Miniature efficient self-circulating electronic cooler

An electronic cooling and self-circulation technology, which is applied in the fields of electrical solid devices, cooling/ventilation/heating transformation, instruments, etc., can solve the problems of low heat flux density, low reliability, high operation and maintenance costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

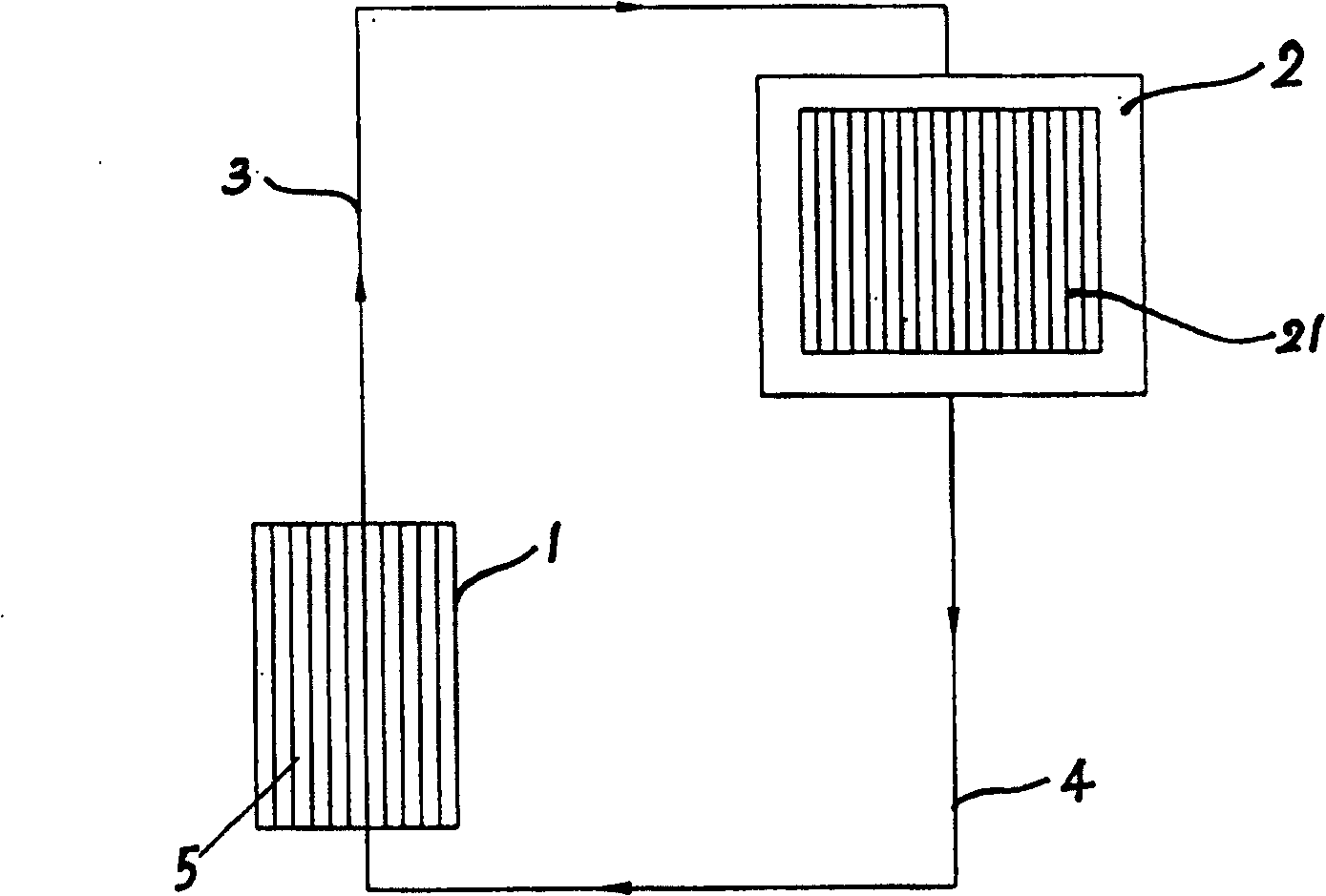

Embodiment 1

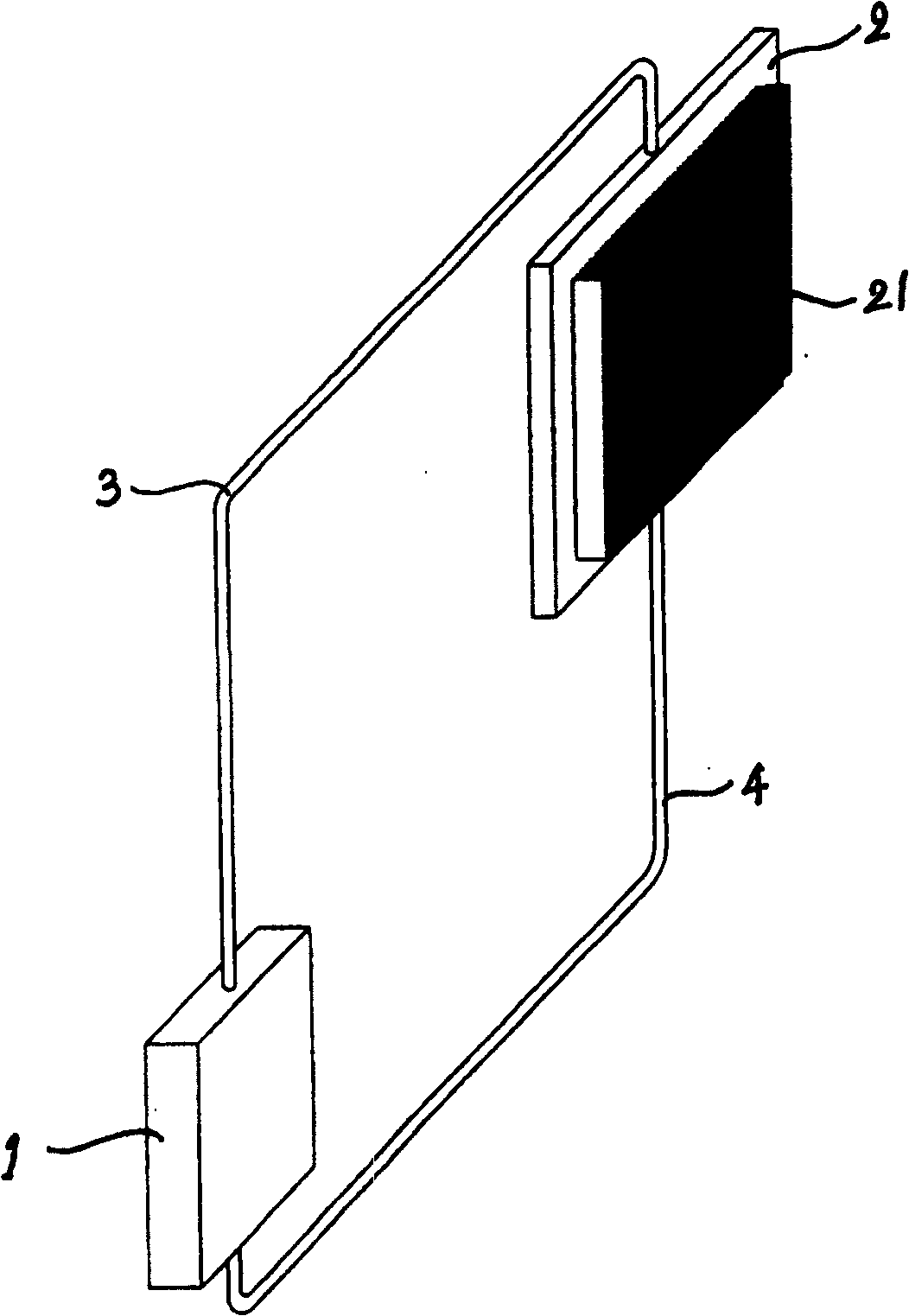

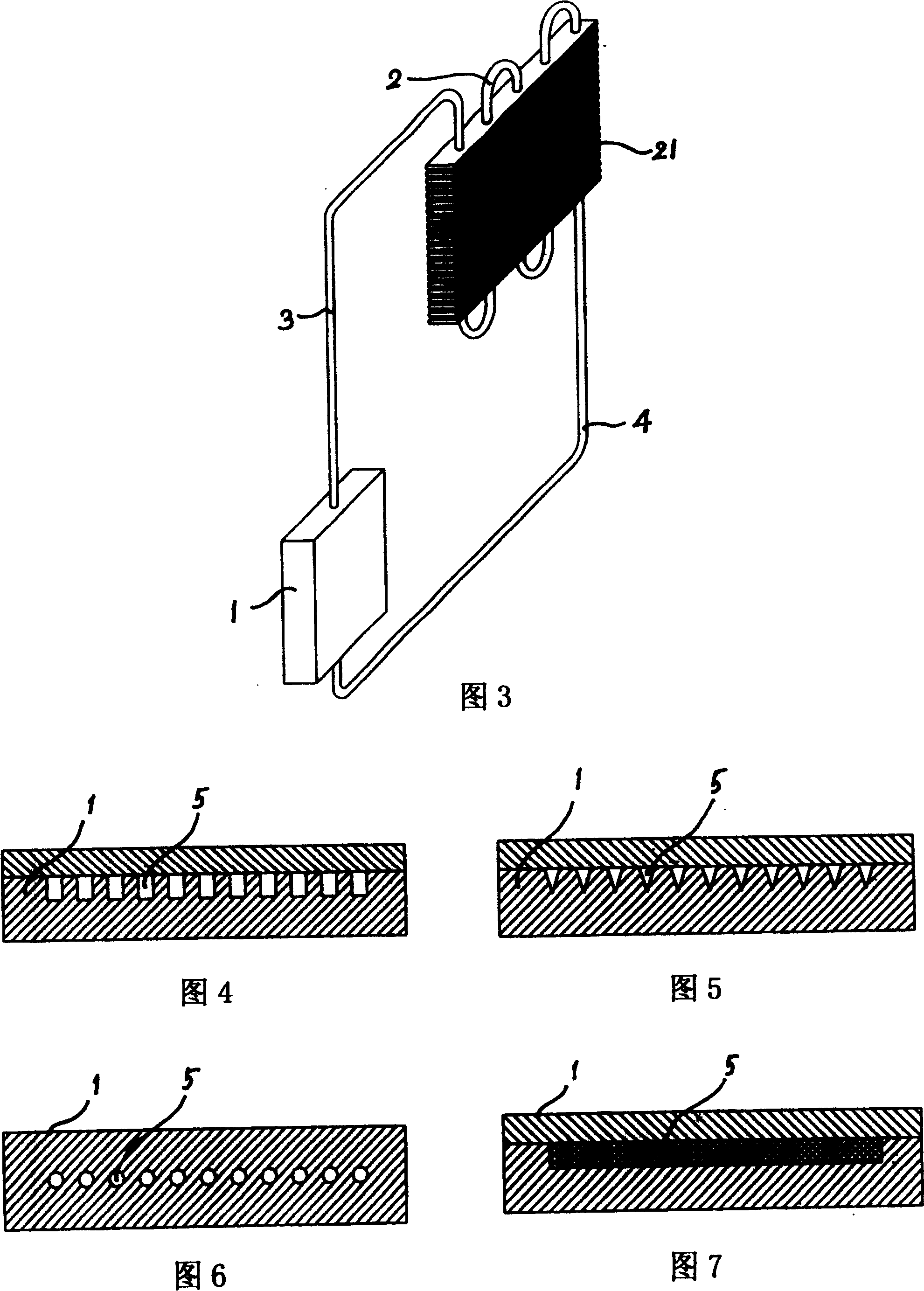

[0024] This miniature high-efficiency self-circulating electronic cooler such as figure 2 As shown, the microchannel evaporator 1, steam pipe 3, condenser 2 and liquid pipe 4 are connected in series in sequence to form a one-way circulation loop, wherein the microchannel evaporator 1 is processed on a copper plate base to process multiple parallel micro Groove is packaged with a copper plate on it, and the two ends are packaged with metal blocks and leave input and output ports, thereby forming the micro channel 5 in the micro channel evaporator 1, the cross section of said micro channel is square, as shown in Figure 4 As shown, the width and depth of the microchannels are within 3 mm. The cross-section of said micro channel can also be triangular or circular, as shown in Fig. 5 and Fig. 6 . The structural form of forming said microchannel can also be shown in Figure 7, that is, a porous medium is assembled in the copper plate base of microchannel evaporator 1 to form said m...

Embodiment 2

[0026] The miniature high-efficiency self-circulating electronic cooler is shown in Figure 3, and the microchannel evaporator 1, the steam pipe 3, the condenser 2 and the liquid pipe 4 are sequentially connected in series to form a one-way circulation loop. Wherein the structure of the microchannel evaporator 1 is basically the same as that of the first embodiment. The condenser 2 is a serpentine copper tube with cooling fins 21 installed on the outside. The condenser 2 is located above the microchannel evaporator 1, so that the liquid working fluid filled in the circuit can form a self-circulation in the circuit under the action of gravity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com