Hydrophobic and oleophobic agent in fluoric solvent type and producing method

A hydrophobic and oleophobic, manufacturing method technology, applied in textiles and papermaking, animal husbandry, chemical treatment of small raw hides/large hides/leather hides/furs, etc. Narrow application range, etc., to achieve the effects of safe and stable physical properties, excellent stability and physical properties, and excellent hydrophobic and oleophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

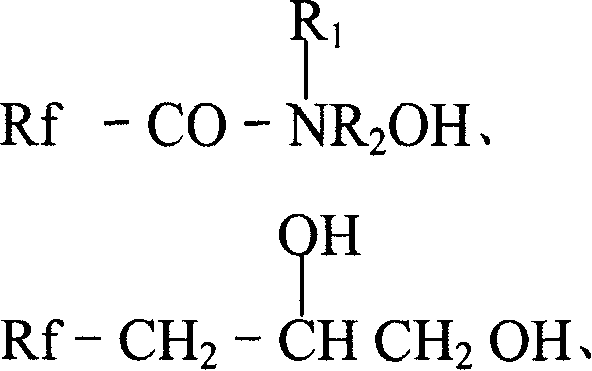

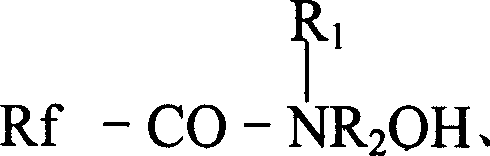

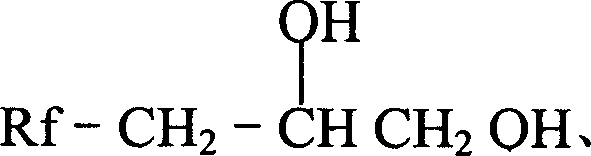

Method used

Image

Examples

Embodiment 1

[0062] Add 24.75 grams of trimethylol propane (Trimethylol propane) into a 2L glass reaction vessel equipped with a stirrer, a vacuum motor, a thermometer and a condenser, etc., and release the vacuum with nitrogen after evacuating for 30 minutes; add 123.75 grams of IPDI, Heat to 85-90°C for 2 hours, then start measuring NCO%, add 231 grams of CF when NCO% reaches 16-18% 3 (CF 2 ) 7 (CH 2 ) 2 OH, heat up to 95°C for constant temperature reaction, start to measure NCO% after constant temperature for 4 hours, add 325.5 grams of butanone when NCO% reaches 1.5-2.0%, and keep the temperature at 70±3°C for 10 hours; cool down to 50±3°C, Add 15 grams of butanone oxime (Butanone oxime) and keep the temperature for 1 hour, then add 600 grams of butanone and 150 grams of butyl acetate and stir for 30 minutes; the polymerization reaction produces a polymer dispersion with a weight of 1470 grams and a solid content of 24.1%. .

Embodiment 2

[0064] Add 24.5 grams of trimethyl alcohol propane into a 2L glass reaction vessel equipped with a stirrer, vacuum motor, thermometer and condenser, etc., and release the vacuum with nitrogen after evacuating for 30 minutes; add 29.5 grams of HDI and 85 grams of IPDI, Heat to 85-90°C, start to measure NCO% after constant temperature for 2 hours, add 231 grams of CF when NCO% reaches 16-18% 3 (CF 2 ) 7 (CH 2 ) 2 OH, heat up to 95°C for constant temperature reaction, start to measure NCO% after constant temperature for 4 hours, add 320 grams of butanone when NCO% reaches 1.5-2.0%, and keep the temperature at 70±3°C for 10 hours; cool down to 50±3°C, Add 15 grams of butanone oxime and keep the temperature for 1 hour, then add 400 grams of butanone and 350 grams of butyl acetate, and stir for 30 minutes; the polymerization reaction produces a polymer dispersion with a weight of 1455 grams and a solid content of 24.3%.

Embodiment 3

[0066] Required raw material, weight and polymerization method are identical with embodiment one, but change the raw material CF of second-stage polymerization reaction 3 (CF 2 ) 7 (CH 2 ) 2 OH is 105 grams of CF 3 (CF 2 ) 7 (CH 2 ) 2 OH with 112.5 g of CF 3 (CF 2 ) 6 (CH 2 ) 2 OH mixed. The polymerization yielded a polymer dispersion weighing 1456.5 grams and having a solids content of 24.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com