Negative electrode for secondary cell,secondary cell, and method for producing negative electrode for secondary cell

A secondary battery and production method technology, which is applied to secondary batteries, battery electrodes, non-aqueous electrolyte battery electrodes, etc., can solve the problems of process yield decline, frequent chamber cleaning, etc., and achieve the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

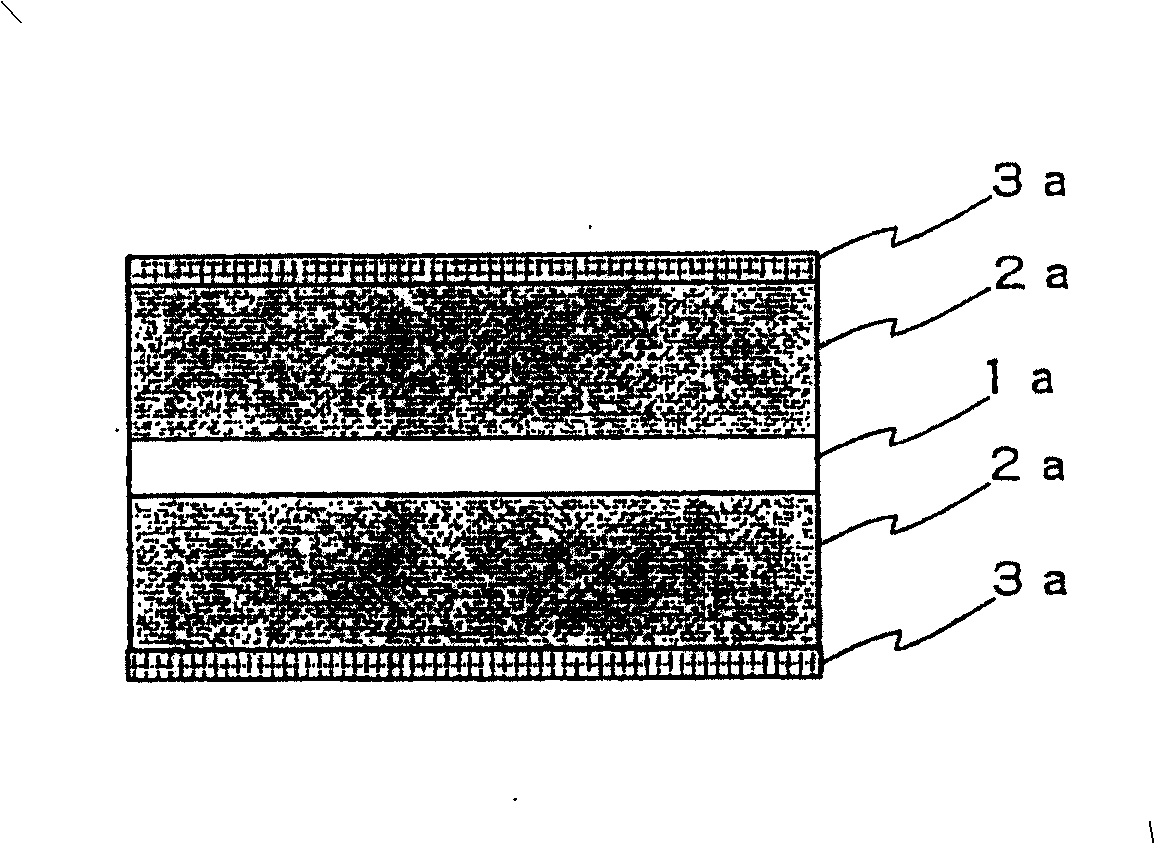

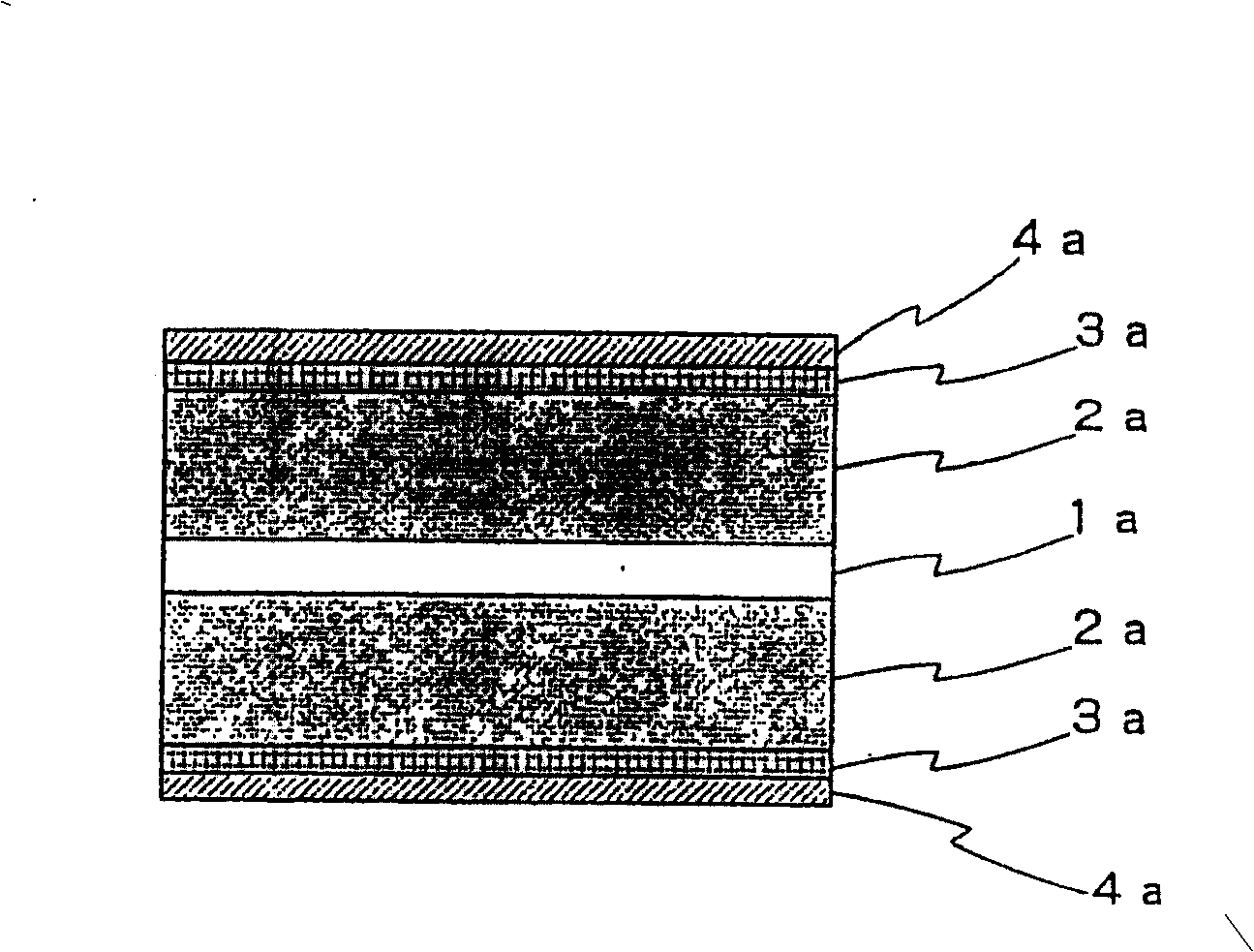

[0054] The present invention is described in detail with Example 1 below. The structure of the battery in this example is the same as figure 1 The same as shown, comprising a first layer 2a and a second layer 3a superimposed on a copper foil 1a providing a collector. Graphite is used as the main component of the carbon negative electrode of the first layer 2a. The second layer is mainly composed of Si powder dispersed in a binder, and is formed by a coating method. Next, the production method of the battery will be described.

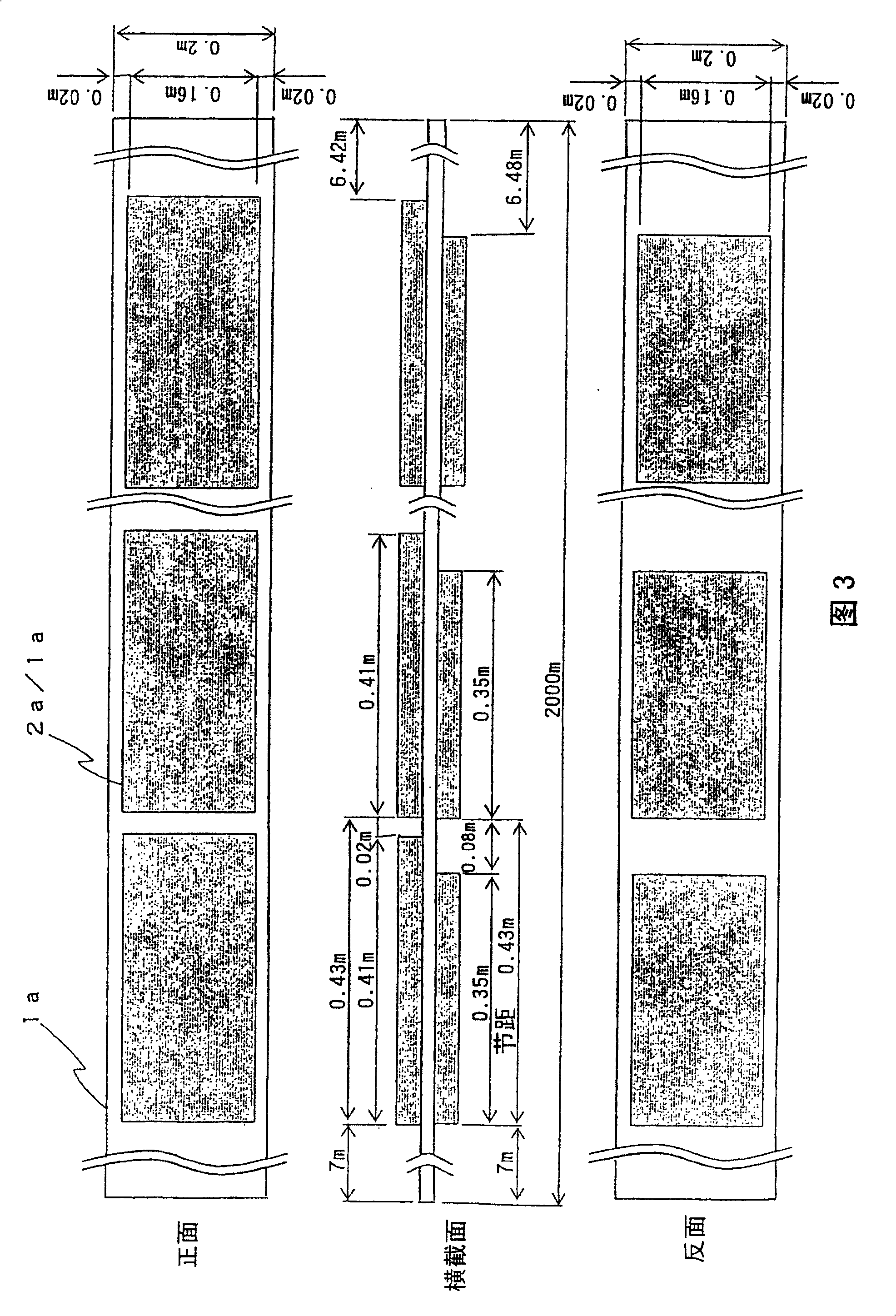

[0055]First, as shown in FIG. 3, a first layer 2a made of graphite with a thickness of about 50 μm is deposited on a copper foil 20 with a length of about 2000 m and a thickness of 10 μm, which serves as a negative electrode collector which is an elastic support. The first layer 2a made of graphite is formed by mixing graphite powder, polyvinylidene fluoride dissolved in N-methyl-2-pyrrolidone as a binder, and a conductive additive to form Paste, t...

Embodiment 2

[0067] The negative electrode was produced in the same manner as in Example 1, except that the active material contained in the second layer 3a was Li:Si alloy, and then the performance of the battery was evaluated. The experimental results are shown in Table 1. The initial charge / discharge efficiency in Example 2 was 92.4%, while that in Comparative Example 2 was 84.4%. It can be understood from the experimental results that the initial charge / discharge efficiency in Example 2 is high compared with Comparative Example 2 in which the second layer 3a (Li:Si alloy) is formed by vacuum deposition.

[0068] Assuming that the discharge capacity for one cycle is 100% when expressed as a percentage, the ratio of the discharge capacity for 500 cycles (C500 / C1 discharge capacity ratio) is greater than 80%, that is, even after the 500th cycle, the discharge capacity remains the same. It can maintain more than 80% of the initial capacity, which is much better than Comparative Example 2 ...

Embodiment 3

[0072] Produce negative pole with the same method as embodiment 1, only the active material that the second layer 3a contains is SiO X , and then evaluate the performance of the battery. The experimental results are shown in Table 1.

[0073] The initial charge / discharge efficiency in Example 3 was 89.1%, while that in Comparative Example 3 was 74.3%. It can be understood from the experimental results that the second layer 3a (SiO X ) is formed by vacuum deposition method Compared with Comparative Example 3, the initial charge / discharge efficiency in Example 3 is high.

[0074] Assuming that the discharge capacity for one cycle is expressed as a percentage, it is 100%, and the ratio of the discharge capacity for 500 cycles (C500 / C1 discharge capacity ratio) is greater than 80%, that is, even after the 500th cycle, the discharge capacity It can still maintain more than 80% of the initial capacity, which is much better than Comparative Example 3 (it is damaged after 200 cycle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com