Steel rail on-line ultrasonic flaw detecting method and apparatus thereof

A flaw detection device, ultrasonic technology, applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, instruments, analysis materials, etc. It can solve the problems of small flaw detection coverage area, no stabilizing device, poor system stability, etc., and achieve adjustable detection range, The effect of reducing labor intensity and stable and reliable walking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

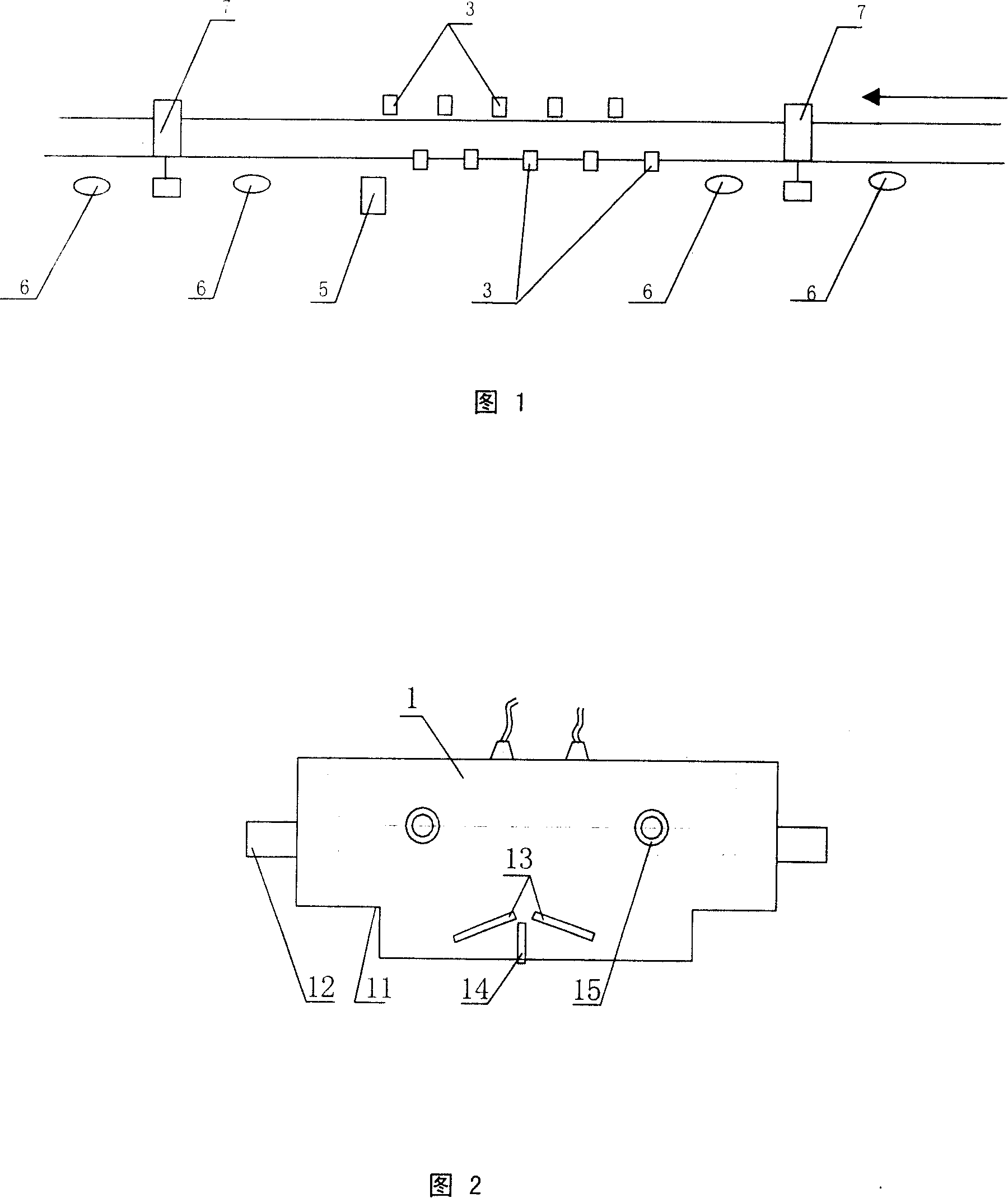

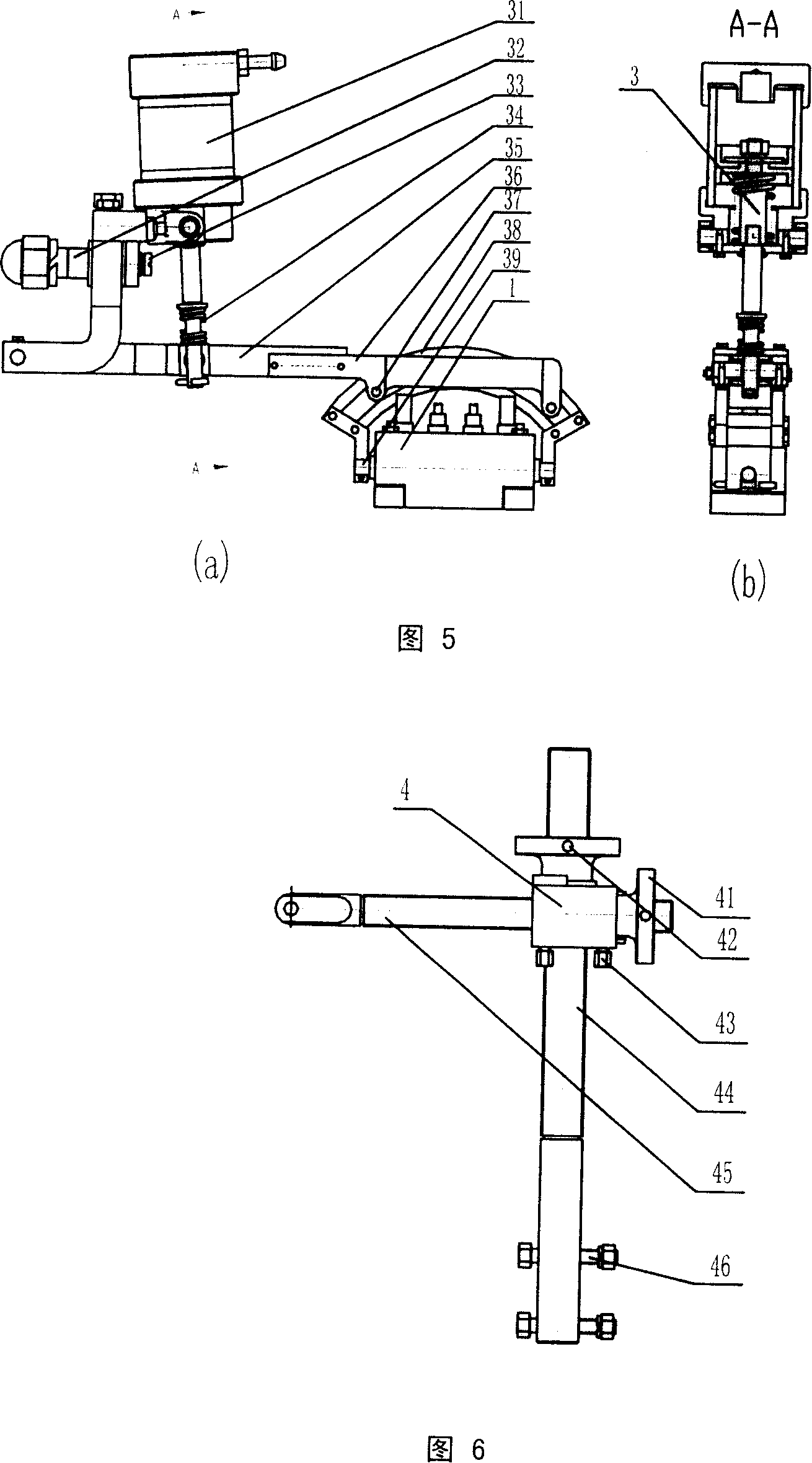

[0030] An on-line ultrasonic flaw detection device for rails. The device includes a mechanical system, an information processing system and an automatic control system. Probe landing gear 3, probe frame adjustment mechanism 4 and marking device 5; information processing system includes digital ultrasonic flaw detector, waveform processing computer and waveform display; automatic control system includes probe landing gear 3 control part, marking device 5 The control part and the speed measuring mechanism 2 control part, wherein the control part of the probe landing gear 3 and the marking device 5 is composed of a proximity switch 6, a photoelectric rotary encoder 7, a PLC controller, an electrical control computer and its display.

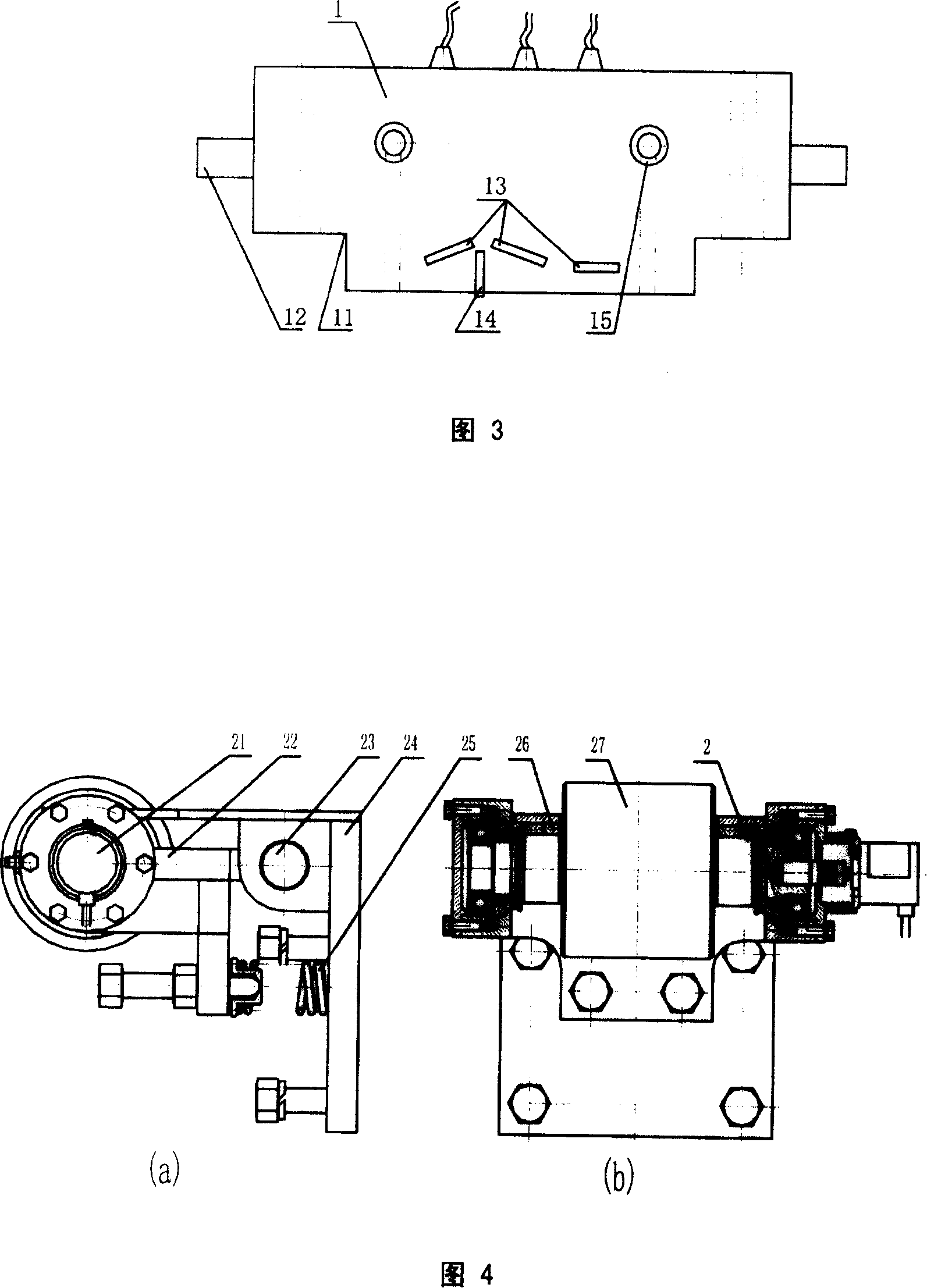

[0031] The coupling mode of the multi-chip probe 1 adopts the direct contact method. The multi-chip probe 1 includes a water tank 11, an installation shaft 12, and a wafer 13, and also includes a sound insulation layer 14 between the wafers 13, and a...

Embodiment 2

[0037] An on-line ultrasonic flaw detection device for rails, the structures of the speed measuring mechanism 2, the contact coupling probe lift 3 and the probe frame adjustment mechanism 4 are the same as those of the embodiment 1, but the probe has three wafers (accompanying drawing 3).

[0038] Using the rail online ultrasonic flaw detection device provided in Embodiment 1 and Embodiment 2, the size of the blind area of the rail flaw detection coverage area and the flaw detection sensitivity are as follows:

[0039] Coverage area (%)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com