Method of preparing synthetic rutile from ore type ilmenite concentrate

A technology of artificial rutile and ilmenite concentrate, applied in the direction of furnace type, titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of difficult reduction technology, ring formation in rotary kiln, long corrosion time, etc. Eliminate hidden dangers, ensure quality, and reduce the effect of reduction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

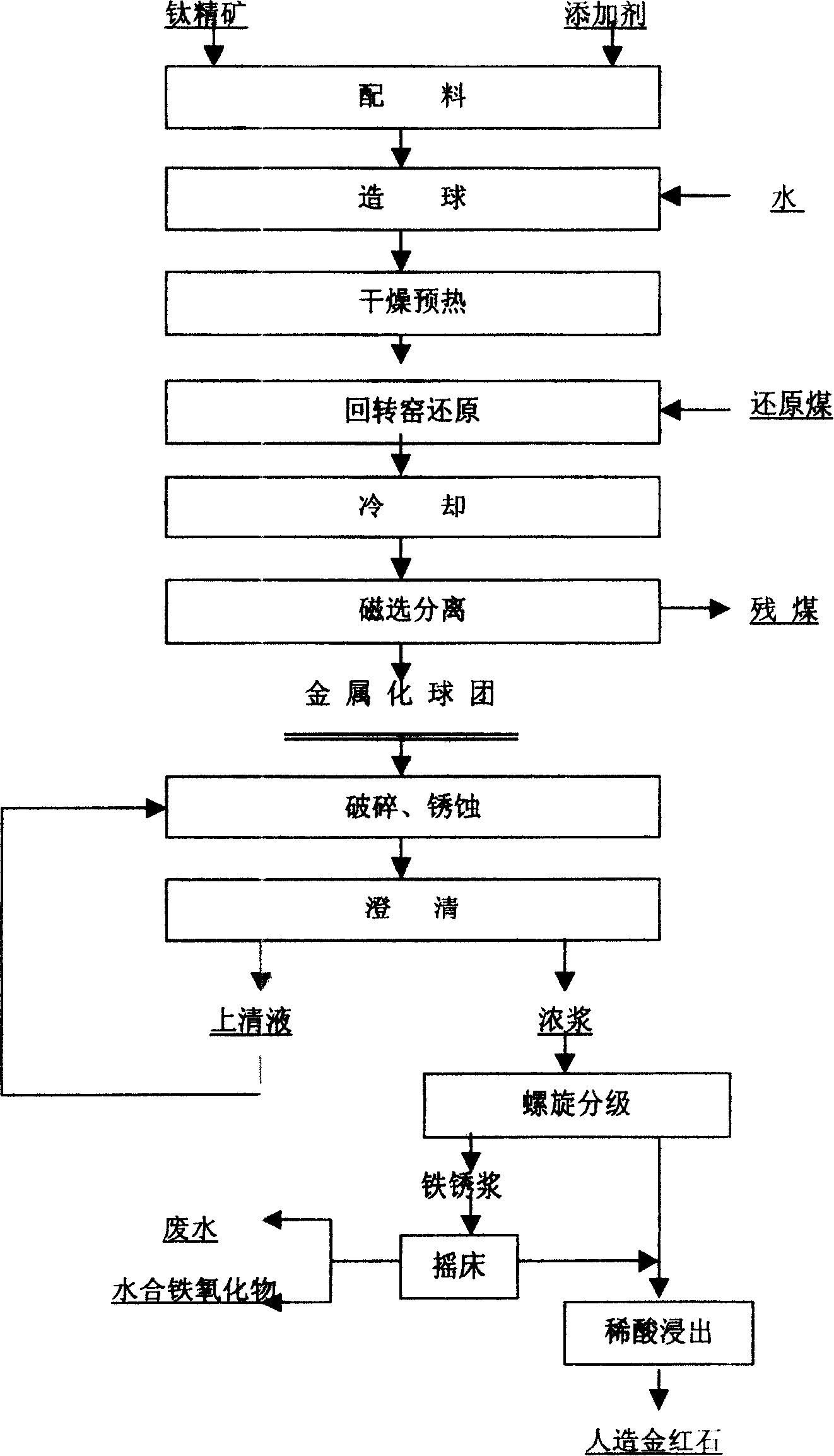

Image

Examples

Embodiment Construction

[0016] 1: Rock ore type ilmenite concentrate (TiO 2 47.16%, TFe 31.47%) with additive pelletizing. The additive sodium humate is added in an amount of 1.5%. After the raw balls are dried and preheated by the grate machine, they enter the rotary kiln for reduction. The drying and preheating system of the grate machine is as follows: the material height is 200mm, the air temperature in the blast drying section is 200°C, the wind speed is 1.0m / s, and the time is 2min. The air temperature in the section is 250°C, the wind speed is 1.0m / s, and the time is 5min. The air temperature in the preheating section is 800-950°C, the wind speed is 1.2m / s, and the time is 12min; , the reduction time is 150min, the C / Fe ratio is 0.8, and the metallization rate of the obtained reduced ilmenite is 93.78%. The reduced ilmenite ore is crushed and ground, and the grinding particle size is controlled at -1mm to account for 100%, and then the rust separation treatment is carried out. The rust sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com