Vertical magnetic recording medium, process for producing the same and magnetic recording apparatus

A technology of perpendicular magnetic recording and magnetic recording layer, which is applied in the direction of magnetic recording, magnetic recording layer, disc carrier manufacturing, etc., and can solve problems such as volume reduction, input signal degradation, thermal fluctuations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

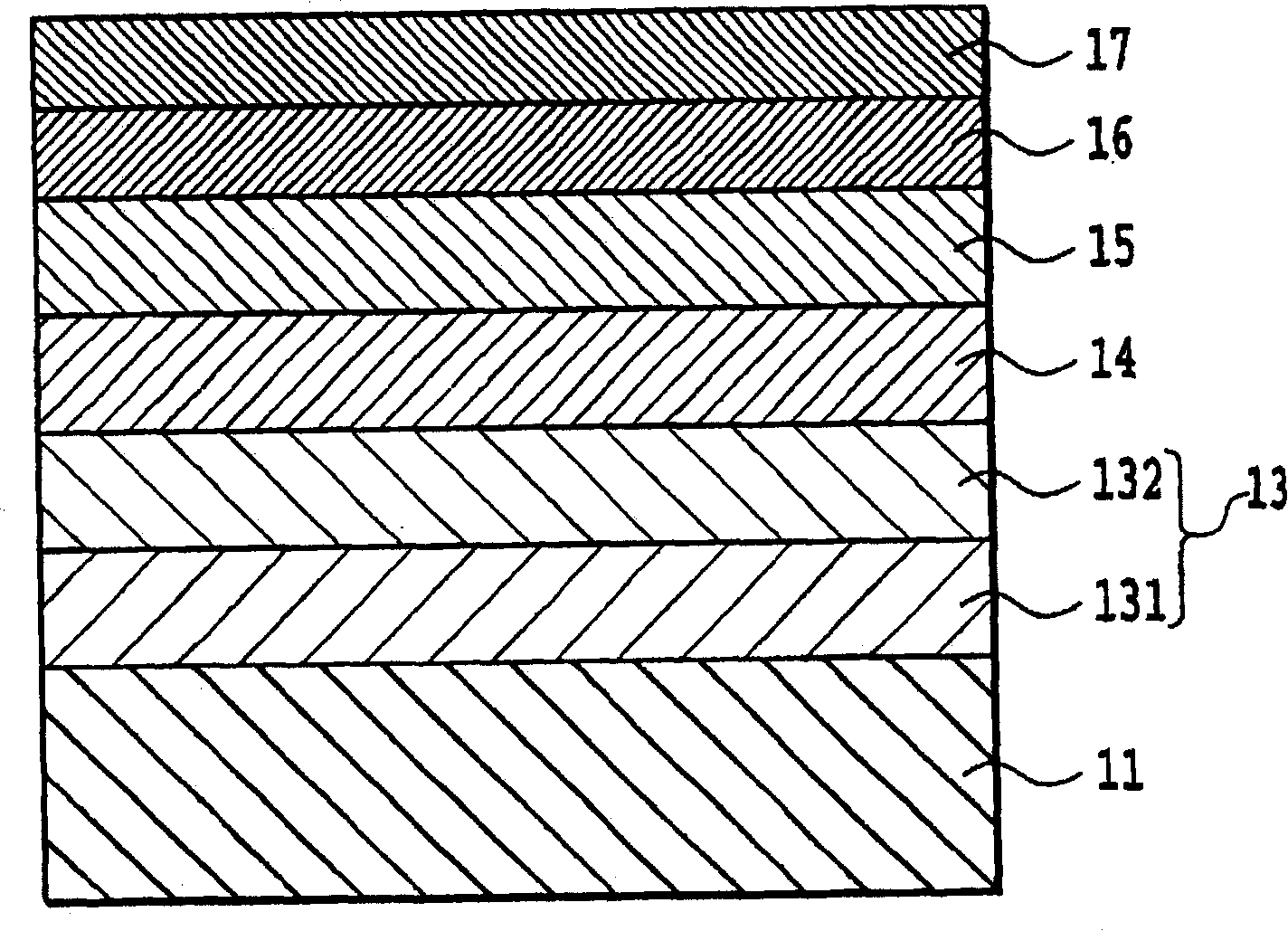

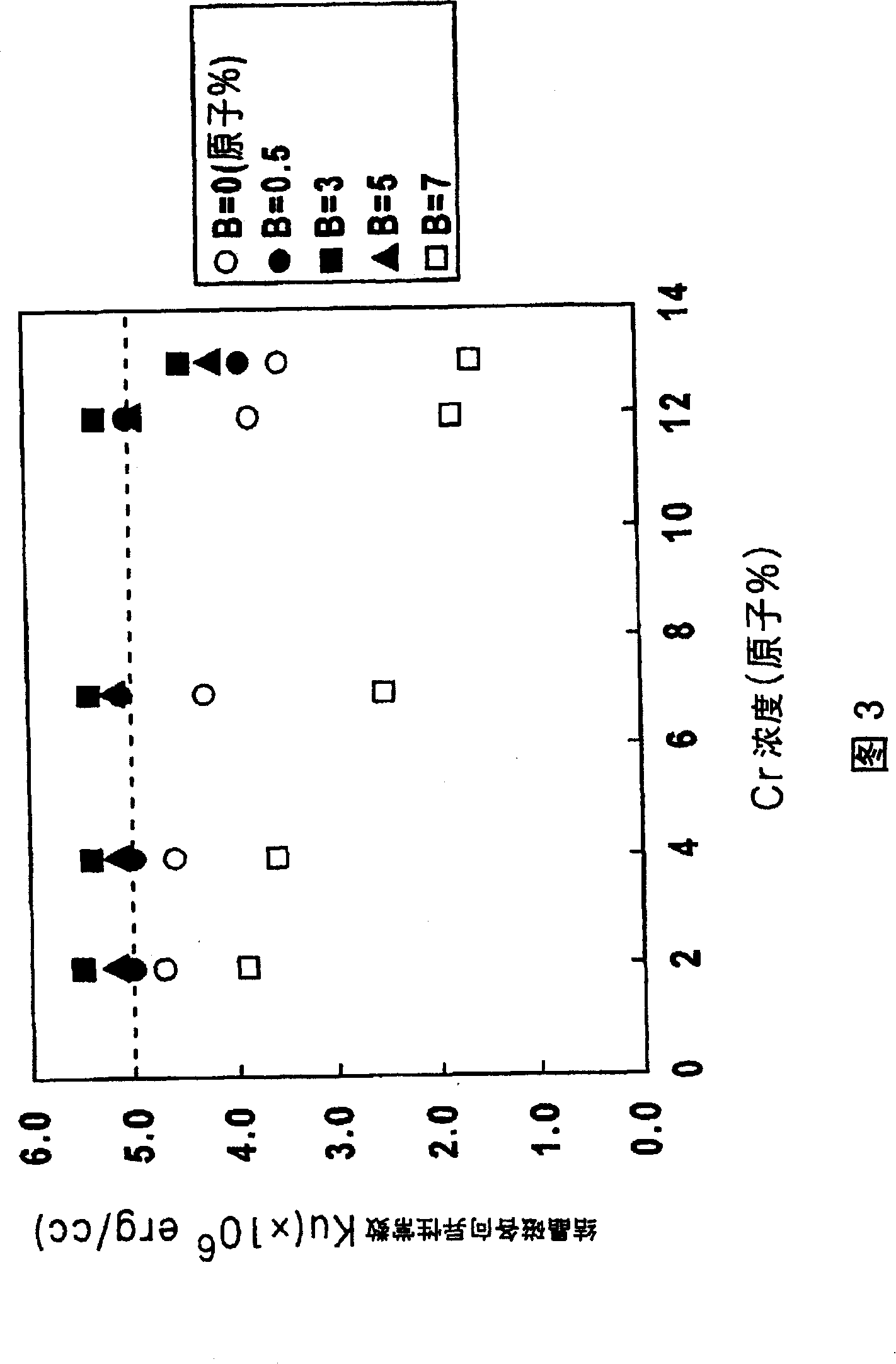

[0067] In this example, for the figure 2 In the single-layer vertical medium of the structure, the example of changing the addition amount of Cr and B will be described.

[0068] A chemically strengthened glass substrate (for example, N-5 glass substrate manufactured by HOYA Co., Ltd.) with a smooth surface is used as the non-magnetic substrate 11. After cleaning, it is introduced into a sputtering device, and a Ta target is used under an Ar gas pressure of 5 mTorr. The first seed layer 131 made of amorphous Ta is formed with a film thickness of 10 nm, and then Ni, which is a non-magnetic Ni-based alloy, is used. 65 Fe 20 Cr 15 The target (the subscript number indicates the composition ratio in atomic %. The same applies hereinafter.), and the second seed layer 132 made of non-magnetic NiFeCr was formed with a film thickness of 15 nm under an Ar gas pressure of 20 mTorr. Furthermore, using an Ir target, under an Ar gas pressure of 30 mTorr, the base layer 14 was formed wit...

Embodiment 2

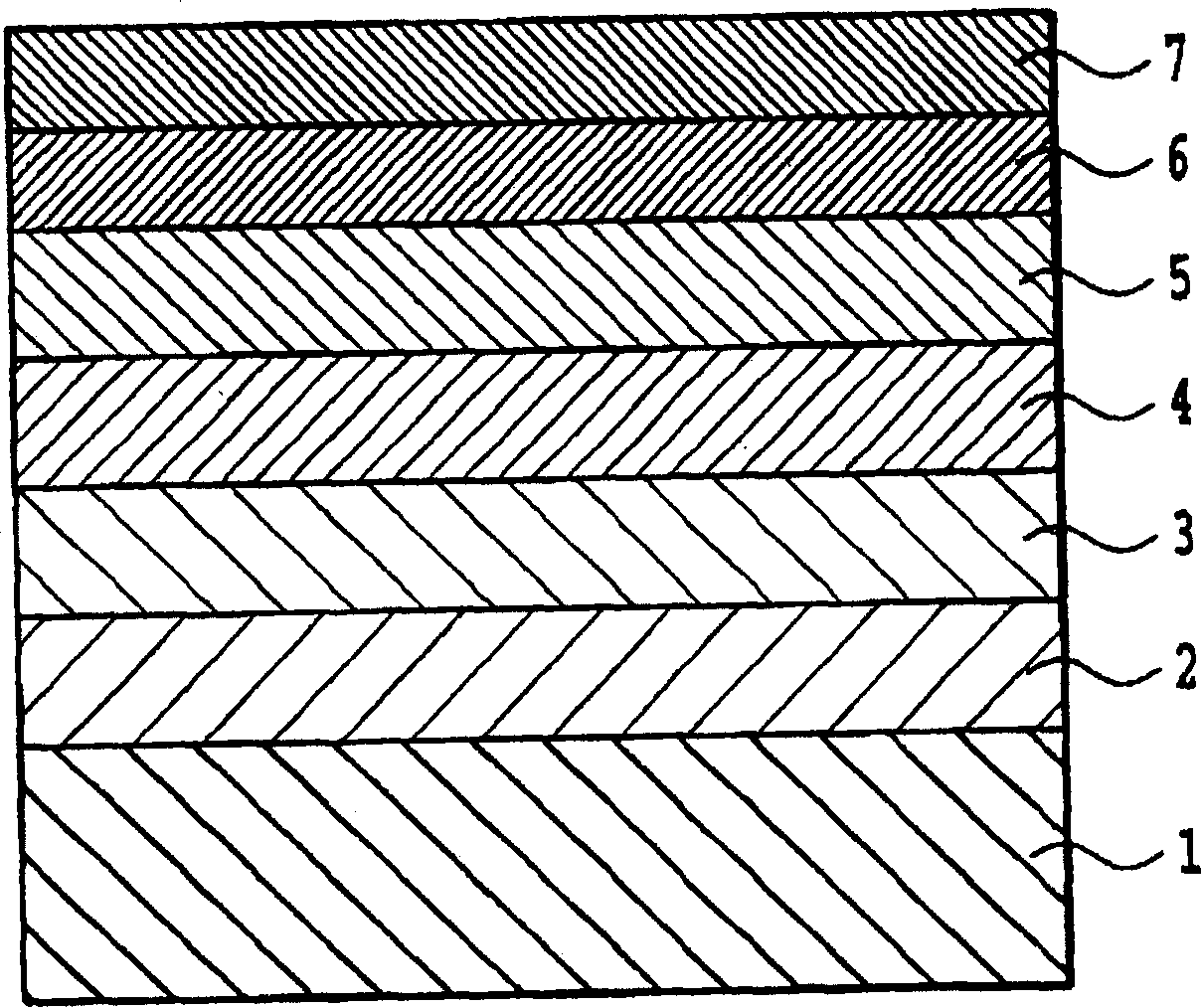

[0071] In this example, for the figure 1 In the two-layer vertical medium of the structure, an example of changing the addition amount of Cr and B will be described.

[0072] As the soft magnetic backing layer 2, Co 91 Ta 4 Zr 5 For the target, under an Ar gas pressure of 5 mTorr, an amorphous CoTaZr soft magnetic backing layer was formed with a film thickness of 150 nm as a single-layer seed layer 3 composed of nonmagnetic NiFeCr (similar to the second seed layer in Example 1) , except that the first seed layer made of Ta was not formed, all were the same as in Example 1, and a two-layer vertical medium was produced.

Embodiment 3

[0074] In this example, for the figure 2 An example of fabrication of a single-layer vertical medium with a structure changed by changing the amount of SiN added will be described.

[0075] When forming a CoPtCrB-SiN magnetic recording layer as a magnetic recording layer, use (100-z) mole % (Co 75 Pt 15 Cr 7 B 3 )-z mol% (SiN) target, in the range of z = 2 to 14, the addition amount of SiN was changed, and each was fabricated. In the same manner as in Example 1, a single-layer vertical medium was fabricated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com