Mesoporous molecular sieve containing Y-zeolite secondary constitutional unit and preparing method thereof

A technology of secondary structural units and mesoporous molecular sieves, applied in molecular sieves and base exchange compounds, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., to achieve improved amorphous structure characteristics, good catalytic performance, and increased acid content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

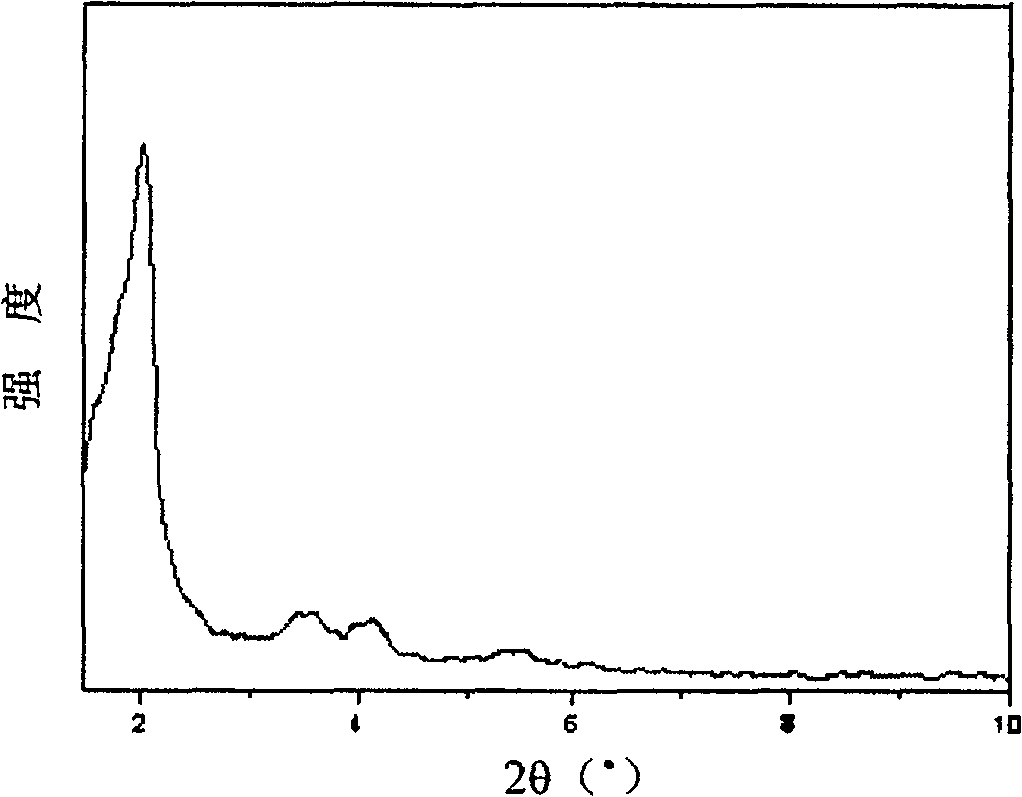

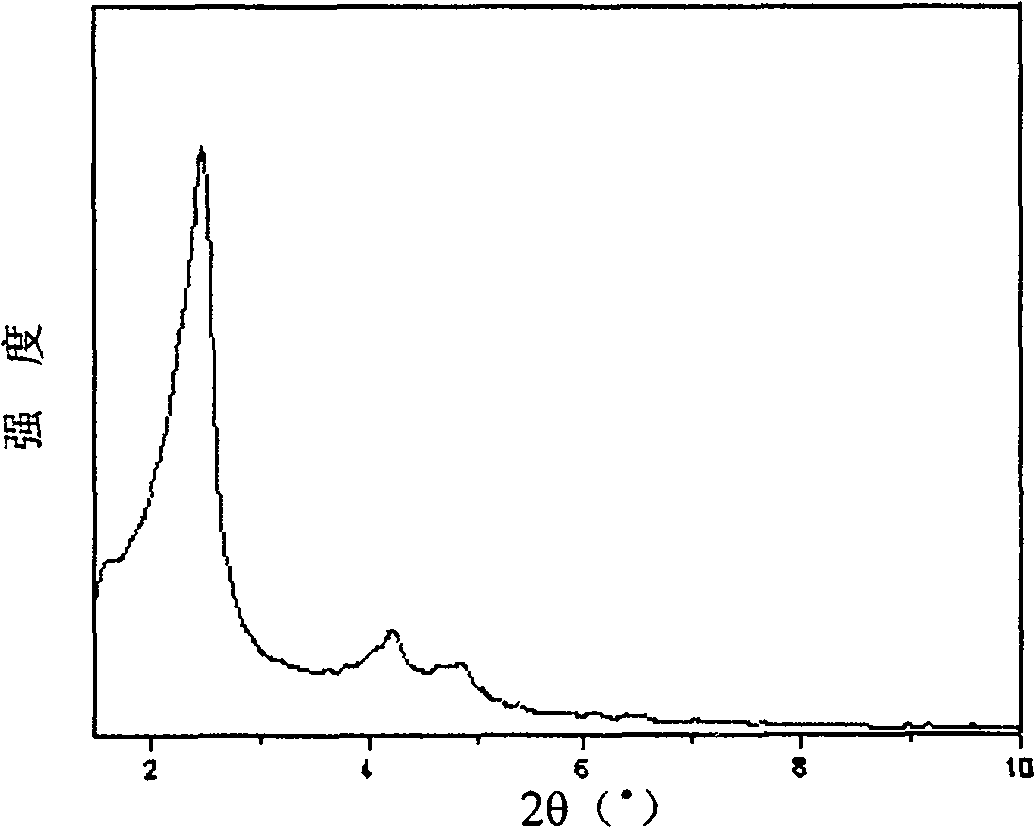

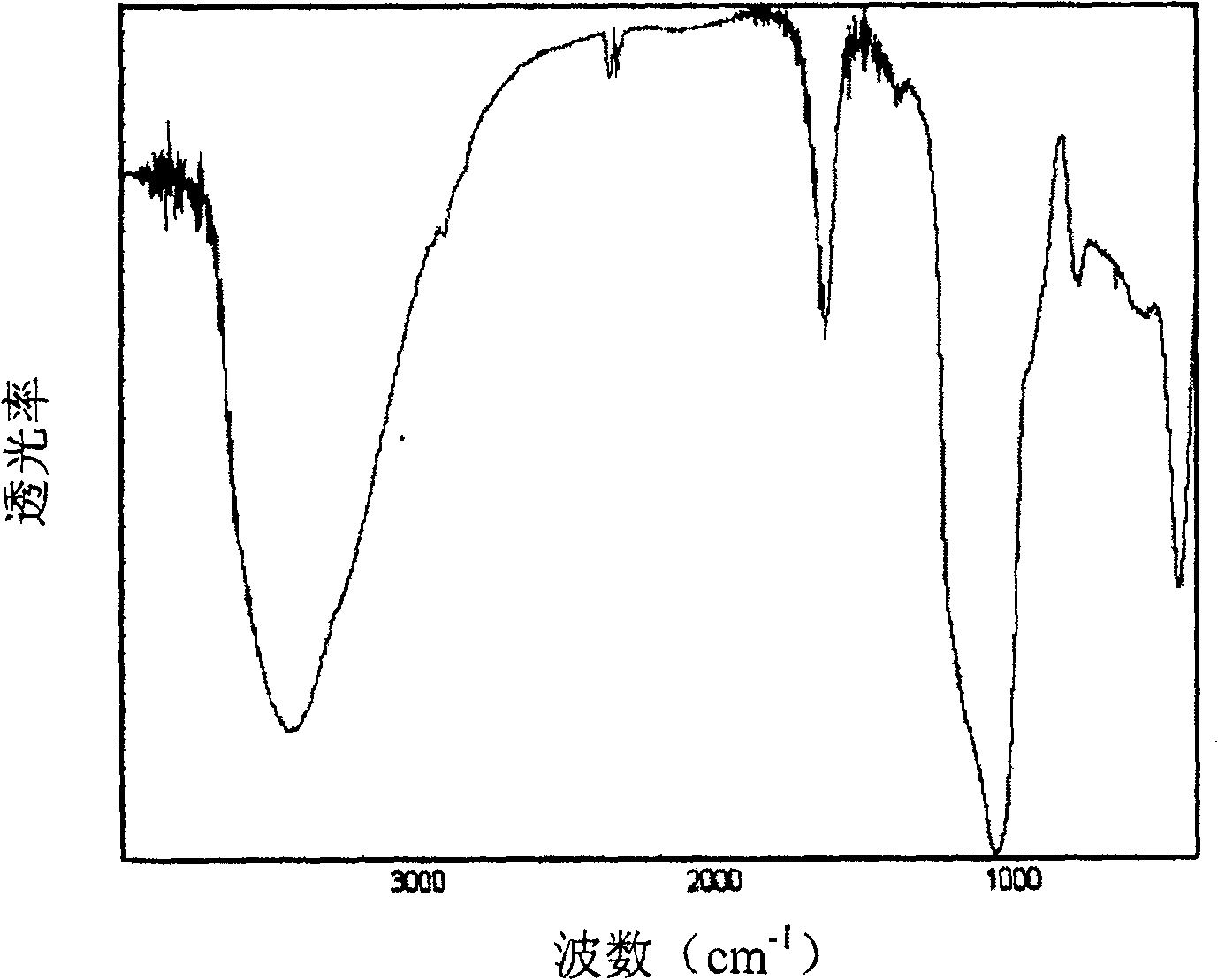

Method used

Image

Examples

Embodiment 1

[0027] Dissolve 0.357g of sodium hydroxide and 0.243g of sodium metaaluminate in 4ml of deionized water, stir and clarify, then add 5ml of homemade sodium silicate solution (SiO 2 25.4%, Na 2 O 7.4%), stirred evenly, put into a sealed polypropylene container, stirred and reacted at 90°C for 18h. The above pretreated sol was dropped into the mixed aqueous solution of CTAB and SL, and the molar composition of the synthetic mixture was: SiO 2 : 0.06 Al 2 o 3 : 0.072CTAB : 0.012SL : 58H 2 O. Then adjust the pH to 11.3 with dilute sulfuric acid, and crystallize at 100°C for 72h. The product was suction filtered, washed, and dried at 80°C to obtain SBU-MCM-41 mesoporous molecular sieve (Si / Al=9).

Embodiment 2

[0029] Take by weighing 0357 sodium hydroxide and 0243g sodium metaaluminate, dissolve completely with 4ml deionized water, add 5ml homemade sodium silicate solution (SiO 2 25.4%, Na 2 O 7.4%), stirred evenly, put into a sealed polypropylene container, stirred and reacted at 120° C. for 9 h. The above pretreated sol is dropped into the mixed aqueous solution of CTAB and SL, and the molar composition of the synthetic mixture is: SiO 2 : 0.06 Al 2 o 3: 0.22 CTAB : 0.015SL : 98H 2 O. Then adjust the pH to 10.8 with dilute sulfuric acid, and crystallize at 120°C for 40h. The product was suction filtered, washed, and dried at 80°C to obtain SBU-MCM-41 mesoporous molecular sieve (Si / Al=9).

Embodiment 3

[0031] Dissolve 0.179g of sodium hydroxide and 0.122g of sodium metaaluminate in 2ml of deionized water, stir and clarify, then add 2.5ml of homemade sodium silicate solution (SiO 2 25.4%, Na 2 O 7.4%), stirred evenly, put into a sealed polypropylene container, stirred and reacted at 100°C for 12h. Add 2.4 ml of sodium silicate solution to the obtained sol, and continue stirring at 100° C. for 12 h. The above pretreated sol is dropped into the mixed aqueous solution of CTAB and SL, and the molar composition of the synthetic mixture is: SiO 2 : 0.028 Al 2 o 3 : 0.16CTAB : 0.013SL : 95H 2 O. Then the pH was adjusted to 11.0 with dilute hydrochloric acid, crystallized at 120°C for 48 h, the product was suction filtered, washed, and dried at 80°C to obtain SBU-MCM-41 mesoporous molecular sieve (Si / Al=18).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com