Method for removing ammonia and dust from a waste gas that results during the production of fertilizers

A technology for preparing fertilizers and removing ammonia, applied in chemical instruments and methods, ammonium salt fertilizers, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

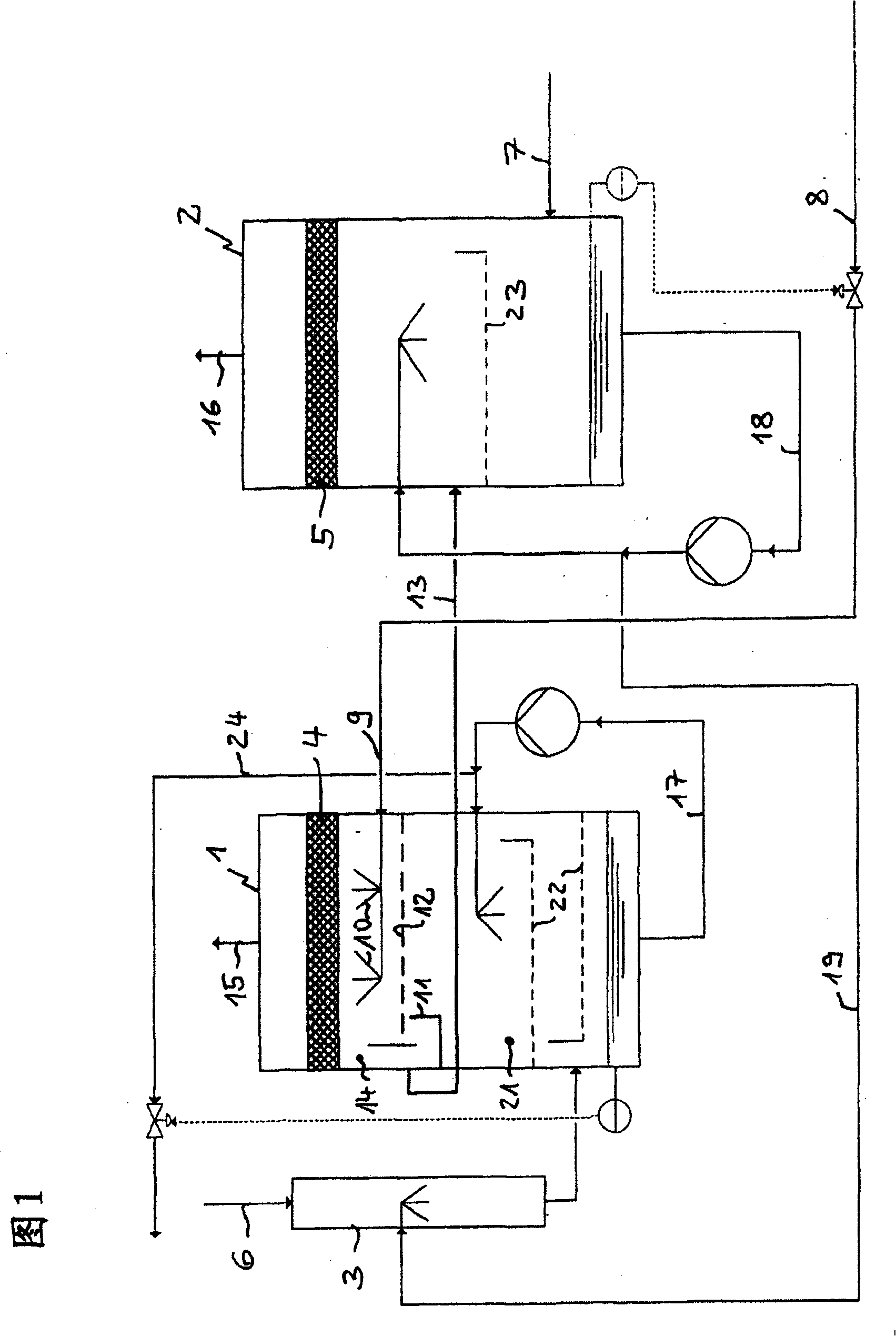

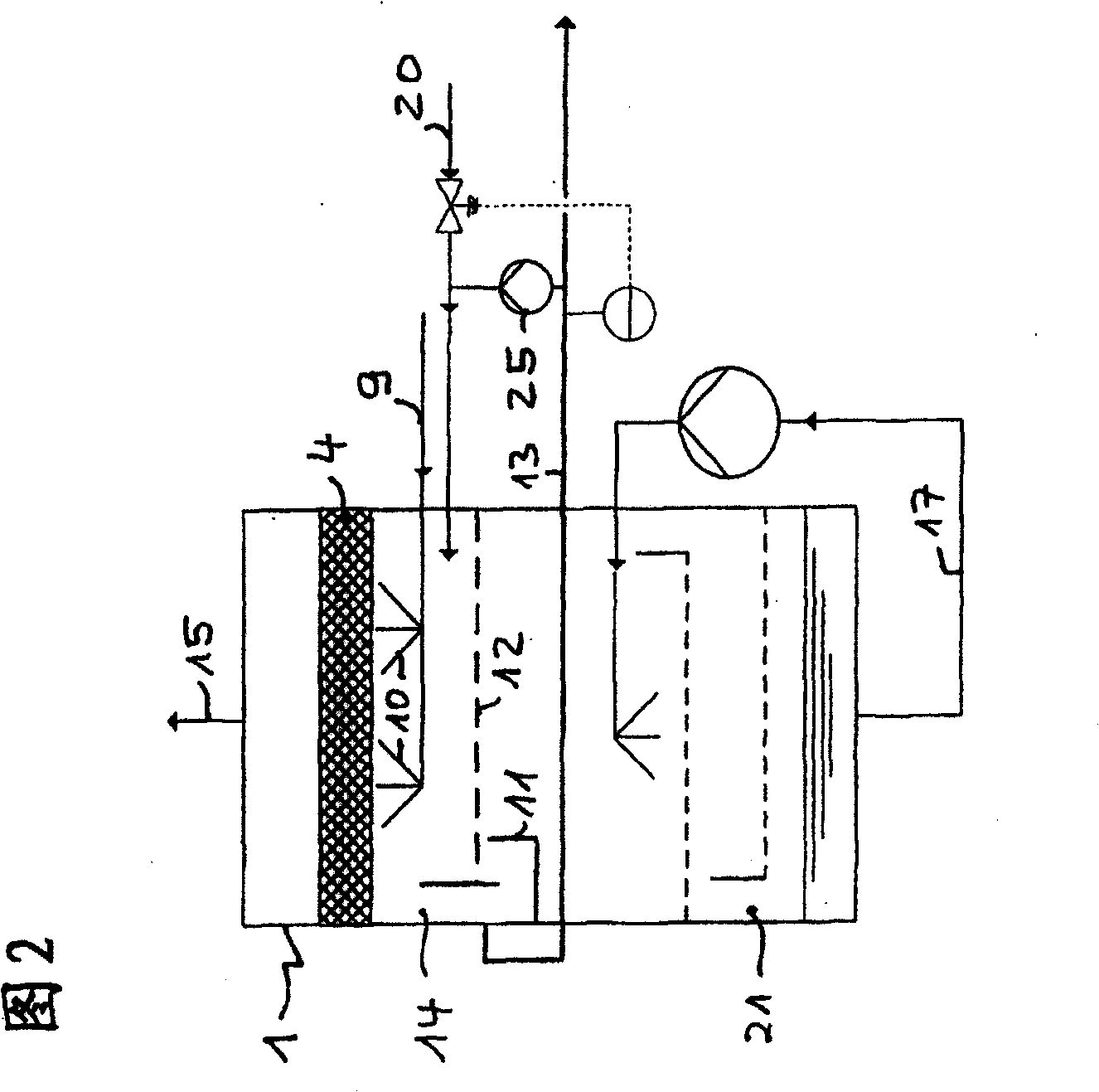

[0015] The plant for carrying out the method initially has a first scrubber 1 and a second scrubber 2 . The first scrubber 1 is preceded by a pre-cleaning stage 3 . A droplet separator 4 (demister) is installed in the upper region of the first scrubber 1 , likewise on the second scrubber 2 there is also a droplet separator 5 . The first scrubber 1 is divided into two scrubbing zones, in which a separating plate 12 (such as a bubble cap plate) and an outlet through which the liquid cannot pass, but which the gas can pass, are provided below the droplet separator 4 in order to form a fine scrubbing zone 14 11. Below the separating plate 12 is the main washing zone 21 of the first washer 1 .

[0016] The aforementioned plant components are preferably part of a plant for the production of fertilizer, preferably urea, and are connected to a granulator and cooler, not shown. The ammonia- and dust-laden exhaust gas is fed from a granulator (not shown) first into the pre-cleaning s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com