Hydraulic or pneumatic shaping method and device of plate material

A hydraulic and pneumatic technology, applied in the field of sheet hydraulic or pneumatic forming methods and devices, can solve problems such as reprocessing molds, and achieve the effects of improving adaptability, improving thickness distribution uniformity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

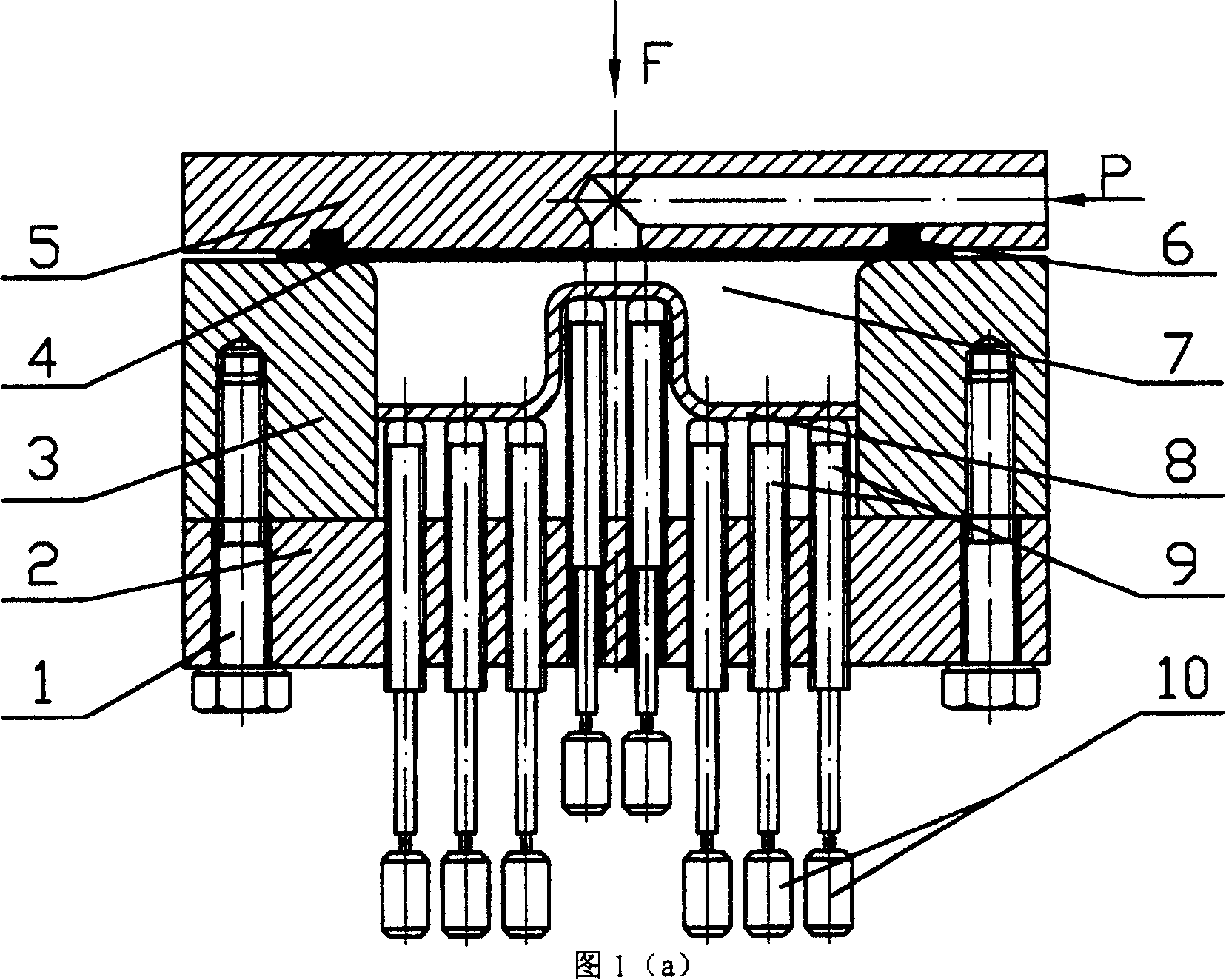

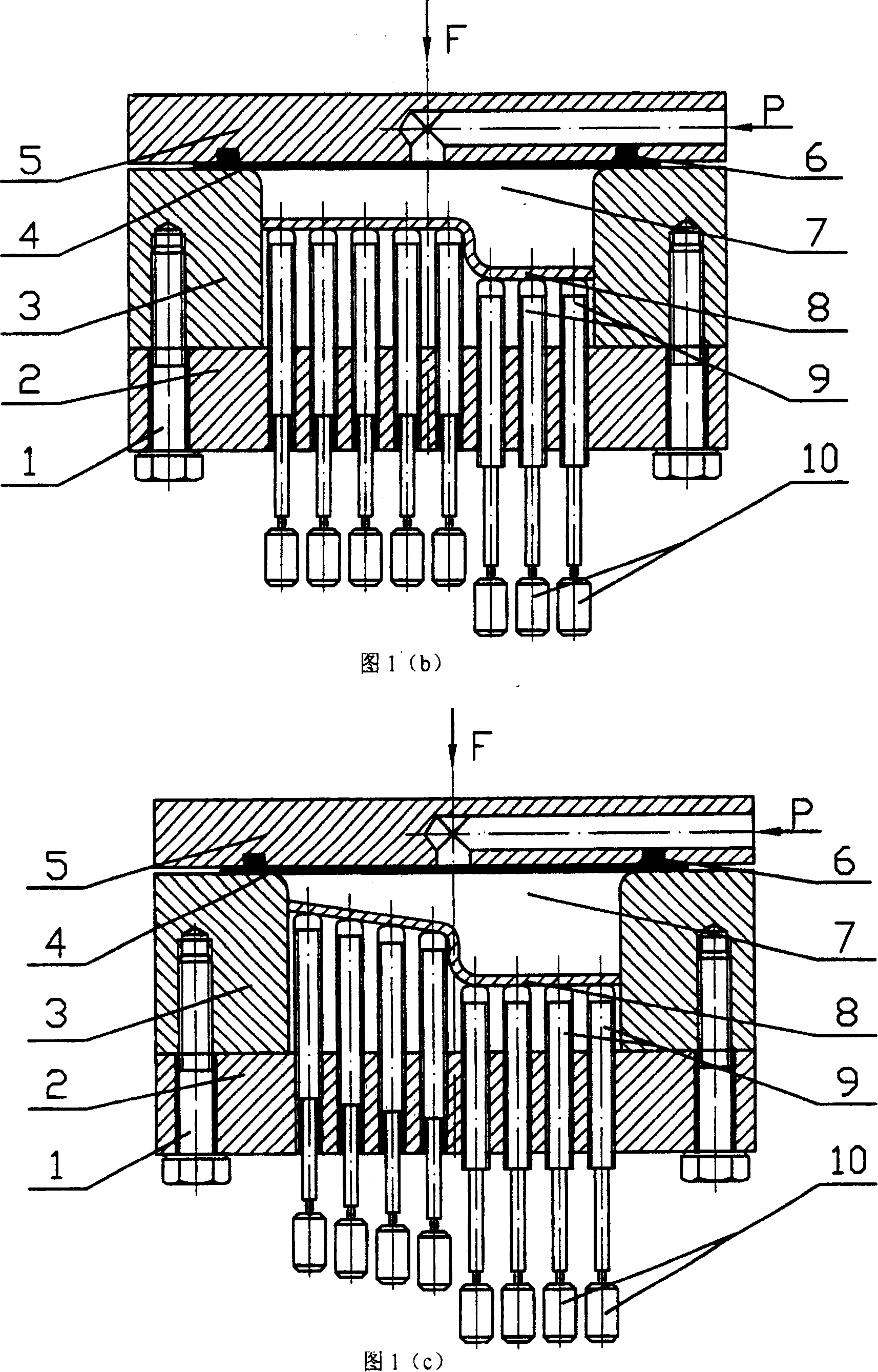

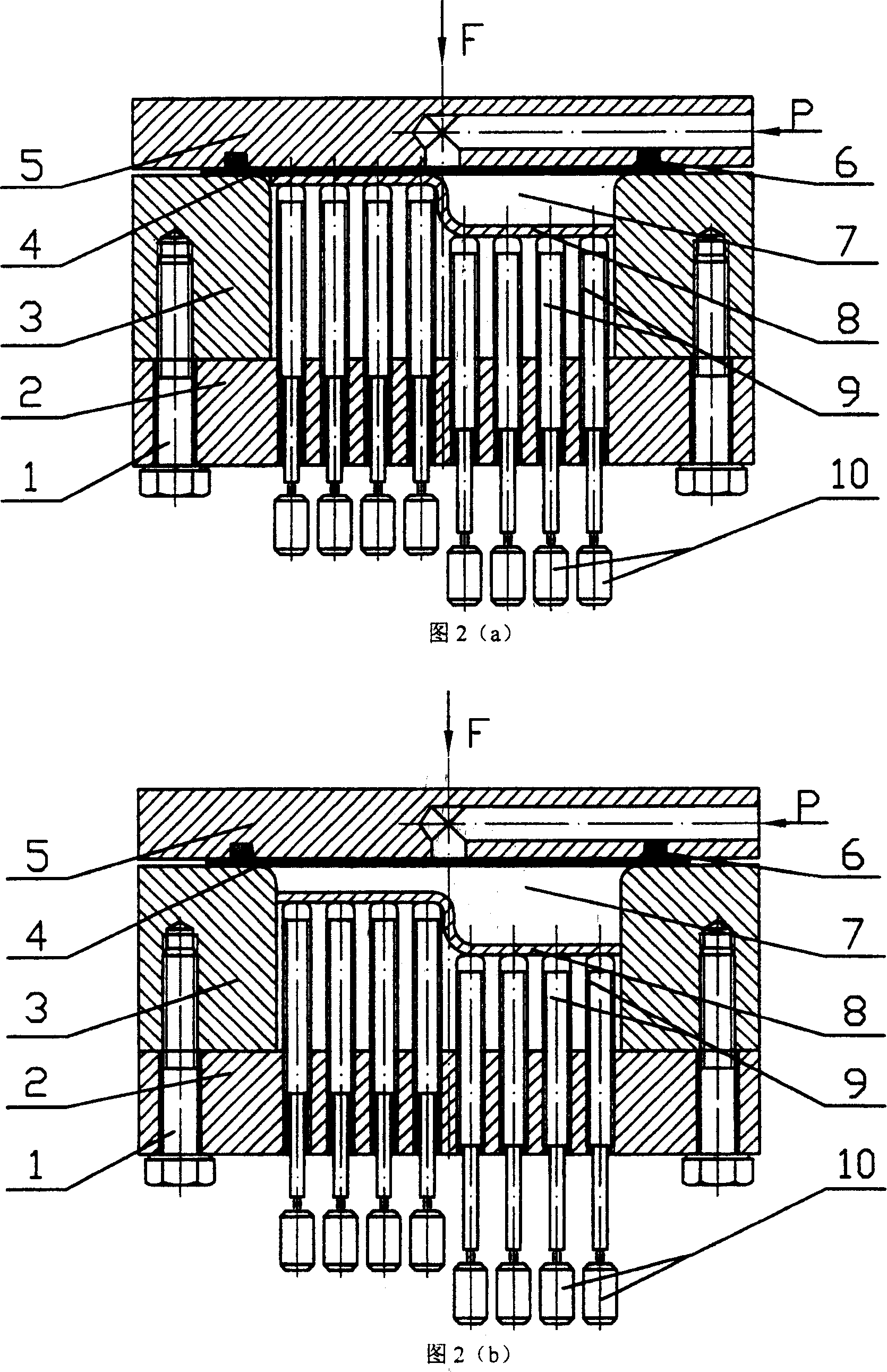

[0019] As shown in Fig. 1 (a), the hydraulic pressure or pneumatic forming device schematic diagram of forming a kind of double-box-shaped plate class part, hydraulic pressure or pneumatic forming device structure of the present invention comprises bolt 1, base 2, die seat 3, pressing plate 5, Sealing ring 6, die cavity 7, backing plate 8, movable unit group 9, motor 10. Die seat 3 central opening forms die cavity 7, and the cross section of die cavity is not only common circle, rectangle or square, also can be other shapes, there are several small punches (movable) in die cavity 7 unit) constitute the movable unit group 9 and the backing plate 8 corresponding to the size of the part to be formed, the punch is cylindrical, and the top of the punch contacting the backing plate can also be other cross-sectional shapes. Blank blanking, hydraulic or pneumatic loading and sealing, etc. are the same as conventional sheet metal hydraulic or pneumatic forming devices. The bolt 1 is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com