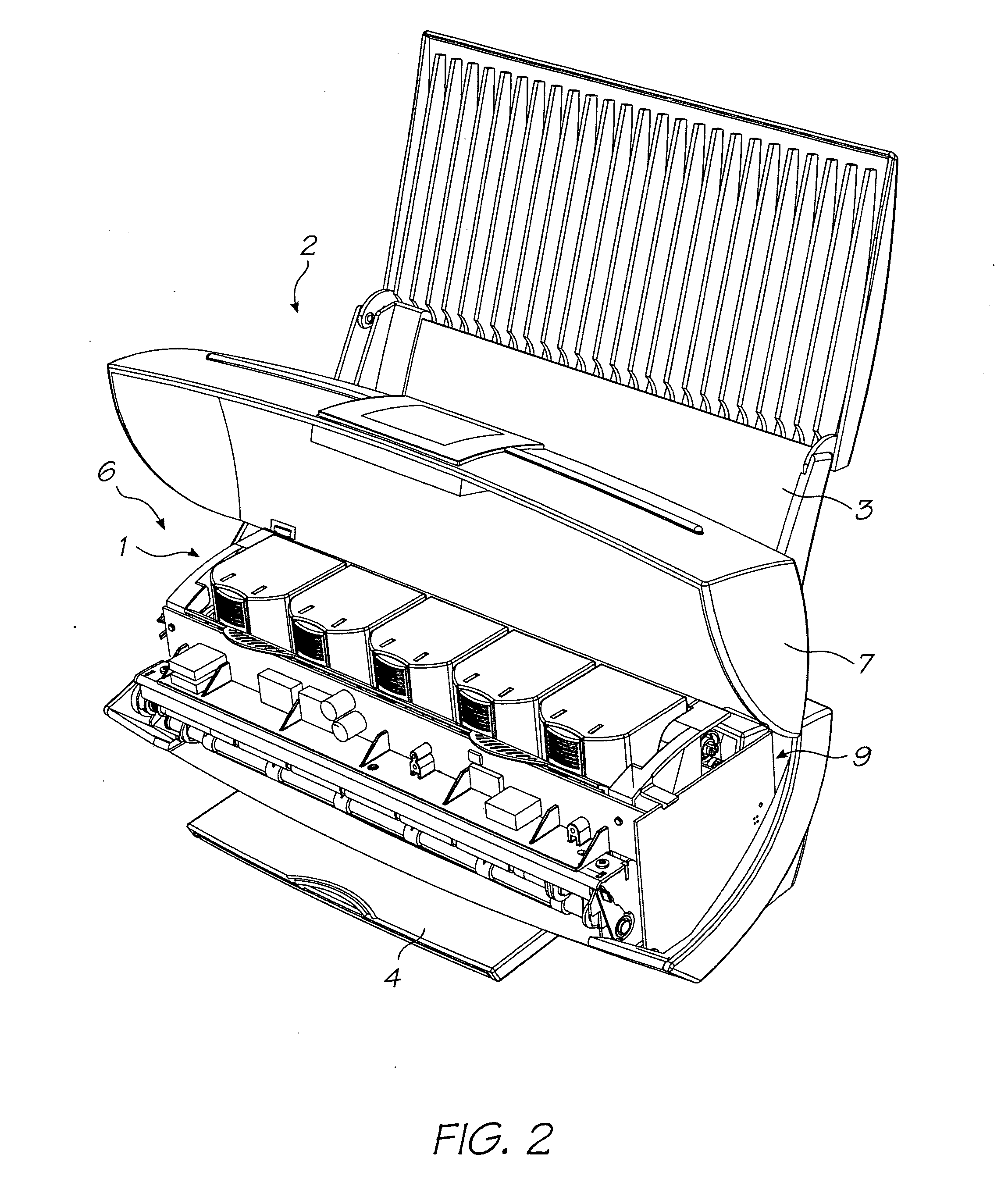

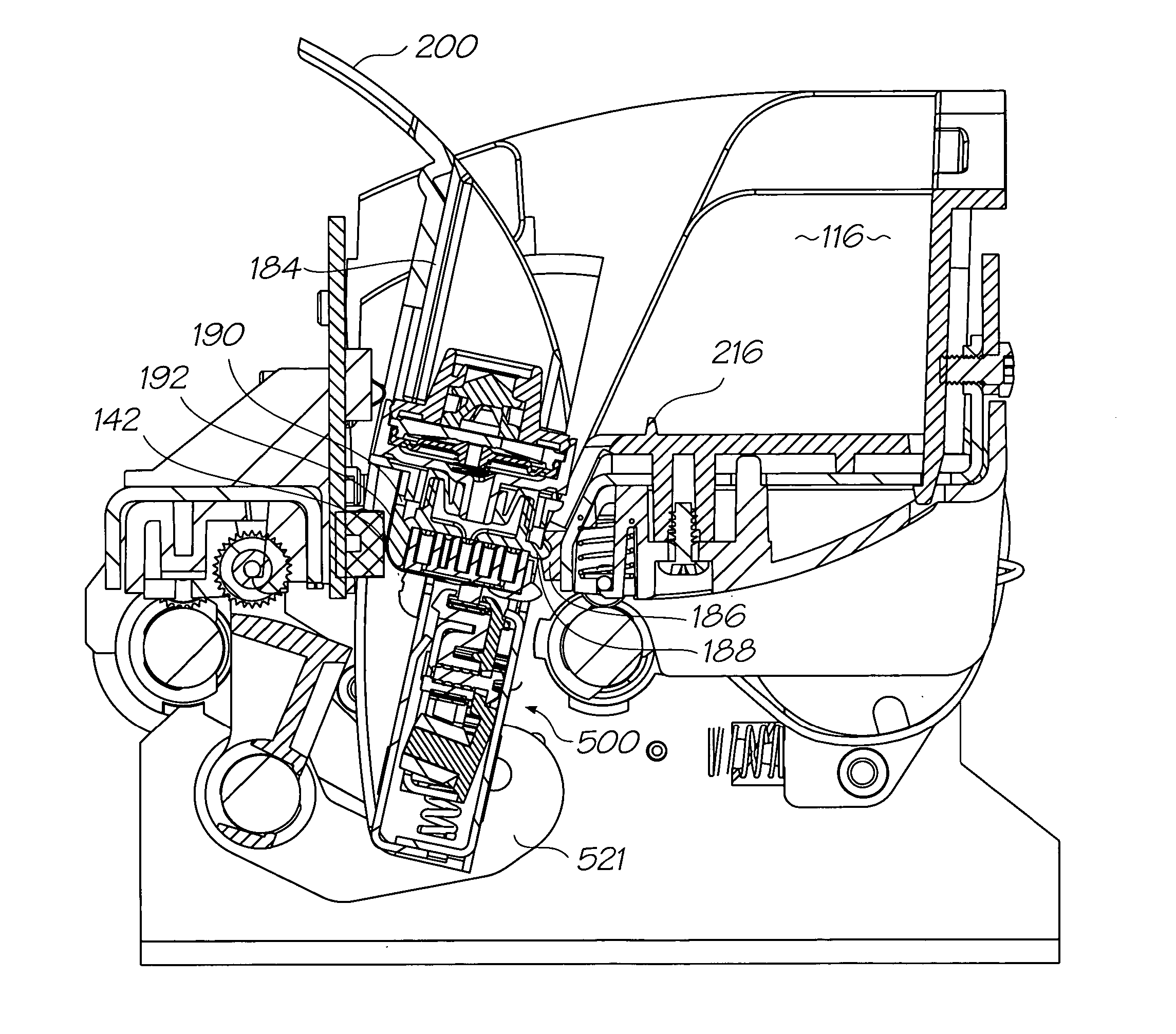

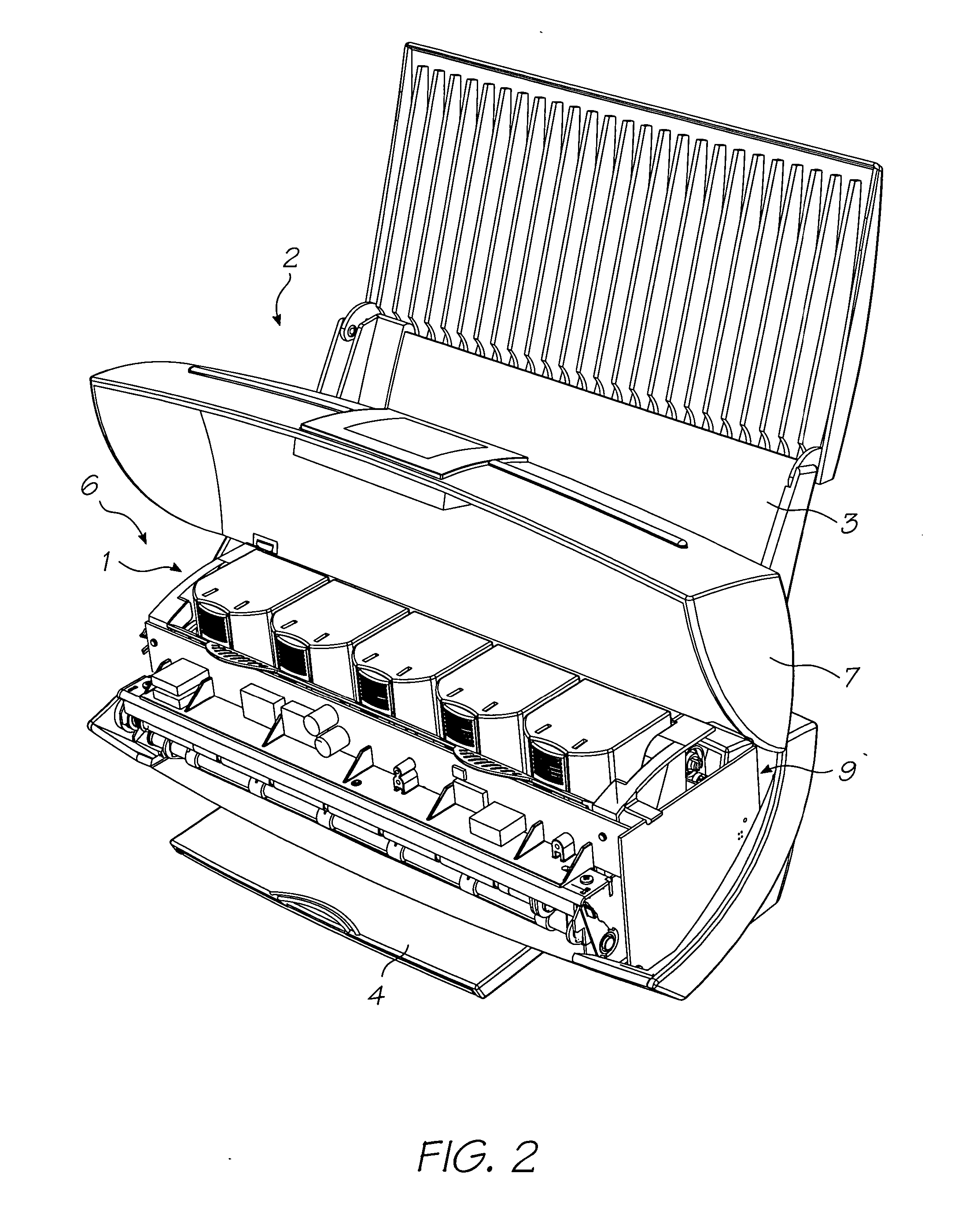

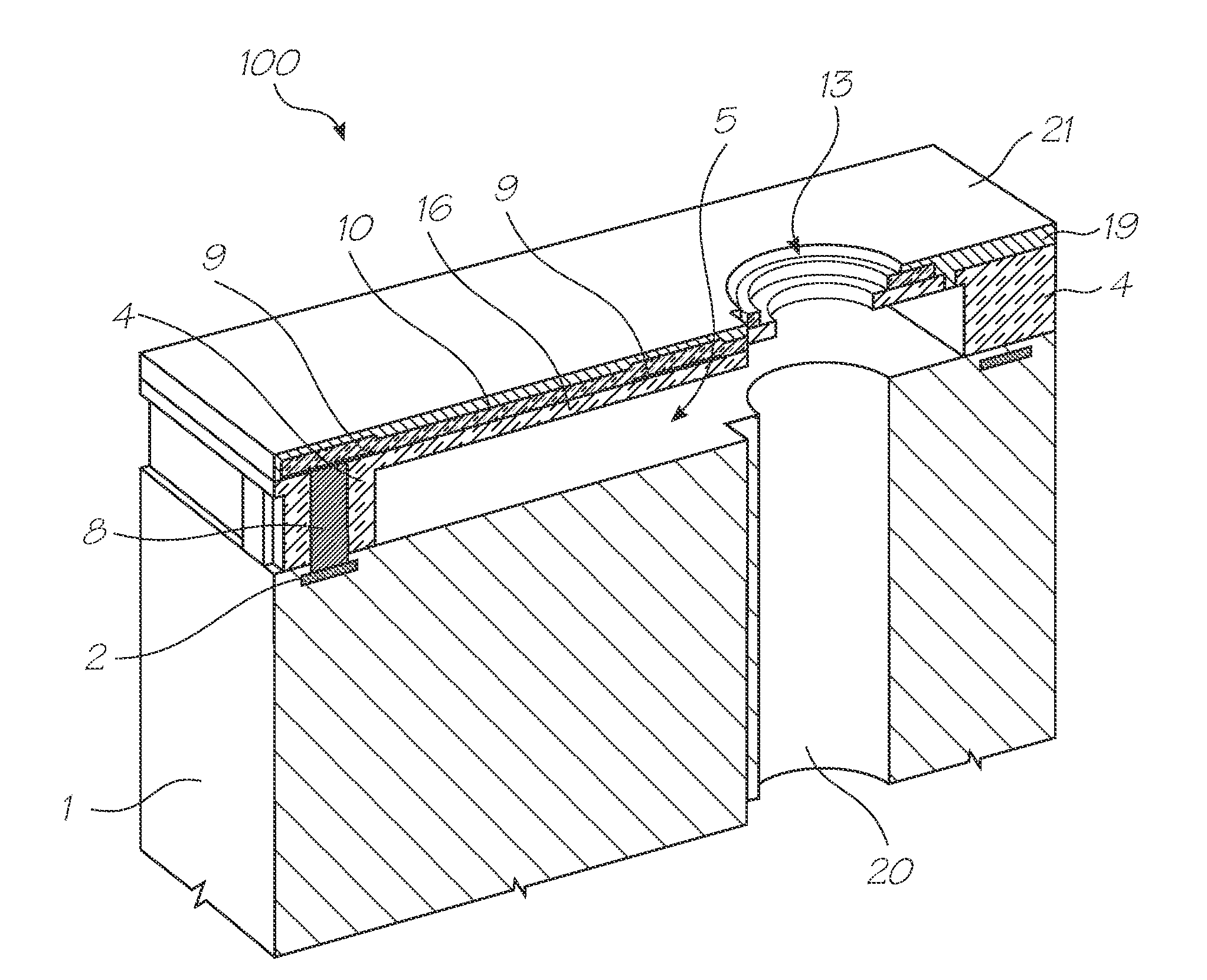

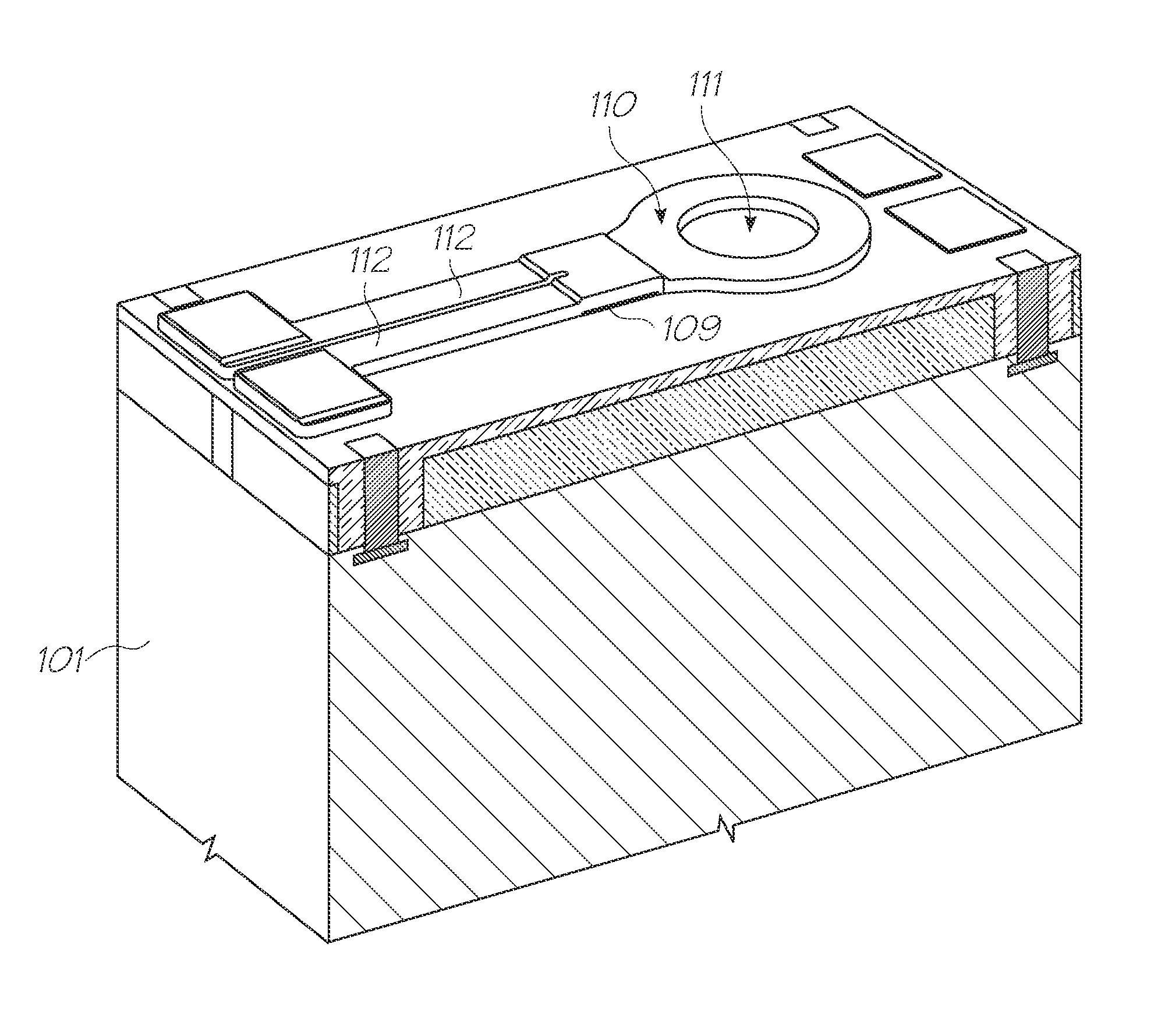

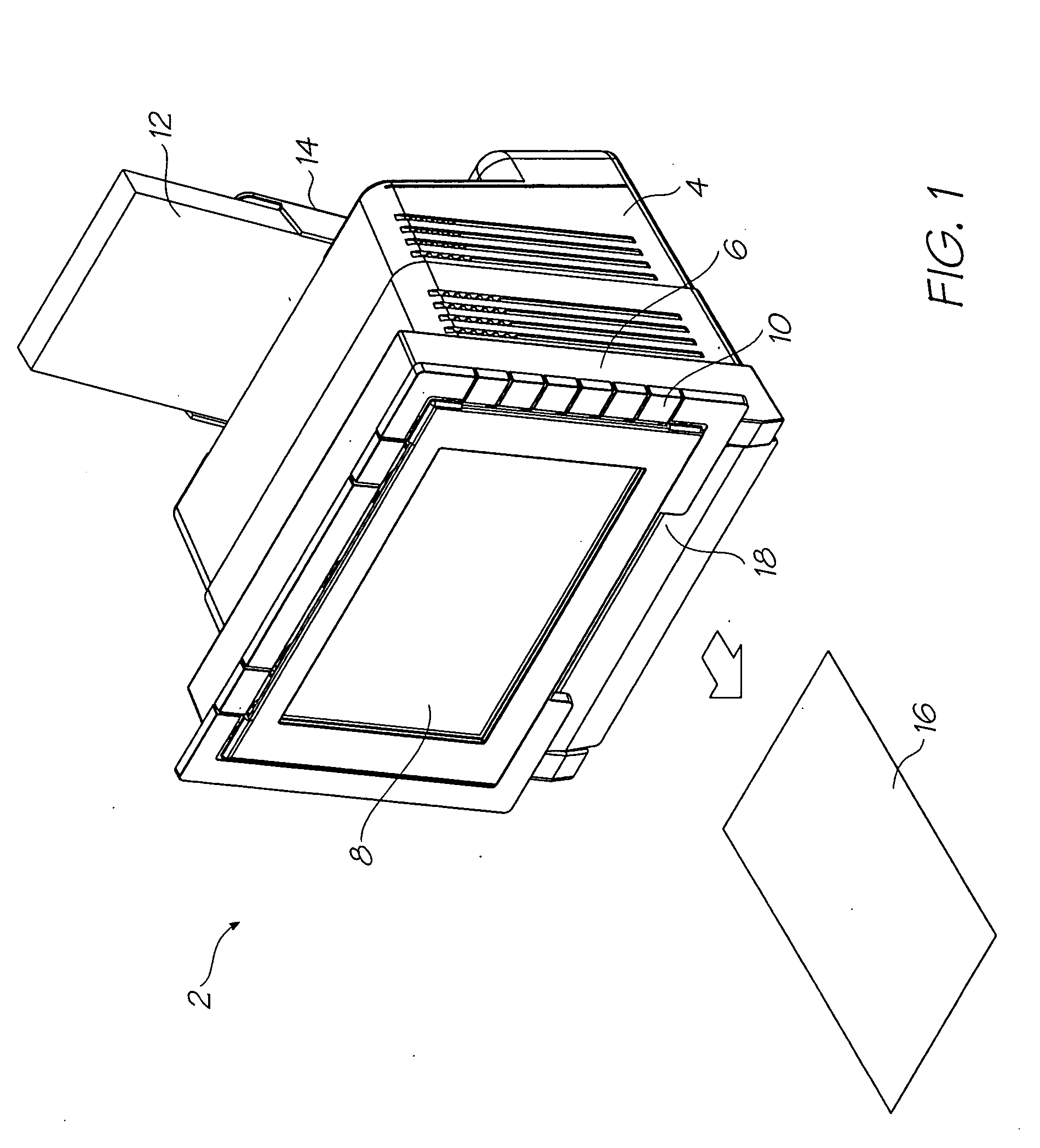

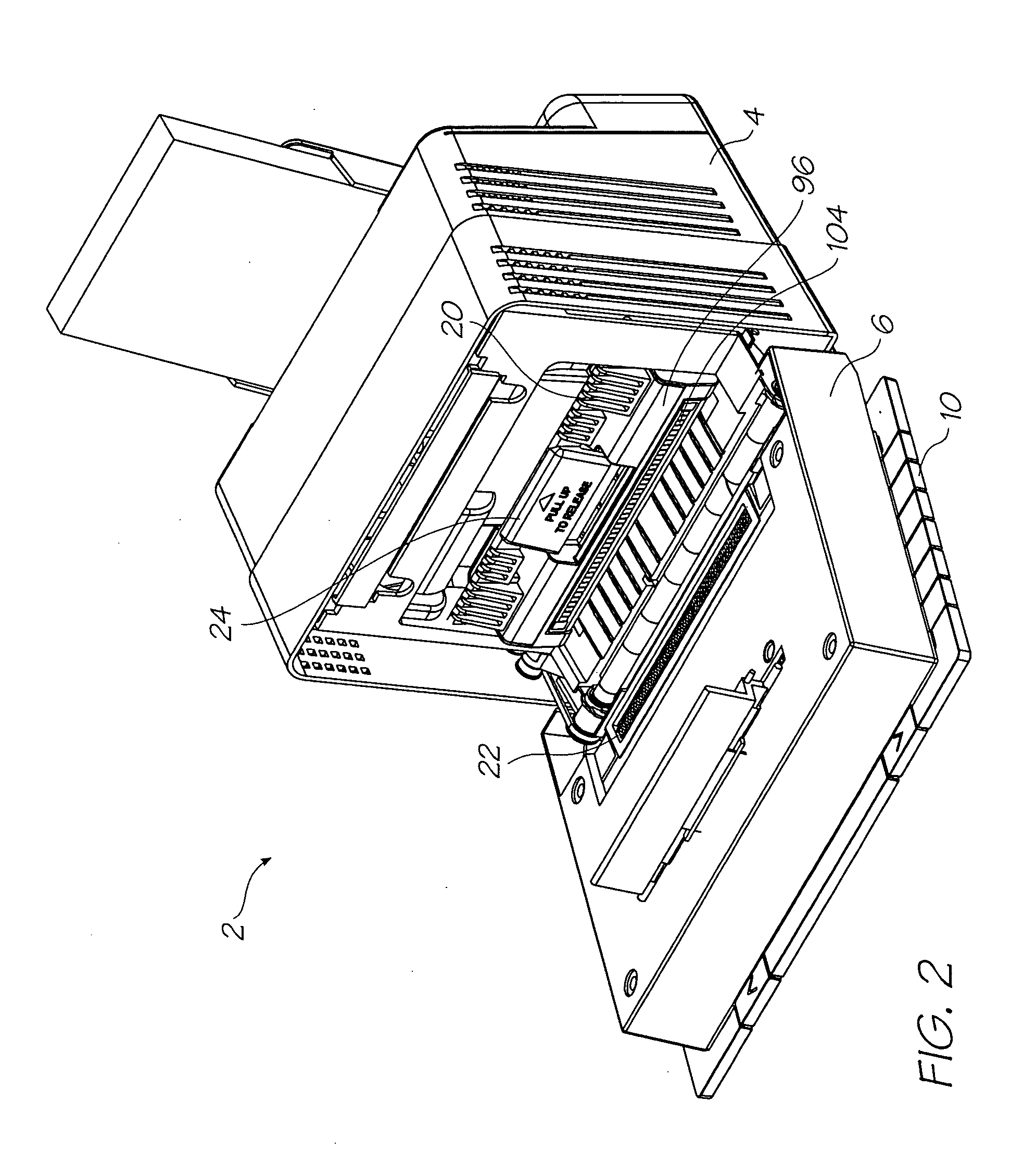

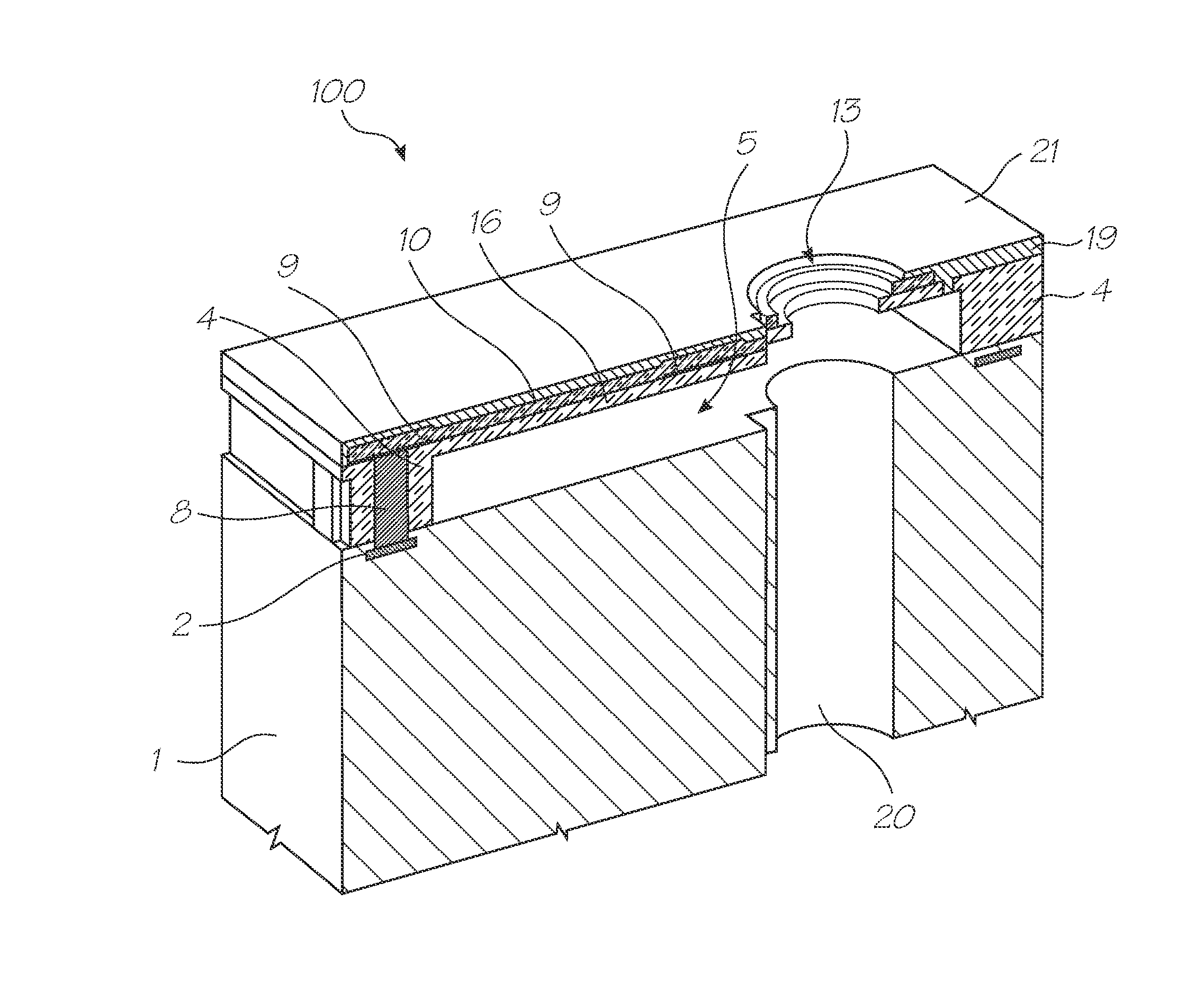

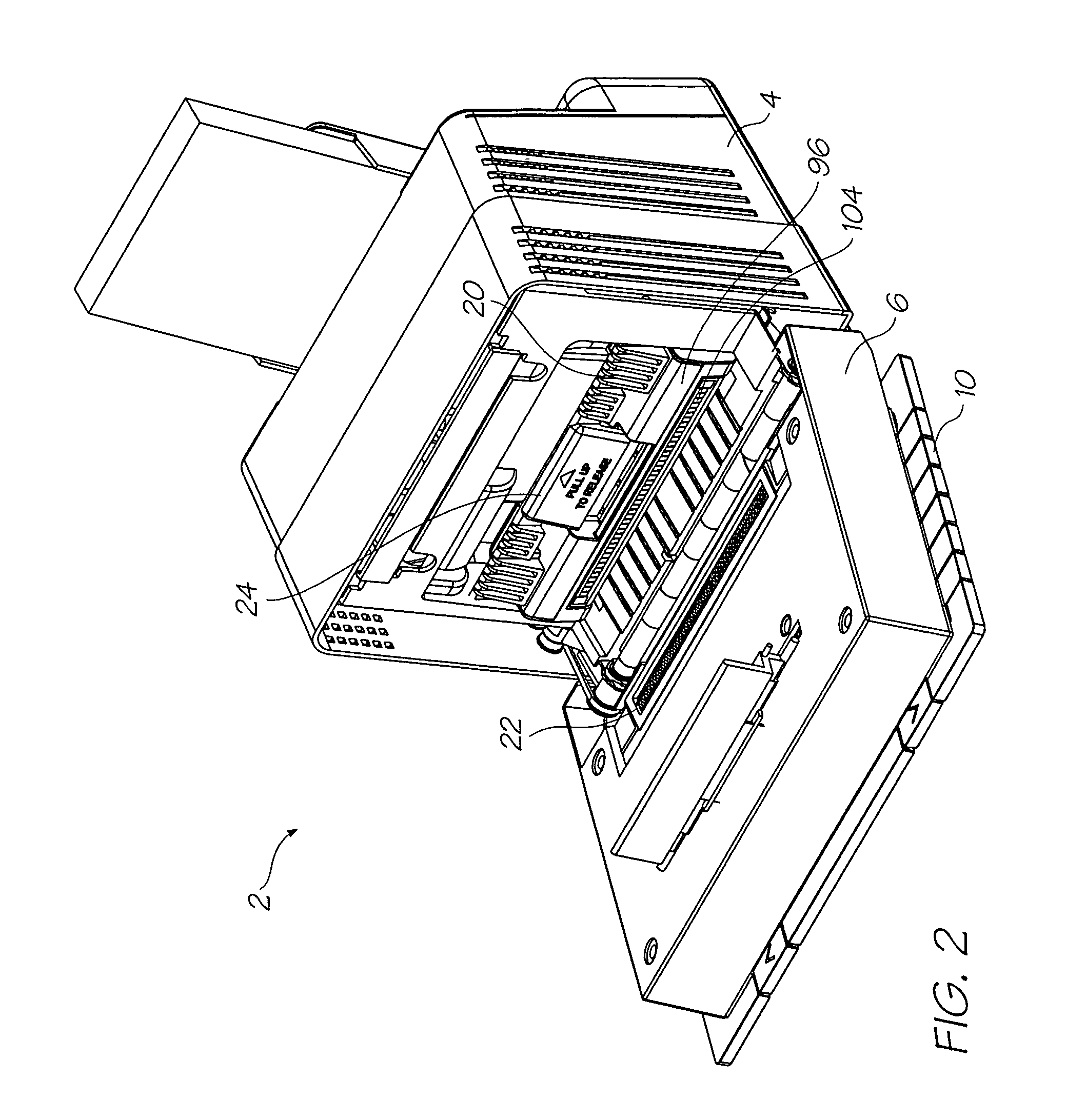

Inkjet printer with printhead cartridge levered into operative position

InactiveUS20070126842A1Minimizes ink leakageReduce effortOther printing apparatusInk printerEngineering

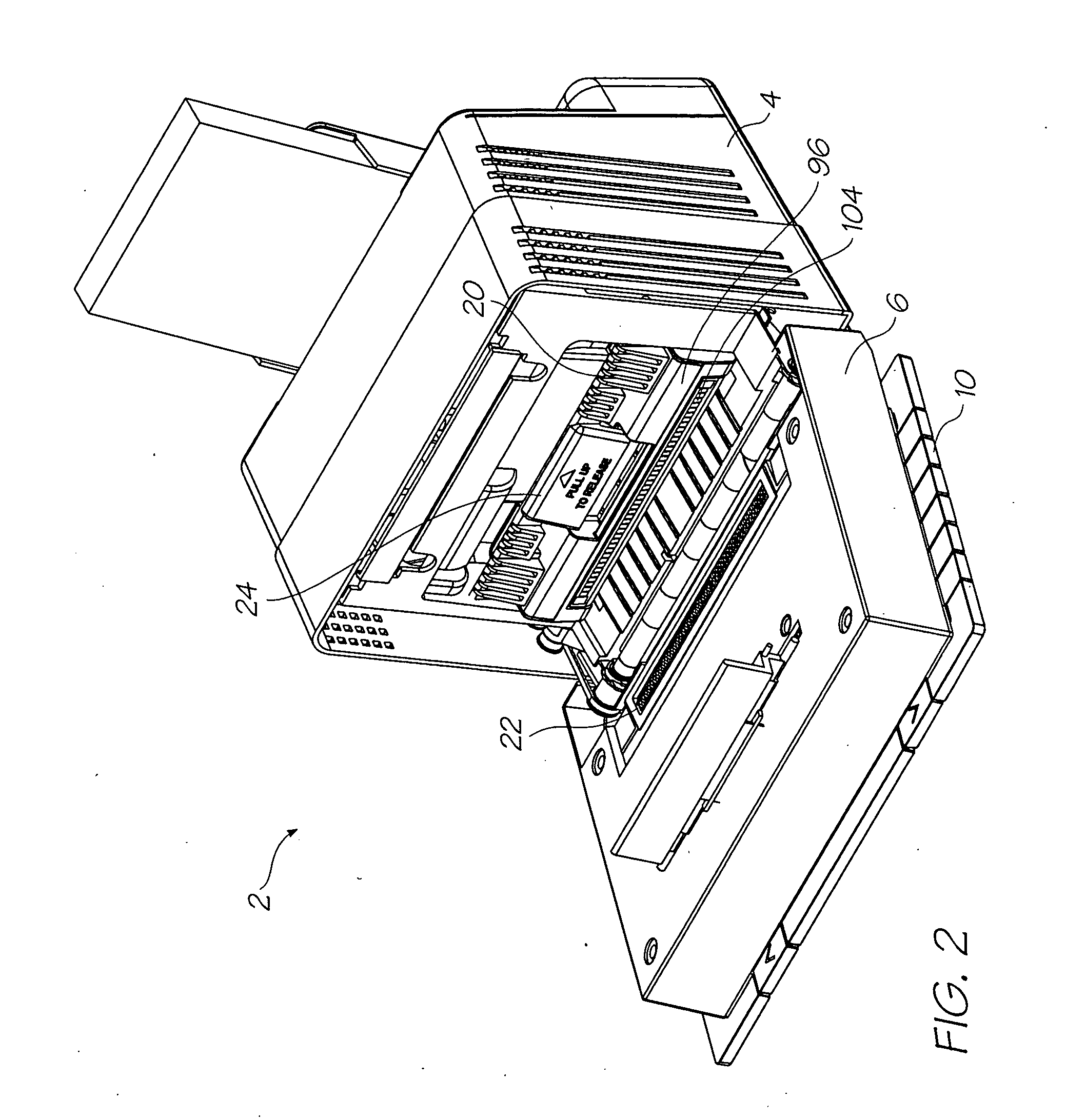

An inkjet printer comprising: a printer body and a replaceable printhead cartridge, the printhead cartridge having a casing that supports a pagewidth printhead and a plurality of contacts for receiving print data from corresponding contacts on the printer body; the printer body having a cradle for holding the printhead cartridge in an operative position such that the pagewidth printhead is adjacent a paper path defined by the printer body and the contacts on the printhead cartridge are connected to the corresponding contacts on the printer body, the cradle having a fulcrum formation for engaging a complementary formation on the casing upon insertion of the cartridge; such that, the cartridge rotates into the operative position and the casing is a lever for pushing the contacts into engagement with the corresponding contacts on the printer body.

Owner:SILVERBROOK RES PTY LTD +1

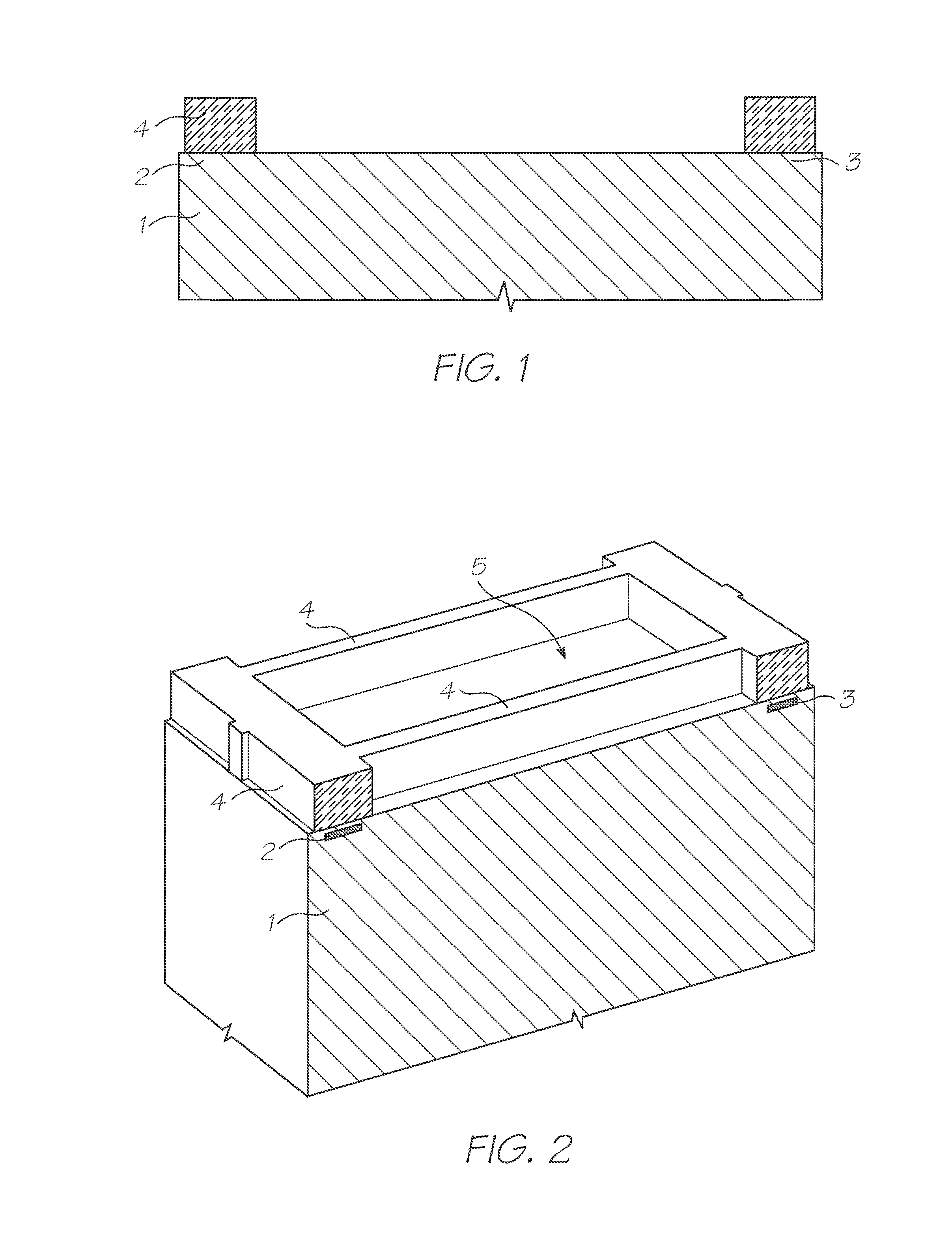

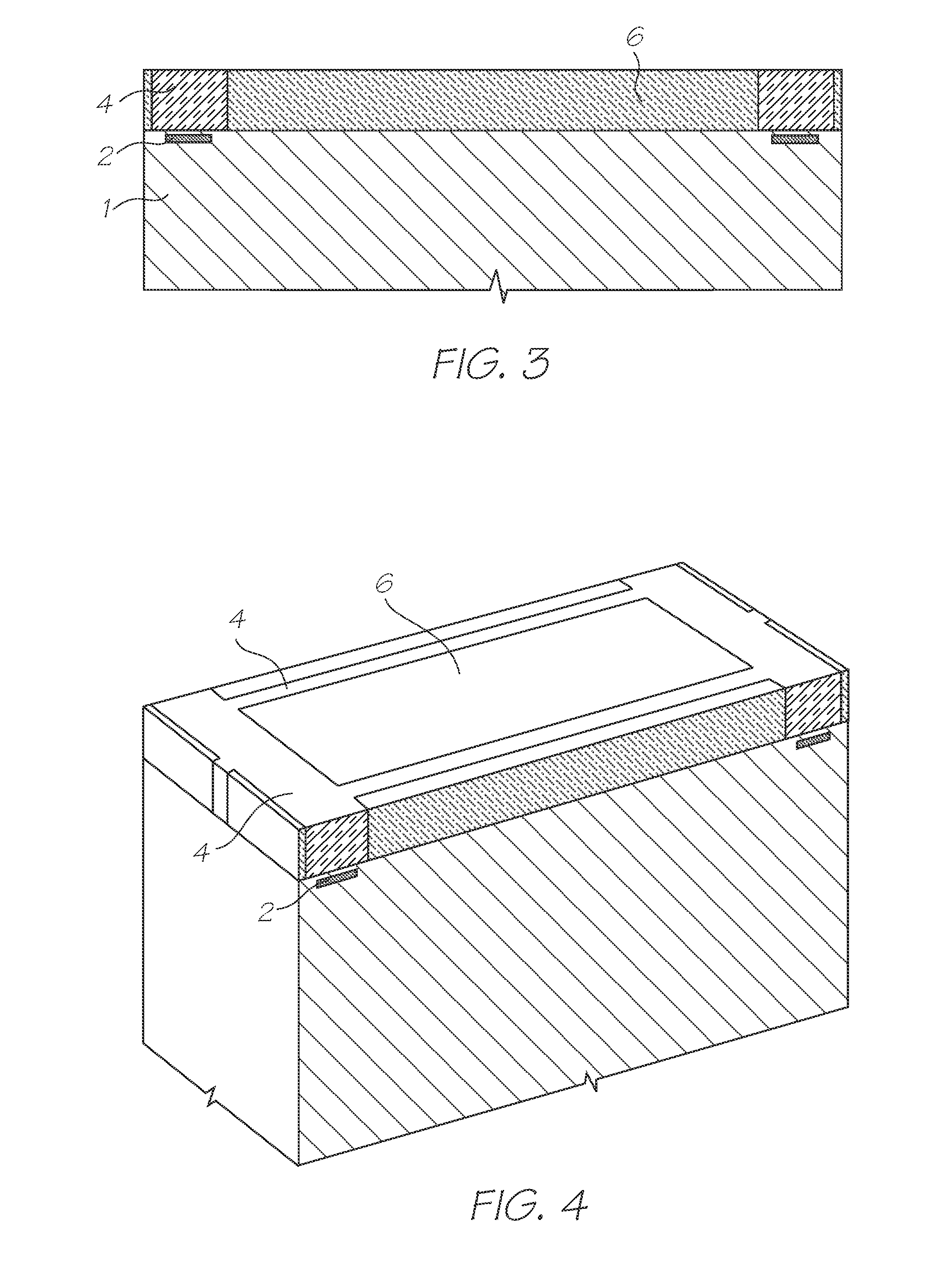

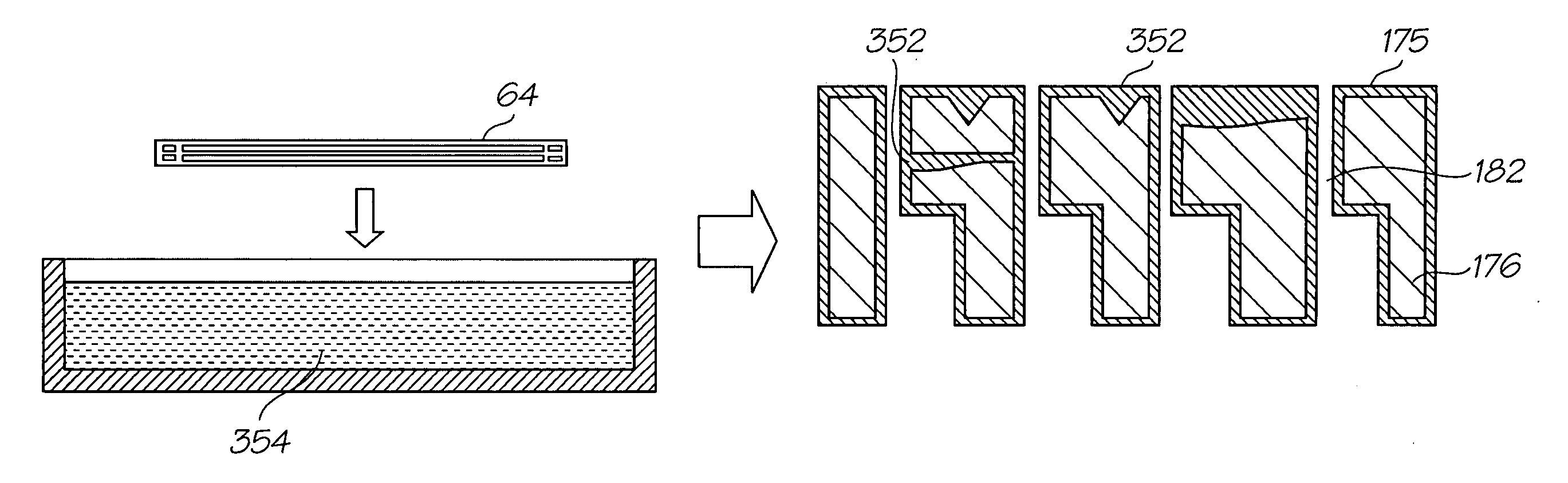

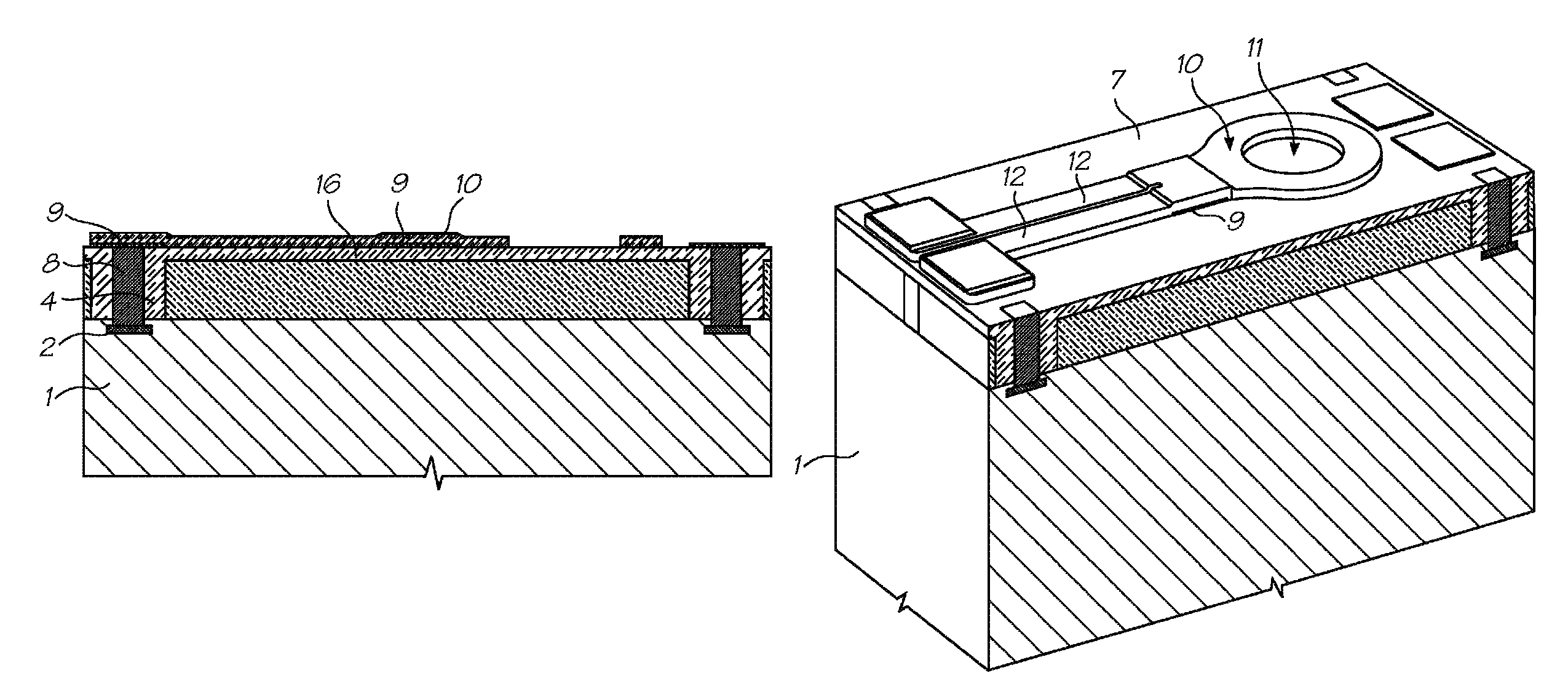

Molded ink manifold with polymer coating

ActiveUS20100149257A1Increased durabilityImprove scratch-resistancePrintingPolymer coatingsEngineering

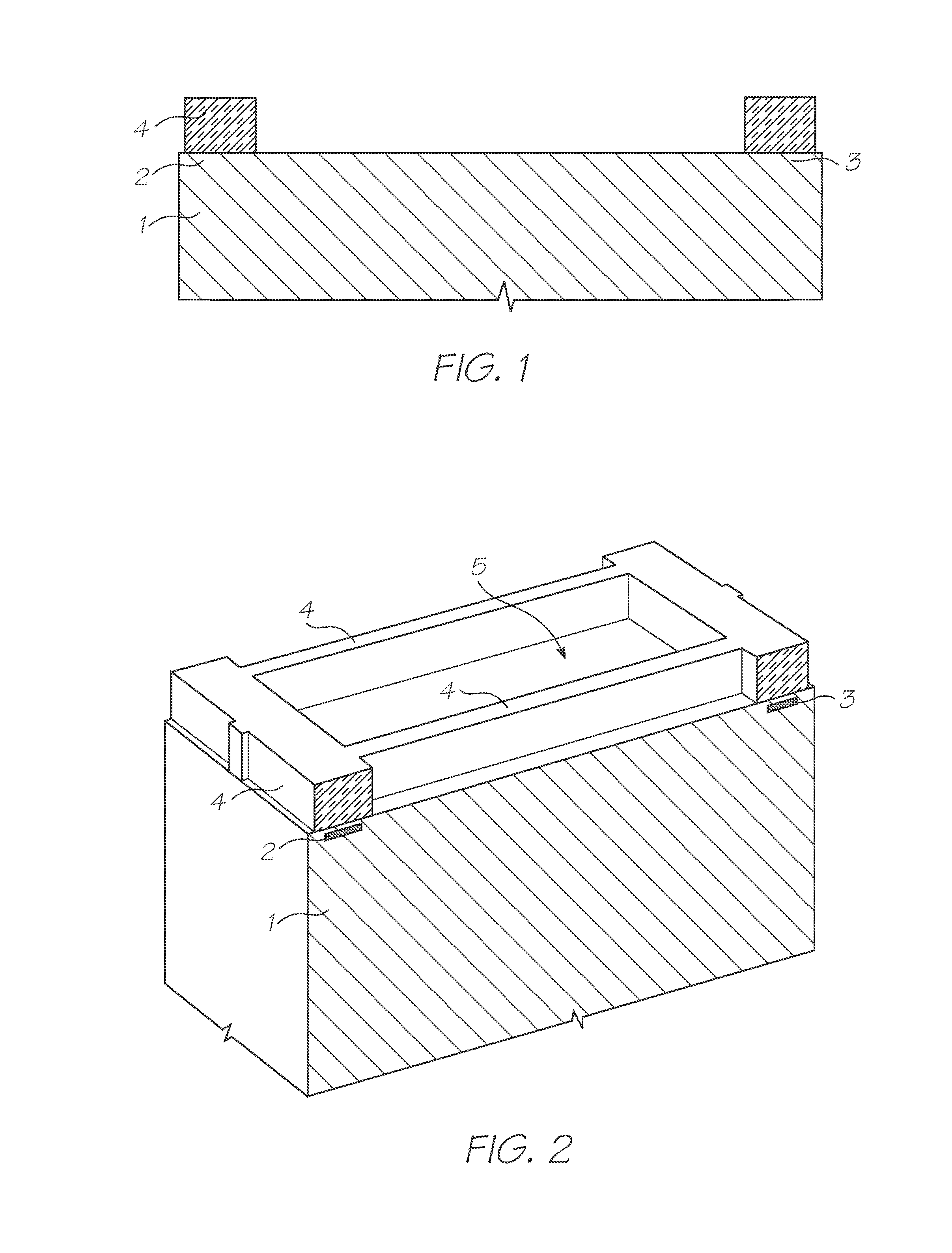

A printhead assembly includes a molded ink manifold, a plurality of printhead integrated circuits, and an adhesive film sandwiched between the ink manifold and the printhead integrated circuits. A manifold bonding surface of the molded ink manifold includes a polymer coating. The polymer coating plugs fissures resulting from a molding process used to mold the ink manifold.

Owner:MEMJET TECH LTD +1

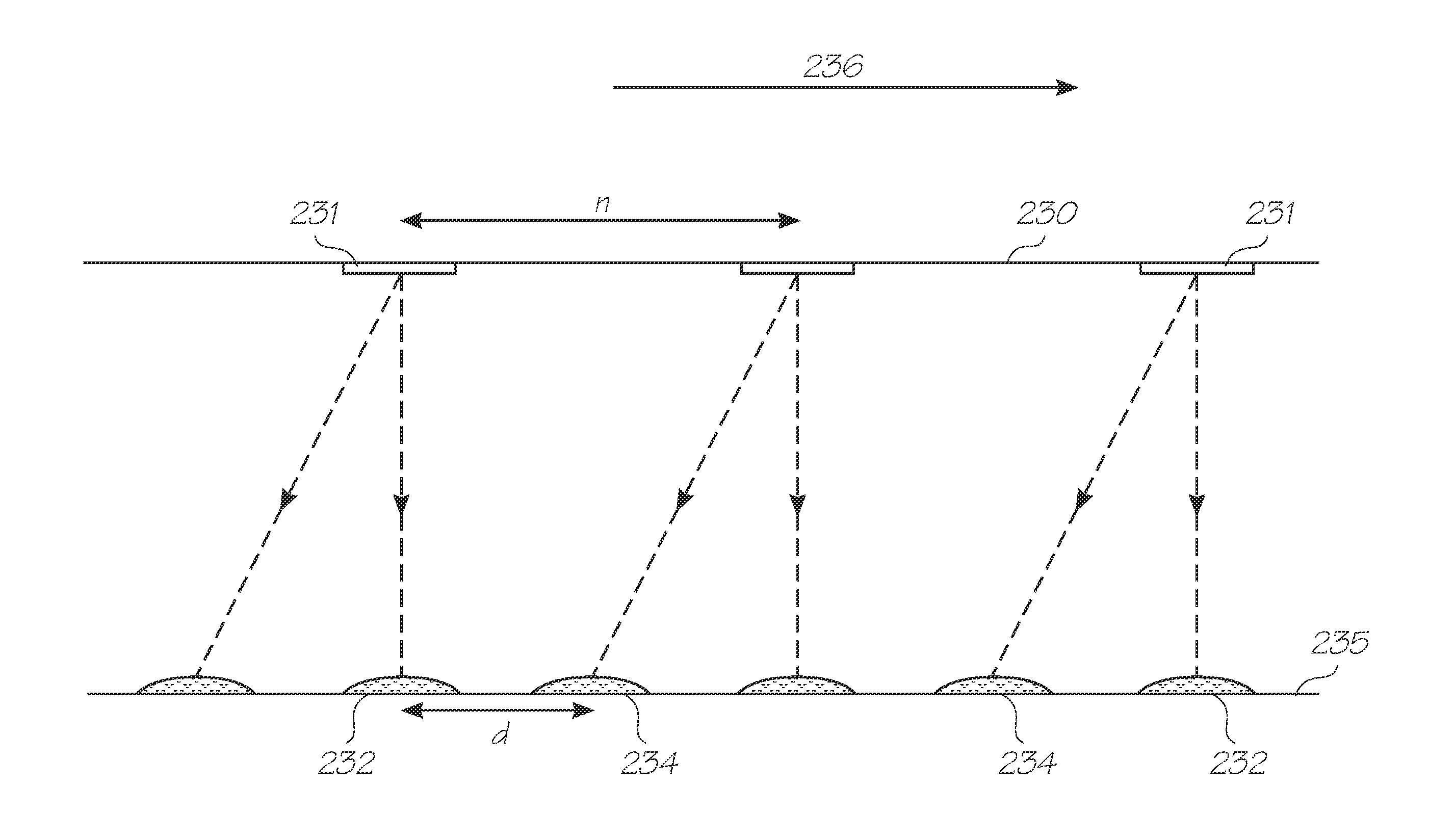

Method of printing at dot density exceeding nozzle density in stationary pagewidth printhead

ActiveUS20120081429A1Minimizes ink leakageInking apparatusOther printing apparatusVolumetric Mass DensityNozzle

A method of printing at a dot density exceeding a nozzle density in a stationary pagewidth printhead. The method includes the steps of: (i) advancing a print medium transversely past the stationary printhead at a rate of one line per one line-time; and (ii) firing droplets of ink from predetermined nozzles in a nozzle row to create successive lines of print. Some or all of the predetermined nozzles fire droplets of ink at a plurality of predetermined different dot positions along a longitudinal axis of the printhead during one line-time, such that the printed dot density in each line of print exceeds the nozzle density.

Owner:MEMJET TECH LTD

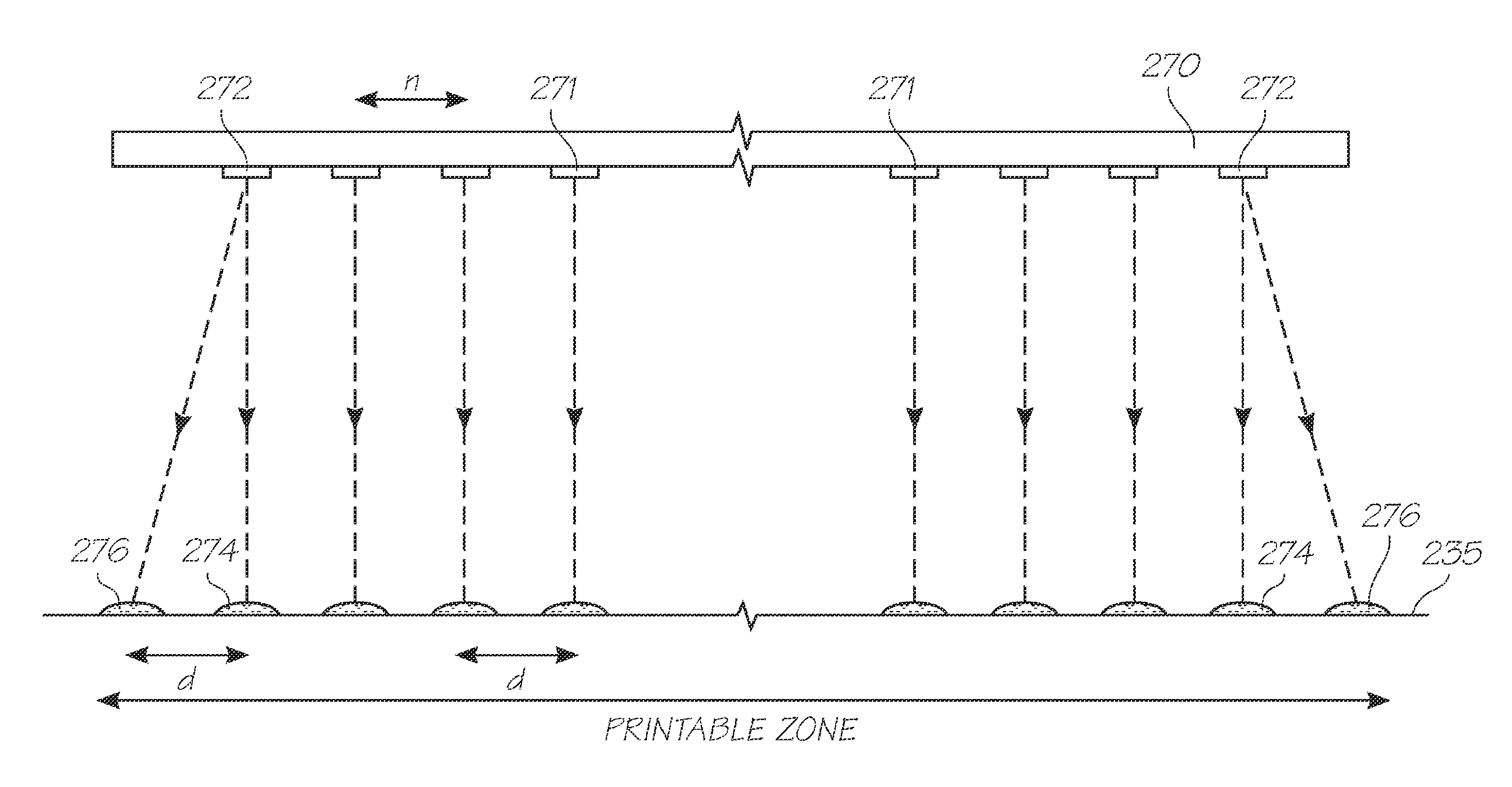

Inkjet printhead with join regions seamlessly compensated by directional nozzles

A stationary pagewidth inkjet printhead has one or more nozzle rows extending along a longitudinal axis of the printhead. The printhead is comprised of a plurality of printhead modules having first and second opposite ends butted across a width of a page. Each butting pair of printhead modules defines a common join region, wherein a nozzle pitch across the join region exceeds one nozzle pitch, one nozzle pitch being defined as a minimum longitudinal distance between a pair of nozzles in a same nozzle row. A first nozzle positioned at the first end of a first printhead module in a butting pair is configured to fire ink droplets into a respective join region.

Owner:MEMJET TECH LTD

Pagewidth inkjet printhead configured such that printed dot density exceeds nozzle density

ActiveUS20120081469A1Minimizes ink leakageOther printing apparatusSpray nozzleVolumetric Mass Density

A stationary pagewidth inkjet printhead has one or more nozzle rows extending along a longitudinal axis of the printhead. Each nozzle is configured to fire a droplet of ink at a plurality of predetermined different dot positions along the longitudinal axis, such that a printed dot density exceeds a nozzle density of the printhead.

Owner:MEMJET TECH LTD

Stationary inkjet printhead with dead nozzle compensation provided by nozzles in same nozzles row

A stationary pagewidth inkjet printhead has one or more nozzle rows extending along a longitudinal axis of the printhead. Each nozzle is configurable to fire a droplet of ink at a plurality of predetermined different dot positions along the longitudinal axis, and each nozzle has an associated primary dot position. The printhead is configured to compensate for a dead nozzle by printing from a selected functioning nozzle positioned in a same nozzle row as the dead nozzle. The selected functioning nozzle is configured to fire some ink droplets at the primary dot position associated with the dead nozzle and to fire some ink droplets at its own primary dot position.

Owner:MEMJET TECH LTD

Printhead having polymer incorporating nanoparticles coated on ink ejection face

A printhead having an ink ejection face, wherein at least part of the ink ejection face is coated with a polymeric material. The polymeric material is comprised of a polymerized siloxane incorporating nanoparticles. The printhead may be compatible with various printhead maintenance operations, ink characteristics and inkjet nozzle types.

Owner:SILVERBROOK RES PTY LTD

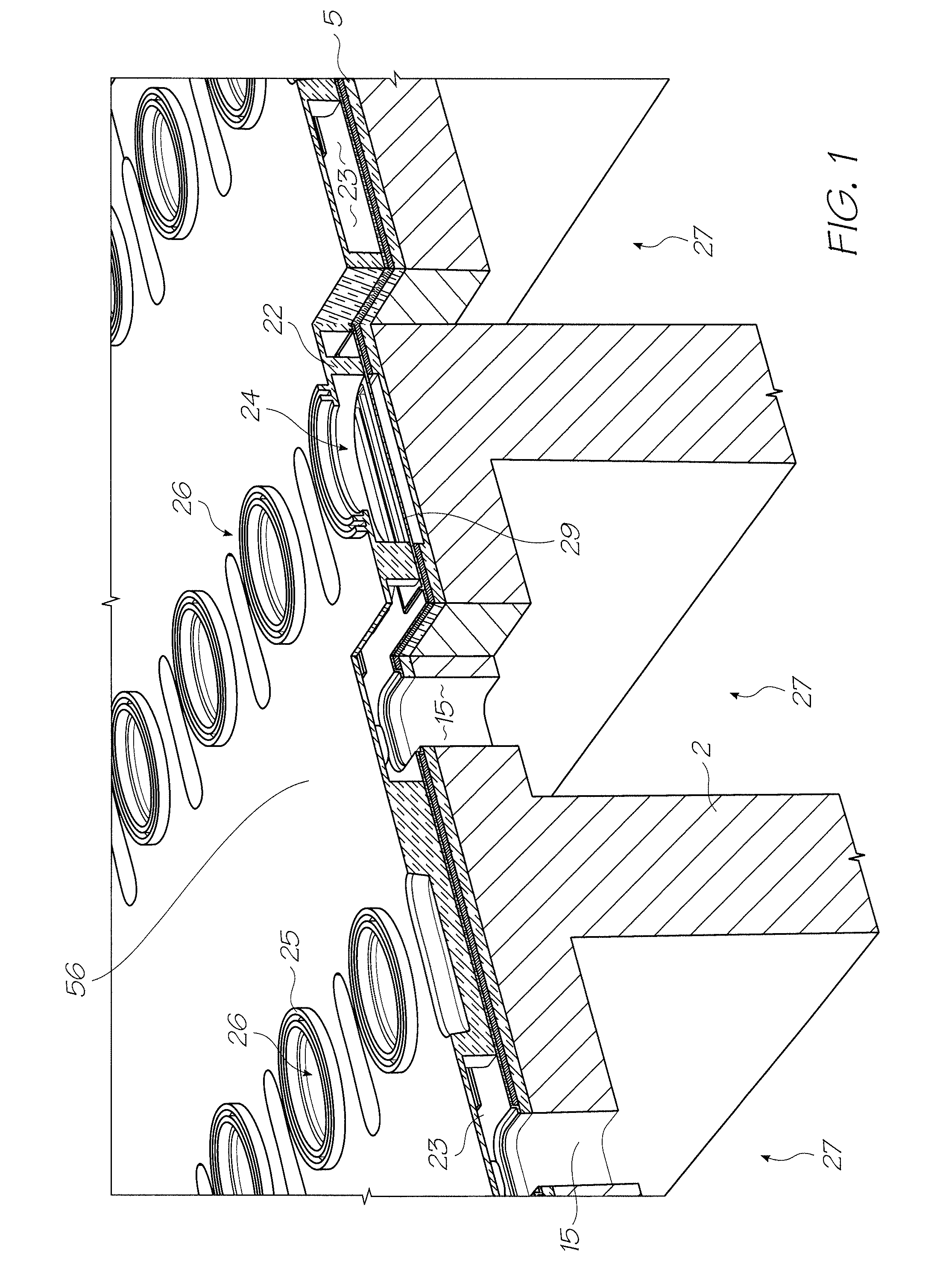

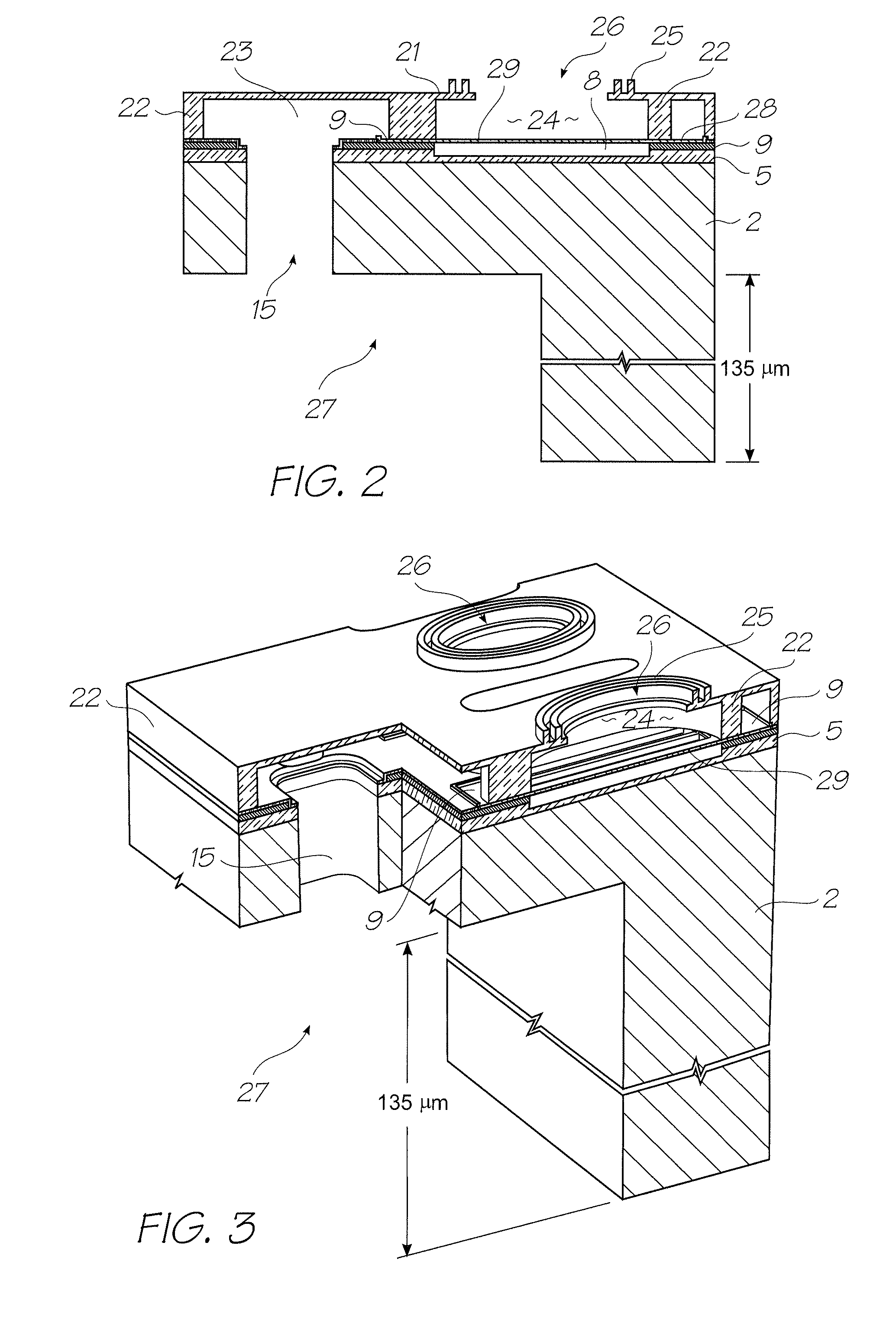

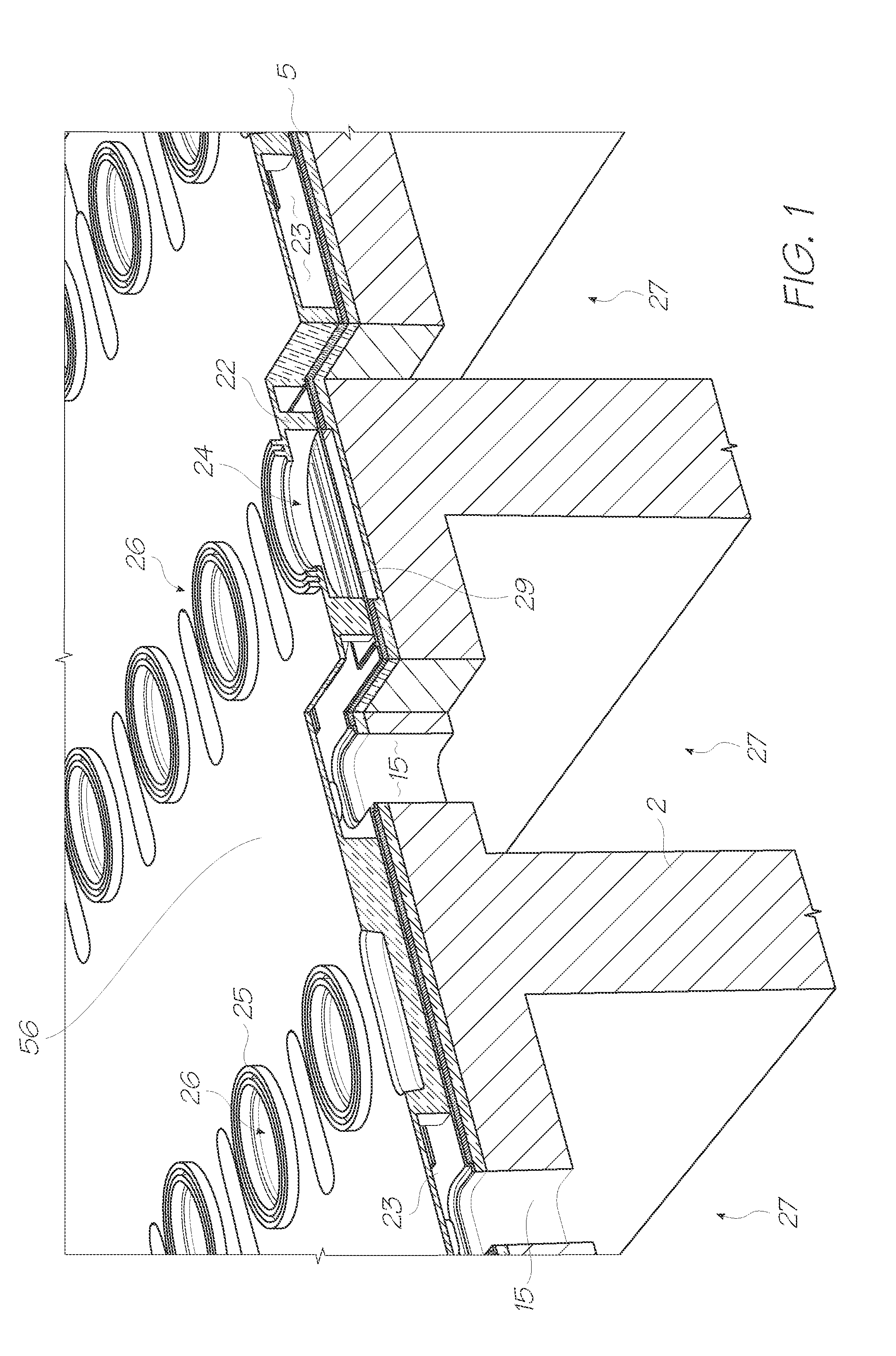

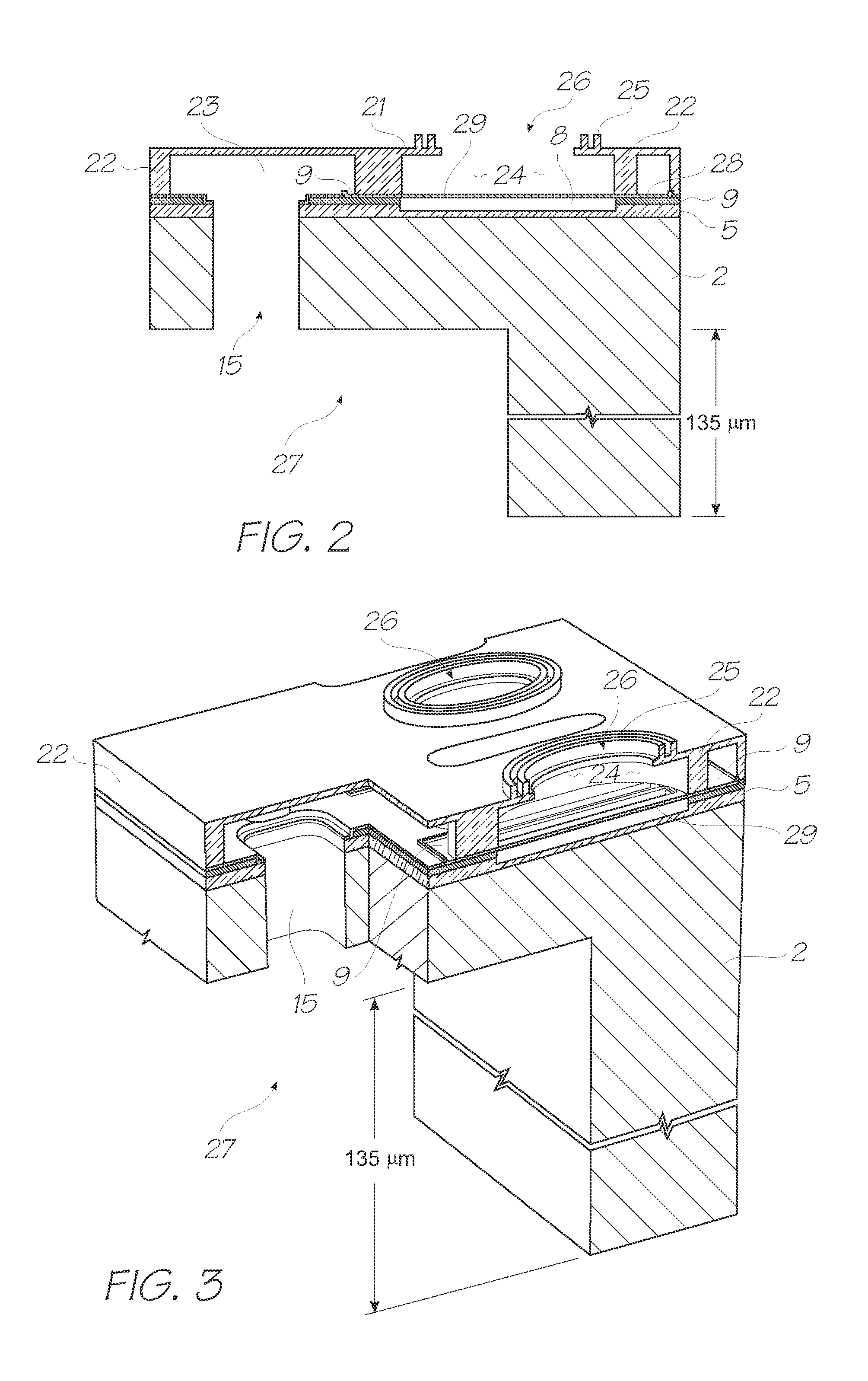

Inkjet nozzle assembly with drop directionality control via independently actuable roof paddles

An inkjet nozzle assembly having: a nozzle chamber for containing ink, the nozzle chamber including a floor and a roof having a nozzle opening defined therein; and a plurality of moveable paddles defining part of the roof. The plurality of paddles are actuable to cause ejection of an ink droplet from the nozzle opening. Each paddle includes a thermal bend actuator, and each actuator is independently controllable via respective drive circuitry such that a direction of droplet ejection from the nozzle opening is controllable by independent movement of each paddle.

Owner:MEMJET TECH LTD

Printhead having polysilsesquioxane coating on ink ejection face

Owner:SILVERBROOK RES PTY LTD

Method of controlling drop directionality from inkjet nozzle using multiple independently-actuable roof paddles

A method of controlling a direction of droplet ejection from an inkjet nozzle having a plurality of moveable paddles, the method includes the steps of: (i) actuating a first thermal bend actuator via respective first drive circuitry such that a respective first paddle bends towards a floor of the nozzle chamber; (ii) actuating a second thermal bend actuator via respective second drive circuitry such that a respective second paddle bends towards a floor of the nozzle chamber; and (iii) thereby ejecting a droplet of ink. Actuation of the first and second thermal bend actuators is independently controlled via the first and second drive circuitry so as to control the direction of droplet ejection.

Owner:MEMJET TECH LTD

Printhead having ink ejection face complementing ink or other features of printhead

An inkjet printhead for ejection of an ejectable fluid. The printhead has an ink ejection face coated with a polymeric material incorporating nanoparticles. The nanoparticles impart predetermined characteristics to the ink ejection face, which complement an inherent property of the ejectable fluid, a printhead maintenance regime associated with the printhead or a type of nozzle actuator.

Owner:SILVERBROOK RES PTY LTD +1

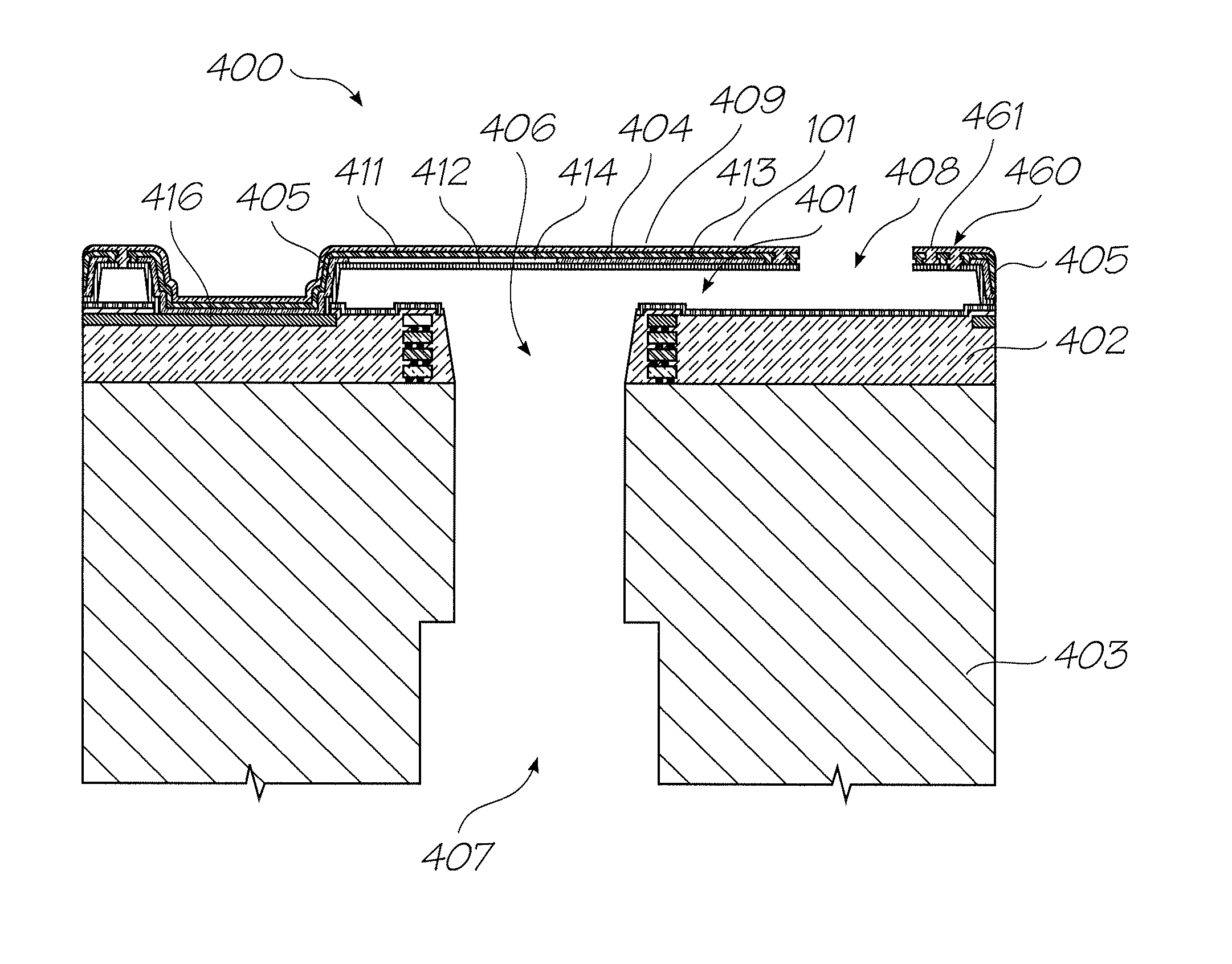

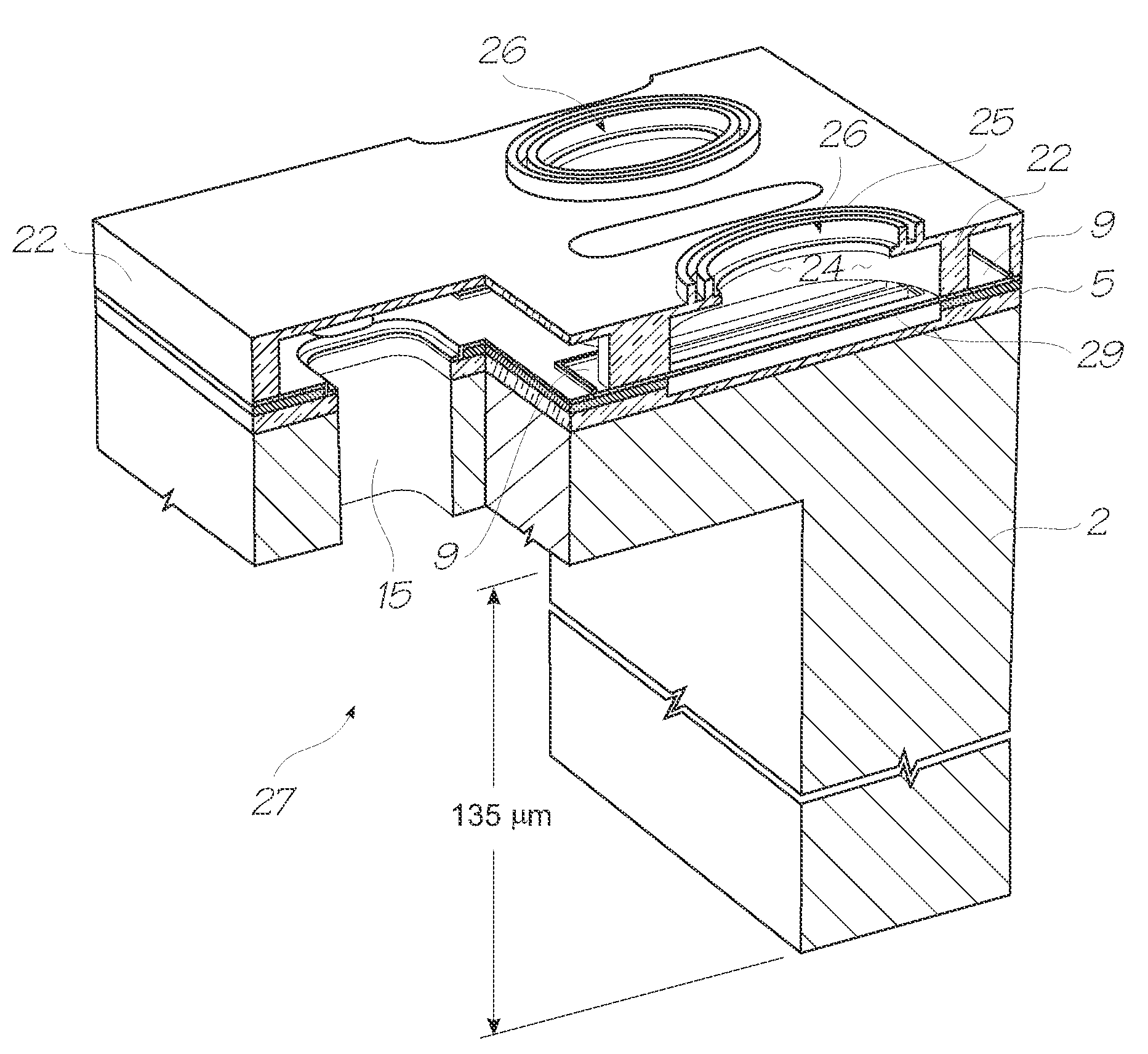

Printhead integrated circuit having common conductive track fused to nozzle plate

An inkjet printhead integrated circuit (IC) includes: a substrate having a drive circuitry layer; a plurality of nozzle assemblies disposed on an upper surface of the substrate and arranged in one or more nozzle rows extending longitudinally along the printhead IC; a nozzle plate extending across the printhead IC; and a conductive track fused to the nozzle plate which extends longitudinally along the printhead IC and parallel with the nozzle rows. The conductive track is connected to a common reference plane in the drive circuitry layer via a plurality of conductor posts extending between the drive circuitry layer and the conductive track.

Owner:MEMJET TECH LTD

Pagewidth inkjet printhead configured such that printed dot density exceeds nozzle density

A stationary pagewidth inkjet printhead has one or more nozzle rows extending along a longitudinal axis of the printhead. Each nozzle is configured to fire a droplet of ink at a plurality of predetermined different dot positions along the longitudinal axis, such that a printed dot density exceeds a nozzle density of the printhead.

Owner:MEMJET TECH LTD

Stationary inkjet printhead with dead nozzle compensation provided by nozzles in same nozzles row

A stationary pagewidth inkjet printhead has one or more nozzle rows extending along a longitudinal axis of the printhead. Each nozzle is configurable to fire a droplet of ink at a plurality of predetermined different dot positions along the longitudinal axis, and each nozzle has an associated primary dot position. The printhead is configured to compensate for a dead nozzle by printing from a selected functioning nozzle positioned in a same nozzle row as the dead nozzle. The selected functioning nozzle is configured to fire some ink droplets at the primary dot position associated with the dead nozzle and to fire some ink droplets at its own primary dot position.

Owner:MEMJET TECH LTD

Printhead having polysilsesquioxane coating on ink ejection face

Owner:SILVERBROOK RES PTY LTD

Method of controlling drop directionality from inkjet nozzle using multiple independently-actuable roof paddles

A method of controlling a direction of droplet ejection from an inkjet nozzle having a plurality of moveable paddles, the method includes the steps of: (i) actuating a first thermal bend actuator via respective first drive circuitry such that a respective first paddle bends towards a floor of the nozzle chamber; (ii) actuating a second thermal bend actuator via respective second drive circuitry such that a respective second paddle bends towards a floor of the nozzle chamber; and (iii) thereby ejecting a droplet of ink. Actuation of the first and second thermal bend actuators is independently controlled via the first and second drive circuitry so as to control the direction of droplet ejection.

Owner:MEMJET TECH LTD

Inkjet printhead having common conductive track on nozzle plate

An inkjet printhead includes: a substrate having a drive circuitry layer; a plurality of nozzle assemblies disposed on an upper surface of the substrate and arranged in one or more nozzle rows extending longitudinally along the printhead; a nozzle plate extending across the printhead; and a conductive track disposed on the nozzle plate which extends longitudinally along the printhead and parallel with the nozzle rows. The conductive track is connected to a common reference plane in the drive circuitry layer via a plurality of conductor posts extending between the drive circuitry layer and the conductive track.

Owner:MEMJET TECH LTD

Method of fabricating printhead assembly

A printhead assembly includes a molded ink manifold, a plurality of printhead integrated circuits, and an adhesive film sandwiched between the ink manifold and the printhead integrated circuits. A manifold bonding surface of the molded ink manifold includes a polymer coating. The polymer coating plugs fissures resulting from a molding process used to mold the ink manifold.

Owner:MEMJET TECH LTD +1

Method of compensating for dead nozzles in stationary pagewidth printhead

A method of compensating for a dead nozzle in a stationary pagewidth printhead. The method includes the steps of: (i) identifying the dead nozzle; (ii) selecting a functioning nozzle in a same nozzle row as the dead nozzle; and firing ink droplets from the selected functioning nozzle at a primary dot position associated with the dead nozzle.

Owner:MEMJET TECH LTD

Inkjet nozzle assembly with drop directionality control via independently actuable roof paddles

An inkjet nozzle assembly having: a nozzle chamber for containing ink, the nozzle chamber including a floor and a roof having a nozzle opening defined therein; and a plurality of moveable paddles defining part of the roof. The plurality of paddles are actuable to cause ejection of an ink droplet from the nozzle opening. Each paddle includes a thermal bend actuator, and each actuator is independently controllable via respective drive circuitry such that a direction of droplet ejection from the nozzle opening is controllable by independent movement of each paddle.

Owner:MEMJET TECH LTD

Inkjet printhead with join regions seamlessly compensated by directional nozzles

A stationary pagewidth inkjet printhead has one or more nozzle rows extending along a longitudinal axis of the printhead. The printhead is comprised of a plurality of printhead modules having first and second opposite ends butted across a width of a page. Each butting pair of printhead modules defines a common join region, wherein a nozzle pitch across the join region exceeds one nozzle pitch, one nozzle pitch being defined as a minimum longitudinal distance between a pair of nozzles in a same nozzle row. A first nozzle positioned at the first end of a first printhead module in a butting pair is configured to fire ink droplets into a respective join region.

Owner:MEMJET TECH LTD

Molded ink manifold with polymer coating

A printhead assembly includes a molded ink manifold, a plurality of printhead integrated circuits, and an adhesive film sandwiched between the ink manifold and the printhead integrated circuits. A manifold bonding surface of the molded ink manifold includes a polymer coating. The polymer coating plugs fissures resulting from a molding process used to mold the ink manifold.

Owner:MEMJET TECH LTD +1

Pagewidth inkjet printhead with drop directionality control

A stationary pagewidth inkjet printhead is comprised of a plurality of printhead integrated circuits butted end-on-end across the pagewidth. The printhead includes one or more nozzle rows extending along a longitudinal axis of the printhead, each nozzle row comprising a plurality of nozzles. One or more of the nozzles are configured to fire a droplet of ink at a plurality of predetermined different dot positions along the longitudinal axis.

Owner:MEMJET TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com