Novel mixed power system structure

A technology of hybrid power system and engine, which is applied in the direction of hybrid vehicles, power devices, air pressure power devices, etc., can solve the problems of high cost, large changes, and inability to achieve serialization, so as to achieve great industrialization potential and reduce development costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] Depend on Image 6 as shown, Image 6 6-1 is the engine cylinder, 6-2 is the motor stator, 6-3 is the engine speed sensor, 6-4 is the transmission housing, 6-5 is the motor rotor, 6-6 is the signal ring gear, 6- 7 is a clutch or hydraulic torque converter, 6-8 is a starter, 6-9 is a starter ring gear, and 6-10 is an engine crankshaft.

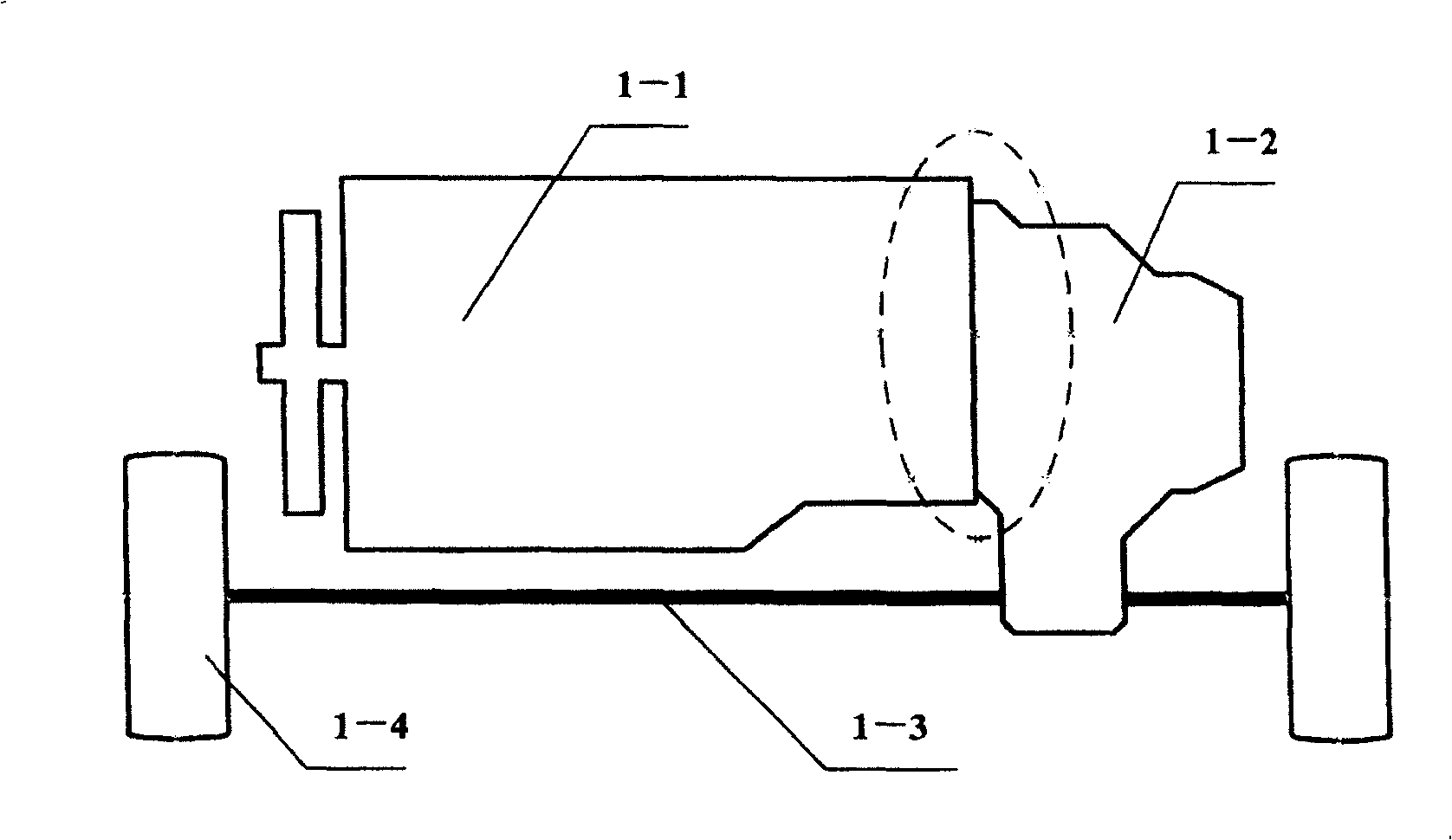

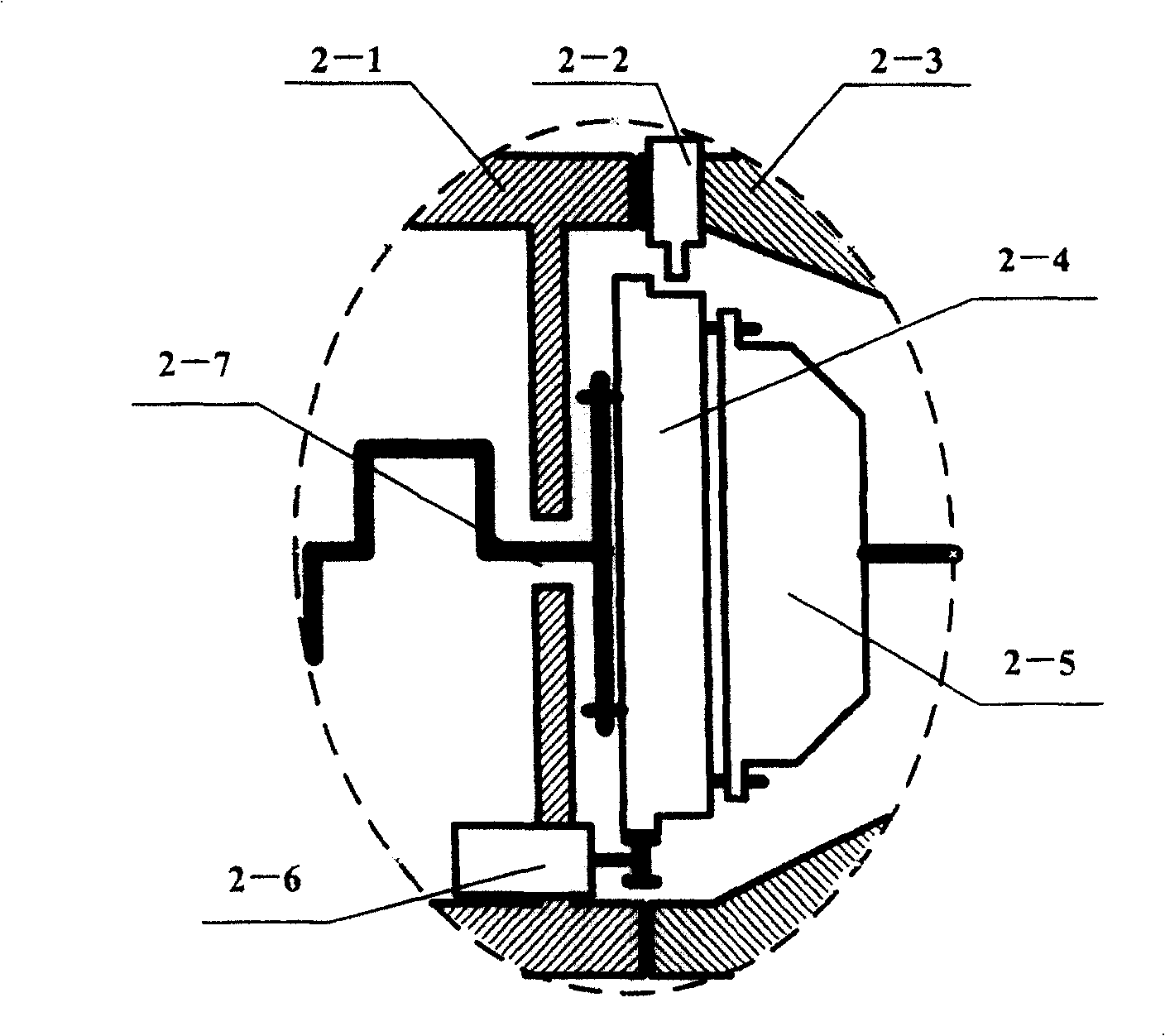

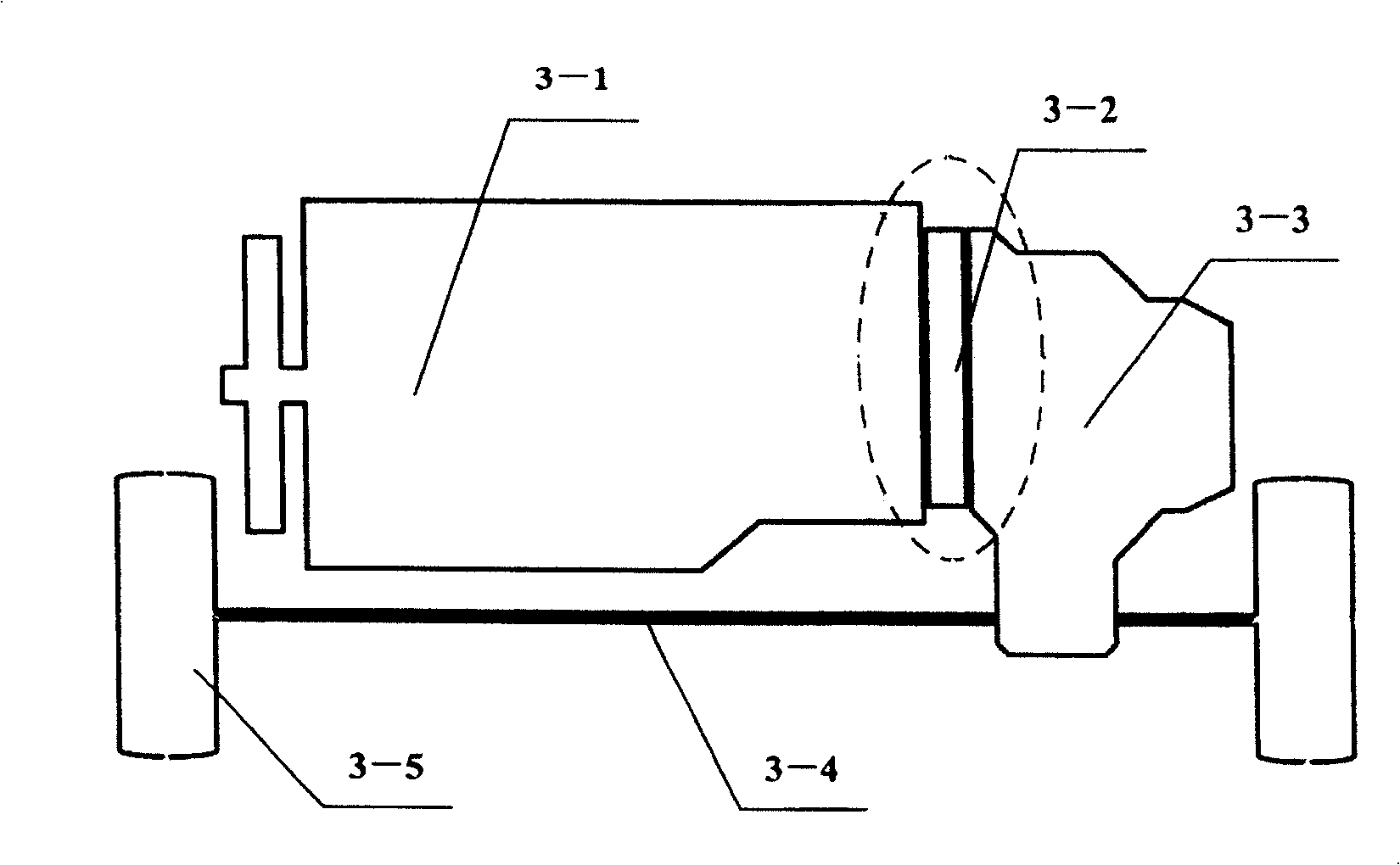

[0030] In the power system of a traditional car and the structure of the existing hybrid system, the starter ring gear and the flywheel are connected together as a whole, such as figure 2 2-4 in, Figure 4 4-5 of them, Figure 5 5-8 of them.

[0031] The present invention as Image 6 , divide the flywheel into two in the thickness direction, and divide it into two separate parts, the starter ring gear (6-9) and the signal ring gear (6-6), and place the motor rotor (6-5) in the middle, The connection sequence is: crankshaft-starting ring gear-motor rotor-signal ring gear-clutch or hydraulic torque converter. Since the flywheel is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com