Fabric used for making warm underclothes

A technology of thermal underwear and processing method, applied in the directions of underwear, dyeing method, fabric surface trimming, etc., can solve the problems of hygroscopicity, unsatisfactory air permeability, unsatisfactory color and brightness and elasticity, and lack of rich hand feeling, etc. Effects of soft texture and hygroscopicity, excellent texture and hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

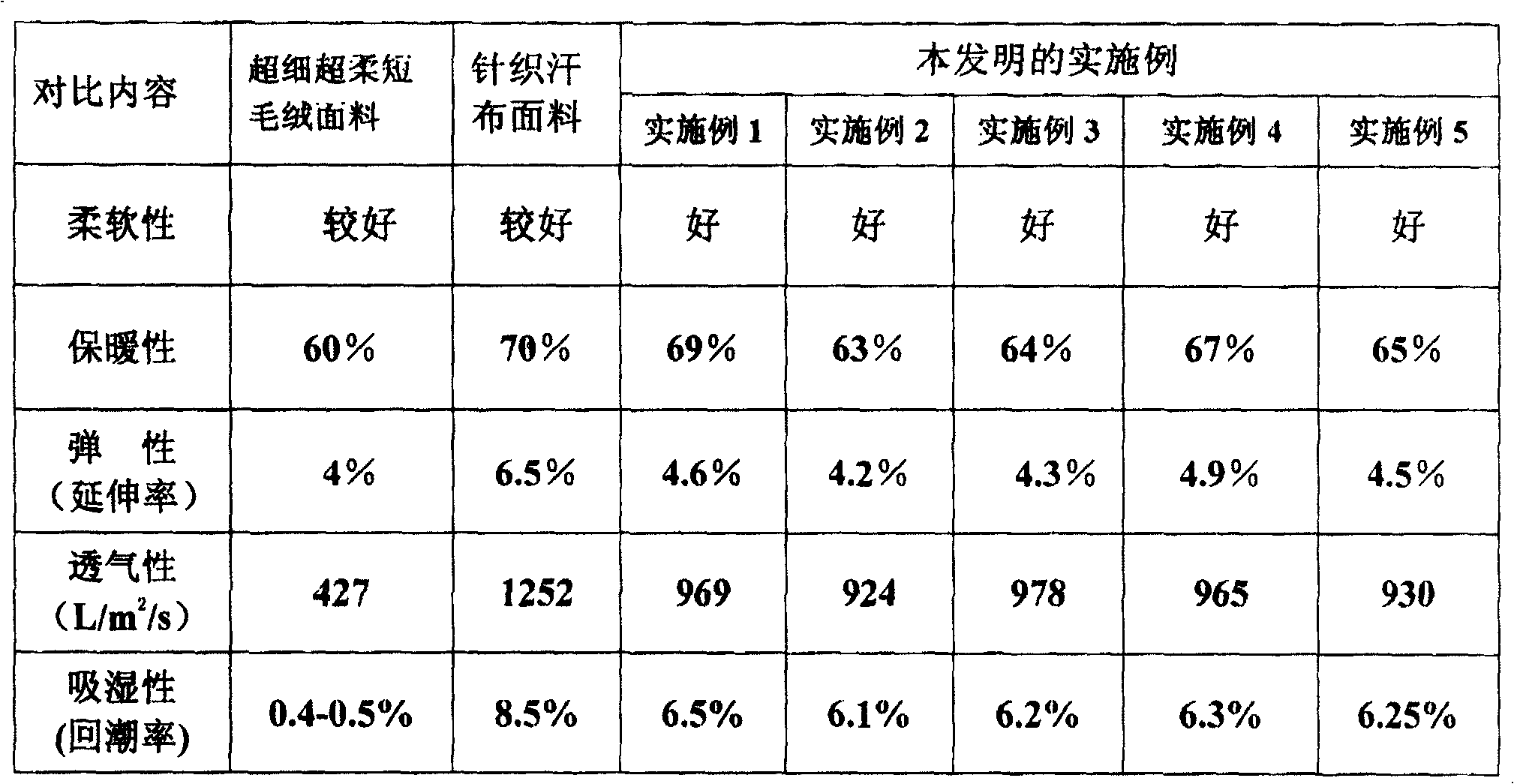

Examples

Embodiment 1

[0023] A) For weaving, select 150D / 288F superfine polyester fiber as the surface structure, and select 32S combed cotton spandex core-spun yarn as the bottom structure, in which: 150D / 288F has a content of 51.5% in the entire fabric, and cotton fiber in the entire fabric The content of spandex fiber in the whole fabric is 46%, and the content of spandex fiber in the whole fabric is 2.5%, and then put it into a double-sided machine such as a 32-needle, 38-hour double-sided large circular machine produced in Taiwan, China or Wuxi Hongwei Knitting Machine, Wuxi City, Jiangsu Province, China The 32-needle, 38-hour double-sided circular machine produced by Machinery Co., Ltd. weaves to obtain white gray cloth;

[0024] B) Put the white gray cloth obtained in step A) into a dyeing machine for pretreatment, such as a high-temperature double-overflow dyeing machine widely used in the printing and dyeing industry, and then add Adding soda ash 2g / L and adding such as the brand produced ...

Embodiment 2

[0029] Only change the content of 150D / 288F in the whole fabric into 61%, cotton fiber and spandex fiber into 38% and 1% respectively in the content of the whole fabric in step A); only change the content of soda ash in the step B) The dosage is changed to 1.5g / L, the scouring agent is changed to 2g / L, the chelating dispersant is changed to 0.9g / L, the temperature of the water bath is changed to 90°C, the processing time is changed to 35min, and the traveling speed of the cloth is changed to 20m / min Only change the softening agent for polyester in step D) into 5%, change the softening agent for cotton into 8%, change the bulking agent into 3%, change the softening agent into 3% for microfiber, and change the brightener into 4% , the bath ratio is changed to 1:8, and the processing time is changed to 65min; only the predetermined setting temperature in step E) is changed to 165°C, the cloth speed is changed to 30m / min, the finished product setting temperature is changed to 155°C...

Embodiment 3

[0031]Only change the content of 150D / 288F in the whole fabric in step A) into 58.5%, cotton fiber and spandex fiber in the content of the whole fabric into 40% and 1.5% respectively; Only change the content of soda ash in step B) The dosage is changed to 2.2g / L, the scouring agent is changed to 2.5g / L, the chelating dispersant is changed to 1.2g / L, the temperature of the water bath is changed to 95°C, the processing time is changed to 32min, and the cloth speed is changed to 22m / L min; only change the softening agent for polyester in step D) to 5.5%, the softening agent for cotton to 9%, the bulking agent to 2.5%, the softening agent for microfiber to 2.5%, and the brightener to 2.5% %, bath ratio is changed into 1: 9, and treatment time is changed into 70min; Only the setting temperature of presetting in step E) is changed into 155 ℃, the cloth speed is changed into 28m / min, and the finished product setting temperature is changed into 158 ℃, Cloth speed changed to 27m / min. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com