A method for recovering ultrafine copper powder from waste liquid containing complexed copper

A technology of complexing copper and fine copper powder, which is applied in the field of recycling ultrafine copper powder, can solve the problems of high price and economic benefits, and achieve the effects of improving thermal conductivity and self-repairing performance, short process flow and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]The electroplating wastewater containing complexed copper was obtained from the line factory, and the measured copper content was 80g / L (about 1.25mol / L). Add 2g / L pvp k30 dispersant to the waste liquid, and then add 1mol / L industrial glucose, Add 6.25mol / L NaOH, stir and react at 90°C for 1h, add thiourea dioxide 1mol / L after the reaction, stir and react at 75°C for 20 minutes, after the reaction is completed, filter, wash twice with water, and wash twice with ethanol , dried in vacuum to make samples. After the reaction, the measured copper content was 0.13g / L, and the copper removal rate reached 99%.

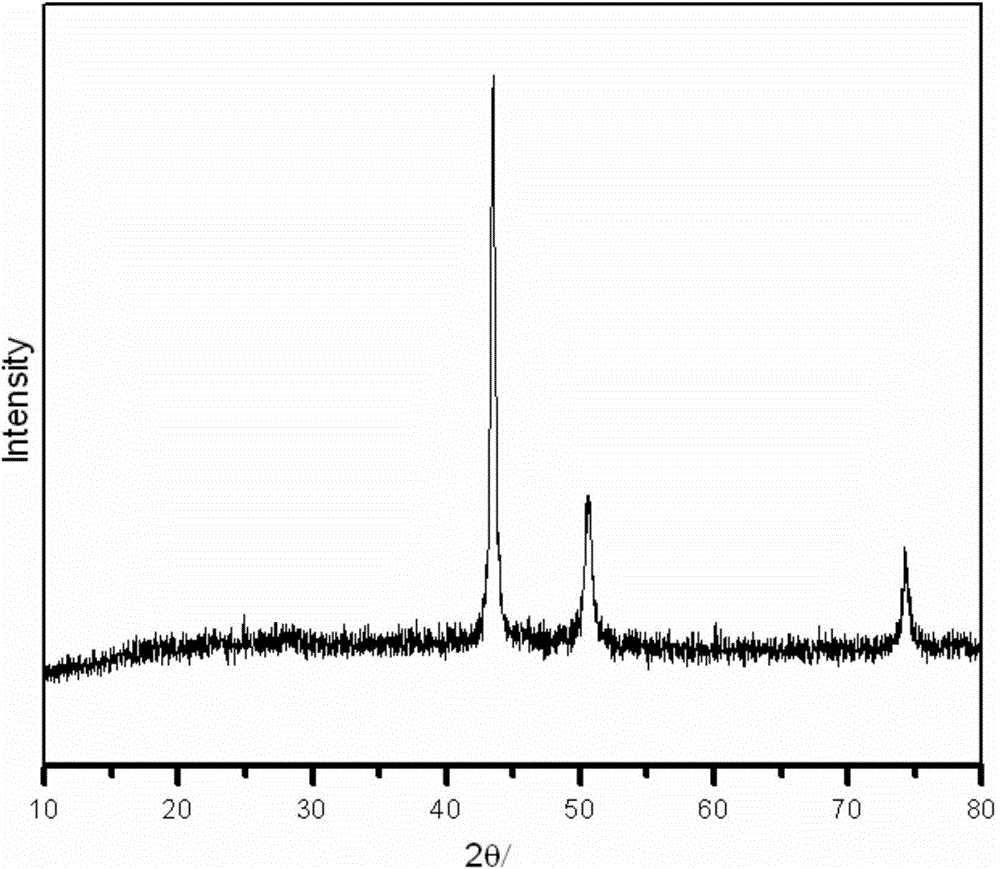

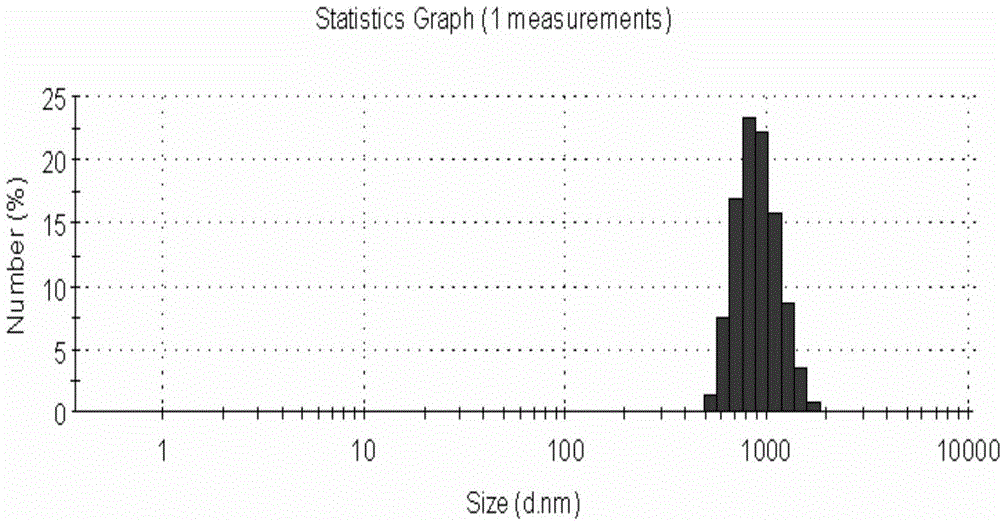

[0032] The XRD pattern was done to the sample, and copper powder with a purity of more than 99.95% (such as figure 1 ), at the same time, the particle size was measured with a zeta potential-particle size analyzer, and the particle size was 700nm to 1500nm (such as figure 2 ).

Embodiment 2

[0034] Take the electroplating wastewater containing complexed copper from the circuit factory, and the measured copper content is 77.6g / L. Add 0.6g / L pvp k30 dispersant to the waste liquid, then add 3.125mol / L industrial glucose, add 2.5mol / L L of NaOH, stirred and reacted at a temperature of 70°C for 4 hours, added thiourea dioxide 0.625mol / L after the reaction, stirred and reacted at a temperature of 80°C for 20 minutes, after the reaction was completed, filtered, washed twice with water, washed twice with ethanol, and dried in vacuum After the reaction, the copper content was measured to be 0.47g / L, and the copper removal rate reached 99%.

Embodiment 3

[0036] Take complex copper-containing electroplating wastewater from the circuit factory, and the measured copper content is 83.4g / L. Add 2g / L pvpk30 dispersant to the waste liquid, then add 0.625mol / L industrial glucose, and add 10mol / L NaOH. Stir and react at a temperature of 105°C for 0.5h, add thiourea dioxide 3.125mol / L after the reaction, stir and react at a temperature of 50°C for 90 minutes, after the reaction is completed, filter, wash twice with water, wash twice with ethanol, vacuum dry, and react After the measurement, the copper content was 0.61g / L, and the copper removal rate reached 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com