Square absorption tower for wet method desulfurization of flue gas

A wet desulfurization and absorption tower technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as slurry deposition and scaling, reduce cost, facilitate processing and installation, improve reaction speed and Effect of desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

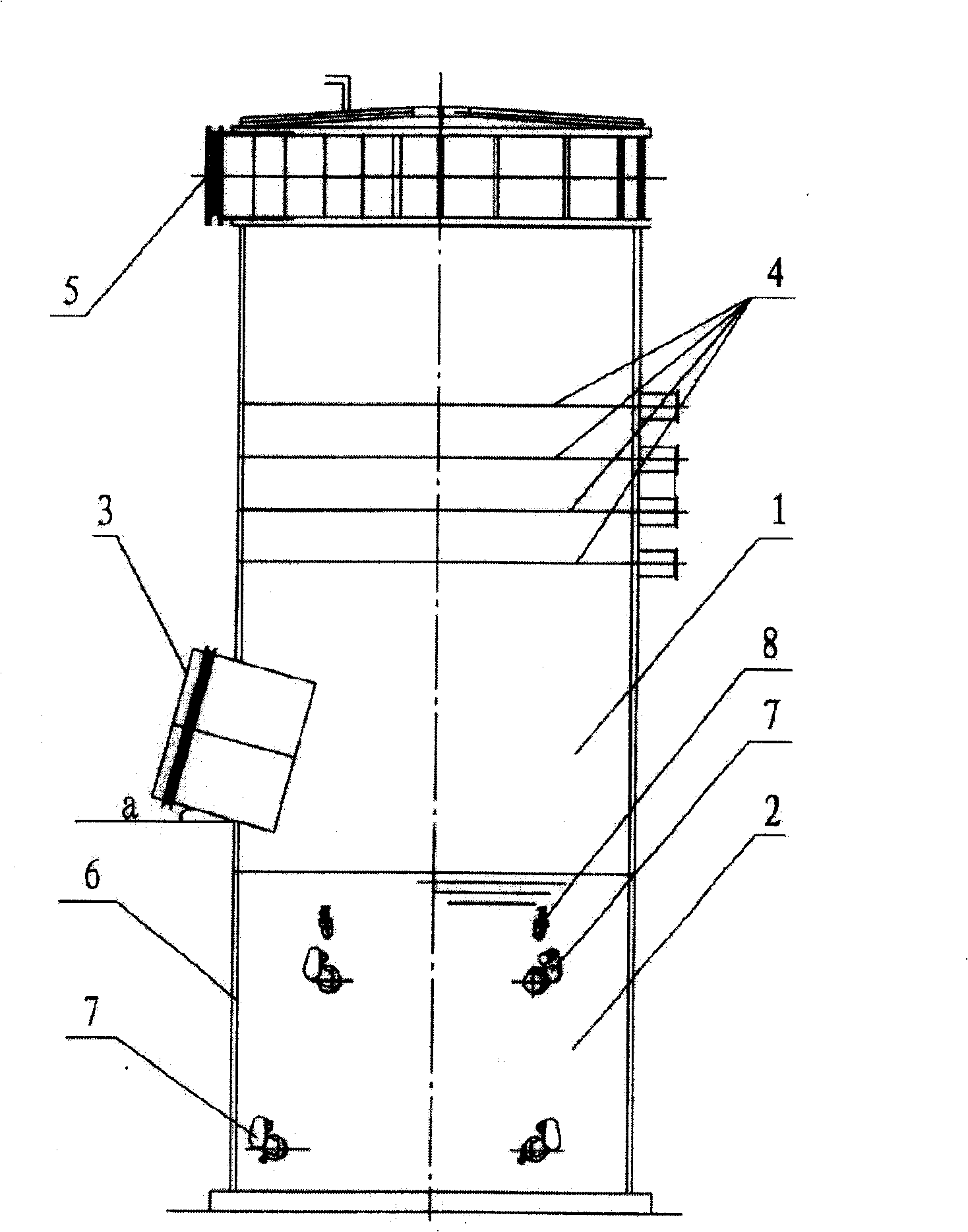

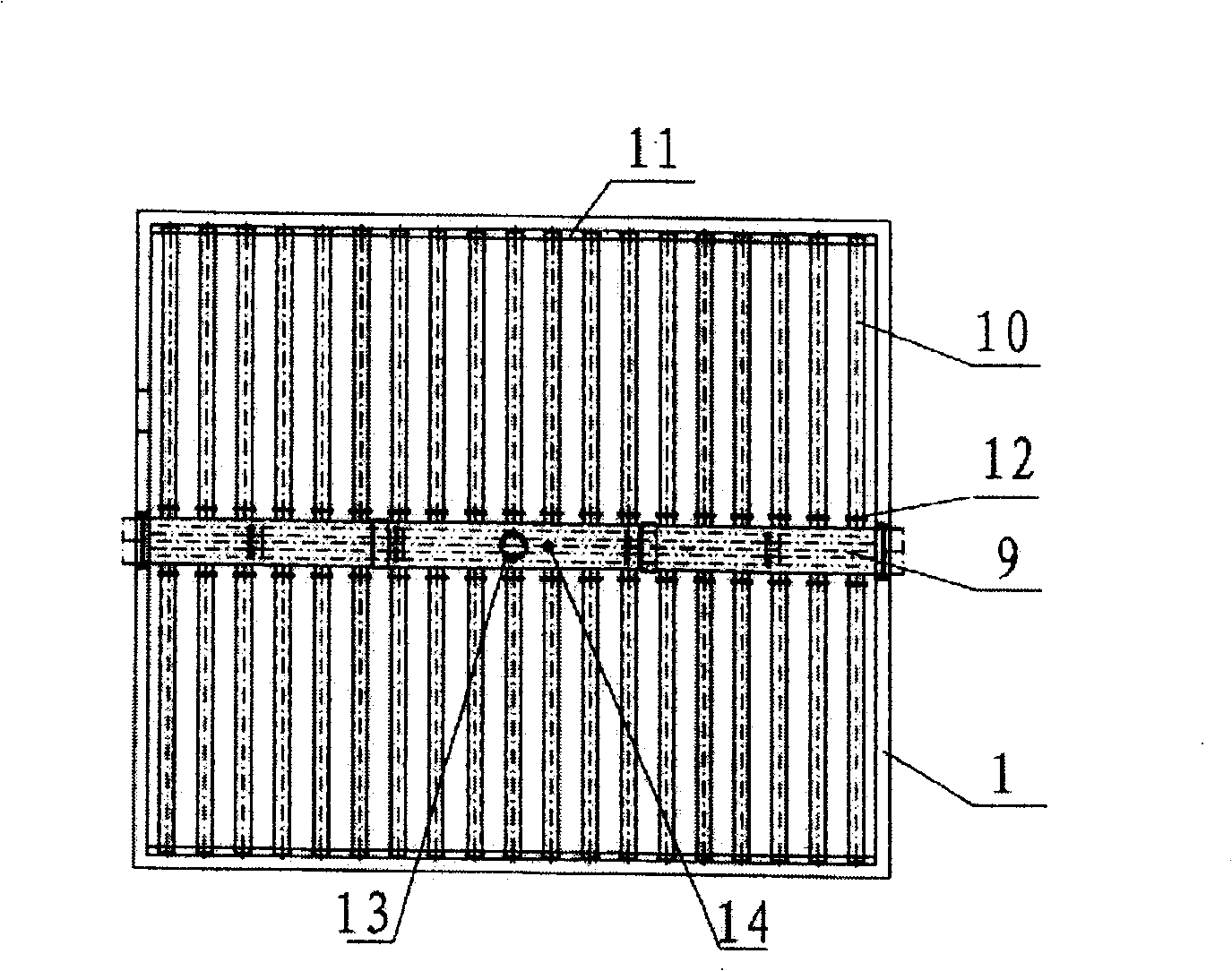

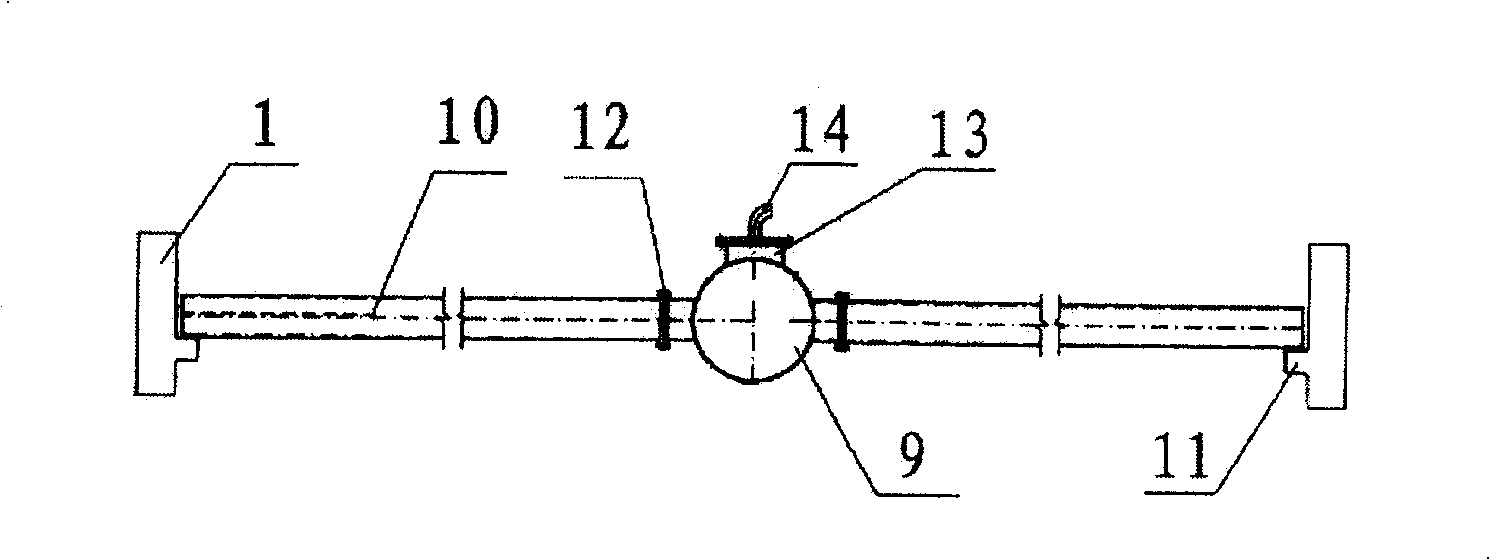

[0018] See Figure 1-3 , This kind of flue gas wet desulfurization square absorption tower, the lower section of the tower body is the circulating slurry tank 2, the upper section of the tower body is the washing reaction tower 1, the upper and lower sections of the tower are rectangular in cross section, and they are vertically connected as a whole. The lower part is connected with the smoke inlet pipe 3, and the middle part of the upper part is equipped with four layers of spray pipes 4, the spray pipe includes a main pipe 9 and branch pipes 10 separated from both sides of the main pipe. The main pipe 9 has an inspection hole 13 and an exhaust hole 14. The main pipe 9 and the branch pipe 10 are connected by a flange 12, and the two ends of the branch pipe are erected on the support 11 on the wall of the absorption tower.

[0019] The tangential direction at the top of the tower body is connected to the flue gas outlet 5. The material of the tower body is steel or concrete structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com