Composite active black dye

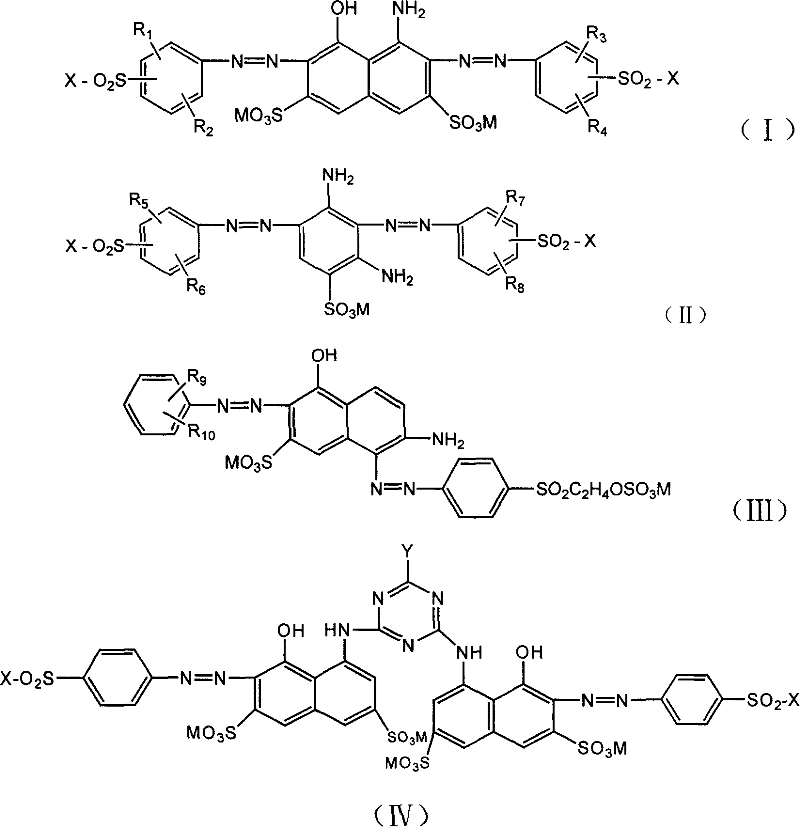

A technology of reactive black and dyes, applied in the direction of organic dyes, etc., can solve the problem of dry and wet friction and staining of white cloth, which is difficult to meet customer requirements, alkali resistance, water fastness, blackness is not ideal, deep dyeing To achieve the effect of ensuring lifting power and dyeing depth, excellent dyeing fastness and good level dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

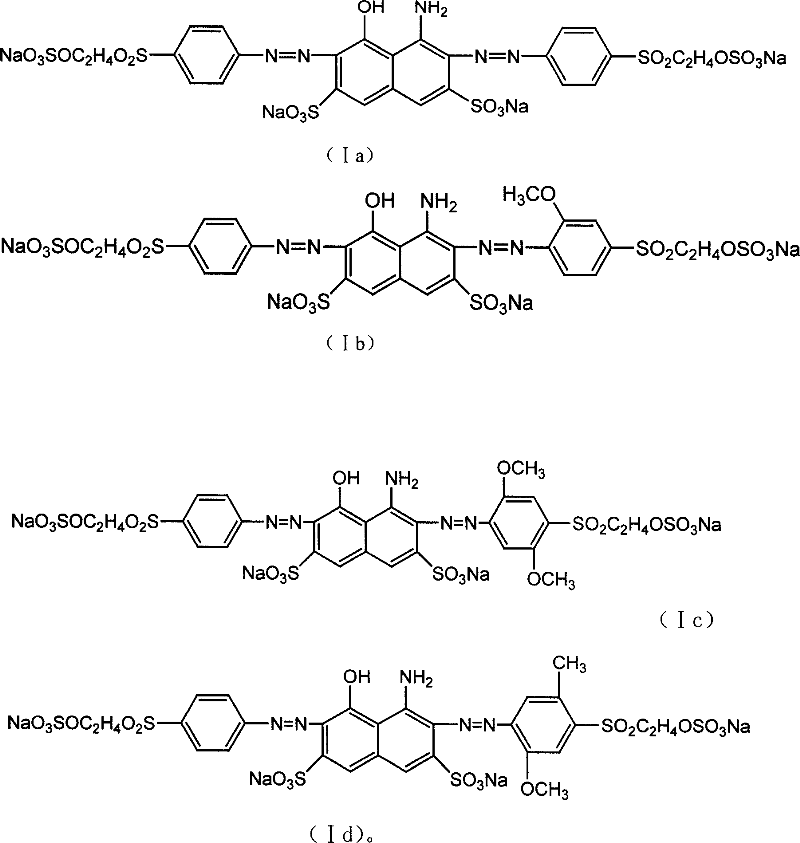

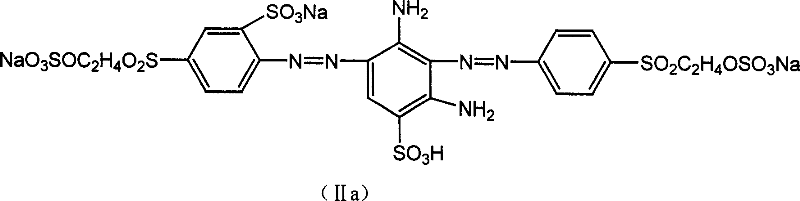

[0026] Get 65 grams of dyestuff A shown in formula (Ia), 17 grams of dyestuff B shown in formula (IIa), 13 grams of dyestuff C shown in formula (IIIb), 5 grams of dyestuff D shown in formula (IVa), yuan 54 grams of starch powder and 100 grams of water are blended, stirred evenly, and then spray-dried to obtain the reactive black dye of the present invention.

Embodiment 2~11

[0028] According to the preparation method of Example 1, dye A, dye B, dye C, and dye D are mixed according to the data shown in Table 1 below as the dye composition used in conjunction. Among them, Ia~Id respectively represent the dye A shown in the formula (Ia)~(Id) in the summary of the invention, IIa~IId respectively represent the dye B shown in the formula (IIa)~(IId), IIIa~IIIc respectively represent the formula (IIIa ) to dye C represented by (IIIc), and IVa and IVb represent dye D represented by formulas (IVa) and (IVb), respectively.

[0029] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com