Apparatus for refrigeration or pyrogenicity or sanitary hot water using generator exhaust or residual heat

A generator and exhaust gas technology, applied in household heating, air heaters, energy-saving heating/cooling, etc., can solve the problems of wasting energy and underutilized heat energy, and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

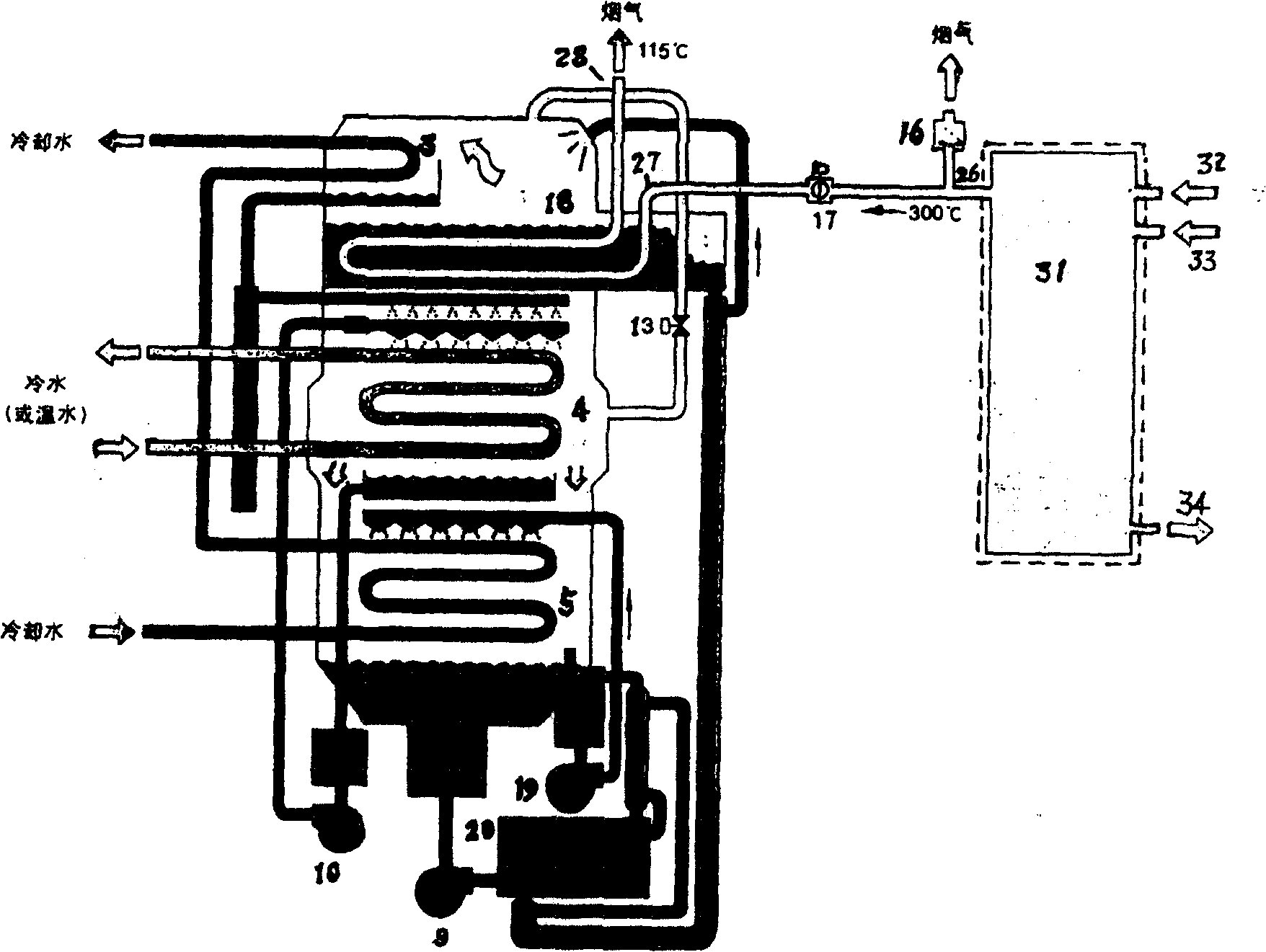

[0015] Embodiment 1: as figure 1 Shown is a schematic structural diagram of the generator and the low-temperature tail gas single-effect cooling and warming water machine of the present invention. The low-temperature flue gas single-effect type has a rated flue gas temperature of 300°C. The generator uses fuel (gas or oil) to provide electricity. Refrigerating machine utilizes the tail gas of generator 230-350 ℃, and generator (18) is that only tail gas utilizes generator pipe (27) to provide tail gas as energy, and single-effect circulation carries out refrigeration or heating.

[0016] Operation adjustment: when the generator is running alone, the exhaust gas does not enter the refrigerator, and is emptied by the self-opening damper (16). When the two are running at the same time, the refrigerator automatically adjusts the exhaust gas volume through the electric smoke valve (17) according to the load, and the excess exhaust gas is discharged through the self-opening damper (...

Embodiment 2

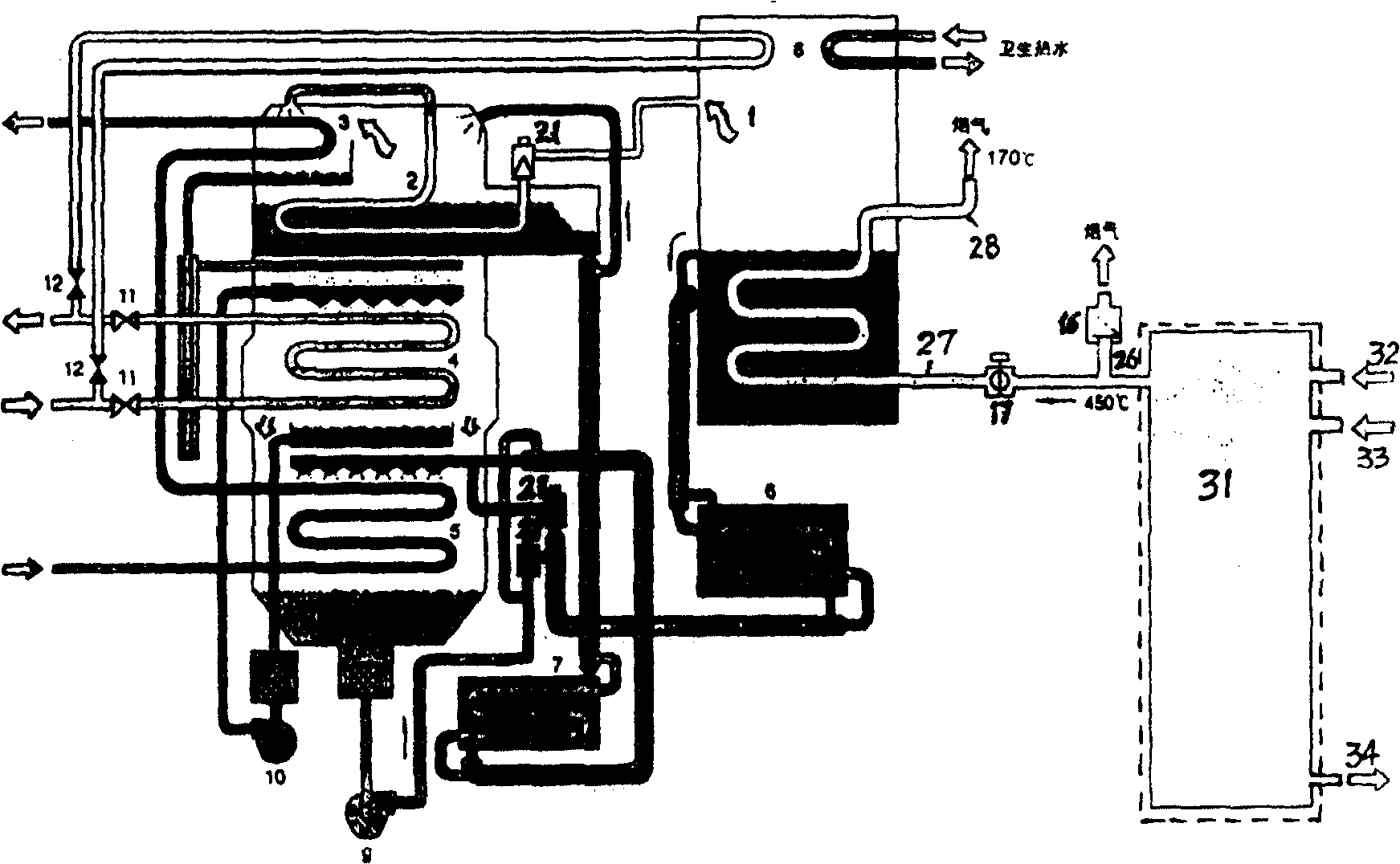

[0017] Embodiment 2: as figure 2 Shown is a schematic structural diagram of the generator and high-temperature exhaust double-effect cooling and warming water machine of the present invention. The high-temperature flue gas double-effect type has a rated flue gas temperature of 450°C. The generator uses fuel (gas or oil) to provide electricity. The refrigerating machine utilizes the tail gas above 380°C of the generator to perform double-effect circulation for refrigerating or heating and provide sanitary hot water.

[0018] Operation adjustment: when the generator is running alone, the exhaust gas does not enter the refrigerator, and is emptied by the self-opening damper (16). When the two are running at the same time, the refrigerator automatically adjusts the exhaust gas volume through the electric smoke valve (17) according to the load, and the excess exhaust gas is discharged through the self-opening damper (16). The tail gas passes through the generator pipe (27) to hea...

Embodiment 3

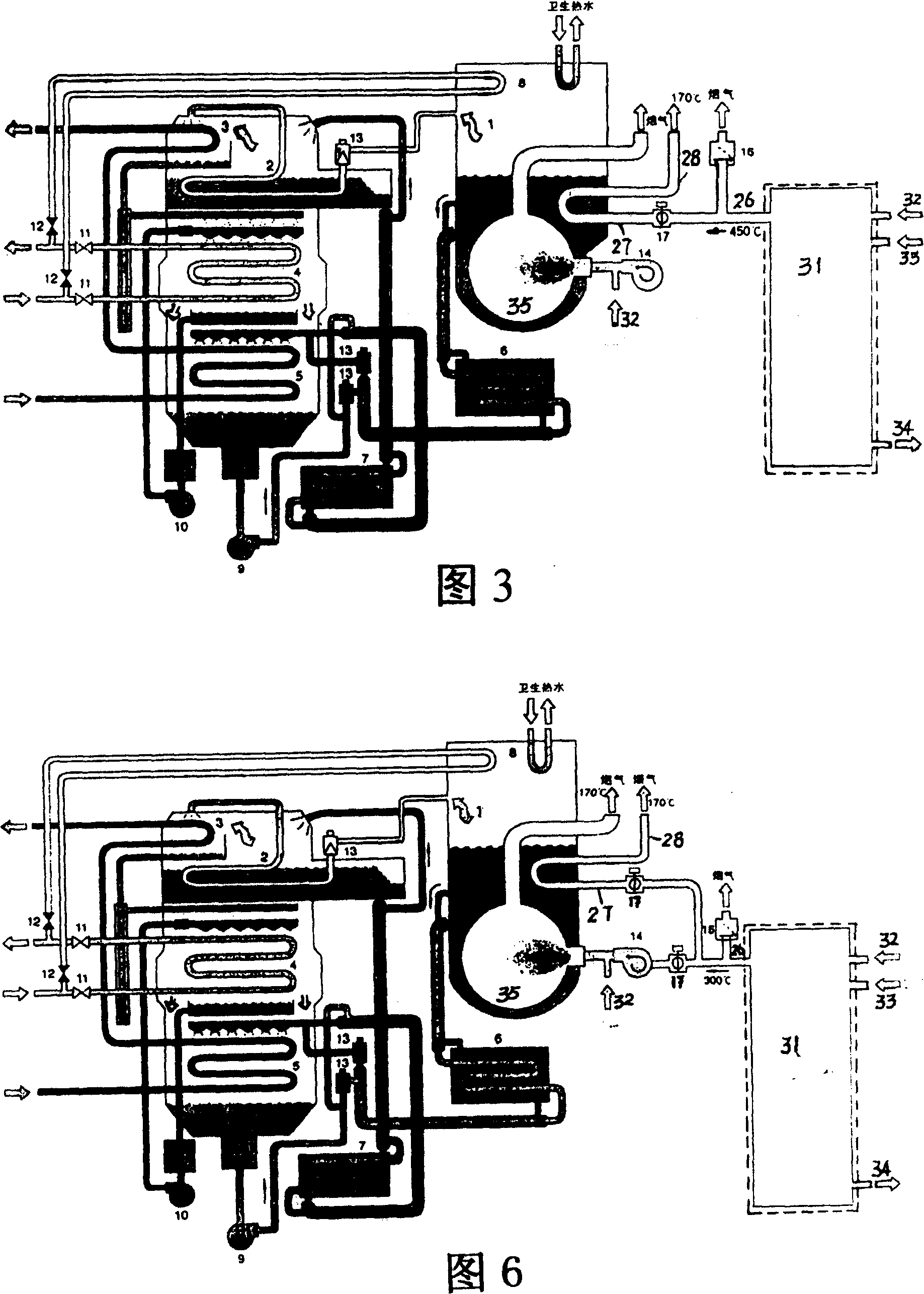

[0019] Embodiment 3: As shown in Figure 3, it is a schematic structural diagram of the generator and the double-effect cold and warm water high-temperature tail gas supplementary combustion type direct combustion engine of the present invention, the high-temperature flue gas double-effect supplementary combustion type, the rated flue gas temperature is 450°C, and generates electricity Machine (31) uses fuel (gas or fuel oil) to provide electric power. The refrigerating machine utilizes two kinds of energy sources, the tail gas above 380°C of the generator and the fuel (gas or oil), to carry out refrigeration, heating and provide sanitary hot water in a double-effect cycle.

[0020] Operation adjustment: when the generator was running alone, the electric flue gas valve (17) was in the closed state automatically, and the generator tail gas did not enter the waste heat direct combustion engine (35), and was emptied by the self-opening damper (16). The waste heat direct combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com