Flow type oil and electricity dual-purpose multifunctional plant stalk block making machine

A multi-functional and mobile technology, applied in presses, manufacturing tools, etc., can solve the problems of lack of pertinence in the production and living characteristics of straw in rural areas, uneconomical long-distance collection costs, improper technology and coordination measures, etc. Long-distance transportation, convenient for long-term storage, and the effect of increasing the effective use area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

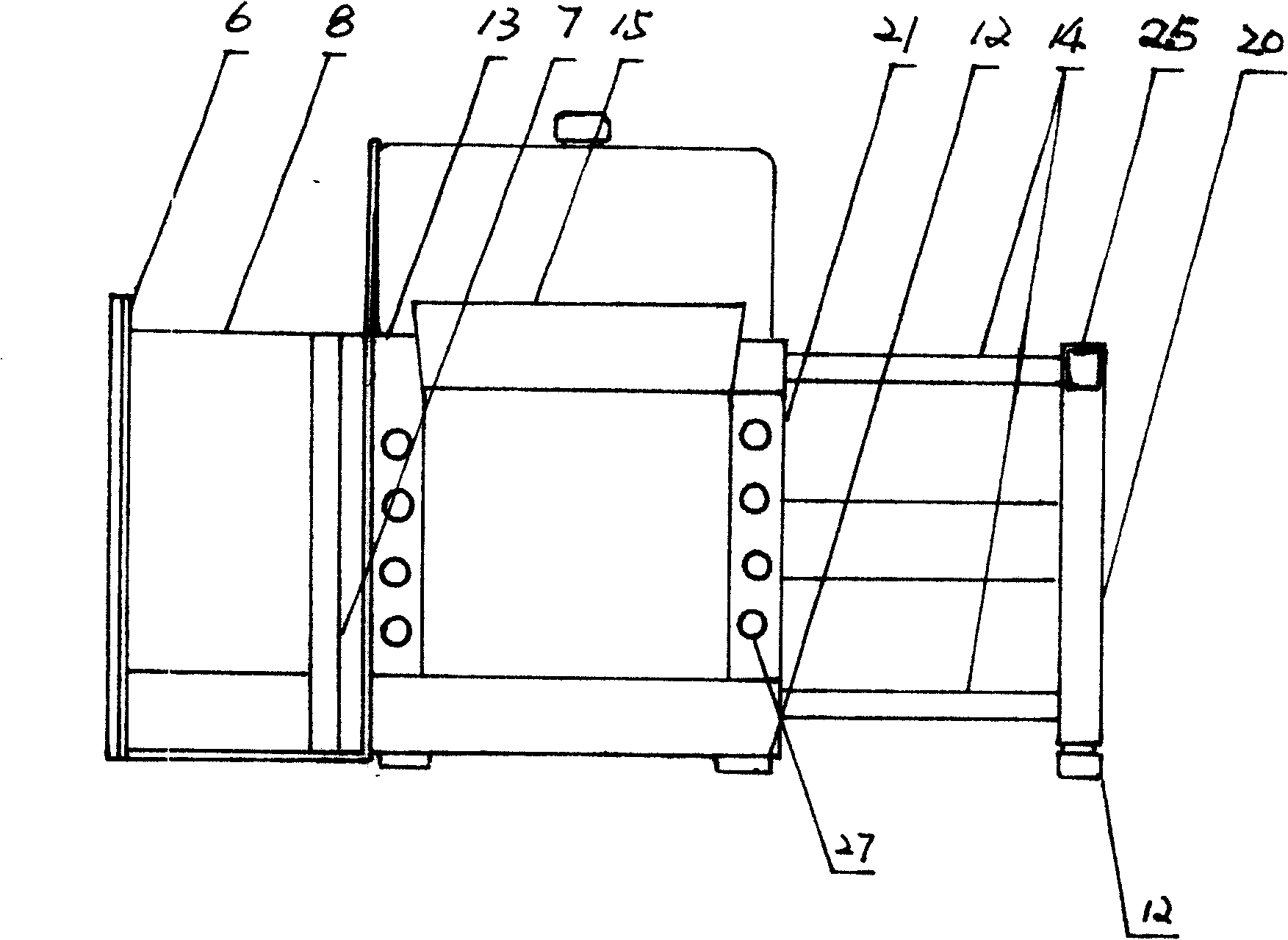

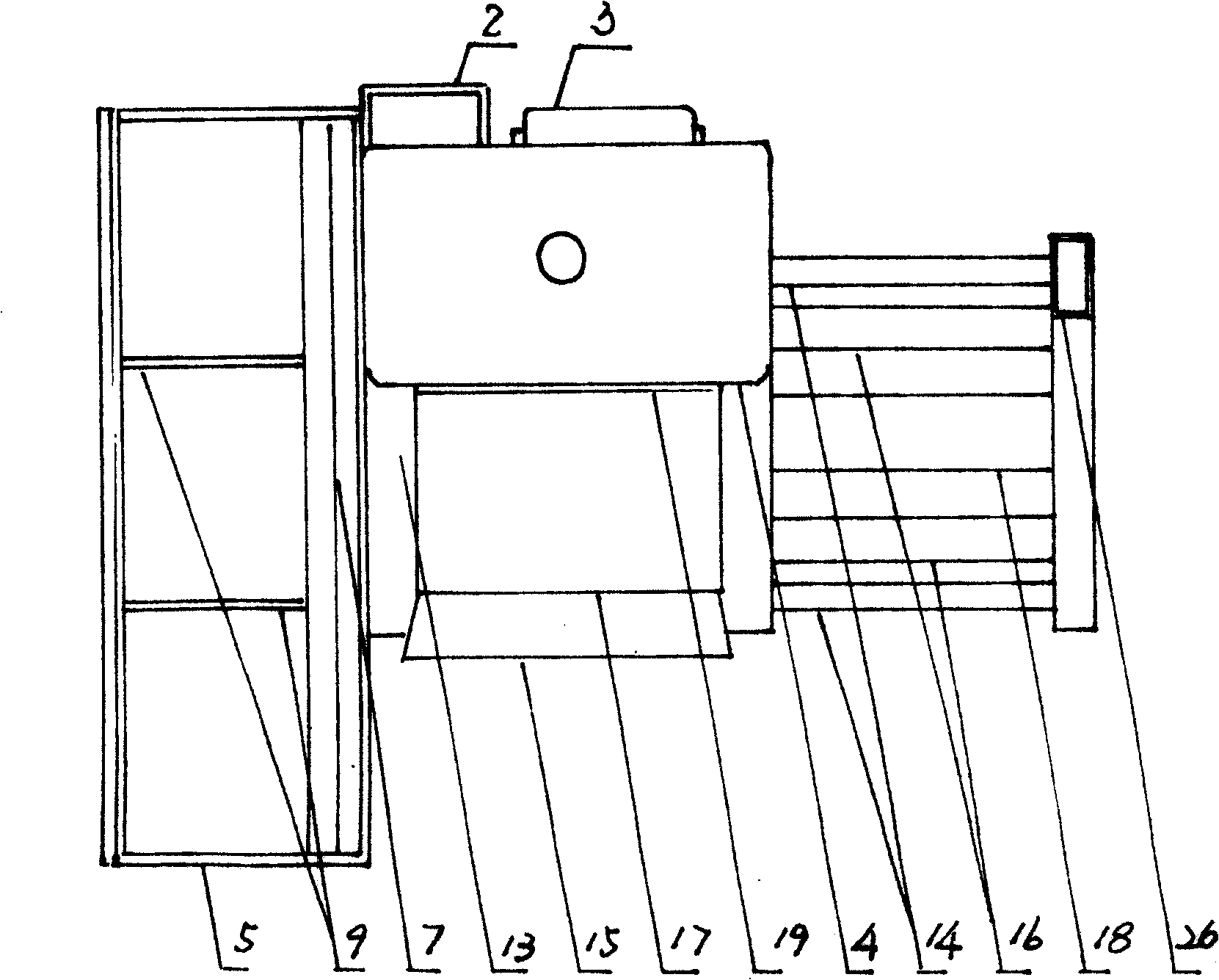

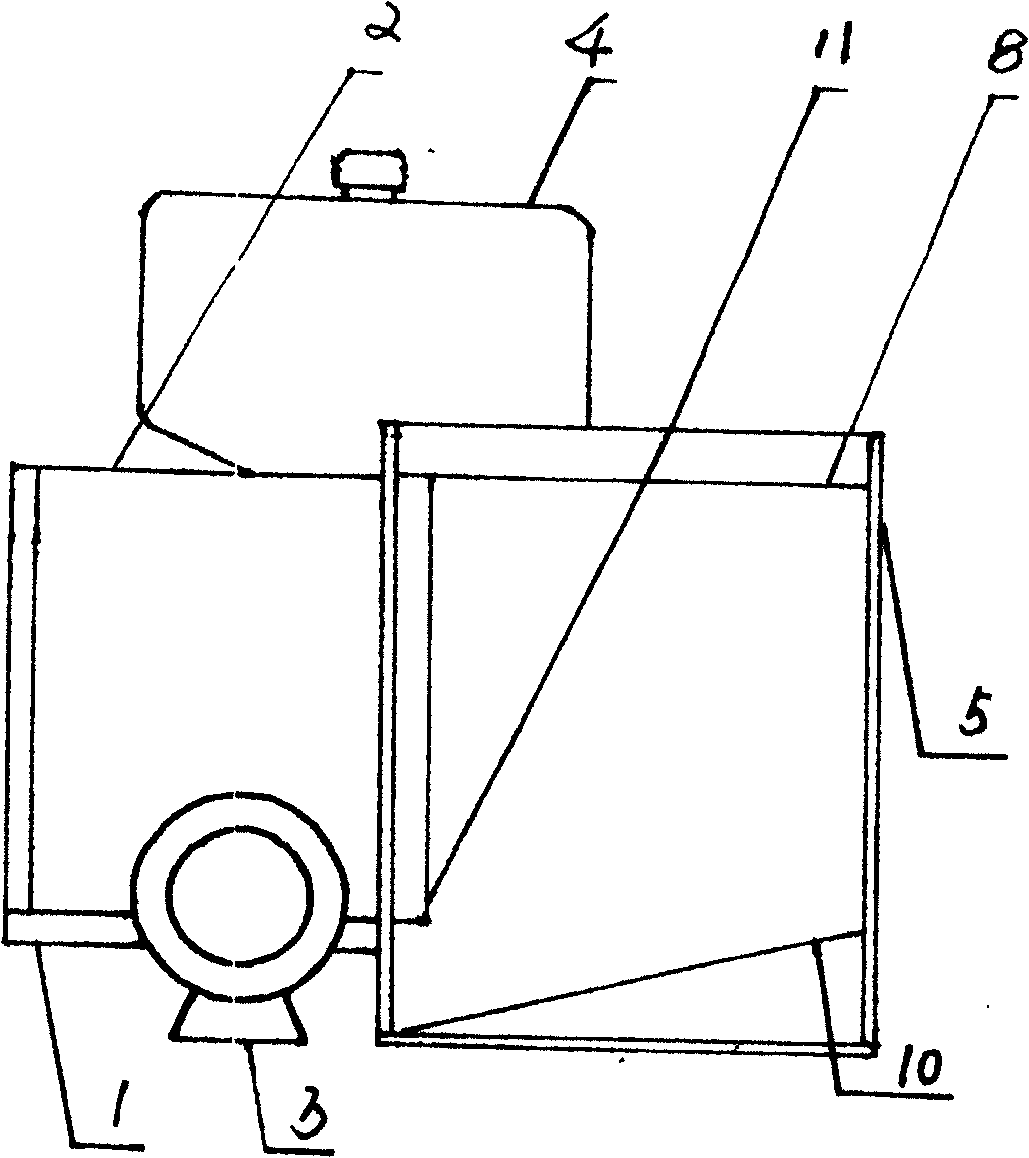

[0025] 1. In combination with FIG. 14, this embodiment includes a plant straw shearing mechanism, a hydraulic forming mechanism and a power output mechanism. The plant straw shearing mechanism is connected to the hydraulic forming mechanism, and is characterized in that the plant straw shearing mechanism includes a storage basket 5 , the shear chamber 8, the adjustable shearing tool 7 arranged on the storage basket 5 and the front guard plate 6 arranged on the side of the storage basket 5, and the hydroforming mechanism includes a return material arranged on the side of the storage basket 5 Aging device, material cavity, oil cylinder, front pressure bearing plate 13, pressure plunger 18, mold cavity side top plate 20 and side pressure plate 21, the front pressure bearing plate 13 is arranged between the material cavity and the plant straw shearing mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com