Single-colour fluorescent powder spraying method for plasma display device

A plasma and phosphor technology, which is applied in the field of phosphor layer production of plasma displays, can solve the problems of inconsistent thickness of phosphor layers, affecting the uniformity of device discharge, deterioration of phosphor luminescence performance, etc. Good performance and chromaticity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

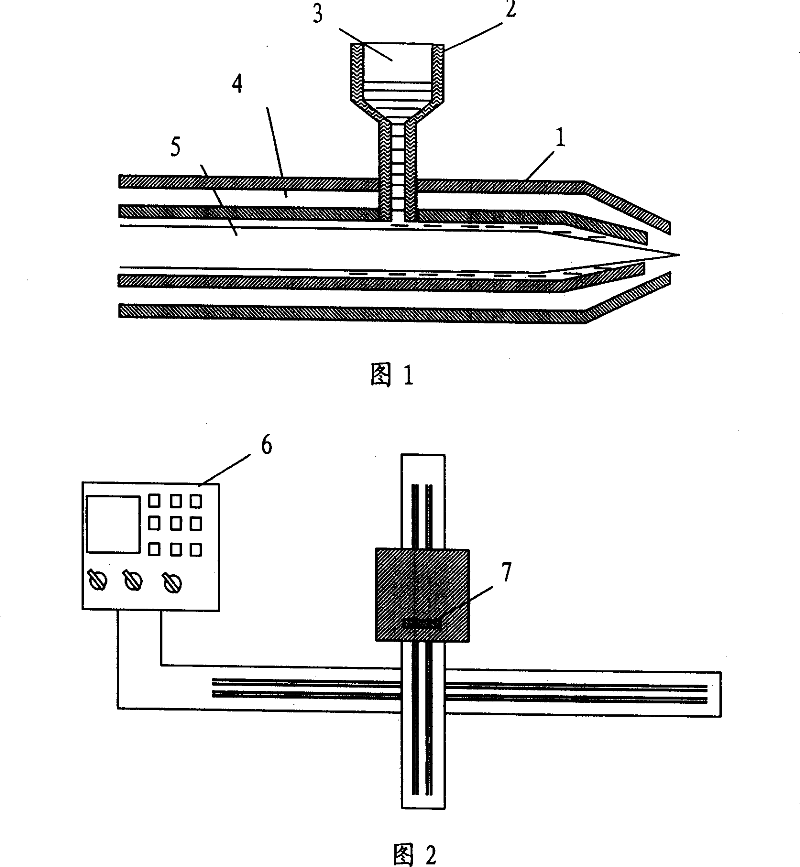

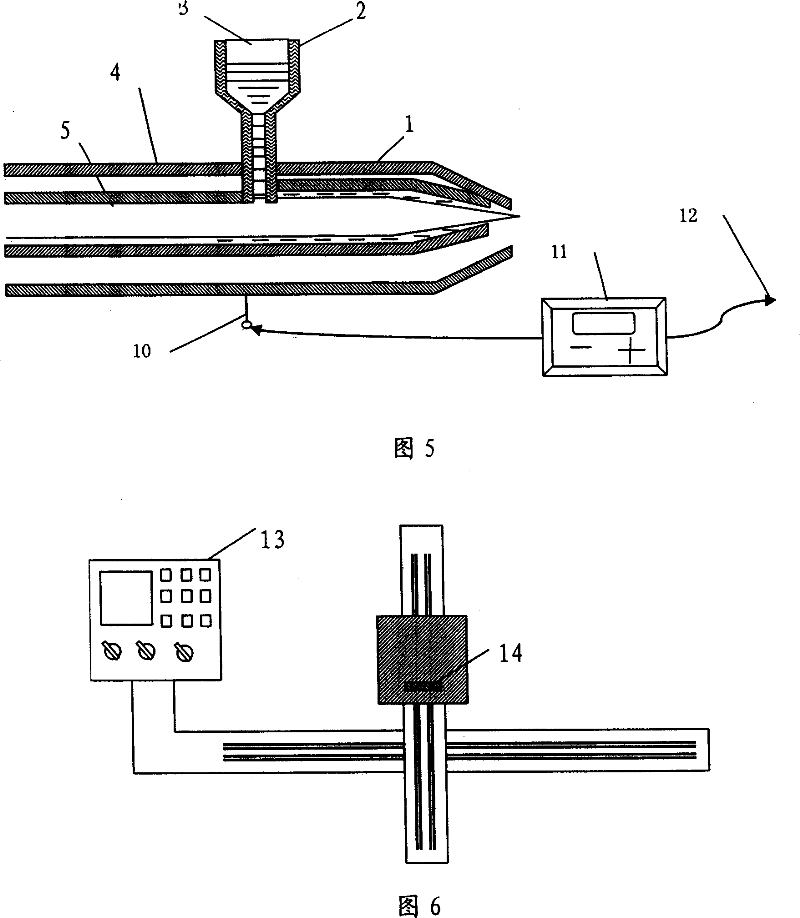

[0027] On the basis of the technical solution of the above invention, the specific structure is further considered, and the following various embodiments are proposed, and the relevant equipment structure is further described through specific embodiments.

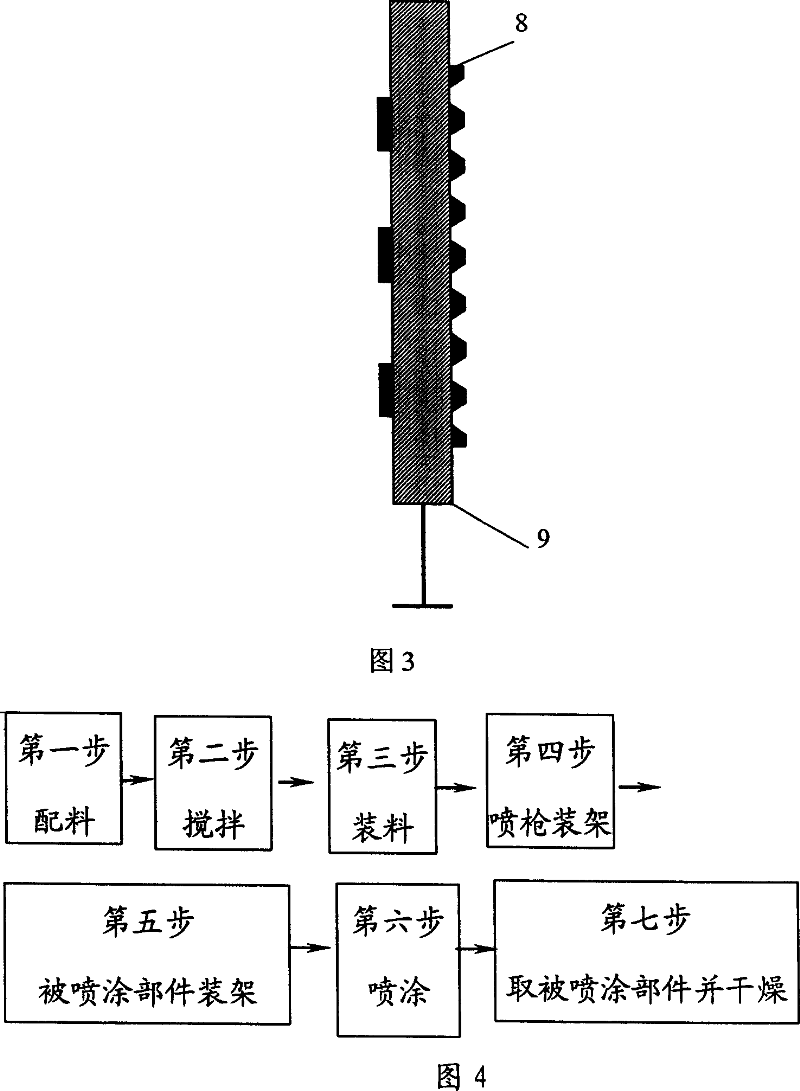

[0028] In the first embodiment of the present invention, the pressure spray gun is used to move two-dimensionally at a constant speed in the x and y planes, and the phosphor slurry is sprayed on the inner wall of the conductive grid plate unit hole in the conductive grid plate structure plasma display to form a single colored fluorescent layer. The steps are as follows:

[0029] The first step, ingredients, mix the phosphor to be prepared with acetone in a certain proportion, the concentration is 100 g / L, and add alkyd resin to adjust the viscosity;

[0030] The second step is stirring, and the phosphor powder slurry 3 is fully stirred;

[0031] The third step is charging, and the phosphor powder slurry 3 is loaded into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com