Manufacture process and apparatus for PTFE supported composite filtering film

A polytetrafluoroethylene and composite filtration technology, applied in the field of filter membranes, can solve the problems of easy deformation, disadvantage, and the inability of polytetrafluoroethylene microporous filter membranes to be self-supporting, so as to improve shrinkage and formability, compact structure, The effect of autoclavable physicochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

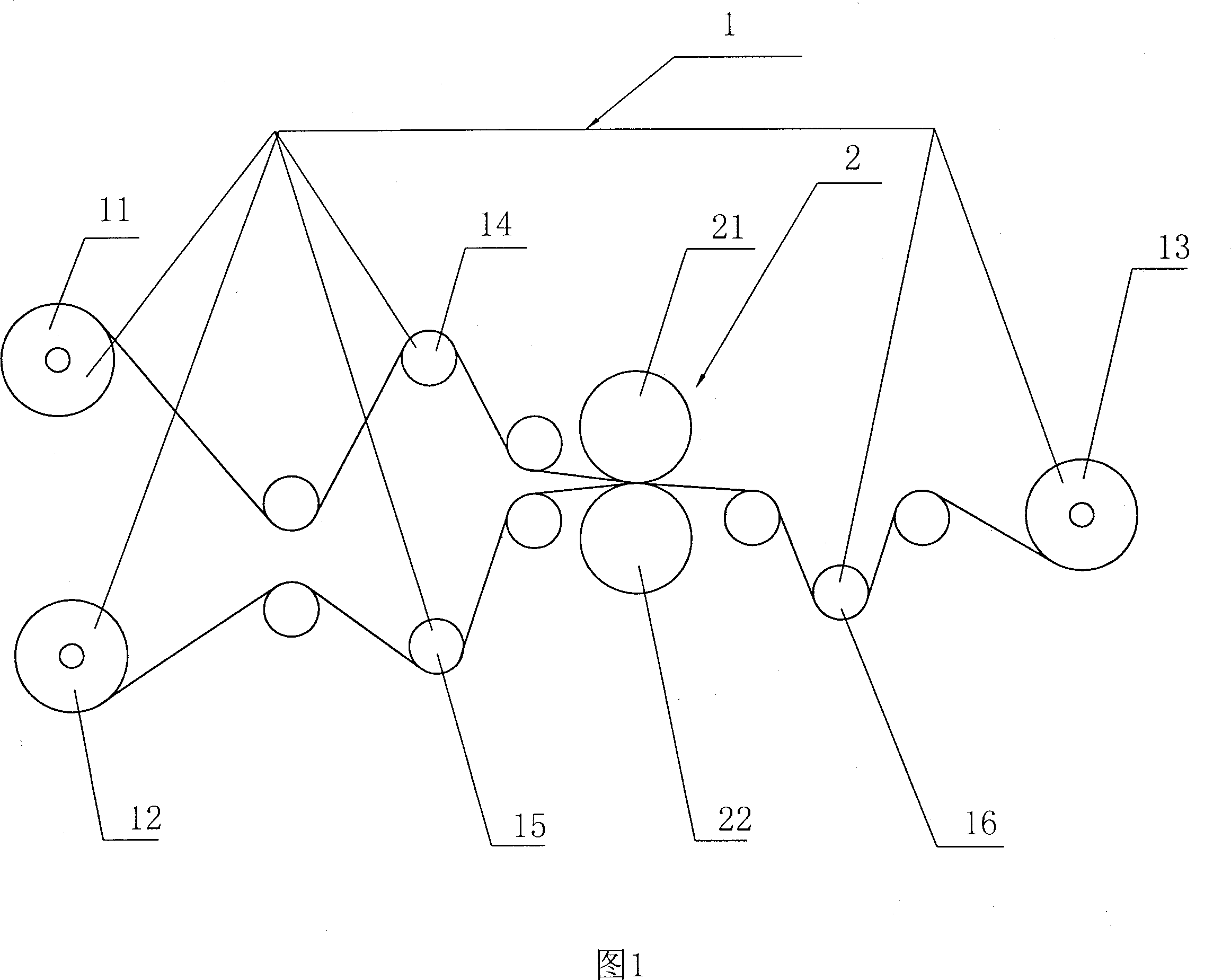

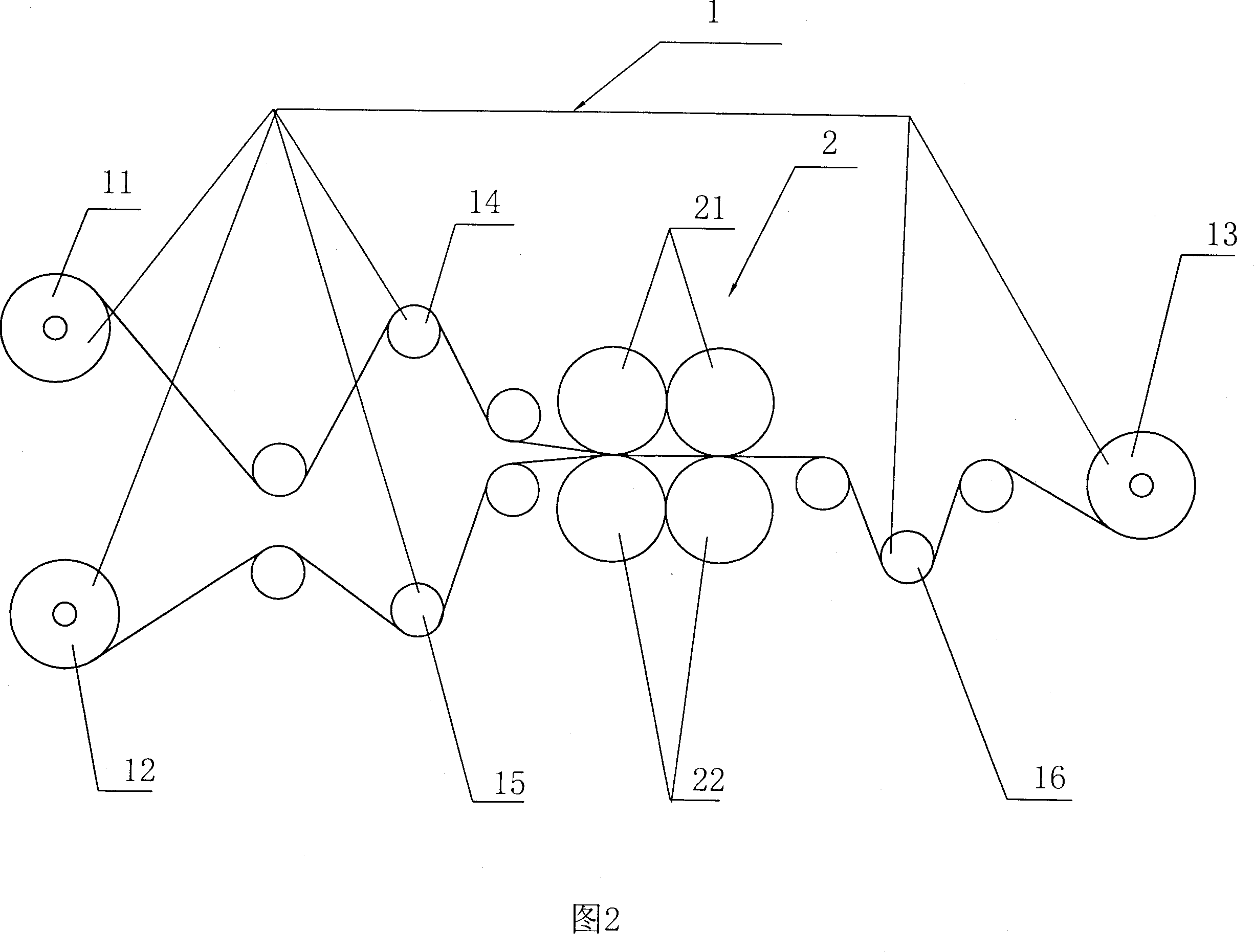

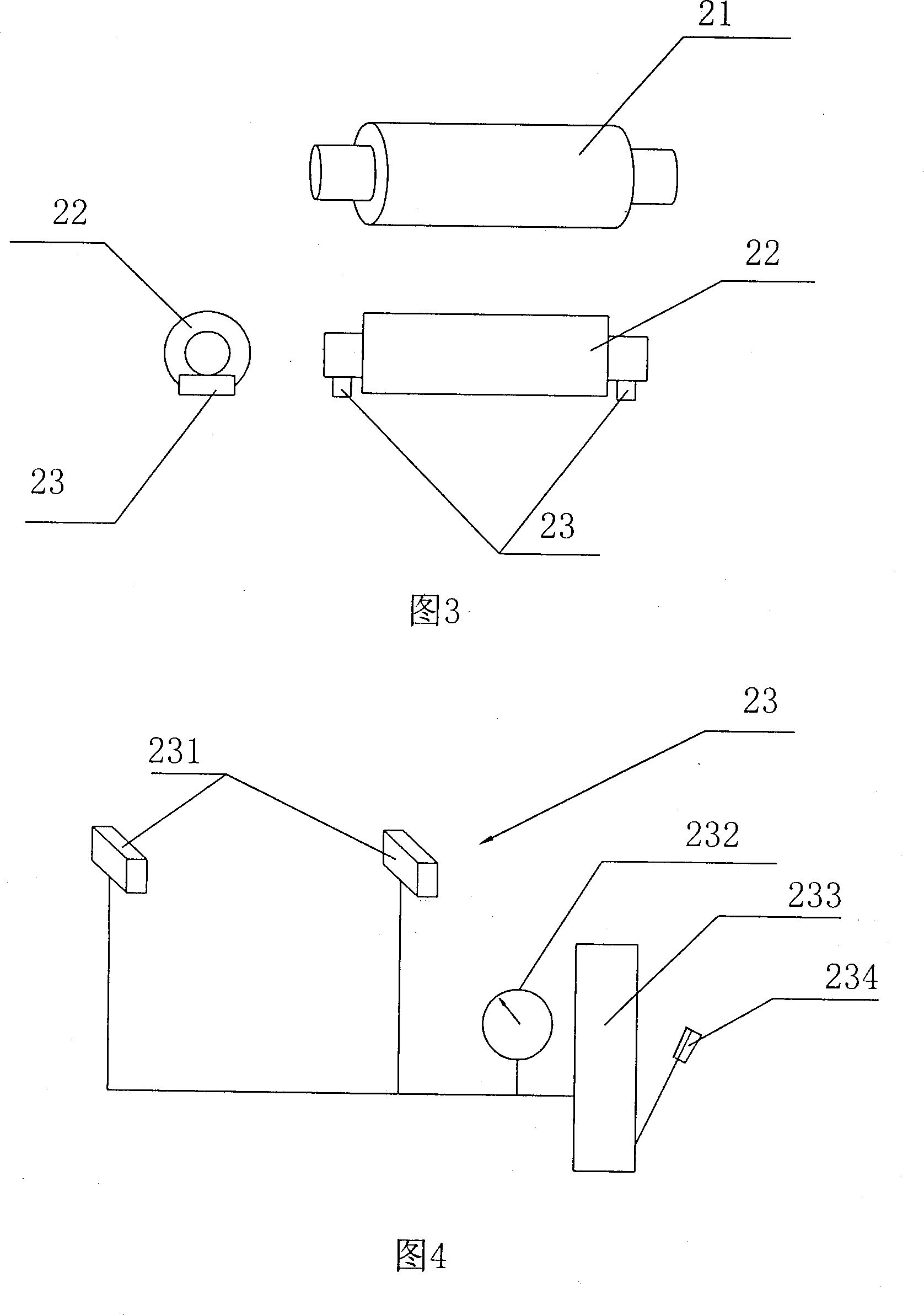

[0019] Example 1: A manufacturing method of a PTFE-supported composite filter membrane, which is manufactured by laminating a PTFE microporous filter membrane with a layer of polypropylene mesh. The manufacturing method is as follows: ① The PTFE microporous filter membrane set on the PTFE microporous filter membrane feed roller and the polypropylene screen set on the support material feed roller are transported to the heated composite roller arranged up and down through the transmission control system. In the pressing device composed of the roller and the cooling composite roller, the PTFE microporous filter membrane is close to the heating composite roller, and the polypropylene screen is close to the cooling composite roller; ②By evenly setting the heating composite roller The heating device composed of 18 halogen lamps in the roller makes the surface temperature of the heating composite roller 300℃, and the cooling device composed of 5 fans arranged in parallel along the axial ...

Embodiment 2

[0020] Example 2: A manufacturing method of a PTFE-supported composite filter membrane. The basic method is the same as that of Example 1. The difference is that in step ②, the surface temperature of the composite roller is heated to 150°C, and the composite roller is cooled. The surface temperature is 85°C, the pressing pressure between the heating composite roller and the cooling composite roller in step ③ is 20 MPa, and the composite linear velocity in step ④ is 15 m / min.

Embodiment 3

[0021] Example 3: A manufacturing method of a PTFE-supported composite filter membrane. The basic method is the same as that of Example 1, except that in step ②, the surface temperature of the composite roller is heated to 230°C, and the composite roller is cooled. The surface temperature is 40°C, the pressing pressure between the heating composite roller and the cooling composite roller in step ③ is 10 MPa, and the composite linear velocity in step ④ is 30 m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com