Technology for manufacturing composite material compesed of organic and inorganis material

A composite profile and manufacturing process technology, applied in layered products and other directions, can solve the problems of high manufacturing process cost, unsatisfactory performance, complex process, etc., and achieve the effects of low production cost, bright surface and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

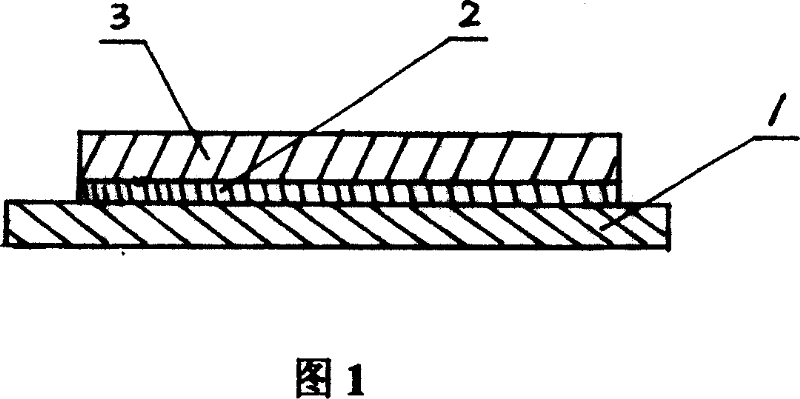

Embodiment 1

[0013] The production process of the thin sheet material: a. Brush a layer of release agent on the surface of the template 1; b. Brush the organic composite interface material 2 evenly on the template 1. The organic composite interface material 2 is added with an appropriate amount of water-based modified amine curing agent Mix water, color paste, and defoamer, then add epoxy resin to make it, and then spread a layer of glass fiber cloth, and use a roller or scraper to apply evenly. It can also be thickened by one layer of material and one layer of cloth according to requirements. C, scraping or rolling the prepared inorganic composite material 3 thereupon, the inorganic composite material 3 is a paste made by stirring raw materials such as magnesium oxide, magnesium chloride additives such as phosphoric acid, phosphate, sulfate; d. After it is cured, it can be demolded.

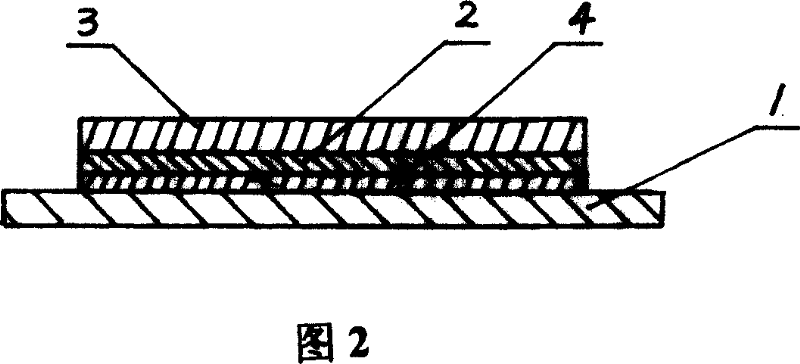

Embodiment 2

[0015] Thick plate production process: a. First construct a layer of organic composite material 4 on the template 1, such as plexiglass; b. After it is cured, paint a layer of organic composite interface material 2 on it, the organic composite interface material 2. It is prepared by water-based modified amine curing agent and epoxy resin; c. Then, construct the inorganic composite material 3 mixed with magnesium oxide, magnesium chloride and wood chips, and scrape it; d. After it is cured, demould, that is Can.

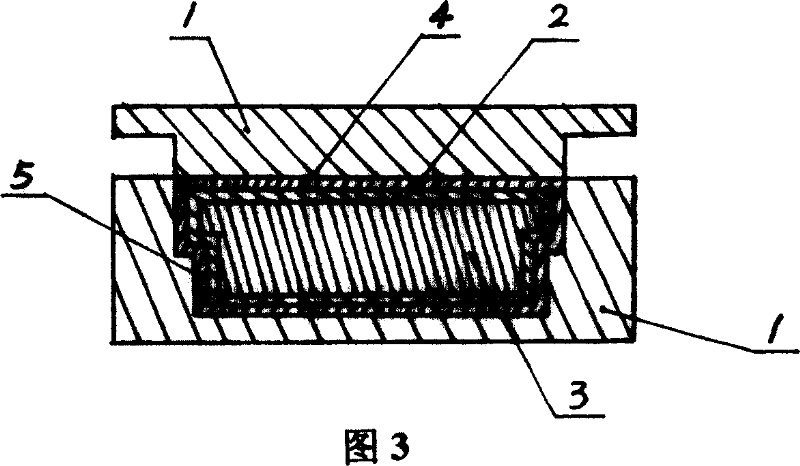

Embodiment 3

[0017] The manufacturing process of the profile: a, apply a release agent on the surface of the upper and lower templates 1; b, construct the organic composite material 4, such as plexiglass, on the inner surface of the template 1; c, after the organic composite material 4 is cured , the organic composite interface material 2 is brushed on the surface of the organic composite material 4 respectively, the organic composite interface material 2 is prepared by water-based modified amine curing agent and epoxy resin; d, then the inorganic composite material that has been stirred 3. Pouring and compacting. The inorganic composite material 3 can be any one of sulphoaluminate cement, iron-aluminate cement, and high-aluminate cement; e. Close the prepared upper mold and fix it under pressure. After it solidifies, it can be removed from the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com