Graphite boat and method for producing tungsten carbide by direct carbonization of WO3+C+H2 using same

A technology of graphite boat and tungsten carbide, which is applied in the field of graphite boat and the direct carbonization of WO3+C+H2 to produce tungsten carbide, which can solve the problems of low production efficiency, complicated process, long process, etc., and achieve the purpose of improving service life, Uniform particle size and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

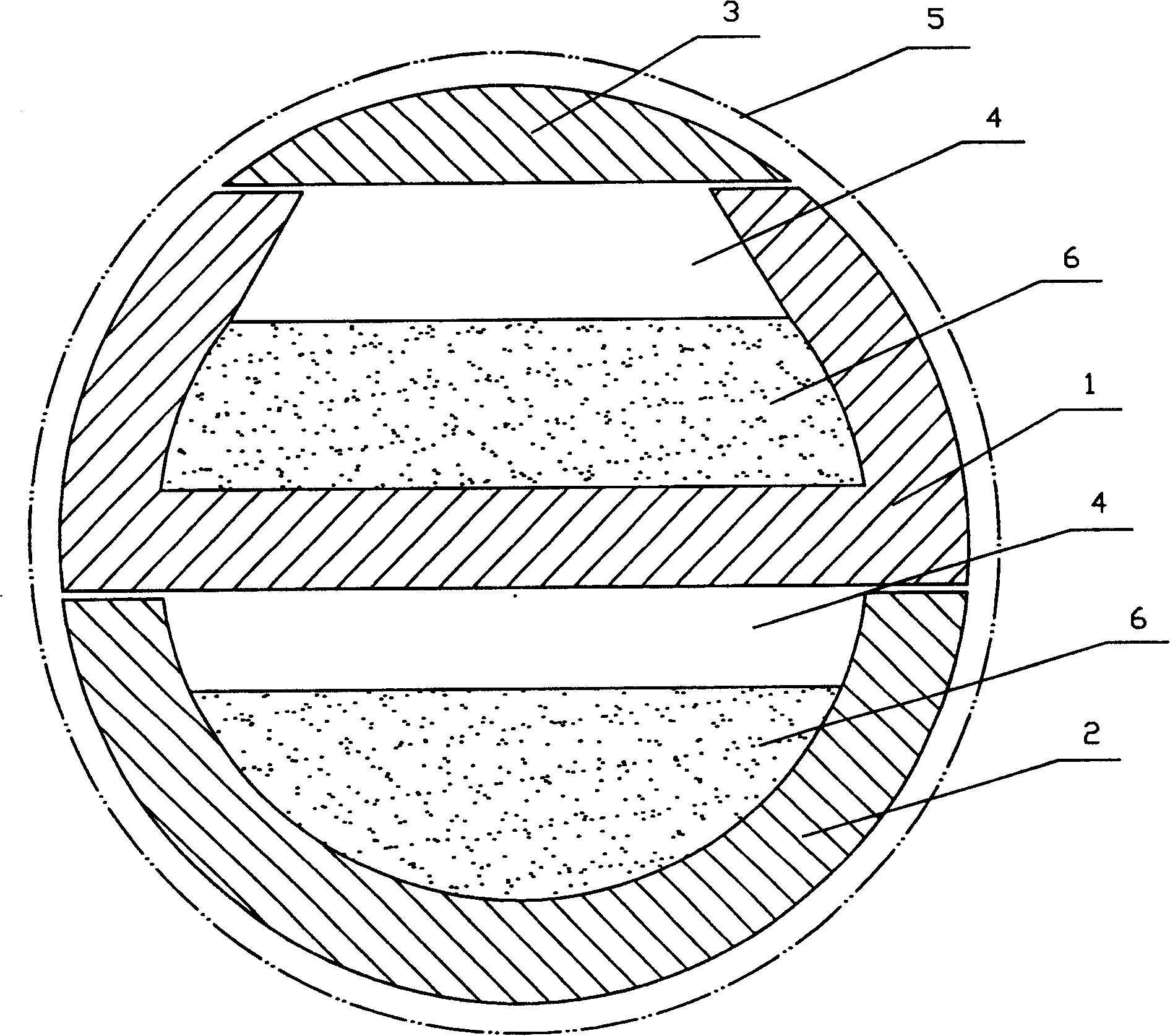

[0010] figure 1 It reflects the structure of the graphite boat of the present invention. As can be seen from the figure, the graphite boat of the present invention has an upper hopper 1, a lower hopper 2 and a loam cake 3 for sealing the upper hopper, and the upper hopper 1 is seated on the lower hopper 2 to start capping and unloading The function of bin 2, the upper cover is used to cover the silo, as a specific embodiment, the upper and lower hopper and the cover form a cylinder and put it into the carbonization furnace. If the currently commonly used carbonization furnace with an inner diameter of 128mm is used, then this The outer diameter of the invention is 120mm, the inner diameter is 94mm, the outer length is 360mm, and the inner length is 330mm. The top of 6 is air channel 4.

[0011] The method for producing tungsten carbide with graphite boat of the present invention is to make WO 3 Mix the powder and C powder evenly, put them into the upper and lower hoppers (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com