Compact multi-element cascade cyclic energy transferring device

A technology of circulators and components, applied in the field of node-type stripline circulators, can solve the problems of increasing the cost of multi-node stripline circulators, adverse effects on the performance of stripline circulators, uneven tolerances, etc., to achieve More consistent return loss values, lower overall cost, eliminates transformer location effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] US Provisional Patent Application No. 60 / 311,709, filed August 10, 2001, is incorporated herein by reference.

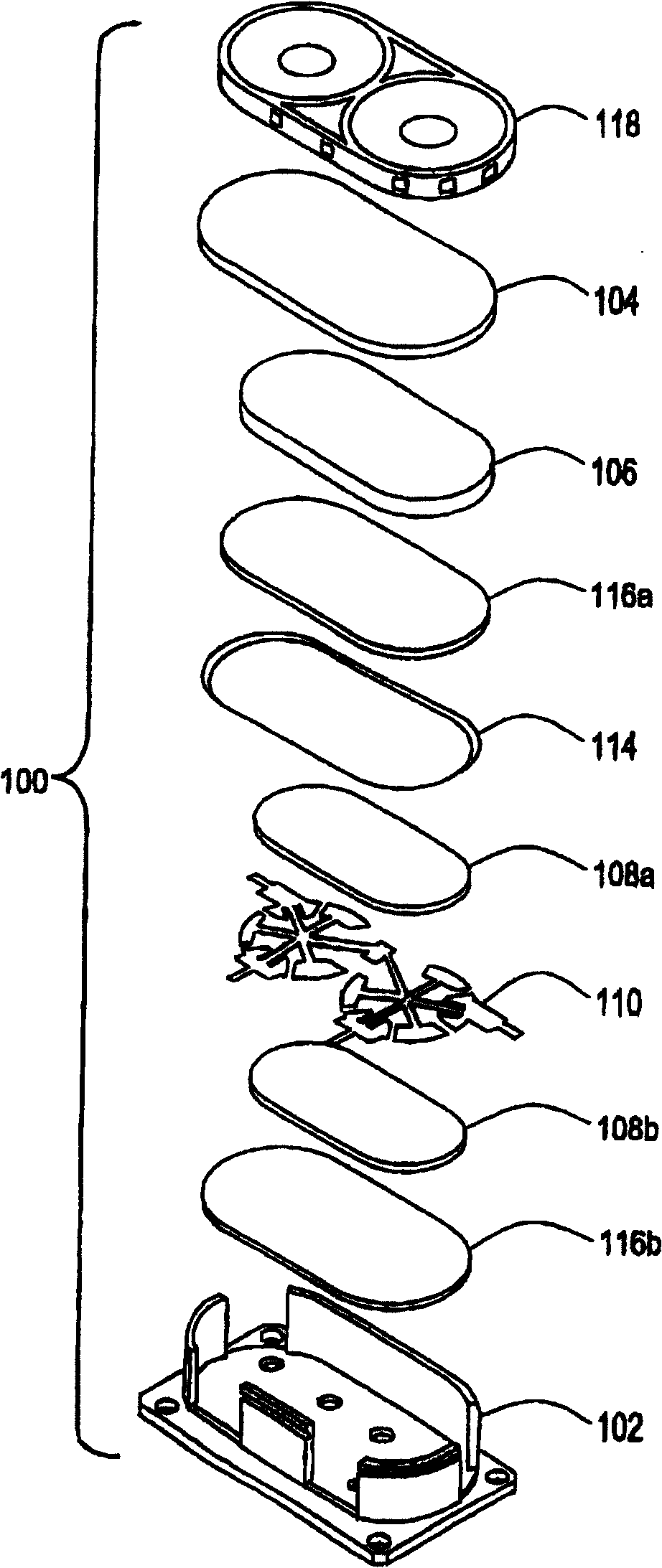

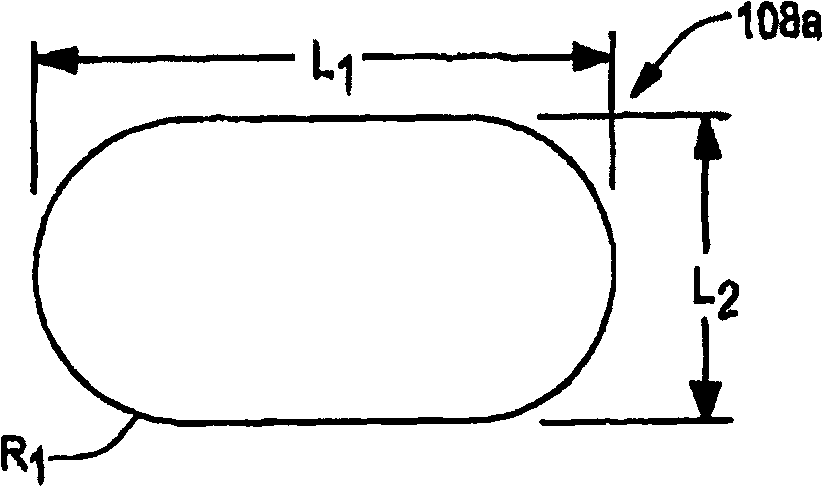

[0022] The junction-type stripline circulator has enhanced electrical and mechanical properties, and reduces manufacturing costs. In the junction-type stripline circulator, oval-shaped permanent magnets and oblong ferrite components are used in multiple junctions of the circulator in order to eliminate uneven tolerance build-up and uneven Permittivity dielectrics, the accumulation of this non-uniform tolerance and non-uniform dielectric constant dielectrics can degrade the mechanical and electrical performance of the device. Furthermore, by providing elliptical permanent magnets and oblong ferrite components in a multi-junction stripline circulator, the overall part count and overall assembly time of the device can be reduced, thereby reducing inventory and manufacturing costs.

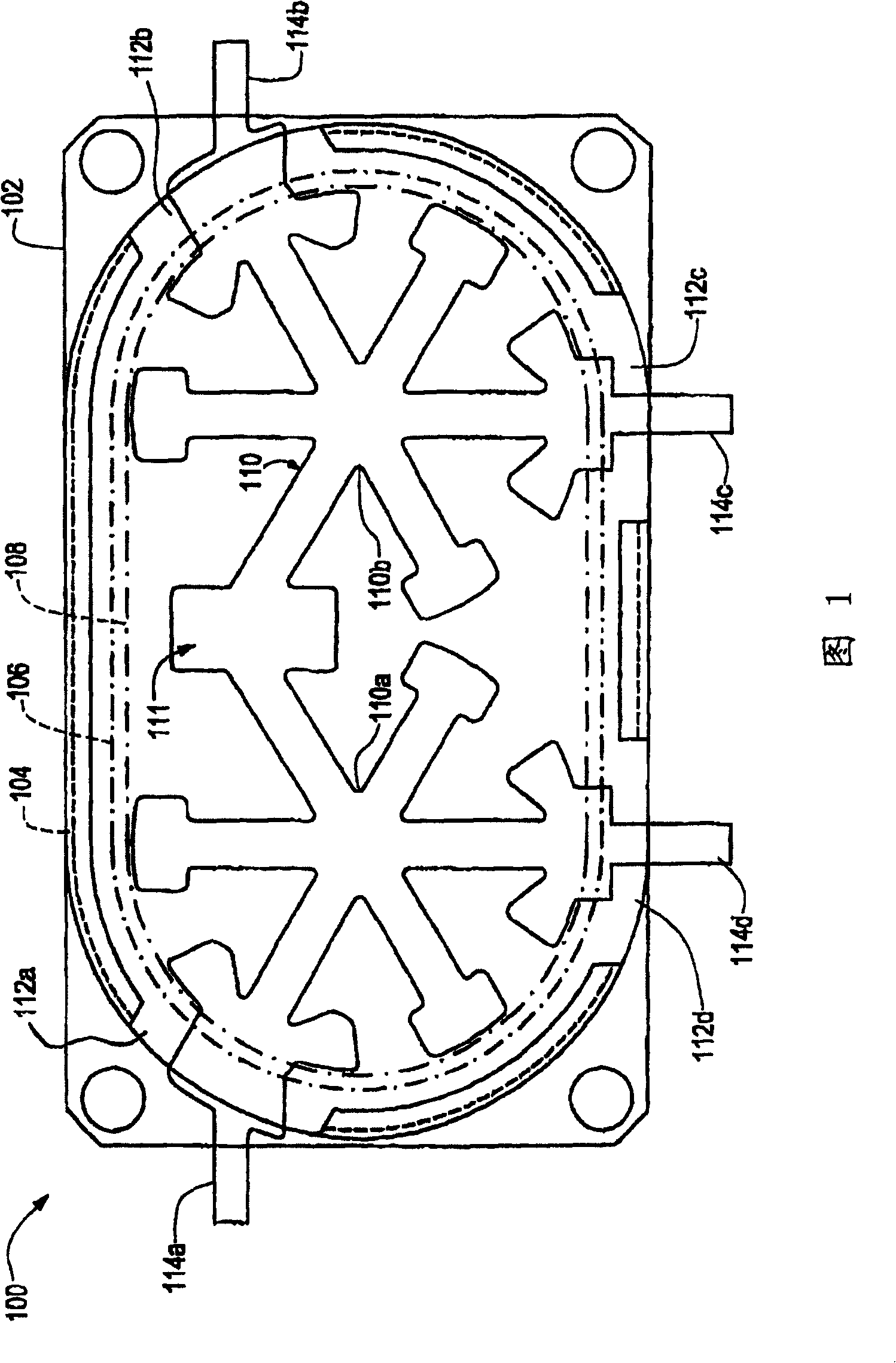

[0023] FIG. 1 shows a plan view of an illustrative embodiment of a compact multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com