Method for processing worn-out fluorescent tube

The technology of a fluorescent tube and a processing method is applied in the field of waste fluorescent tube processing to achieve the effects of reducing processing costs, ensuring recycling and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

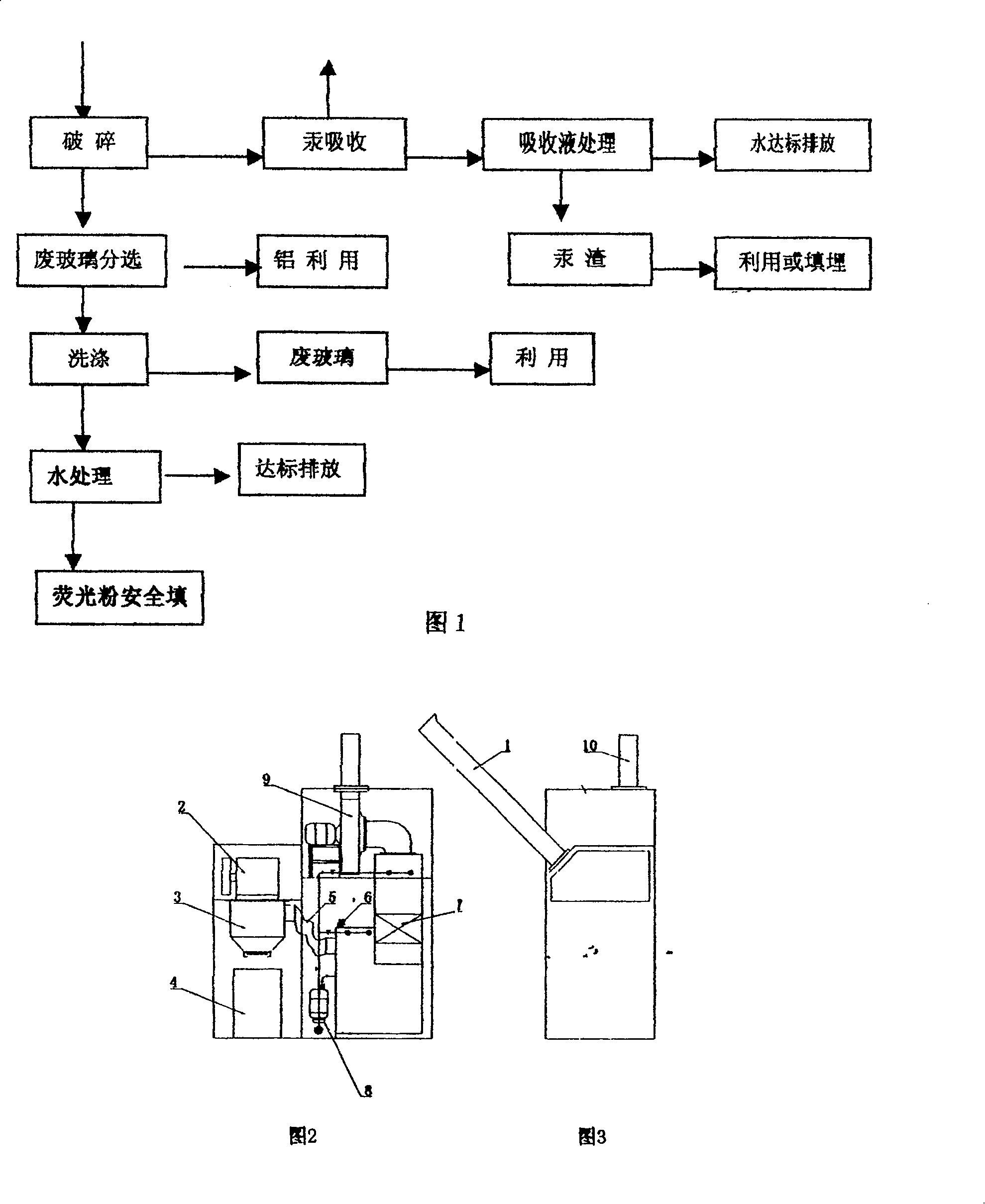

[0007] The processing method of this waste and old fluorescent tube of the present invention is carried out according to steps, distribution:

[0008] ■Crushing and absorbing unit

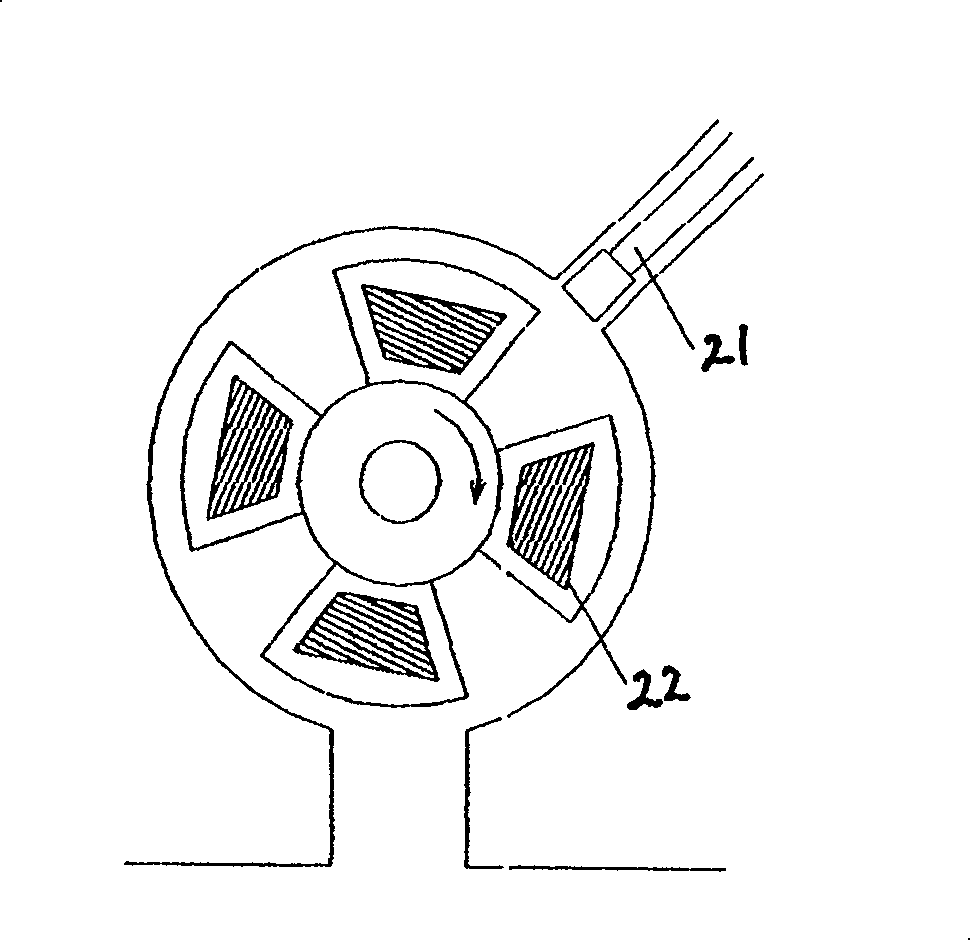

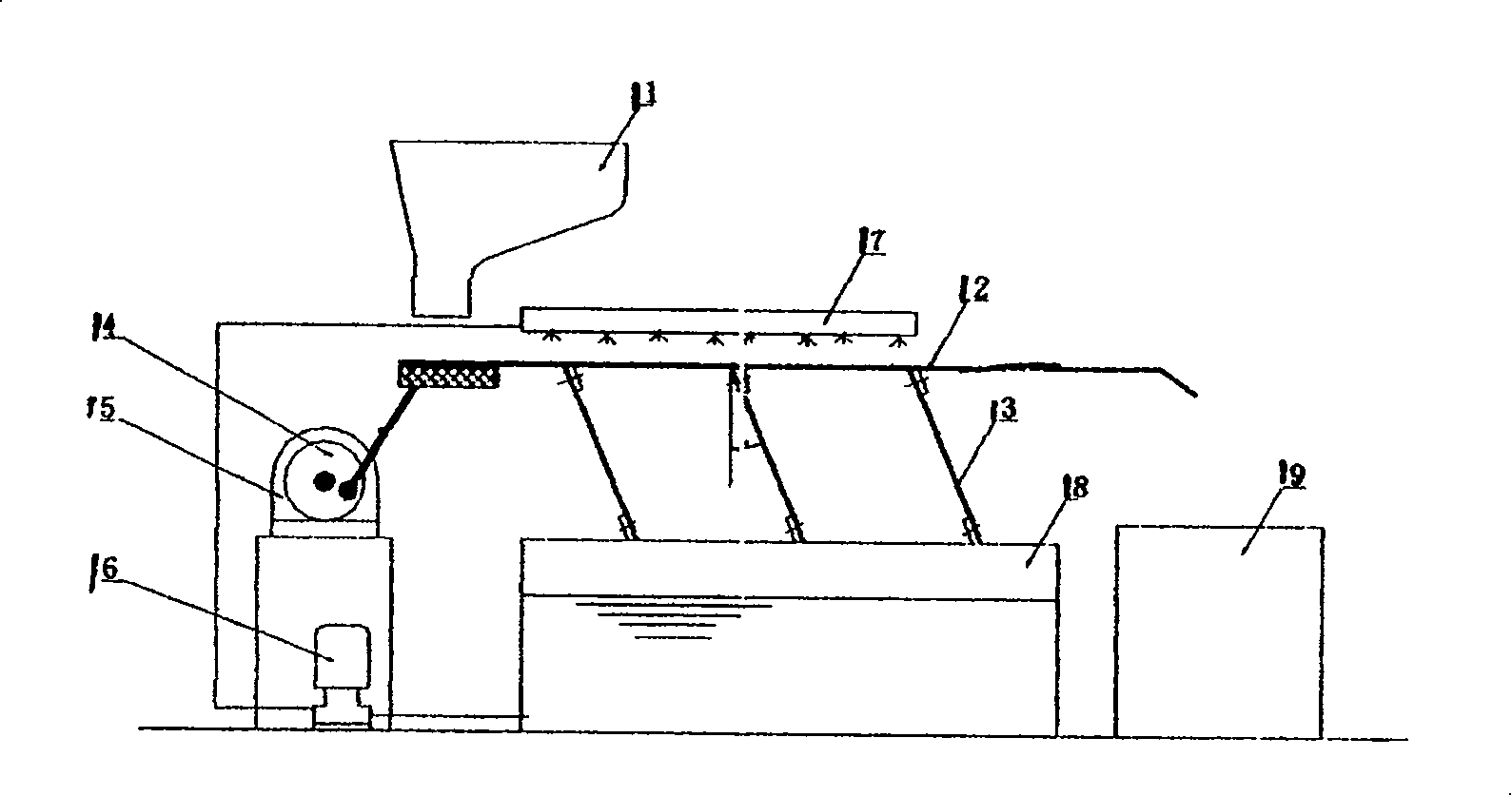

[0009] Waste fluorescent tubes enter the crushing system and are crushed by the horizontal rotary crusher 2. The crushed glass fragments and scrap metal enter the container storage tank, and the mercury vapor generated at the same time enters the absorption system 8 under the guidance of the negative pressure airflow generated by the fan 9. The absorption system is divided into two stages of absorption. The first stage is the Venturi tube 6 Absorption method, the second stage is reverse spraying packed tower 7 absorption, the original absorption liquid is 1% potassium permanganate aqueous solution, when the absorption concentration drops to 0.8%, or supplement potassium permanganate to make the concentration rise to 1 %, or replace the absorbent. The consumption of active ingredients in the absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com