External control type fan coupling device

An external control and coupling device technology, applied in pump devices, clutches, fluid clutches, etc., can solve the problems that the size and weight of the fan coupling device cannot be reduced, the size and weight of the electromagnet are increased, and the flexibility of valve components is reduced. The effect of improving suction efficiency, reducing size and weight, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

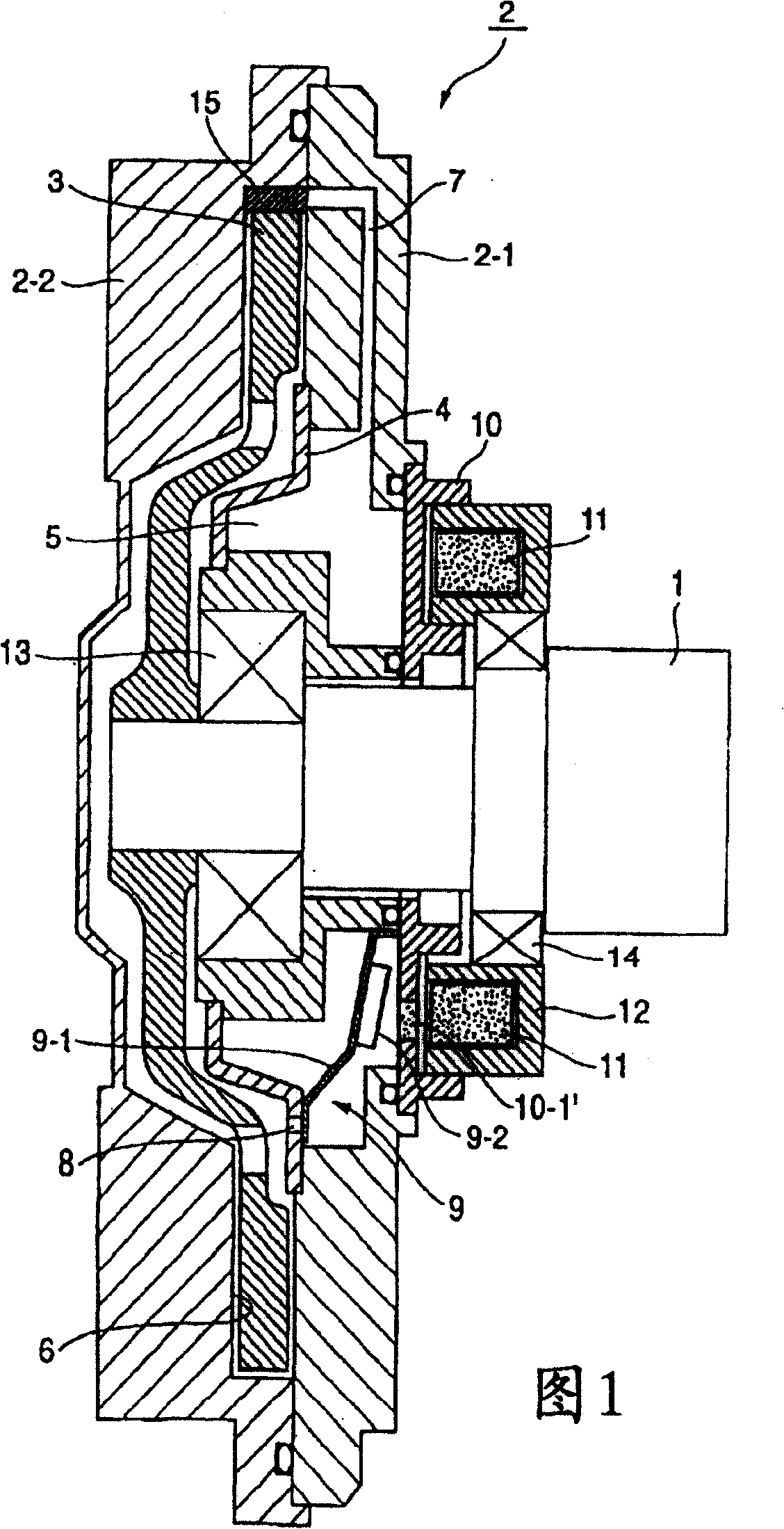

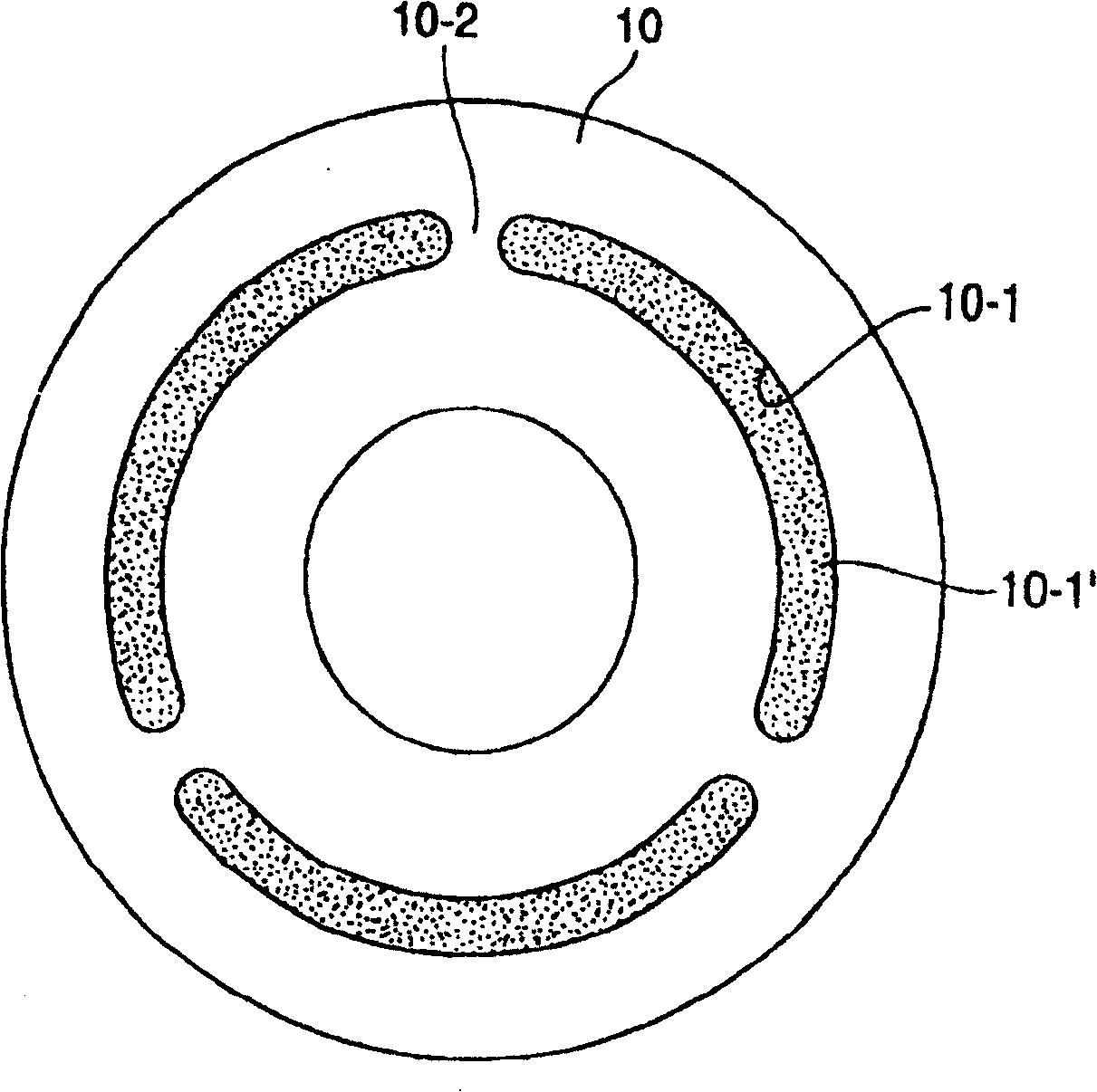

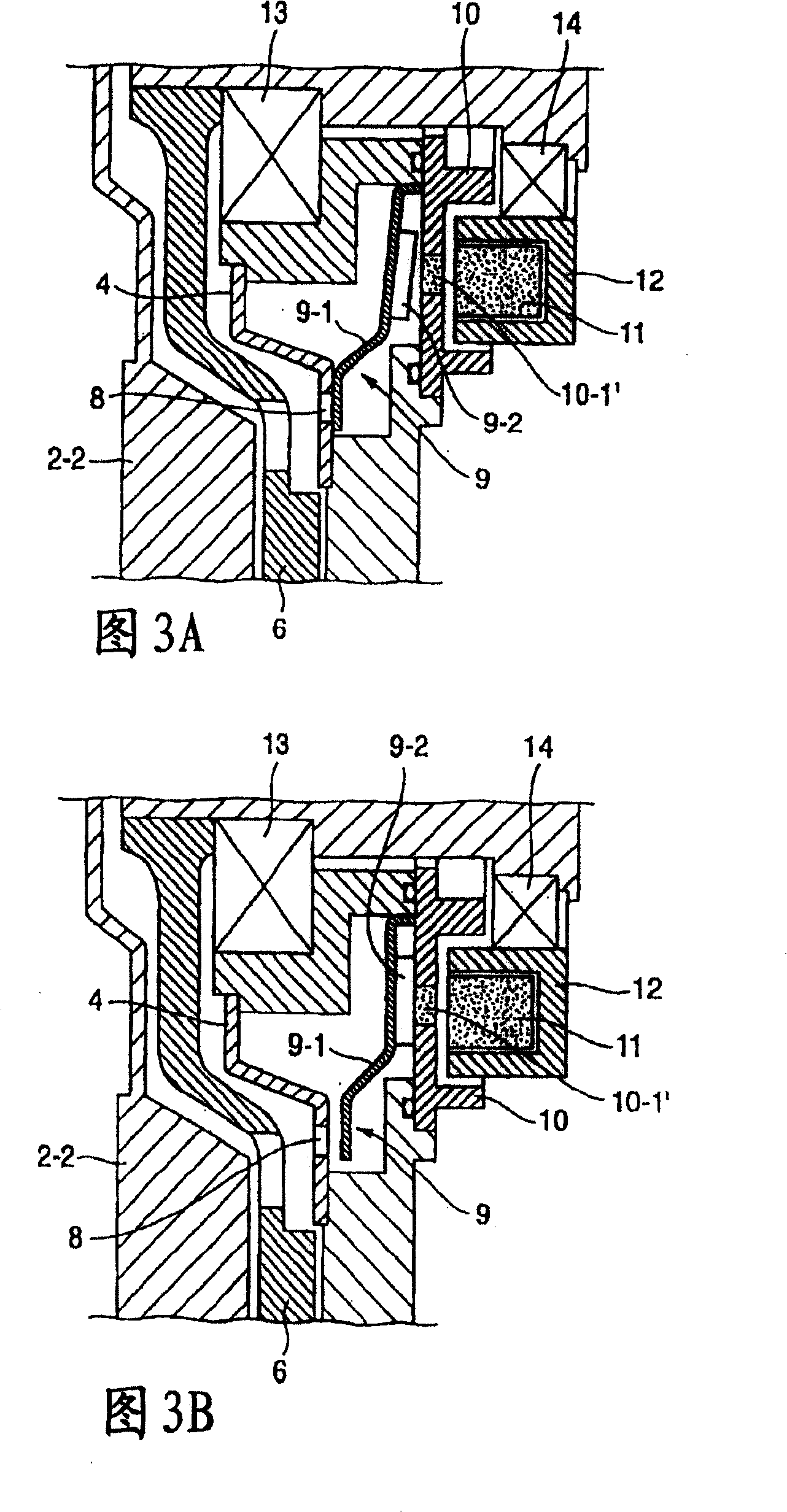

[0020] In Figure 1 to Figure 9 Among them, the number 1 indicates the rotating shaft (or drive shaft); the number 2 indicates the sealed shell; the number 2-1 indicates the shell; the number 2-2 indicates the cover; the number 3 indicates the drive plate; Oil tank; number 6 indicates torque transmission cavity; number 7 indicates oil recovery circulation channel; number 8 indicates oil supply adjustment hole; number 9 indicates oil supply valve parts; number 9-1 indicates leaf spring; number 9-2 indicates armature; number 10 Indicates a disc-shaped magnetic coil element (or magnetic component) having an annular portion and an arc-shaped slot; numerals 20 and 30 indicate annular magnetic coil elements (or magnetic components); numeral 40 indicates a non-annular magnetic coil element (or magnetic component); Numeral 11 denotes an electromagnet; Numeral 12 denotes an electromagnet support; Numerals 13 and 14 denote bearings; Numeral 15 denotes a baffle.

[0021] In the external...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com