Electric pressure cooker

An electric pressure cooker and pressure technology, which is applied in pressure cookers and other directions, can solve the problems that users cannot know the changes of elastic properties such as pressure and elastic coefficient in the pot at any time, and the coordination is not tacit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

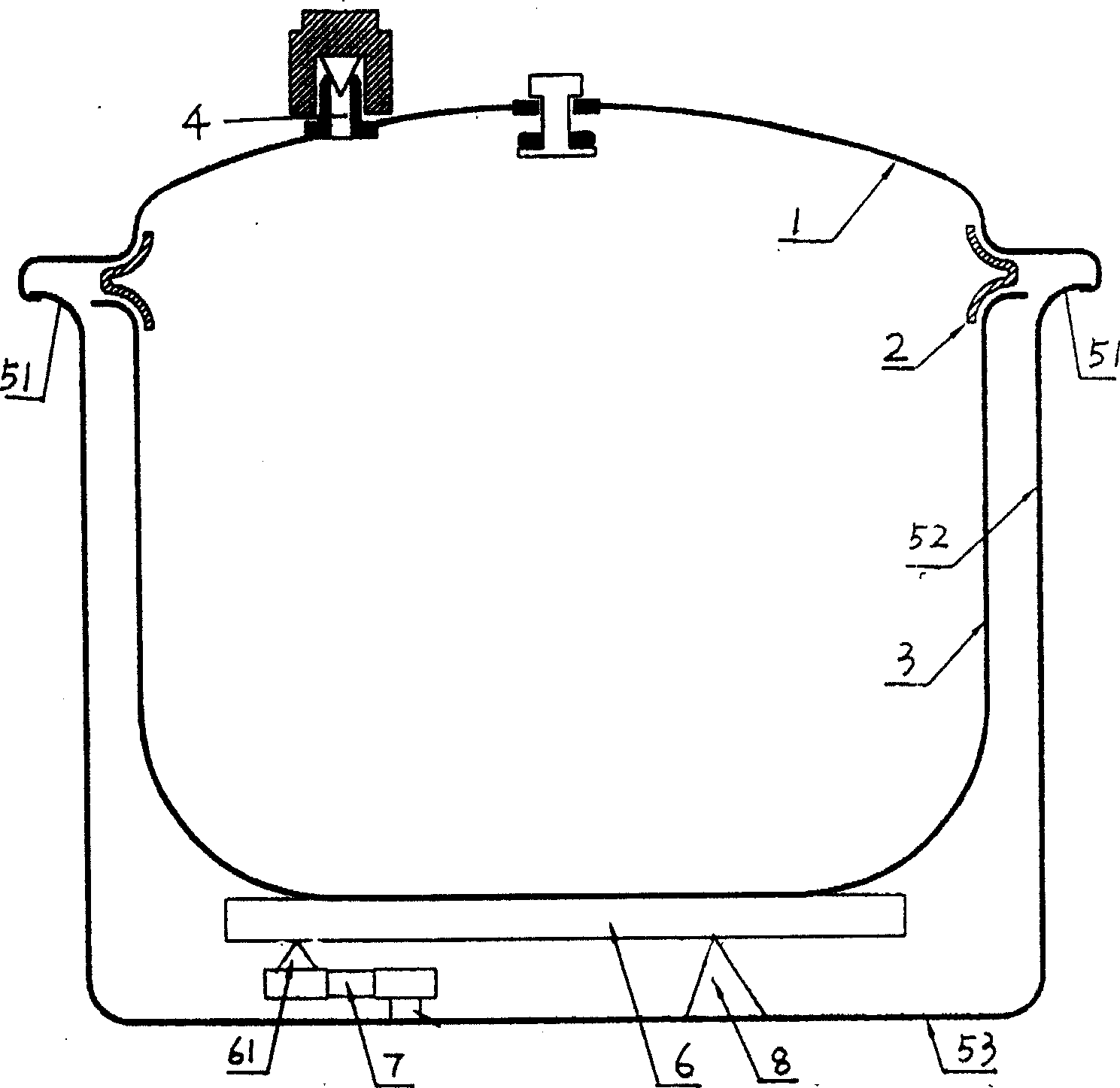

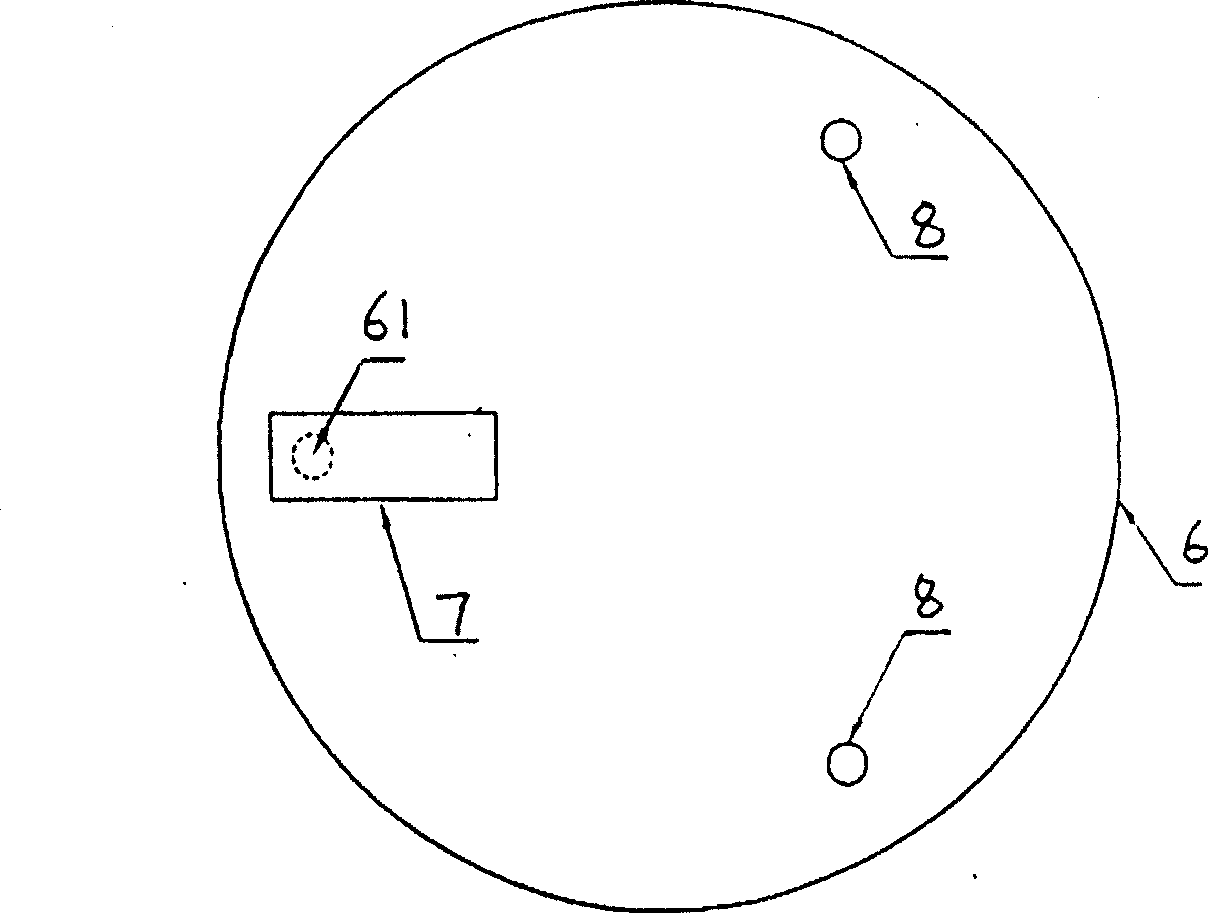

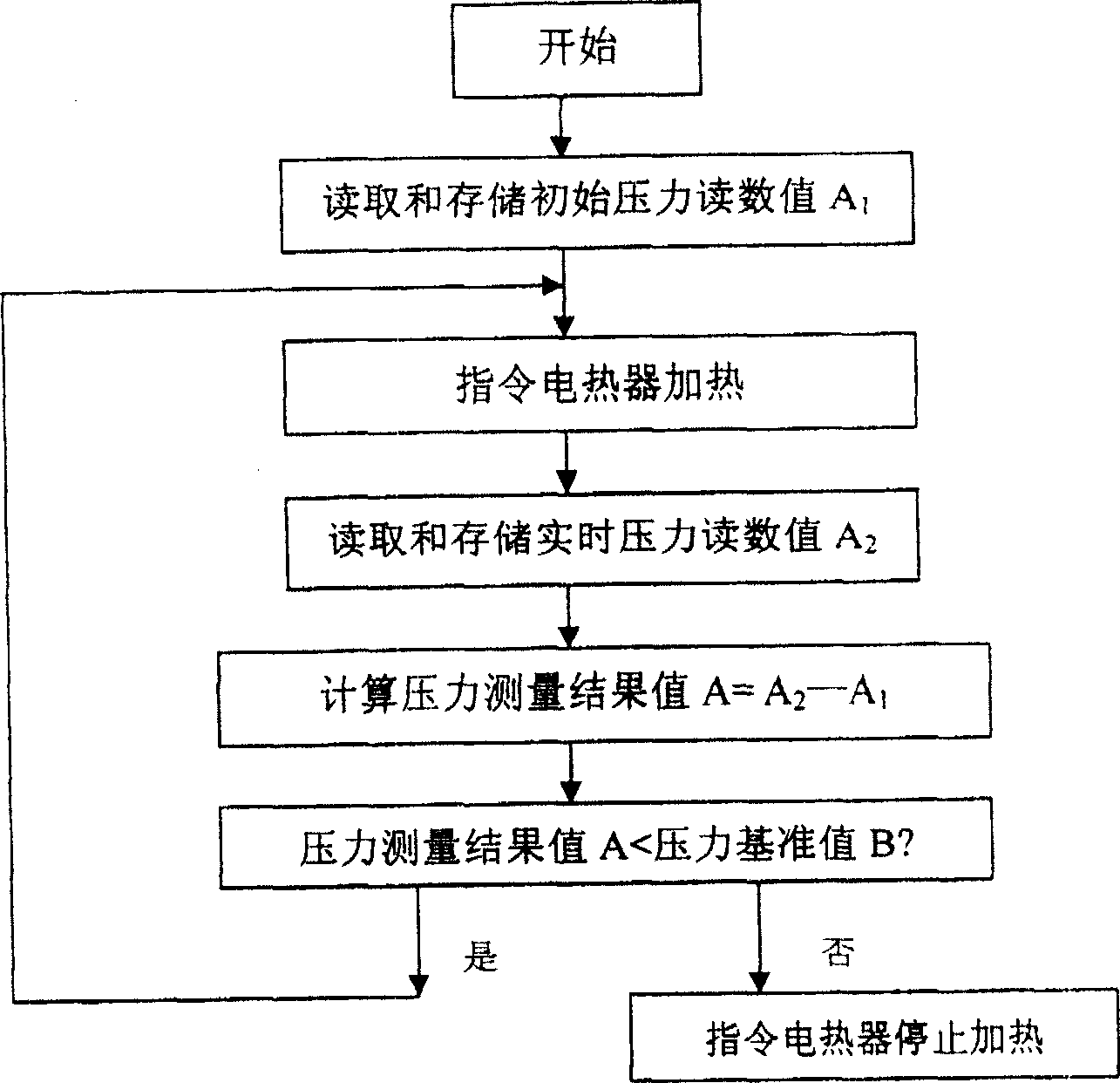

Method used

Image

Examples

Embodiment 2

[0038] Such as Figure 4 As shown, a lever 9 is provided between the first support point 61 of the electric heater 6 and the load cell 7, one end of the lever 9 is pivotally connected to the fixed block 91, and the other end of the lever 9 is mounted on the load cell 7, The first supporting point 61 is mounted on the middle position of the lever 9 . All the other are the same as the first embodiment. The lever mechanism of this embodiment can reduce the pressure of the first supporting point by 1 / 2 and transmit it to the load cell 7, so the pressure reading measured by the load cell 7 is 1 / 6 of the downward pressure of the pot body.

Embodiment 3

[0040] In the third embodiment of the present invention, the support point of the electric heater 6 is changed into one, and the support point 61 is close to the center of the pot bottom; the fulcrum of the lever 9 is hinged on the fixed block 91, and the support point 61 is mounted close to the lever At the 1 / 3 length of the fulcrum, the other end of the lever 9 is mounted on the load cell 7 . The rest are basically the same as in Embodiment 1.

[0041] In the present invention, the shape of the rigid integral frame formed by the fixed connection of the rigid beam, the rigid vertical connecting plate, and the rigid horizontal supporting plate can be either barrel-shaped, or “匸”-shaped, or “匸”-shaped. status, etc.

[0042] In the present invention, the heater can be an electric heating element, or a heating element using the principle of magnetic field induction eddy current heating.

[0043] In the present invention, the circuit control device can be either a single-chip mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com