Camellia board decoration wall and its preparation method

A camellia board and decorative wall technology, applied in the field of interior wall decoration materials, can solve the problems of high cost, toxic and harmful to human body, etc., and achieve the effects of strong practicability, high use value and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

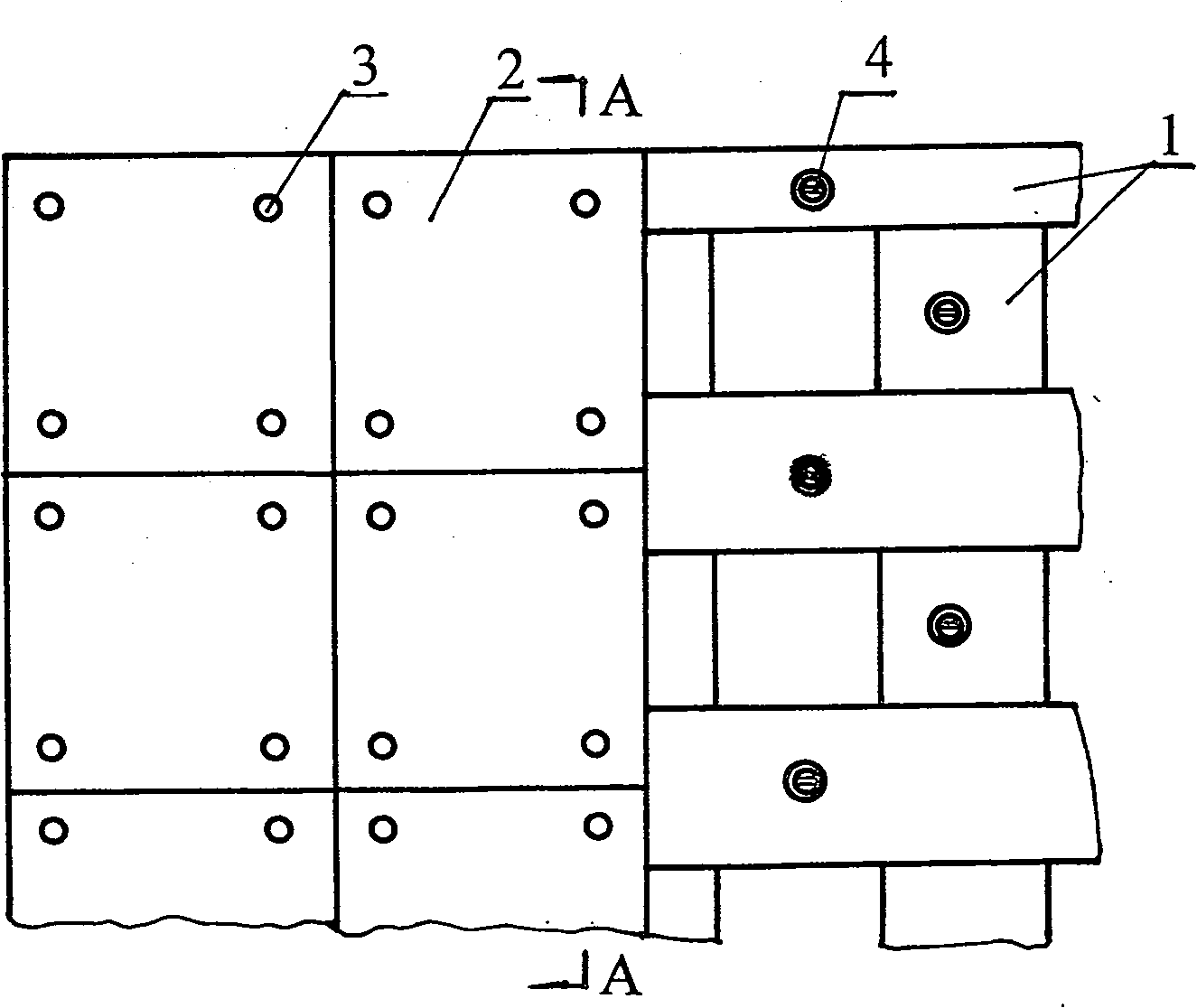

[0039] Example 1: In figure 1 , figure 2 , image 3 , Figure 4 Among them, the bracket 1 made of horizontally and vertically intersecting strips is fixedly connected to the wall with bracket screws 4, and the camellia board 2 is a square thin plate with a thickness of 3 cm. The pin holes connect the camellia boards with the brackets, the bamboo nails are non-polluting and rust-proof, and are safe to use. The camellia boards on the wall are spliced with each other to form a spliced camellia board decorative wall.

Embodiment 2

[0040] Example 2: In Figure 5 , Figure 6 Among them, the periphery of the camellia plate 2 is installed with a cross-section "T"-shaped strip partition, and the partition screw 6 is connected with the support 1 through the strip partition. The two sides of the "T" shape of the bar-shaped partition can be pressed and fixed to the side of the adjacent camellia board. The camellia board is a rectangular thin plate with a thickness of 2cm. There are partitions between the camellia boards on the wall. Made into a clapboard type camellia board decoration wall.

Embodiment 3

[0041] Example 3: In Figure 7 , Figure 8 Among them, the camellia plate 2 is a diamond-shaped thin plate with a thickness of 1.5 cm, which is inlaid in the lattice frame formed by the intersection of horizontal and vertical strips of the support 1. Made of mosaic camellia plate decoration wall.

[0042] The preparation method of the camellia plate decorative wall is:

[0043] Production of camellia raw materials: in September every year, the blooming flowers of tea trees, that is, camellias, are picked, cooled, dried at a constant temperature of 30°C and flower selection production process to make camellia raw materials;

[0044] Production of tea raw materials: picking fresh leaves of tea trees in July every year, spreading them for 4 hours, with a thickness of 25cm; curing them for 1 hour at a temperature of 110°C; kneading for 4 minutes at the beginning, so that 80% of the leaves are wrinkled; Part of the tea stalks, keep the stem content below 4%; dry, remove 75% of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com