Large capacity titanium alloy pulse micro arc anode oxidation dynamic control power source

A micro-arc anodic oxidation and control method technology, which is applied in the direction of anodic oxidation, electrolytic coating, electrical components, etc., can solve the problems of power supply in the production process of titanium alloy pulsed micro-arc anodic oxidation, and achieve high precision and circuit Reasonable design and flexible control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

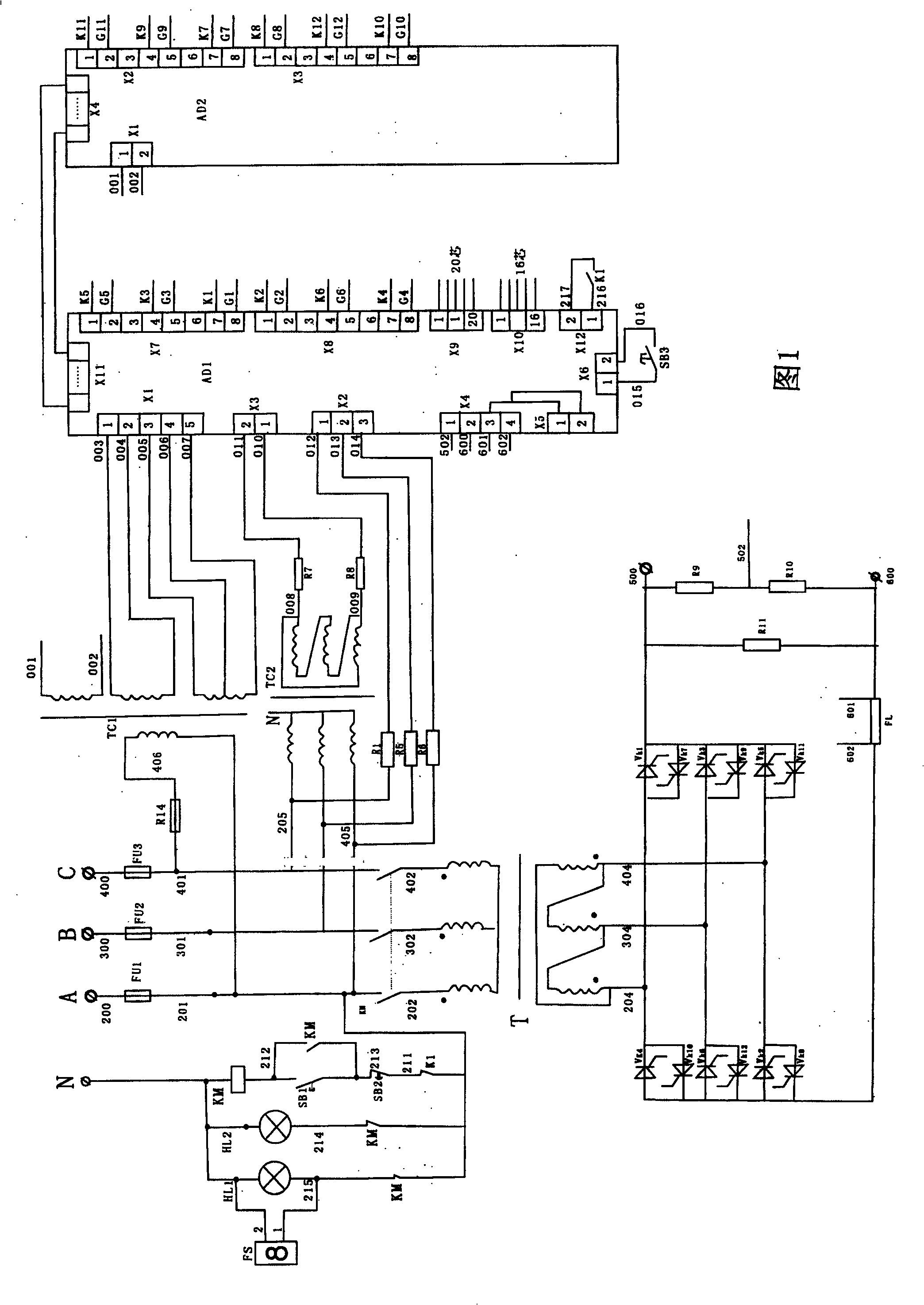

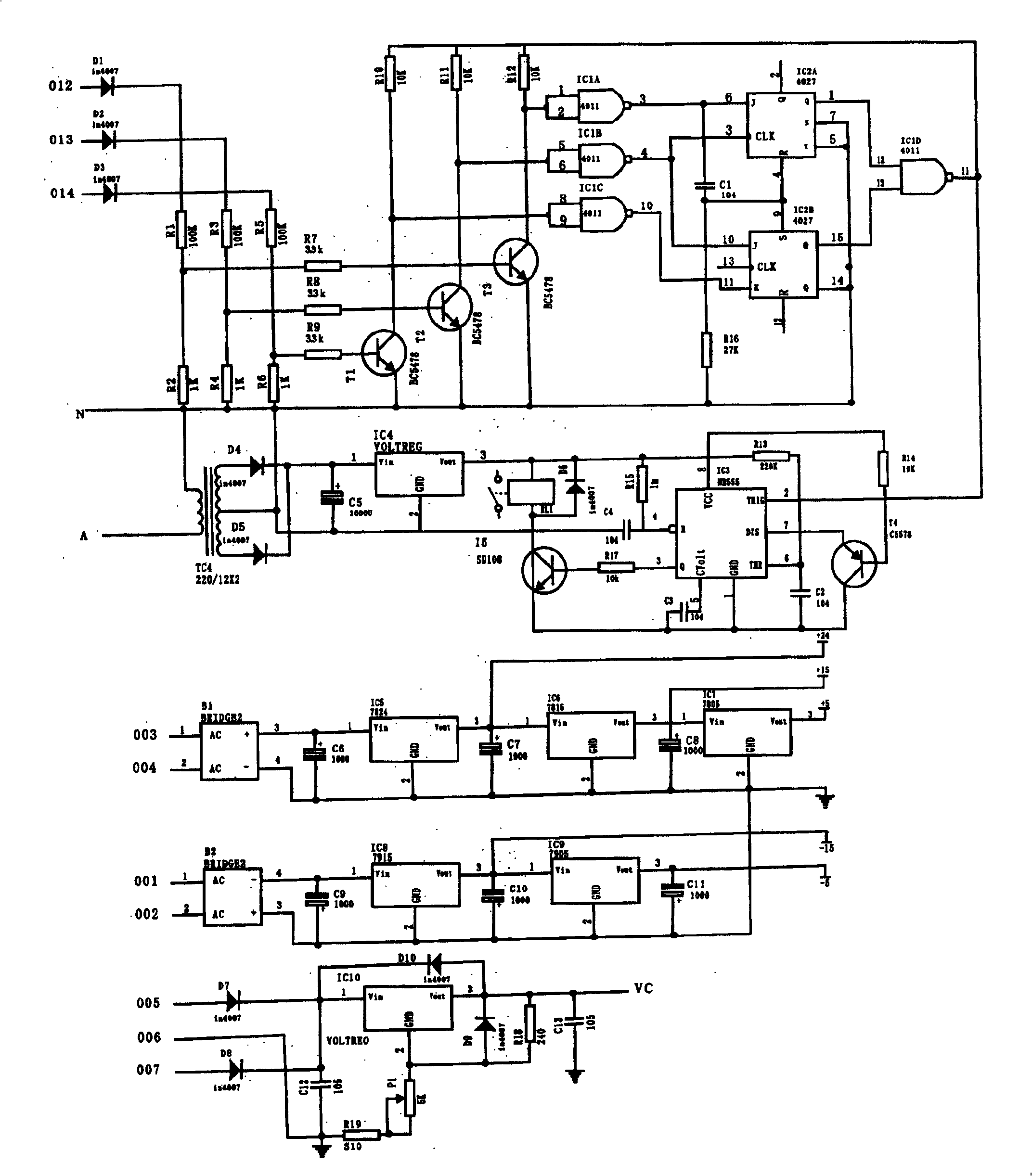

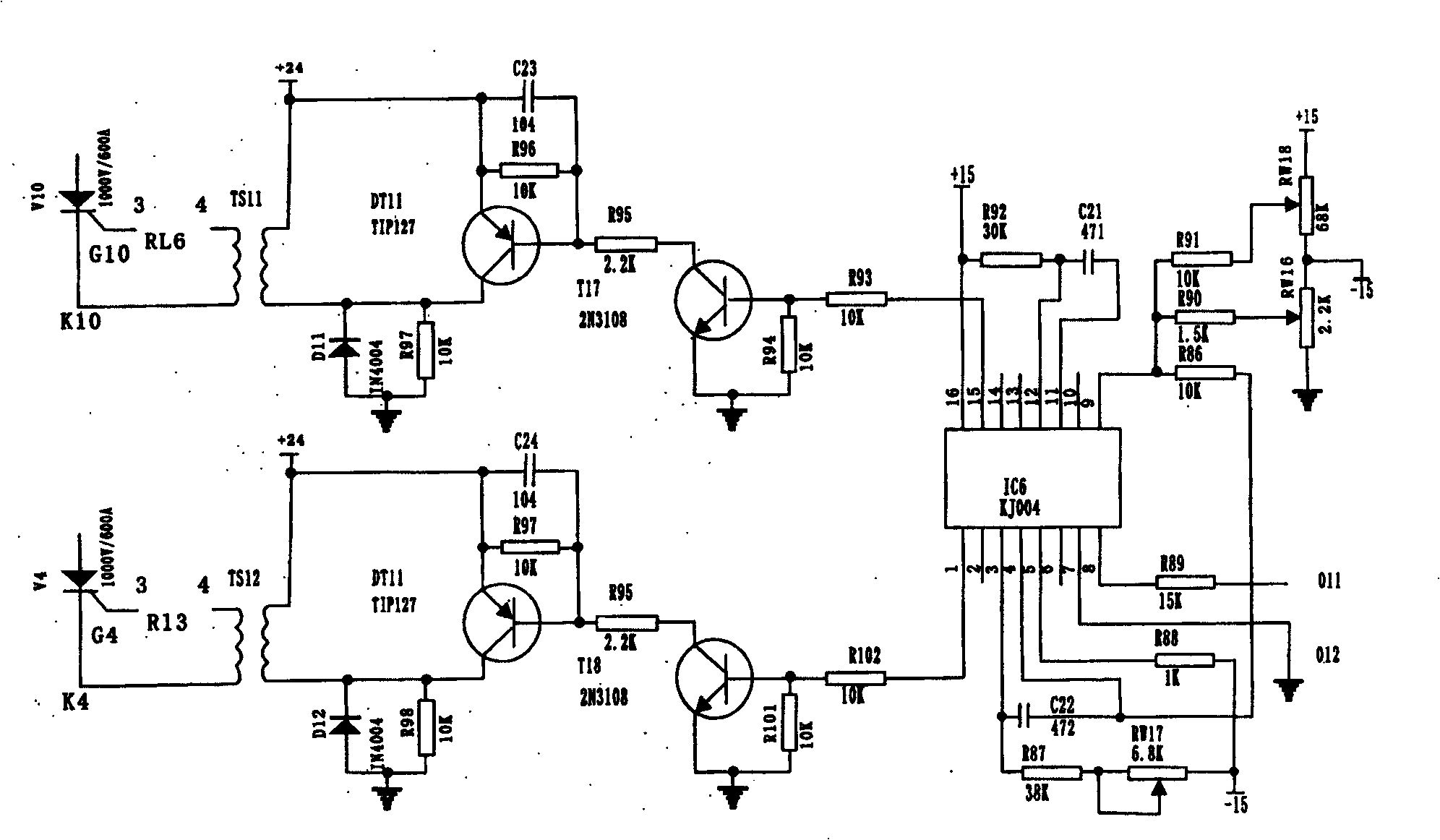

[0055] The detailed structure and working principle of the present invention are described in detail in conjunction with accompanying drawings.

[0056] The hardware part of the present invention is composed of internal and external circuits, wherein the internal power supply of the machine: -15V, -5V power supply: through the secondary 001 and 002 of the TC1 transformer, through the B2 positive current C9 filter, the stabilized voltage 7915 is filtered and then output -15V. After the 7905 regulator block C11 filter output -5V.

[0057] +24V, +15V, +5V power supply: TC1 transformer times 003, 004, and B1 positive current C6 filter 7824 voltage regulator block C7 filter output +24V. +24V is filtered by C8 of the 7815 voltage regulator block to output +15V, and +15V is output by the 7805 voltage regulator block to +5V.

[0058] Display DC power supply: after TC1 transformer secondary 005, 006, 007, it is filtered by D7, D8 full-wave positive current, C12, and then adjusted by P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com