Method for producing multi-exponent read-only mother disc

A master disc and disc technology, applied in the field of digital storage, can solve problems affecting the crosstalk between sequence codes and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

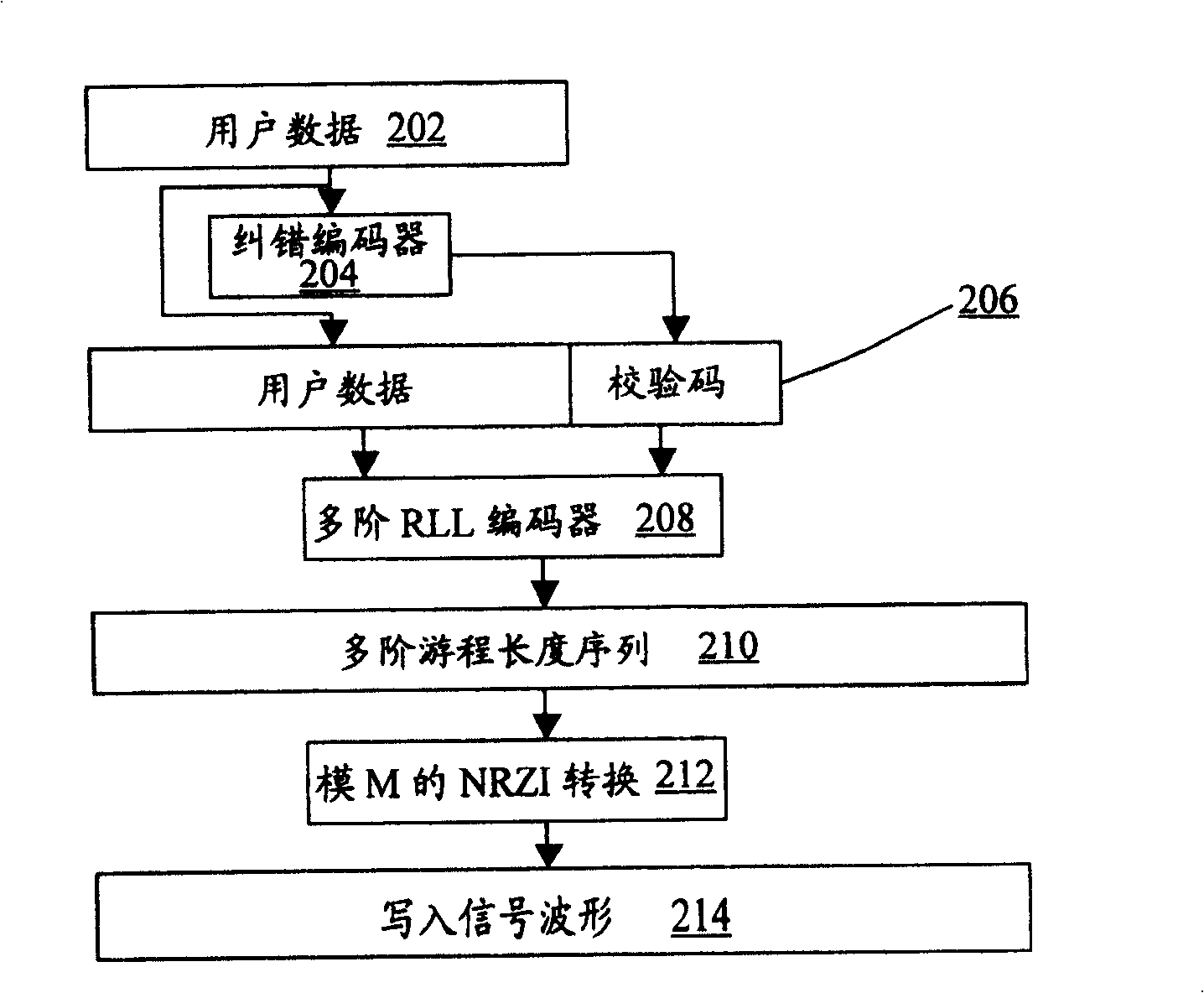

Method used

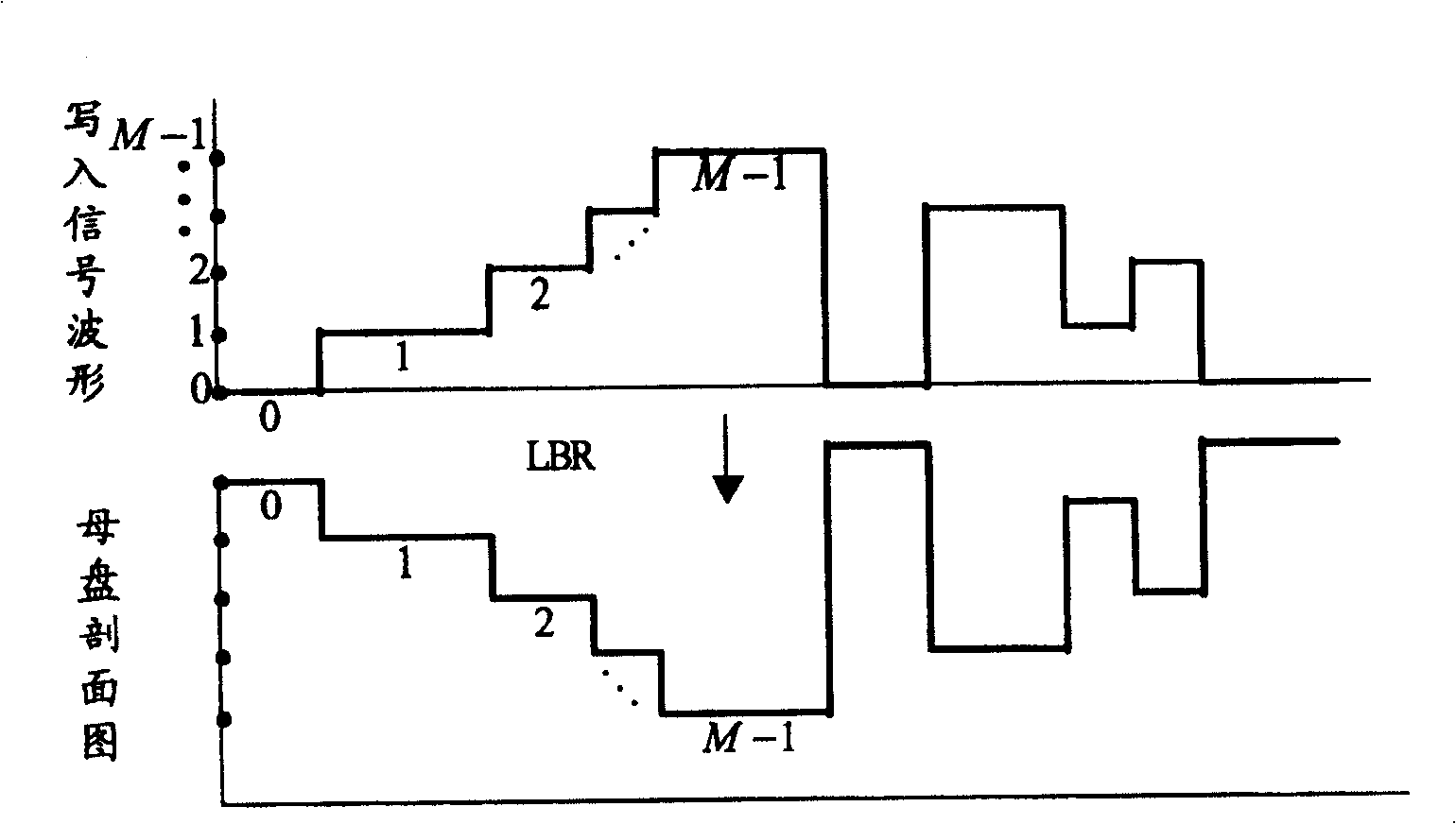

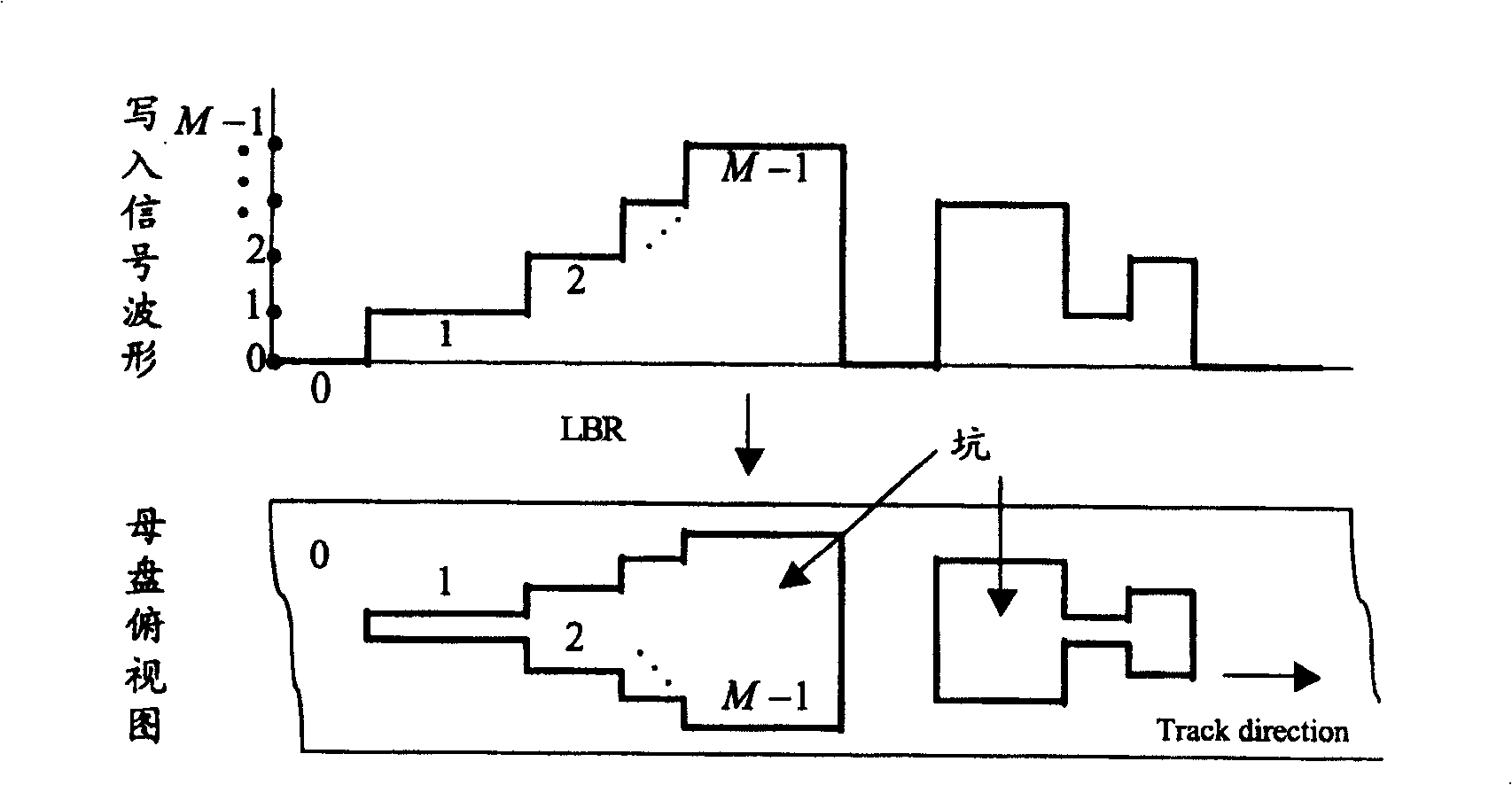

Image

Examples

Embodiment Construction

[0103] In the making process of optical disc, make master disc usually earlier, the step of making master disc comprises: coating one deck master disc photoresist on glass substrate (in the present invention, adopt the model of Rohm&Haas of Britain to be Microposit S1800-4 photoresist), use the master disk recording system (in the present invention, the ∏ mastering System of NIMBUS in England) to record the master disk, adopt the laser of the model NLHV 500C of Nichia in Japan) to expose the photoresist, develop, and make Master disk.

[0104] Then, use this master disc as a mould, use a glass disc sputtering machine (in the present invention, adopt the model of Swiss UNAXIS to be the sputtering machine of Pyramet) glass substrate is carried out sputtering (sputtering process), coat a layer A thinner metal layer is then plated with a relatively thicker metal layer to obtain a metal negative image sub-disc, which can be used as a stamper for injection molding replication. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com