High impact tough alloy material containing Al, Si, Mgi used for making automobile hub and its producing method

A technology for alloy materials and automobile wheel hubs, applied in the field of metal-based functional materials and manufacturing, can solve the problems of alloy silicon segregation, affecting the impact toughness of alloys, etc., and achieve the effects of improving mechanical properties, improving yield, and preventing component segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

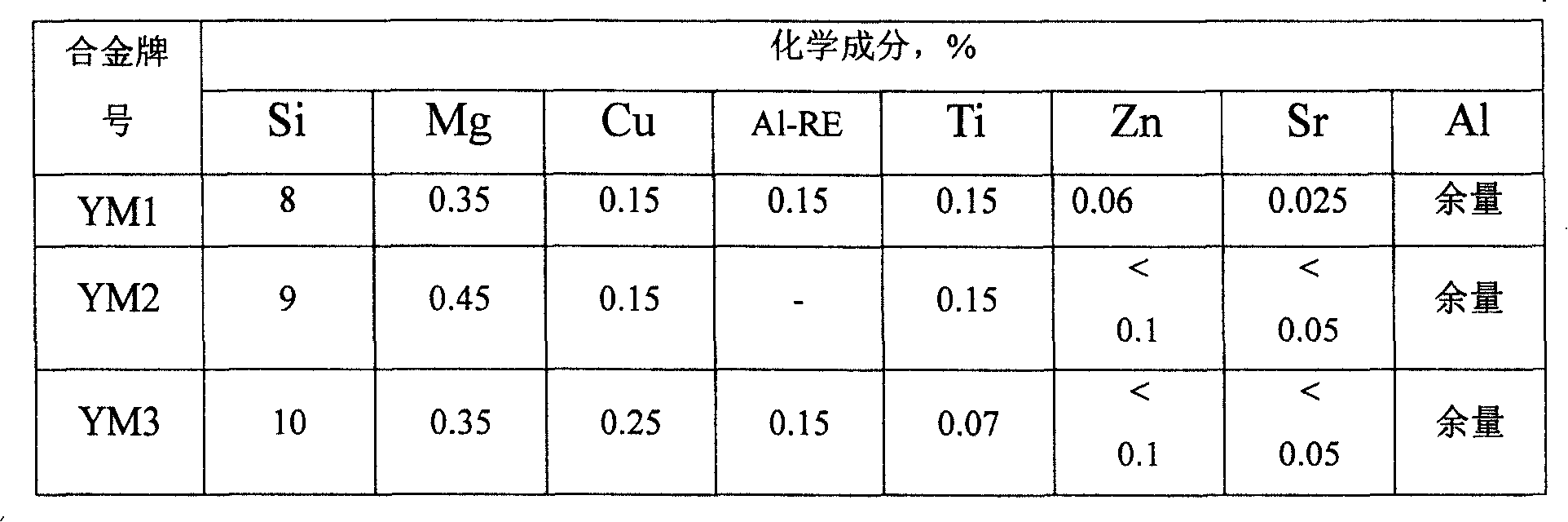

Embodiment 1

[0027] 1. First, according to the quality of industrial pure silicon 9%, aluminum-magnesium alloy 0.5%, aluminum-copper alloy 0.2%, aluminum rare earth (60%La+40%Ce) master alloy 0.2%, titanium powder 0.2%, aluminum-strontium alloy 0.03% The percentage is added to the melting furnace, and then 89.8% of the electrolytic pure aluminum liquid is added to the melting furnace;

[0028] 2. Use the high temperature (880°C) of electrolytic aluminum liquid to melt industrial pure silicon, aluminum-magnesium alloy, aluminum-copper alloy, aluminum rare earth intermediate alloy, aluminum-strontium alloy and titanium powder;

[0029] 3. When the temperature of the aluminum alloy liquid in the furnace reaches 760°C, use ultrasonic waves for homogenization treatment for 15 minutes, then let it stand for 20 minutes, and then introduce the aluminum alloy liquid into the degassing box;

[0030] 4. Use high-purity nitrogen to degas the aluminum alloy liquid in the degassing box;

[0031] 5. The...

Embodiment 2

[0035] 1. First, according to the quality of industrial pure silicon 7%, aluminum-magnesium alloy 0.4%, aluminum-copper alloy 0.05%, aluminum rare earth (60%La+40%Ce) master alloy 0.05%, titanium powder 0.08%, aluminum-strontium alloy 0.03% The percentage is added to the melting furnace, and then 92.39% of the electrolytic pure aluminum liquid is added to the melting furnace;

[0036] 2. Use the high temperature (880°C) of electrolytic aluminum liquid to melt industrial pure silicon, aluminum-magnesium alloy, aluminum-copper alloy, aluminum rare earth intermediate alloy, aluminum-strontium alloy and titanium powder;

[0037] 3. When the temperature of the aluminum alloy liquid in the furnace reaches 760°C, use electromagnetic waves for homogenization treatment for 15 minutes, let it stand for 20 minutes, and then introduce the aluminum alloy liquid into the degassing box;

[0038] 4. Use high-purity nitrogen to degas the aluminum alloy liquid in the degassing box;

[0039] 5....

Embodiment 3

[0044] 1. First, according to the quality of industrial pure silicon 12%, aluminum-magnesium alloy 1.0%, aluminum-copper alloy 0.4%, aluminum rare earth (60%La+40%Ce) master alloy 0.3%, titanium powder 0.5%, aluminum-strontium alloy 0.06% The percentage is added to the melting furnace, and then 92.39% of the electrolytic pure aluminum liquid is added to the melting furnace;

[0045] 2. Use the high temperature (880°C) of electrolytic aluminum liquid to melt industrial pure silicon, aluminum-magnesium alloy, aluminum-copper alloy, aluminum rare earth intermediate alloy, aluminum-strontium alloy and titanium powder;

[0046] 3. When the temperature of the aluminum alloy liquid in the furnace reaches 760°C, use electromagnetic waves for homogenization treatment for 15 minutes, let it stand for 20 minutes, and then introduce the aluminum alloy liquid into the degassing box;

[0047] 4. Use high-purity nitrogen to degas the aluminum alloy liquid in the degassing box;

[0048] 5. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com