Fuel injection valve for internal combustion engines and a method for hardening said valve

一种燃料喷射阀、内燃机的技术,应用在燃料喷射装置、特殊燃料喷射装置、机械设备等方向,能够解决硬化方法不再能满足这种应用等问题,达到改善可加工性、减小原始硬度、加工余量减小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

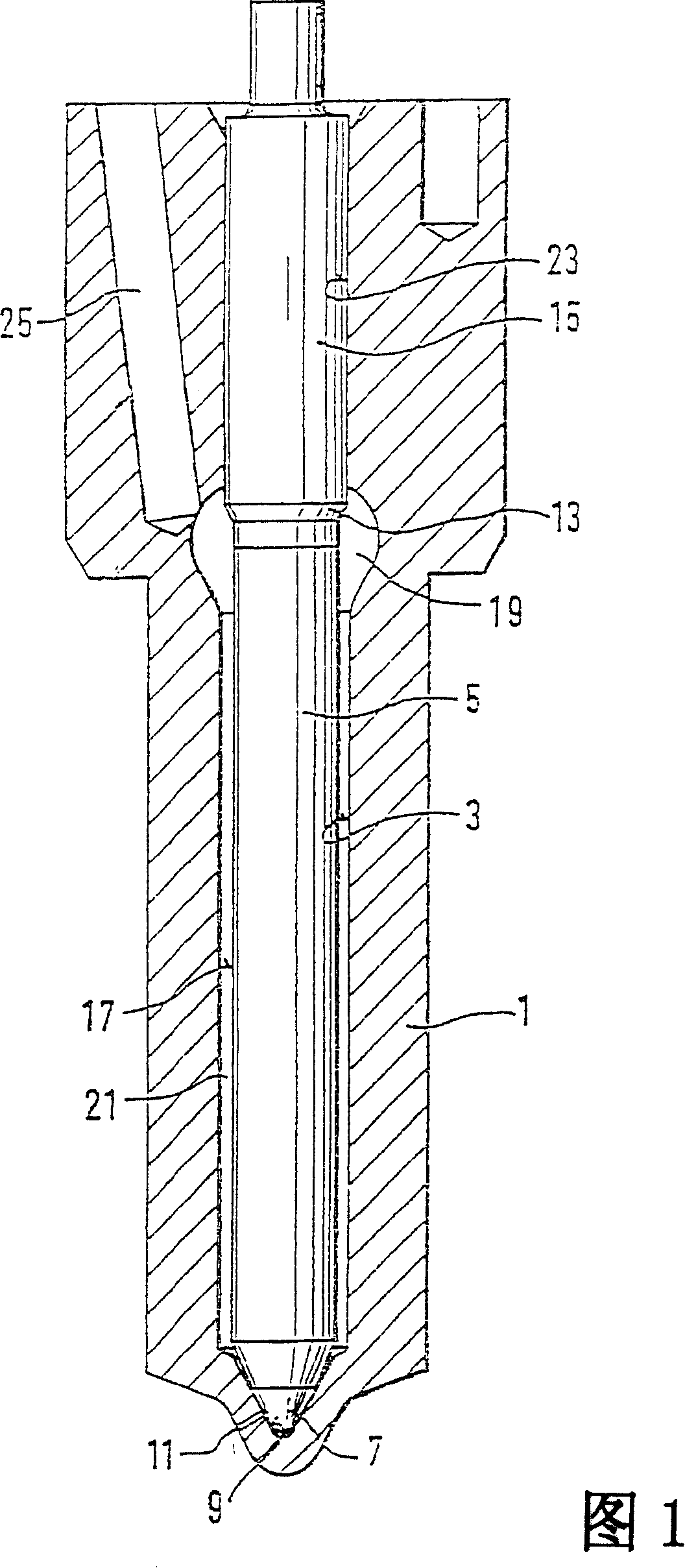

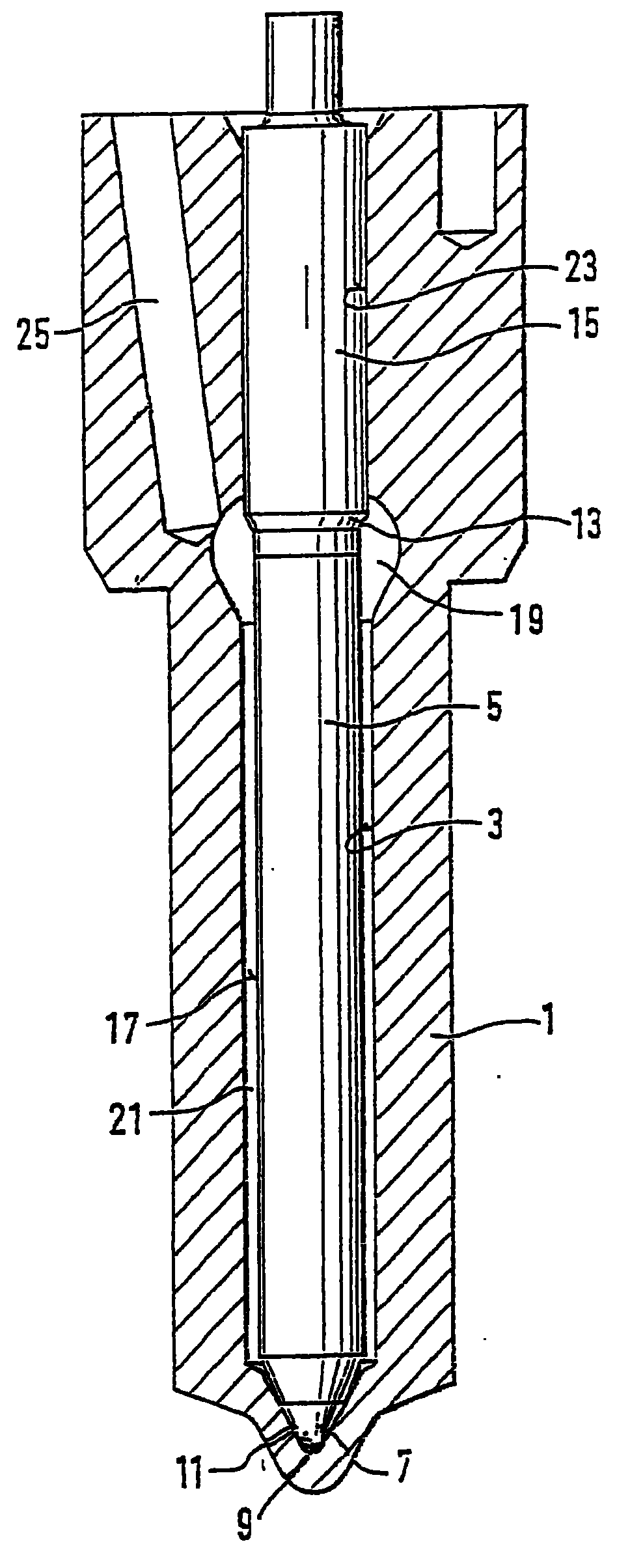

[0012] The fuel injector shown in FIG. 1 has a valve body 1 in which a valve needle 5 is arranged longitudinally displaceable in a bore 3 . A substantially conical valve seat 9 is formed at the end of the bore 3 on the combustion chamber side, in which at least one injection opening 11 is formed, which connects the bore 3 to the combustion chamber of the internal combustion engine. The valve needle 5 has a guide section 15 through which the valve needle is guided in a sealing manner in a guide section 23 of the bore 3 . The valve needle 5 tapers in the direction of the valve seat 9 and forms a pressure shoulder 13 and transitions into a rod section 17 of reduced diameter. At the end of this section, a substantially conical valve sealing surface 7 is formed on the valve needle 5, which cooperates with the valve seat 9 and when it rests on the valve seat 9, it opposes at least one injection hole 11. Hole 3 is closed.

[0013] A pressure chamber 19 is formed at the level of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com