Measuring method for leakage of hydraulic system and its application

A technology of hydraulic system and measurement method, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and decrease rate of fluid, etc., which can solve the problems of poor versatility and cumbersome measurement methods, and achieve strong versatility and measurement The method is simple and fast, and the effect of reducing production and equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

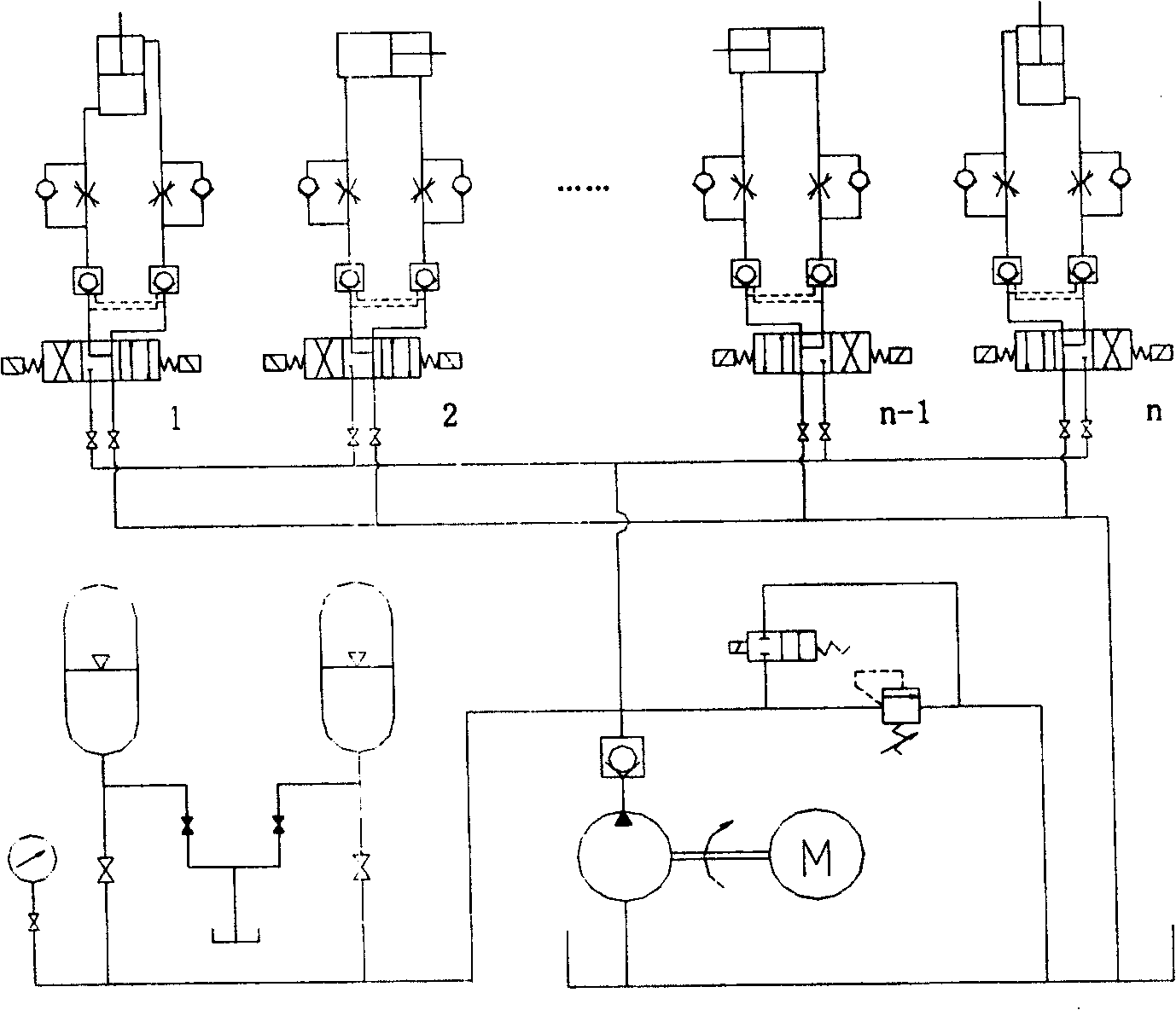

[0033] 1. Basic principles

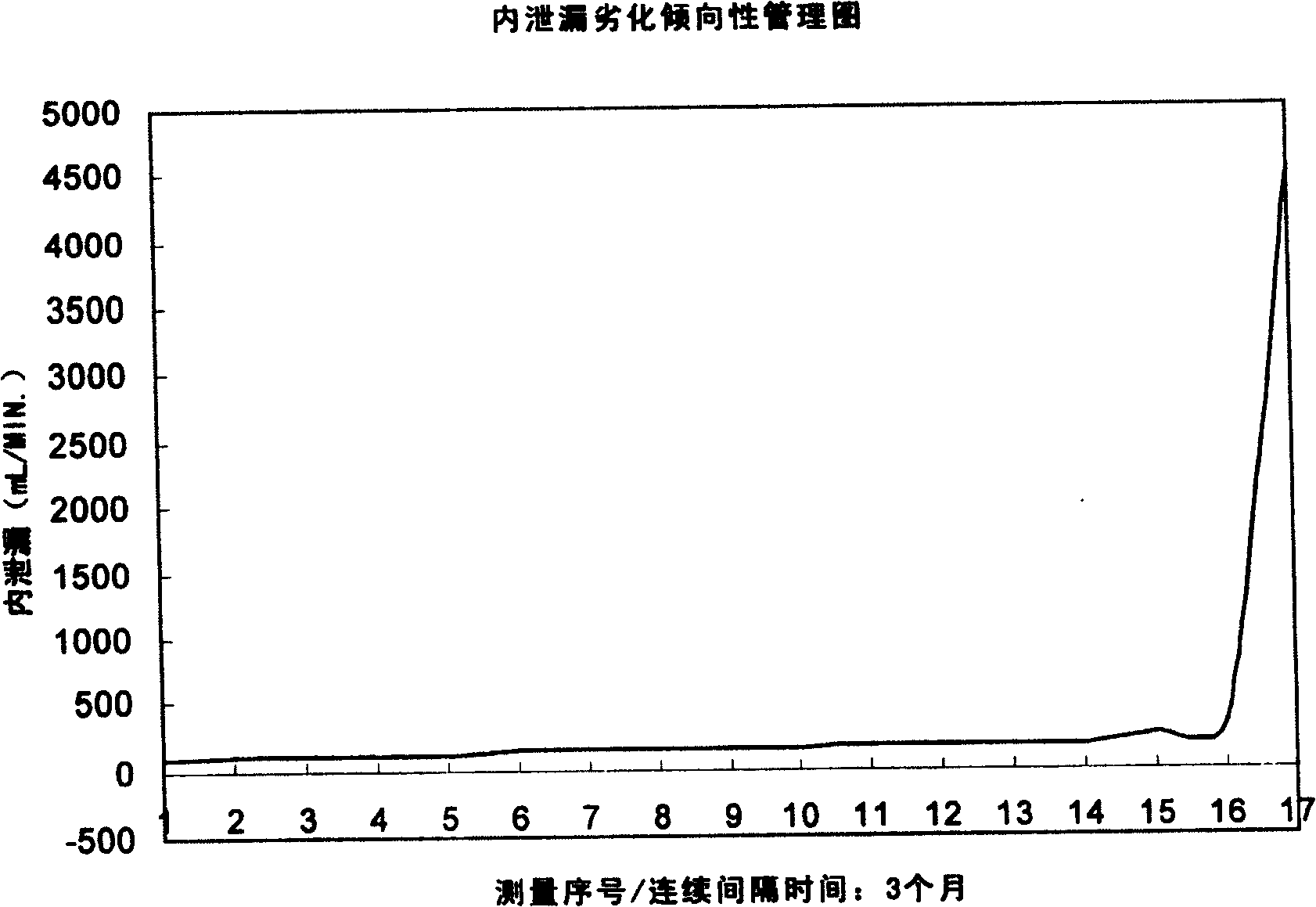

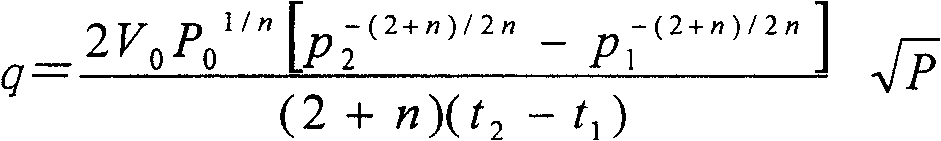

[0034] Under certain conditions, the accumulator is used as an independent oil supply source, the internal leakage is the only load, and the internal leakage orifice is regarded as a small orifice orifice. All internal leakage is directly leaked from the high-pressure chamber to the low-pressure chamber. Using the pressure oil provided by the accumulator and the internal leakage of the system to establish an equation, two basic algorithms for the internal leakage flow of the hydraulic system can be obtained: 1. The average value algorithm; 2. The calculation method of the small orifice throttling formula:

[0035] Q ‾ = ΔV ΔT = V 0 [ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com