Device and method for measuring flux in continuous casting of hot metal

A technology for molten metal and flow metering, which is used in metal processing equipment, casting melt containers, casting equipment, etc., and can solve problems such as severe fluid flow asymmetry, liquid metal discharge asymmetry, and uncontrollable metal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The invention relates to a metering nozzle for flow control of liquid metal and capable of reducing clogging. The metering nozzle includes a top plate, and the axis of the flow channel in the top plate deviates from the main central axis of the nozzle.

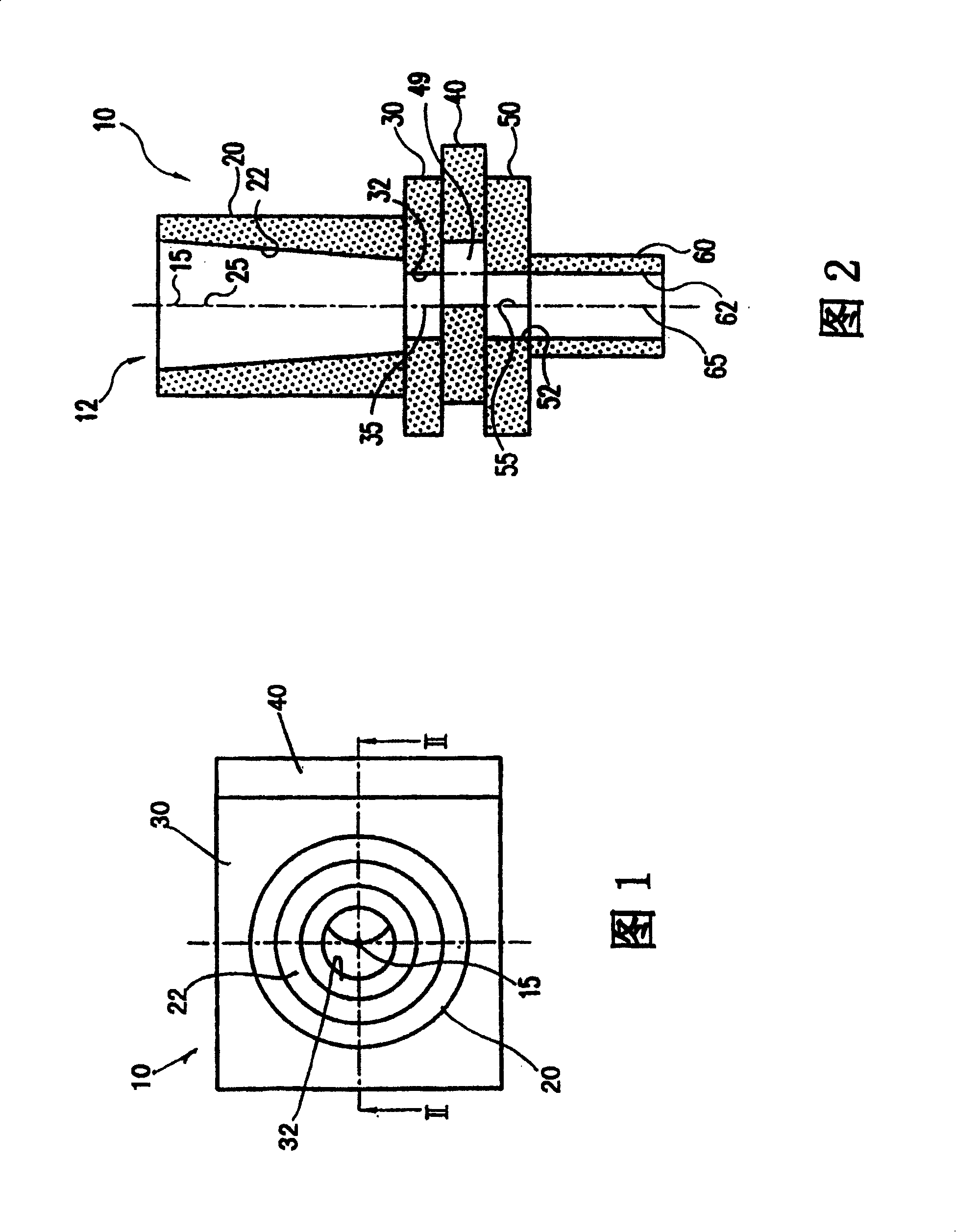

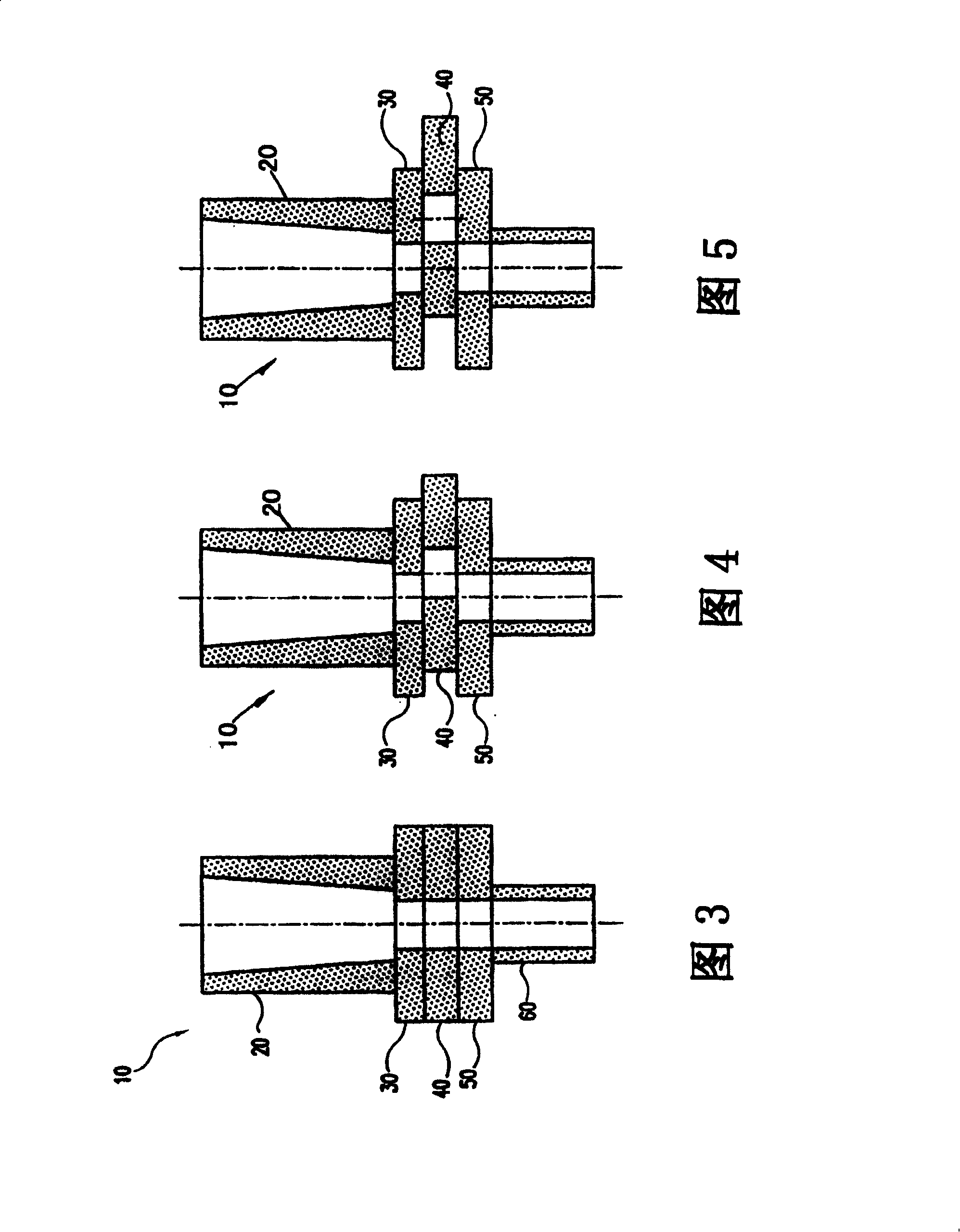

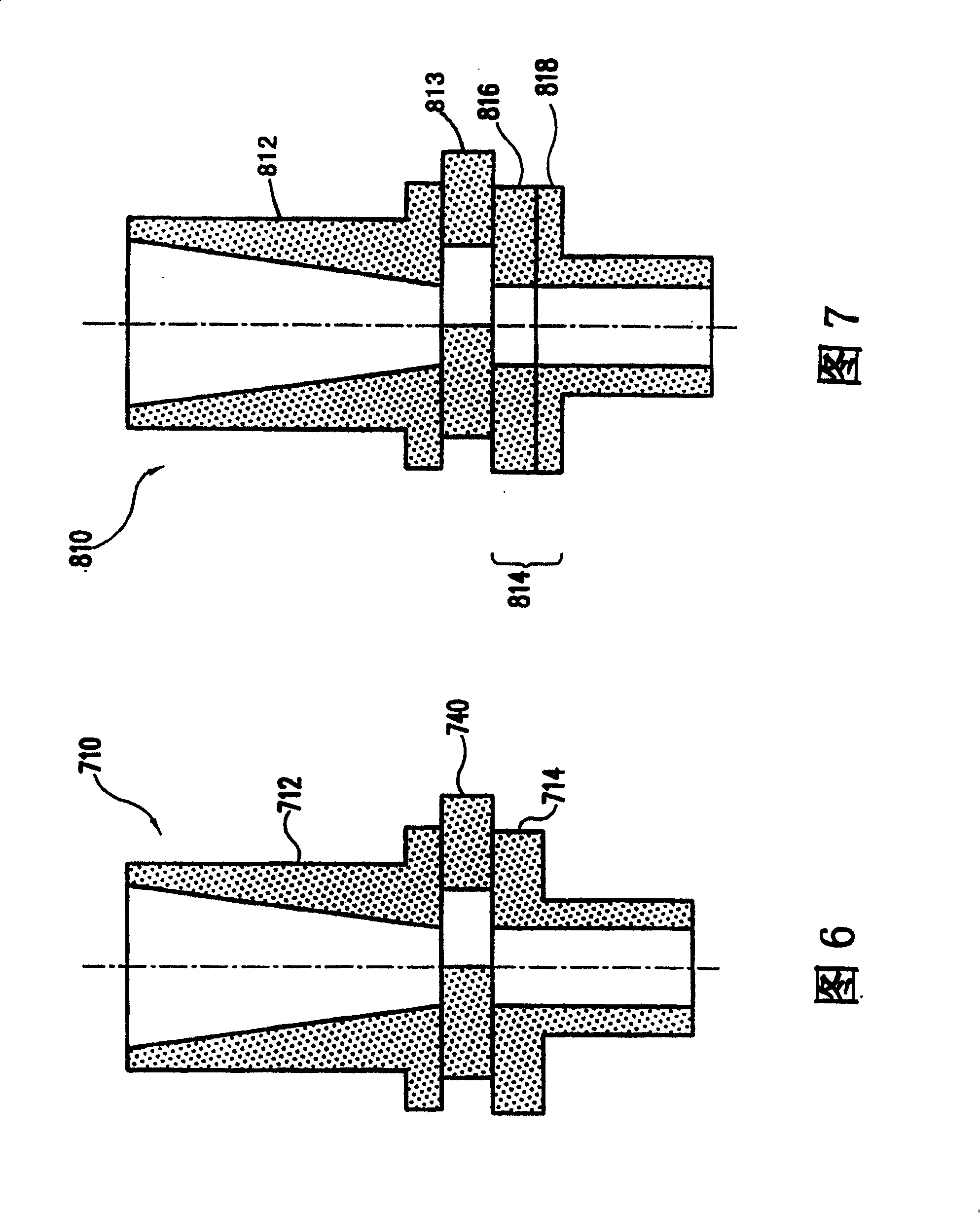

[0077] Referring to FIGS. 22-28 , the first embodiment of the metering nozzle 1010 of the present invention includes an injection nozzle 1020 , a top plate 1030 , a throttle plate 1040 , a bottom plate 1050 and an outlet pipe 1060 . The flow channel hole 1022 in the injection nozzle 1020 may have a conical cross-section, but other shapes may also be used. The flow channel holes 1042 and 1052 in the throttle plate 1040 and base plate 1050 are shown as simple cylinders, but other shapes may be used. Likewise, the flow channel holes 1062 in the outlet tube 1060 are shown as cylindrical, but other shapes may be used.

[0078]As shown in FIG. 23 , flow channel bores 1022 , 1052 and 1062 of injection nozzle 1020 , base plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com