Soil curing agent of road

A soil stabilizer and activator technology, applied in soil conditioning materials, applications, chemical instruments and methods, etc., can solve the problems of low strength, poor soil consolidation effect and high cost, and achieve resource saving, capital saving and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Use a ball mill to grind the undisturbed water-quenched slag (purchased from Shaanxi Longmen Iron and Steel Works) into a surface area of 439m 2 / kg of superfine powder, the density is 2.83g / cm 3 , the particle size distribution was measured with a laser particle size analyzer (Mastersizer 2000, Malvern Instrument Co., Ltd., UK), and the average particle size was calculated to be 14.120 μm. Slaked lime (purchased from Shaanxi Jingyang Lime Factory) was sieved with a 2.36mm sieve. The slag ultrafine powder of 68.57kg is mixed with the hydrated lime powder of the sieve of 28.57kg, and the III class industrial sodium sulfate (purchased from Shaanxi Baohua Chemical Co., Ltd.) of 2.86kg is added, and stirred evenly, promptly obtains the soil of the present invention Hardener. In this embodiment, the weight ratio of slag, slaked lime and sodium sulfate is 12:5:0.5.

Embodiment 2~9

[0037] According to the weight ratios of slag, slaked lime and sodium sulfate in Table 1, the same preparation method as in Example 1 was adopted to prepare the soil stabilizers of Examples 2-9 respectively.

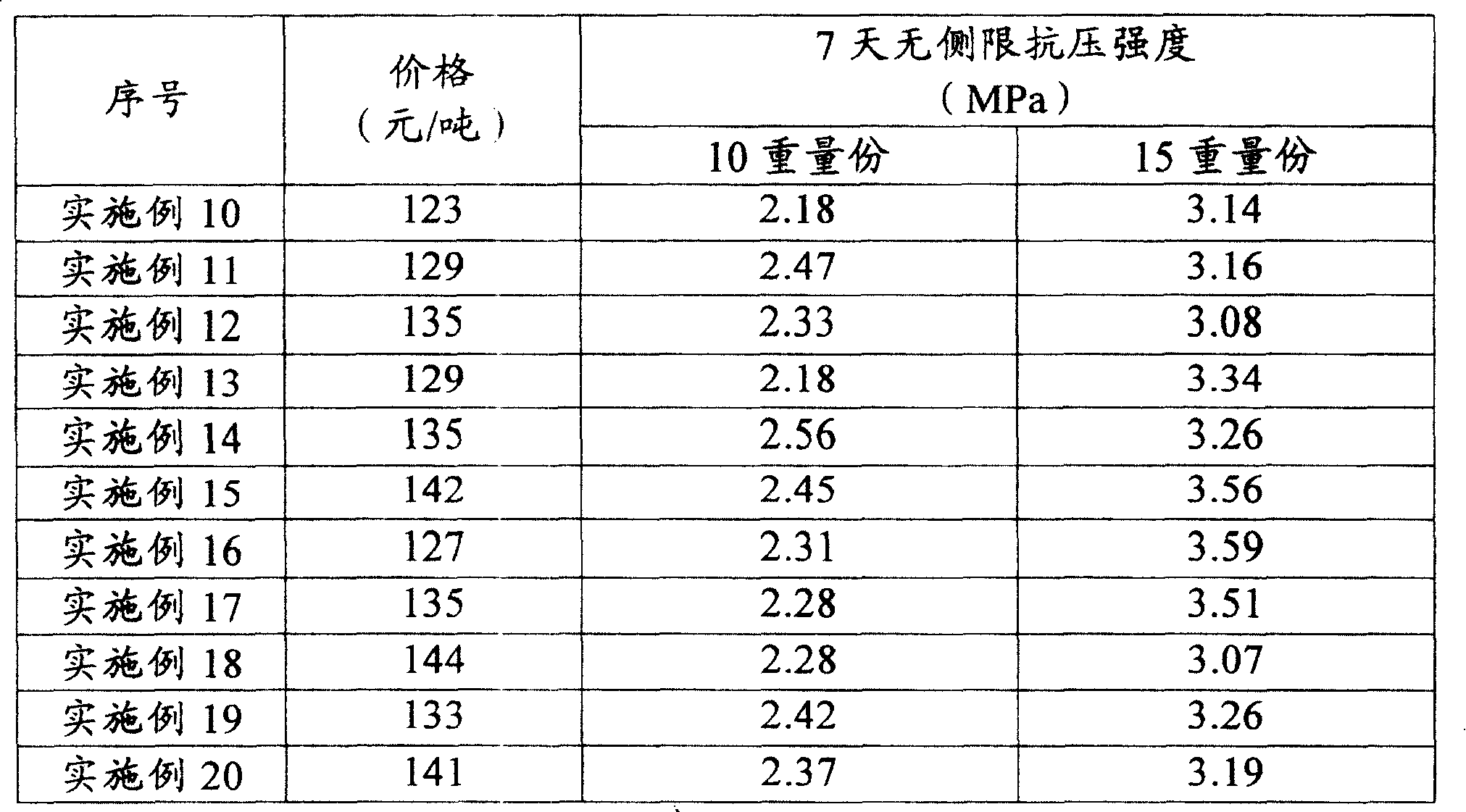

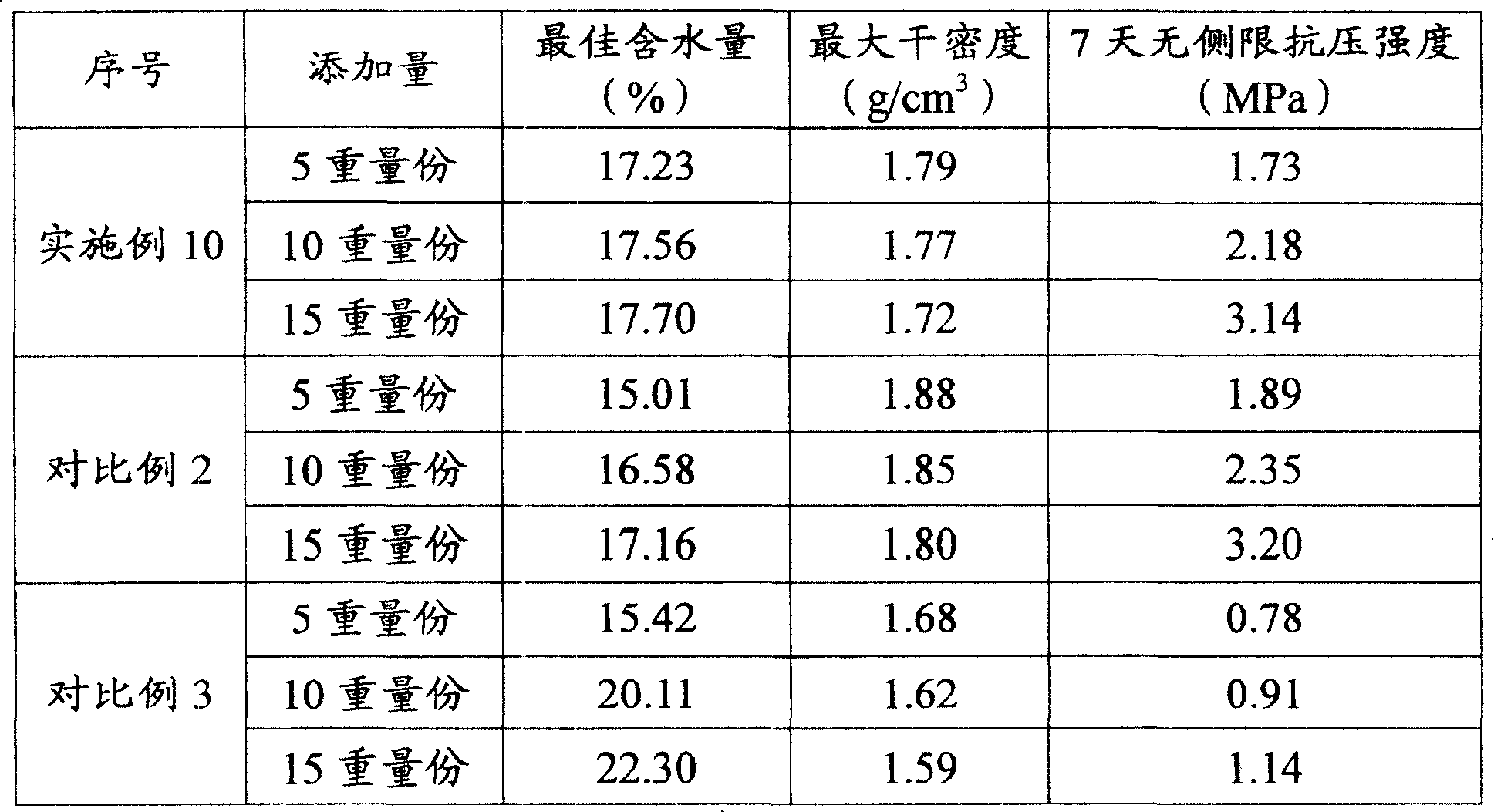

Embodiment 10~20

[0039] In Examples 10-20, the same preparation method as in Example 1 was adopted, except that fly ash (purchased from Shaanxi Weihe Power Plant) was further added to slag, slaked lime and sodium sulfate. The weight ratio of each raw material is shown in Table 1. These raw materials were mixed together and stirred evenly to obtain the soil curing agent of Examples 10-20 of the present invention.

[0040] serial number

[0041] Table 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com