TFT LCD array base board structure and its producing method

A technology of array substrate structure and manufacturing method, which is applied in the directions of optics, instruments, electrical components, etc., can solve problems such as the influence of data transmission, and achieve the effects of reducing signal delay, increasing storage capacitance, and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with description of drawings and preferred specific embodiments, the present invention is described in further detail:

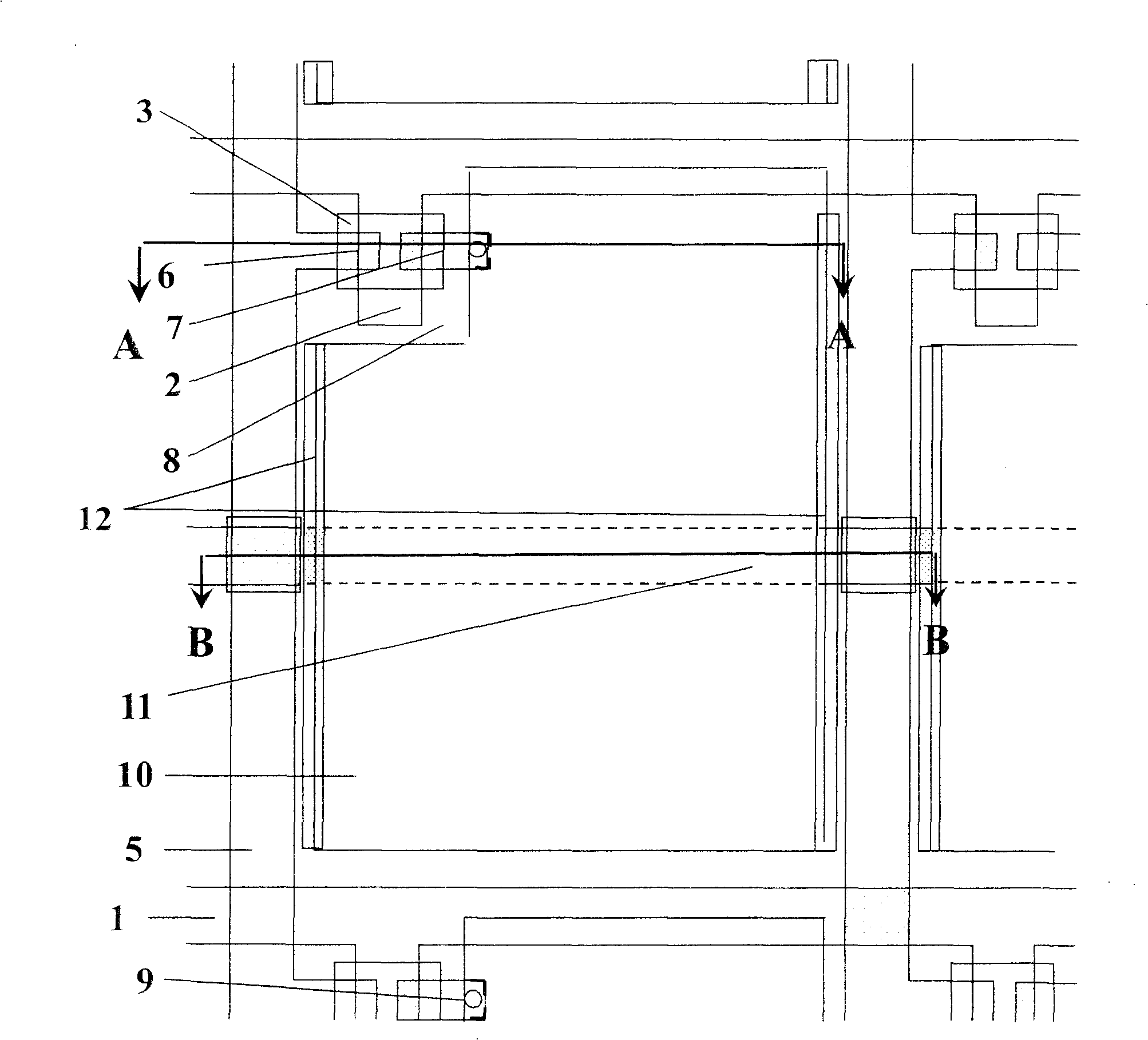

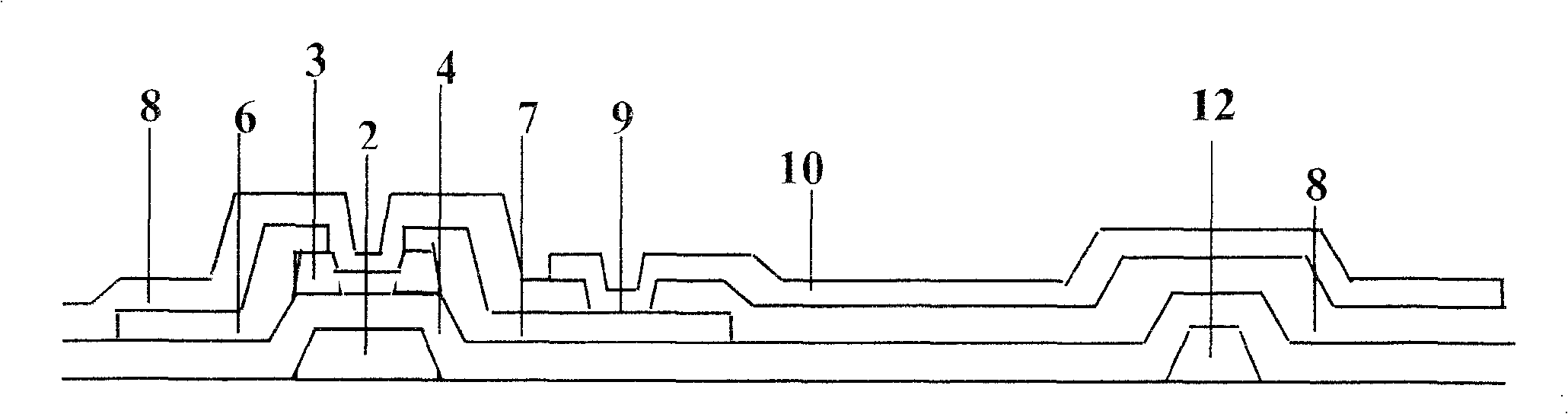

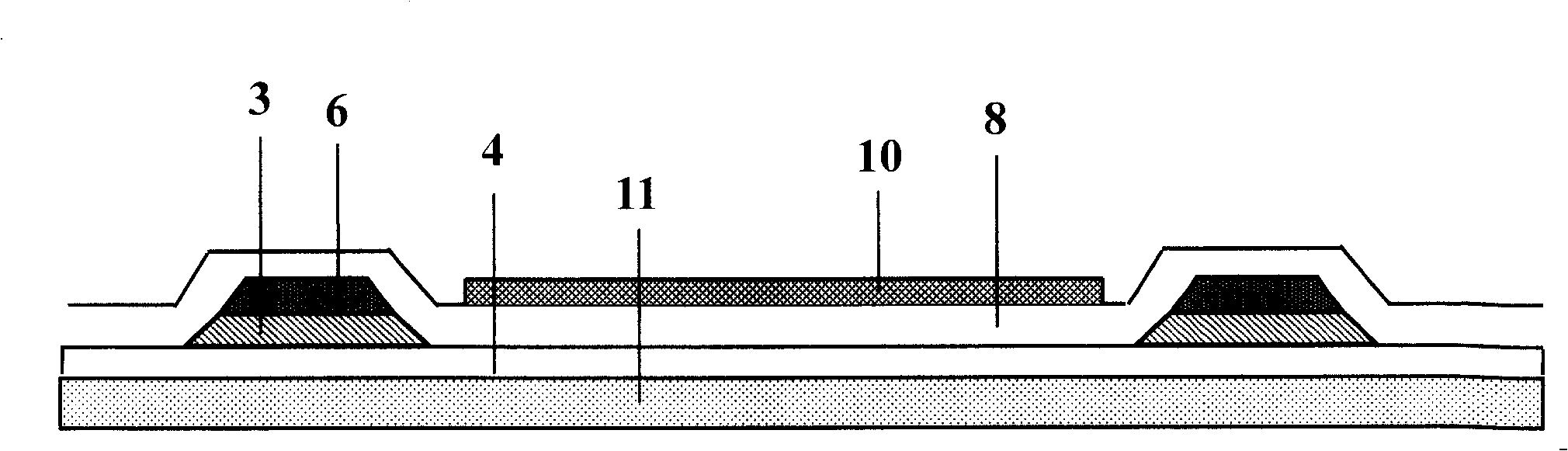

[0044] Such as image 3 As shown, the array substrate of the TFT LCD has a group of gate scanning lines 1 and light blocking bars 12 parallel thereto, and a common electrode 11 perpendicular thereto, vertical light blocking bars 12 and a group of data scanning lines 5 . Each intersection of adjacent gate scan lines and data scan lines defines a pixel area. A pixel includes a TFT switch device, a pixel electrode 10 and a part of the common electrode 11 . Such as Figure 3aAs shown, the TFT device is composed of a gate electrode 2 , a gate insulating layer 4 , a semiconductor active layer 3 , and a source 6 and a drain 7 . The pixel electrode 10 is connected to the drain 7 of the TFT through the via hole 9 in the passivation layer. The above part is the same as a TFT pixel structure in the prior art. The TFT LCD pixel structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com