Production method of thermoplastic resin microporous membrane

A technology of thermoplastic resin and microporous membrane, which is applied in the field of manufacturing thermoplastic resin microporous membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

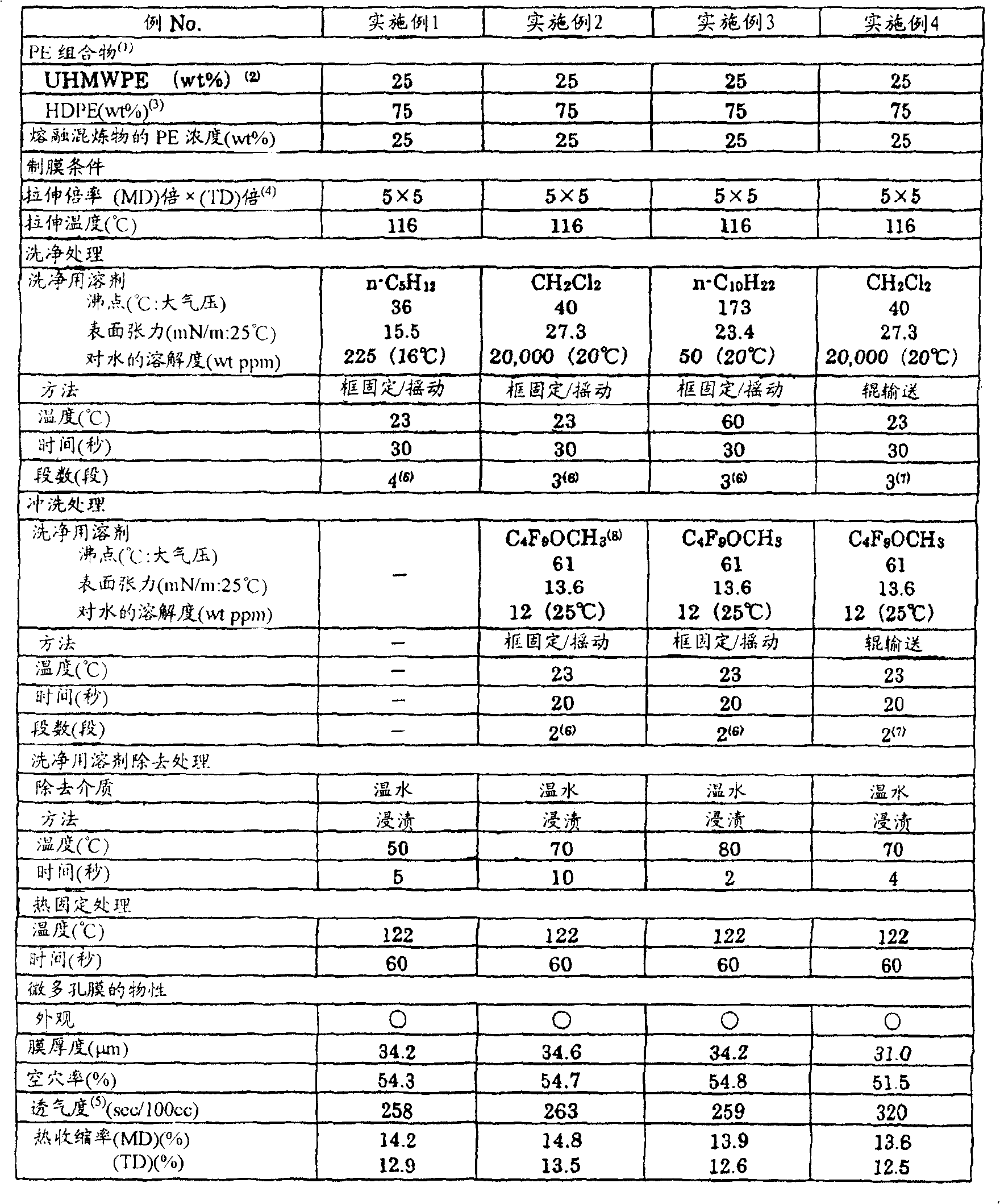

Embodiment 1

[0177] At a weight average molecular weight of 2.0×10 by 25% by mass 6 The ultra-high molecular weight polyethylene (UHMWPE) and 75% by mass have a weight average molecular weight of 3.5×10 5 In polyethylene (melting point 135°C, crystallization dispersion temperature 90°C) composed of high-density polyethylene (HDPE) with Mw / Mn=16, 0.375 mass parts of tetrachloride as an antioxidant is added to every 100 mass parts of the composition. [methylene-3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]methane to give a polyethylene composition. 25 parts by mass of the obtained polyethylene composition was charged into a twin-screw extruder (inner diameter 58 mm, L / D=42, strong mixing type), and 75 parts by mass of The liquid paraffin was melt-kneaded under the conditions of 200° C. and 200 rpm, and a polyethylene solution was prepared in an extruder. Next, the polyethylene solution was extruded from a die provided at the front end of the extruder so as to have a thickness of about 4...

Embodiment 2

[0179] In the same manner as in Example 1, the biaxially stretched film produced was fixed on the frame plate, and immersed in methylene chloride [surface tension: 27.3mN / m (25°C), boiling point: 40.0°C, temperature adjusted to 23°C, Solubility in water: 20000 ppm (mass basis) (20° C.)], washing while shaking at 100 rpm for 30 seconds in the first washing tank. While replacing the dichloromethane with a new solution as appropriate, the above-mentioned series of cleaning operations were repeated twice. Next, the film was fixed on the frame plate, and immersed in methyl perfluorobutyl ether [compositional formula: C 4 f 9 OCH 3 , Trade name: Nobetsuku HFE-7100, manufactured by Sumitomo 3M Co., Ltd., surface tension: 13.6mN / m (25°C), boiling point: 61°C, solubility in water: 12ppm (mass basis) (25°C), no flash point] in the second cleaning tank (rinsing tank), the rinsing process was performed while shaking at 100 rpm for 20 seconds. Replace the methyl perfluorobutyl ether wi...

Embodiment 3

[0181] In addition to the first cleaning tank with n-decane [surface tension: 23.4mN / m (25°C), boiling point: 173°C, solubility in water: 50ppm (mass basis) (20°C)] adjusted to 60°C In the same manner as in Example 2, except that the temperature of warm water was set to 80° C., a polyethylene microporous membrane was produced (the number of times of washing: three times in total). The time required to remove the cleaning solvent was 2 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com