Method for refining poor diesel oil by using compound solvent

A technology of compound solvent and inferior diesel oil, which is applied in the refining hydrocarbon oil, petroleum industry and other directions, can solve the problems of high diesel oil loss, complex process and solvent consumption, and achieve the effects of less diesel loss, simple equipment and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

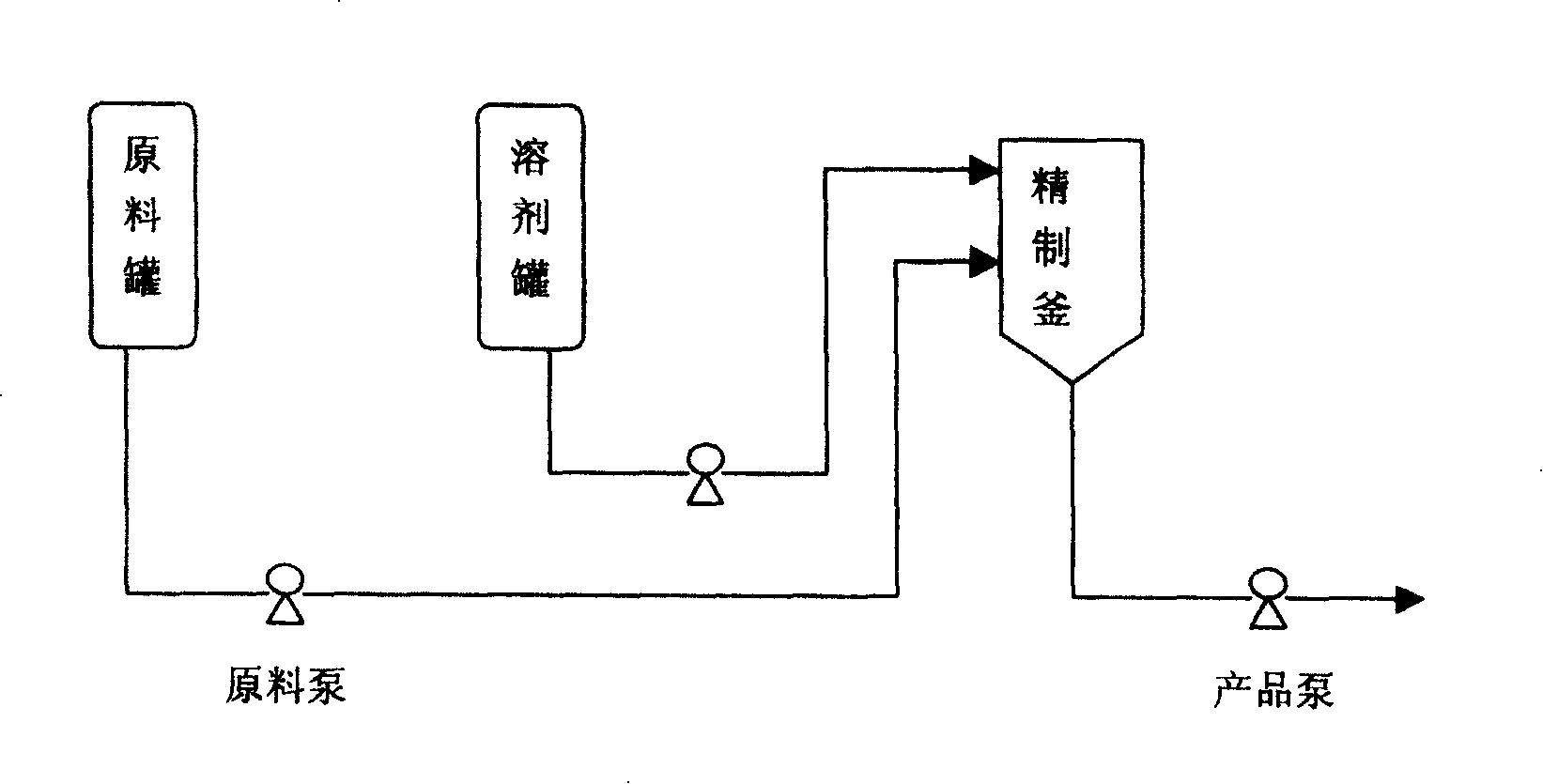

[0011] In conjunction with the accompanying drawings, the process description is as follows:

[0012] Inferior diesel oil and composite solvent are stored in the raw material tank and solvent tank respectively, and are pumped into the refining kettle by the raw material pump and solvent pump respectively according to the appropriate ratio. The amount of composite solvent pumped into the solvent pump by the solvent pump in the same time is equal to the inferior diesel oil pumped by the raw material pump. The amount of 0.07%, the raw material and the composite solvent are mixed evenly by the agitator in the refining tank, and after standing and settling for 2 hours, a very small amount of black residue is discharged from the bottom valve of the tank to obtain a clear, transparent, odorless, and colorimetric. Diesel fraction of 2.0, the refined product is pumped out through the product pump.

[0013] The composite solvent is composed of furfural:methanol:hexamethylenediamine:hypo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com