Large-scale semi-solid state die forging hydraulic press

A semi-solid die forging and hydraulic press technology, which is applied in the driving device of the forging press, forging/pressing/hammering machinery, forging/pressing/hammer device, etc., which can solve the problems affecting the accuracy of the machine, unqualified, and lack of workpieces, etc. , to achieve the effect of safe and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

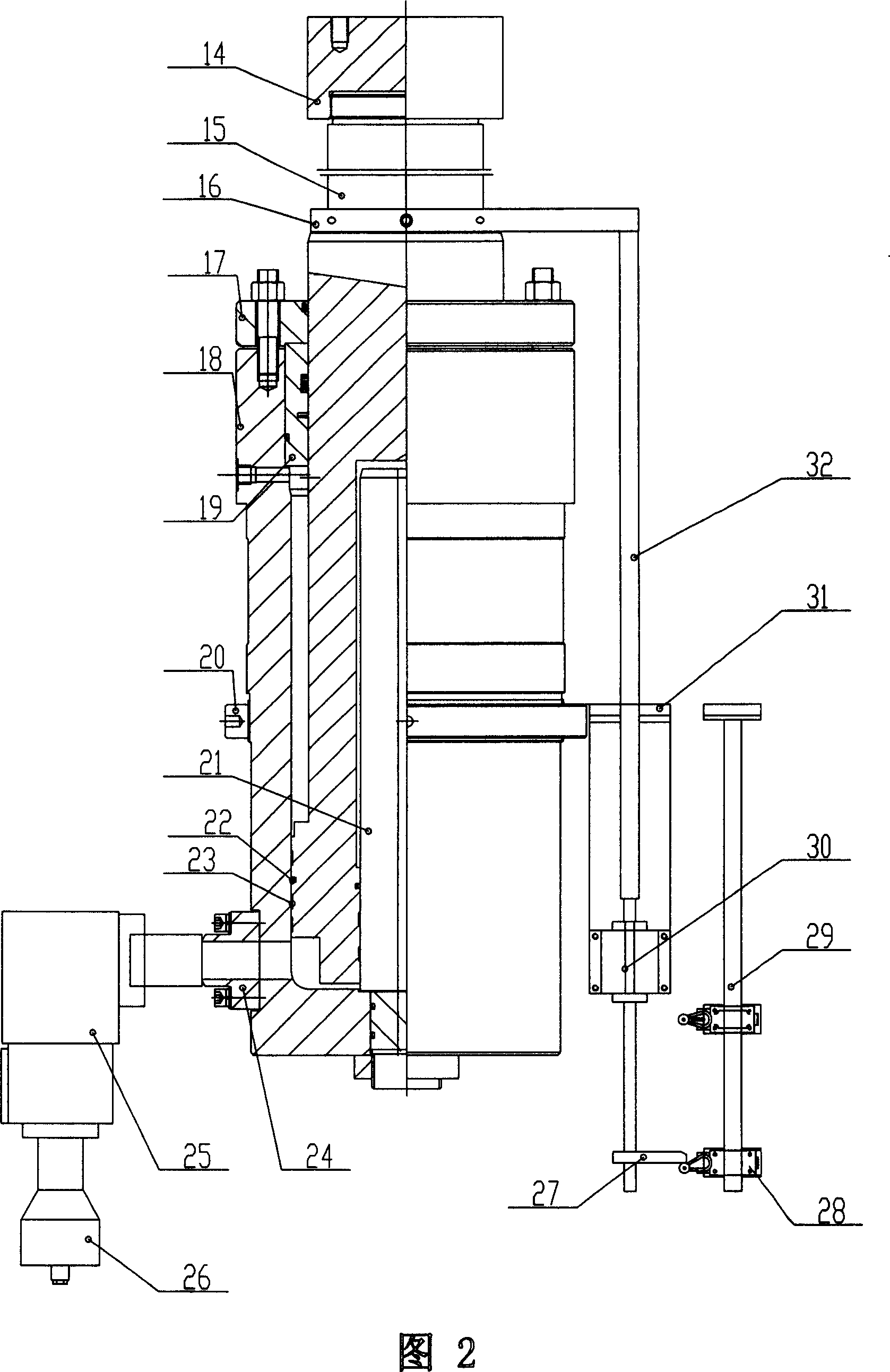

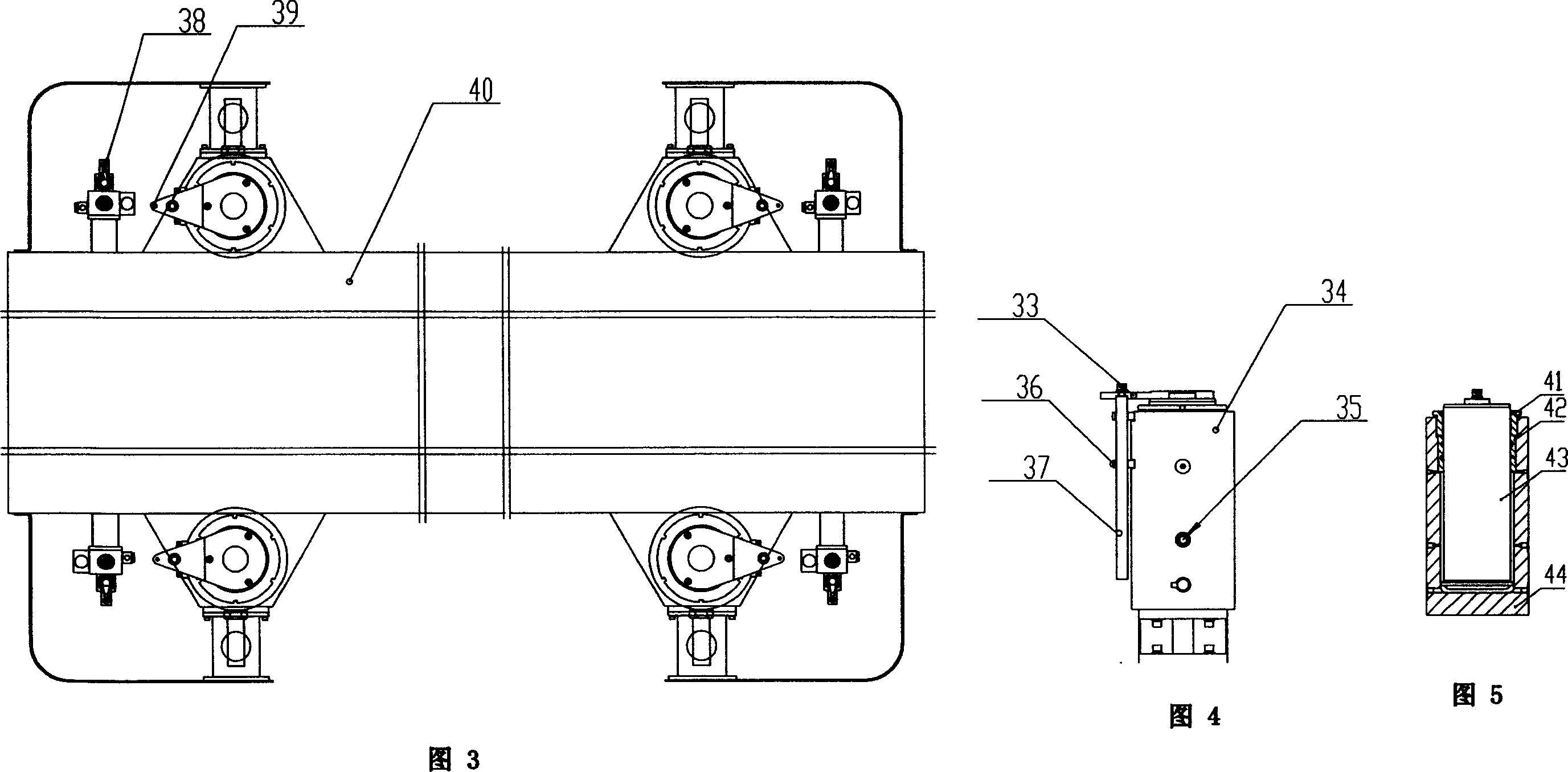

[0045] See Figure 1, Figure 2, Figure 3, Figure 4, Figure 6, Figure 7, and Figure 8.

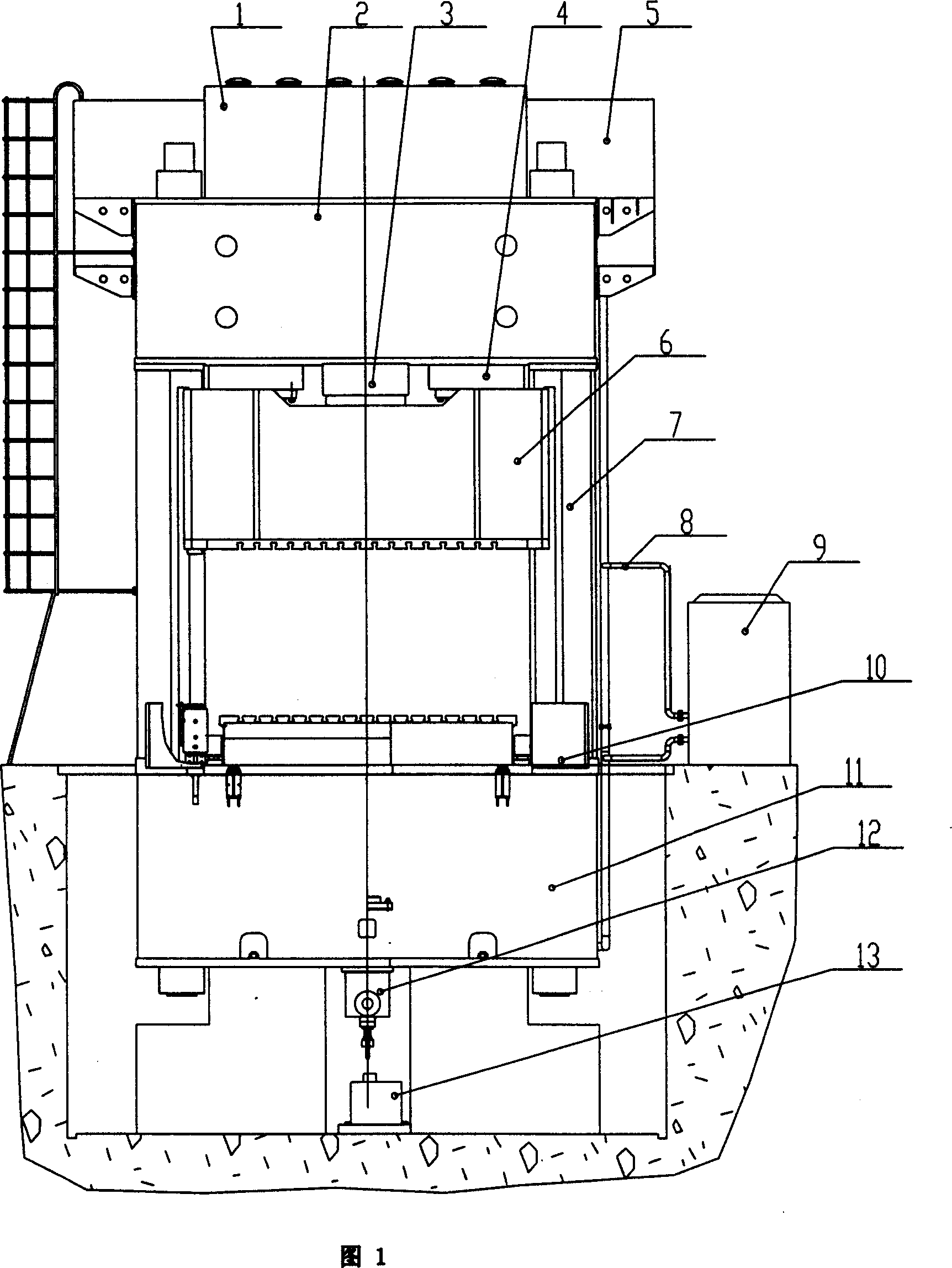

[0046] The large semi-solid die forging hydraulic press consists of a fuselage 2, a frame platform 5, a master cylinder 3, a power system 1, and an electrical system 9. The fuselage is composed of upper beams, lower beams 11, sliders 6, and pillars 7 through tie rods. The master cylinder 3 and the side cylinder 4 are connected with the power system 1 , and the electrical system 9 controls the power system 1 . The pressing process action is realized through the main cylinder 3 and the side cylinder 4. Energy is provided by the power system 1, and the rack platform 5 is used as a safety and protection device. The electrical system 9 realizes automatic contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com