Preionizing device for impusle gas laser

A pulsed gas and pre-ionization technology, applied in gas laser parts, laser parts, etc., can solve problems such as uneven pre-ionization, and achieve the effects of improving service life, increasing average output power, and increasing injection energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

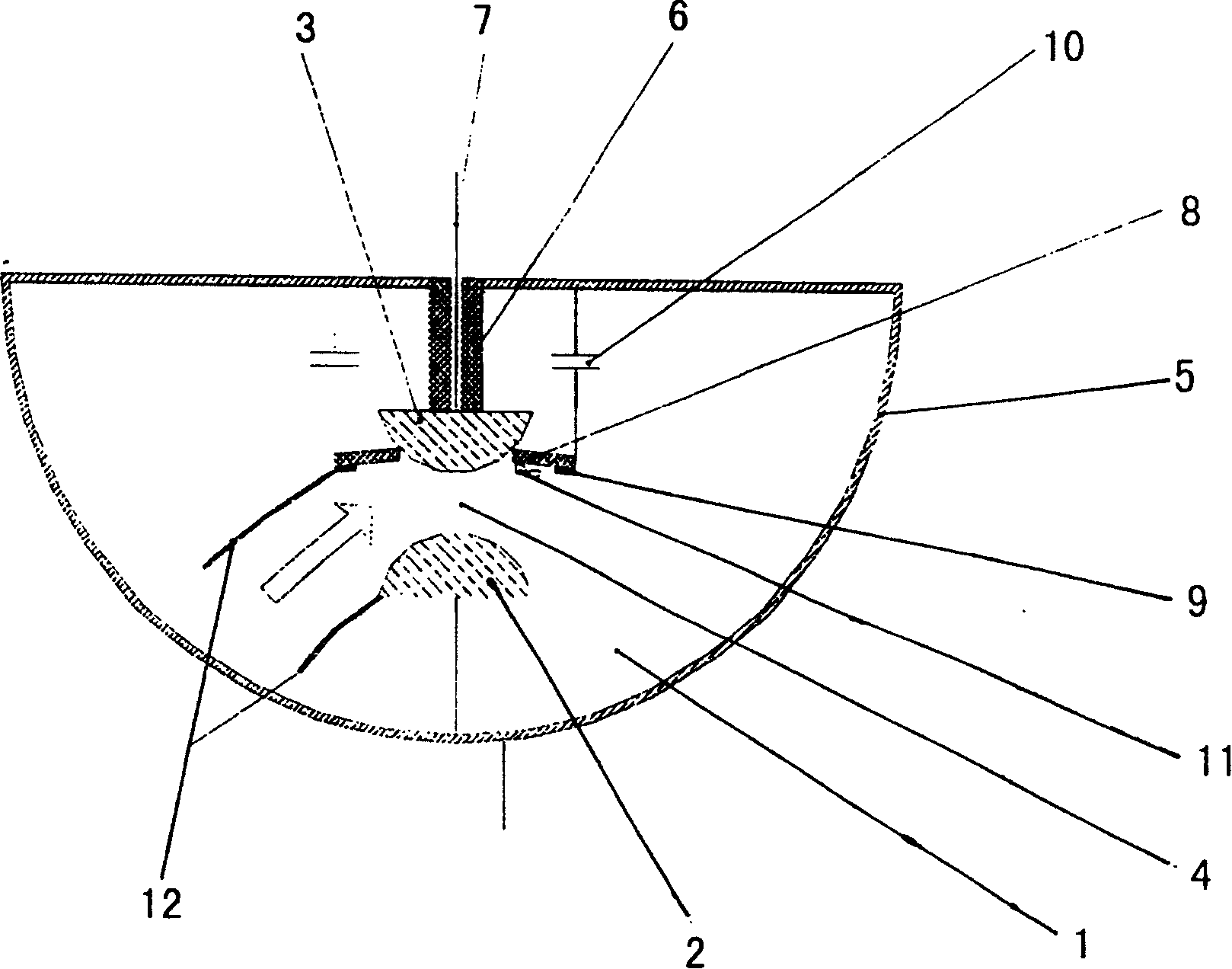

[0019] A pre-ionization device for a pulsed gas laser is a surface multi-channel sliding flash pre-ionization device, which is characterized in that the device is placed on one side or both sides of the main discharge cathode. The device consists of multiple groups of pre-ionization electrodes arranged side by side. The main discharge cathode is a common electrode of the pre-ionization electrode group, and the other electrode of the pre-ionization electrode group is the same narrow metal sheet. The metal sheet should have strong anti-burning Corrosive, and easy to process, such as nickel sheet. In order to ensure the spatial uniformity of pre-ionization, the distance between adjacent narrow metal sheets is equal, generally 1-4 cm, and the specific number of metal sheets depends on the size of the laser. The electrode pair for pre-ionization consists of a piece of ablation-resistant, chemically stable insulating material (Al 2 o 3 , BaTiO 3 , SrTiO 3 etc.) dielectric plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com