Spacer and image-forming apparatus, and manufacturing method thereof

An image and separator technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., to achieve the effects of high brightness, high mechanical strength, and high color purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

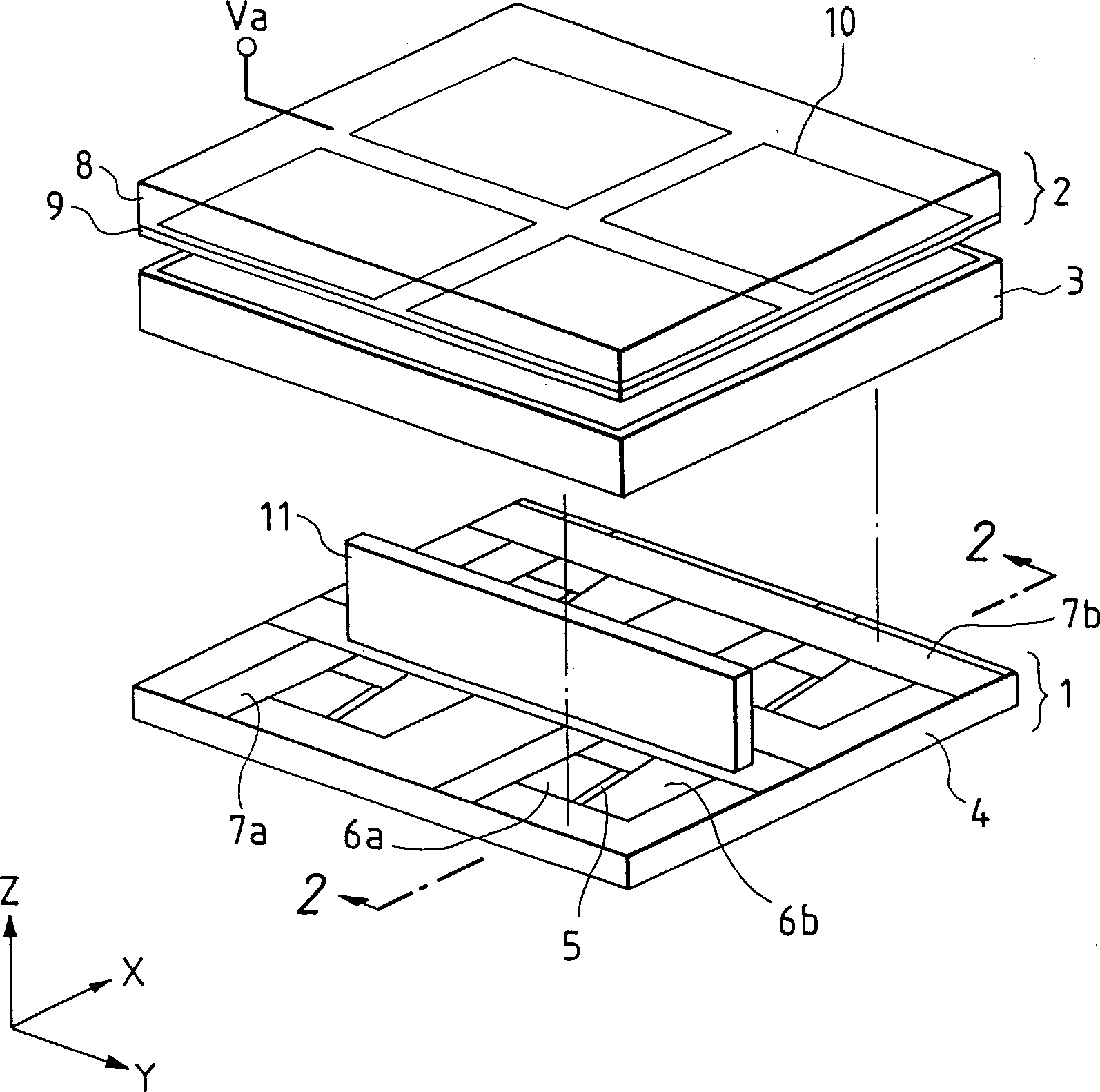

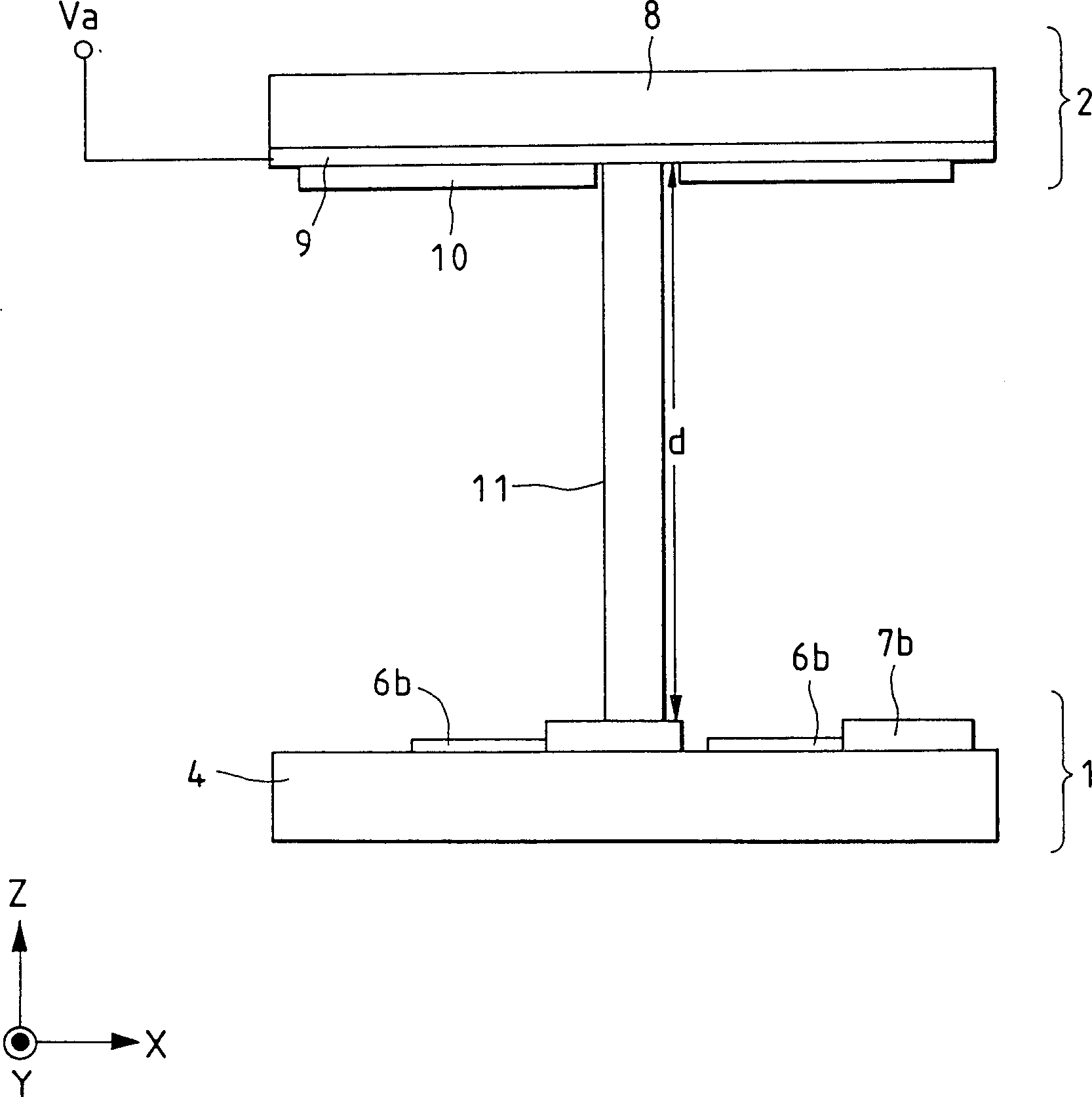

[0188] The basic structure and figure 1 and figure 2 The structure shown is the same, and the overall structure is shown in Figure 9, wherein, with figure 1 , 2 The same components as 8 are indicated by the same reference numerals. Reference numeral 91 denotes a metal back layer.

[0189] The method of manufacturing the image forming apparatus of the present invention such as Figure 10A to Figure 10H shown. Next, refer to Figure 9 and Figure 10A to Figure 10H The basic structure of the image forming apparatus of the present invention and its manufacturing method will be described. In this example, the substrate 4 itself has the function of the backplane, so in Figure 10A to Figure 10H and Figure 11 It is represented by the label 1 or 4 in it.

[0190] For simplicity, Figure 10A to Figure 10H The electron-emitting devices and the preparatory steps in their vicinity are shown, but this example provides an image forming apparatus formed by a simple matrix arrangem...

example 2

[0228] In this example, the process is the same as in Example 1 up to step h.

[0229] (step i)

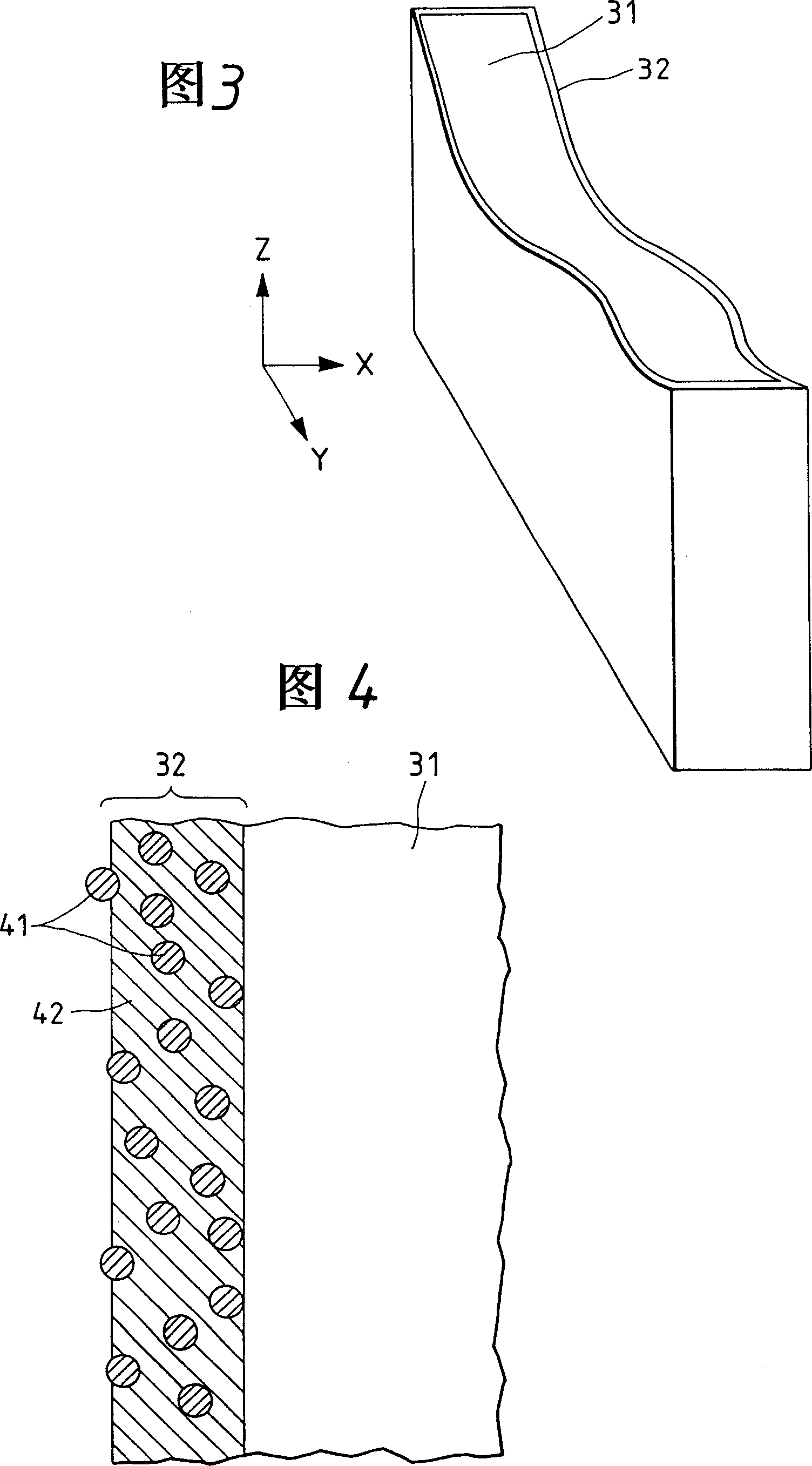

[0230] In this example, a small glass plate cut and ground to a size of 1 x 40 x 0.2 mm was cleaned, and an amorphous polyimide solvent (Toray Co. . Toreniece #3000) for spin coating. The spin coating first constitutes a surface (1 x 40 mm face) and the glass sheet is prebaked on a hot plate at 100° C. for 10 minutes. Then, the other side was made by spin coating, and the glass piece was prebaked on a hot plate at 100°C for 10 minutes. Curing was performed by placing the coated glass sheet in a clean oven, raising the temperature from room temperature to 300°C, and then maintaining the glass sheet at 300°C for one hour. The polyimide resin thus obtained had a thickness of about 1 µm.

[0231] (step j)

[0232] On the upper wiring 7b of the backplane 1 at the position for placing the spacer, Toreniece #3000 was applied with a dispenser to temporarily fix the spacer 11 prepared...

example 3

[0253] In this example, the process is the same as in Example 1 up to step h.

[0254] (step i)

[0255] In this example, a cleaned glass rod with a diameter of 0.2 mmφ was diluted five times in volume with N-methyl-ethylpyrrolidone by immersing and detaching the glass rod from the liquid. ) for dip coating. Pre-bake the raised glass rod in a clean oven at 100°C for 10 minutes, and proceed by placing the glass rod in a clean oven, raising the temperature from room temperature to 300°C and maintaining it at 300°C for one hour solidify. The polyimide resin film thus obtained had a thickness of about 1 µm.

[0256] This glass rod surface-coated with polyimide resin was cut into a length of 1 mm to obtain a plurality of cylindrical partitions 11 .

[0257] (step j)

[0258] At the position for placing the spacer on the upper wiring 7b of the back plate 1, Toreniece #3000 was applied with a dispenser to temporarily fix the spacer 11 prepared in step i. In this operation, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com