Treatment method for thick collapsed loess foundation

A technology of collapsible loess and treatment method, applied in the field of treatment of deep collapsible loess foundation, to achieve the effects of low compression deformation, high bearing capacity and strong water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

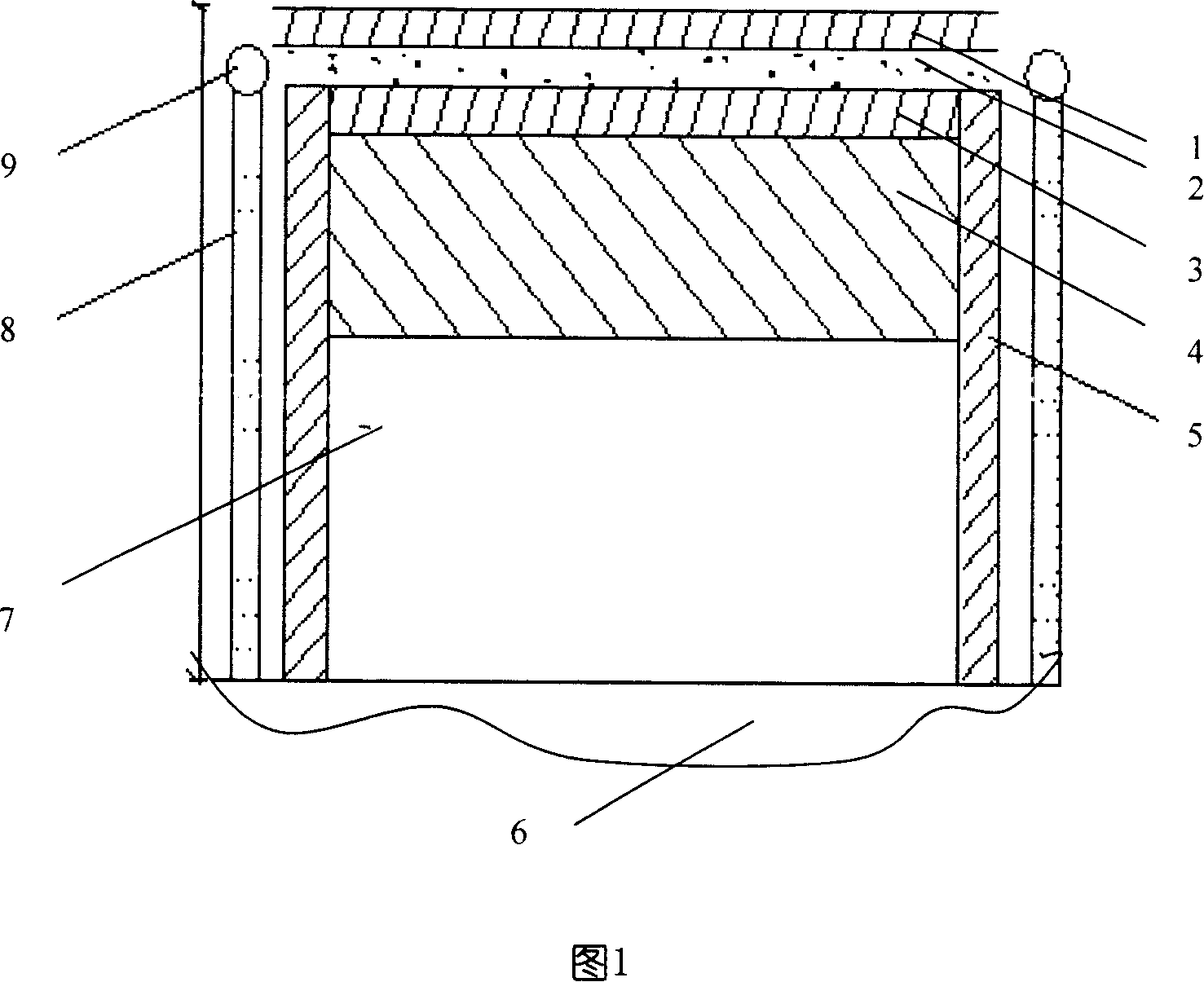

[0015] a) Artificially fill a layer of waterproof cushion 3 on the foundation treatment layer 4, and compact it with lime soil, and the filling thickness is 60cm.

[0016] b) Fill a layer of water-conducting cushion 2 on the waterproof cushion 3, using coarse sandy soil as the material, and the filling thickness is 30cm.

[0017] c) Fill a layer of water-blocking cushion 1 on the water-conducting cushion 2, and compact it with lime soil, with a thickness of 30cm.

[0018] d) Around the foundation treatment layer 4 and at the connection between the upper part and the waterproof cushion 3, build a seepage cut-off wall 5. The seepage cut-off wall 5 is composed of a continuous wall with a width of 50 cm, which can be formed by slotting and backfilling lime soil. The seepage cut-off wall 5 Form a closed water-cutting "hat" shape with the waterproof cushion layer 3, and its depth is 16m; if the total thickness of the foundation treatment layer 4 and the collapsible loess layer 7 is ...

Embodiment 2

[0021] a) Artificially fill a layer of waterproof cushion layer 3 on the foundation treatment layer 4, and use the lime-soil replacement layer and the foundation compaction layer or compacted layer to jointly fill, and the thickness of the upper lime-soil replacement layer is 80cm.

[0022] b) Fill a layer of water-conducting cushion 2 on the waterproof cushion 3, using coarse sandy soil as the material, and the filling thickness is 20cm.

[0023] c) Fill a layer of water-blocking cushion 1 on the water-conducting cushion 2, and use a lime-soil cushion to tamp it densely, with a thickness of 50cm.

[0024] d) Around the ground treatment layer 4, at the junction of the upper part and the waterproof cushion 3, a seepage cut-off wall 5 is built. The seepage cut-off wall 5 is made of a continuous wall with a width of 60 cm, and the seepage cut-off wall 5 uses the DDC method to reinforce the compacted soil method, the cut-off wall 5 and the waterproof cushion 3 form a closed water-...

Embodiment 3

[0027] a) Artificially fill a layer of waterproof cushion 3 on the foundation treatment layer 4, and compact it with lime soil, and the filling thickness is 100cm.

[0028] b) Fill a layer of water-conducting cushion 2 on the waterproof cushion 3, using coarse sandy soil as the material, and the filling thickness is 30cm.

[0029] c) Fill a layer of water-blocking cushion 1 on the water-conducting cushion 2, and use a lime-soil cushion to tamp it densely, with a thickness of 40cm.

[0030] d) Around the foundation treatment layer 4, the upper part and the junction of the waterproof cushion 3 are surrounded by a seepage cut-off wall 5, the seepage cut-off wall 5 is made of a continuous wall with a width of 30 cm, and the seepage cut-off wall 5 is formed by slotting and solidifying mud, The seepage cutoff wall 5 and the waterproof cushion 3 form a closed water-cutting "hat" shape; its depth is 15m; if the total thickness of the foundation treatment layer 4 and the collapsible lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com