Method for fabricating fire resistant communication cable, and products

A communication cable and production method technology, applied in the direction of insulated cables, cable/conductor manufacturing, conductor/cable insulation, etc., can solve problems such as unsatisfactory mechanical properties, can only reach 80°C, and easy attenuation of signal transmission performance, etc., to achieve The internal molecular arrangement is tight, the voltage resistance ability is improved, and the mechanical properties are improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

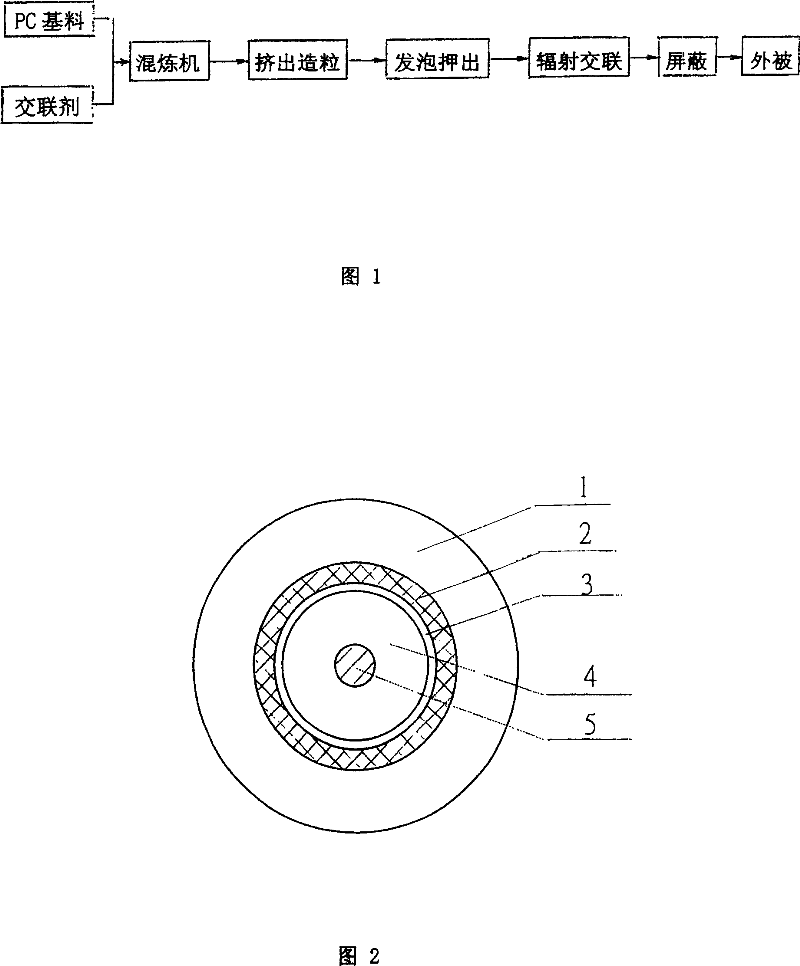

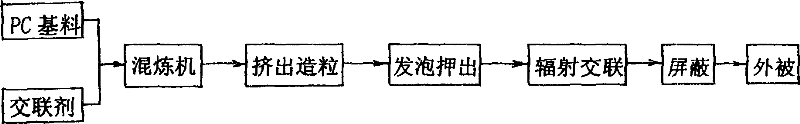

[0014] Below in conjunction with embodiment and accompanying drawing, the present invention is further narrated: present embodiment is the process of producing RG-58 coaxial cable product of an example, and this product is to implement a model in the wire and cable standard MIL-C-13, and all in the standard The material used is polyethylene (referred to as PE) or foamed polyethylene (referred to as FMPE). Cross-linked foamed polyethylene (referred to as XL-FMPE) material, according to the structure of Figure 2 to produce high temperature resistant coaxial cables, the specific production process is as follows:

[0015] 1. Mixing: The polyethylene with the grade of DGDA6944 and the crosslinking agent with the grade of TA001 are mixed according to the ratio of 98:2, and mixed on the mixer. The mixing temperature is 100°C, the time is 6 minutes, and the rotation speed is 100RPM.

[0016] 2. Granulation: The above homogeneous mixture is directly put into the granulator for extrusio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com