Drop pill for treating pharyngitis and its preparation method

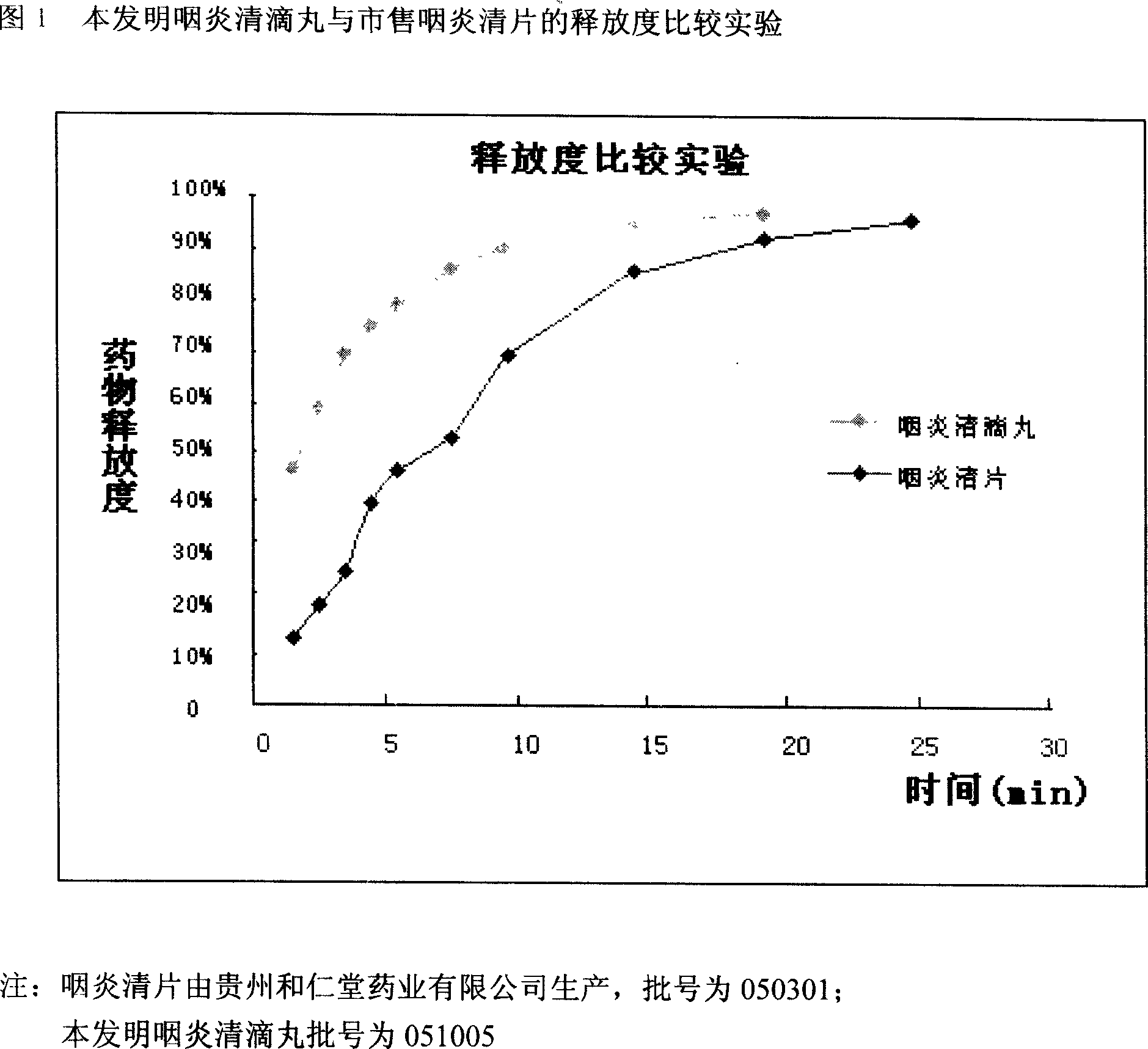

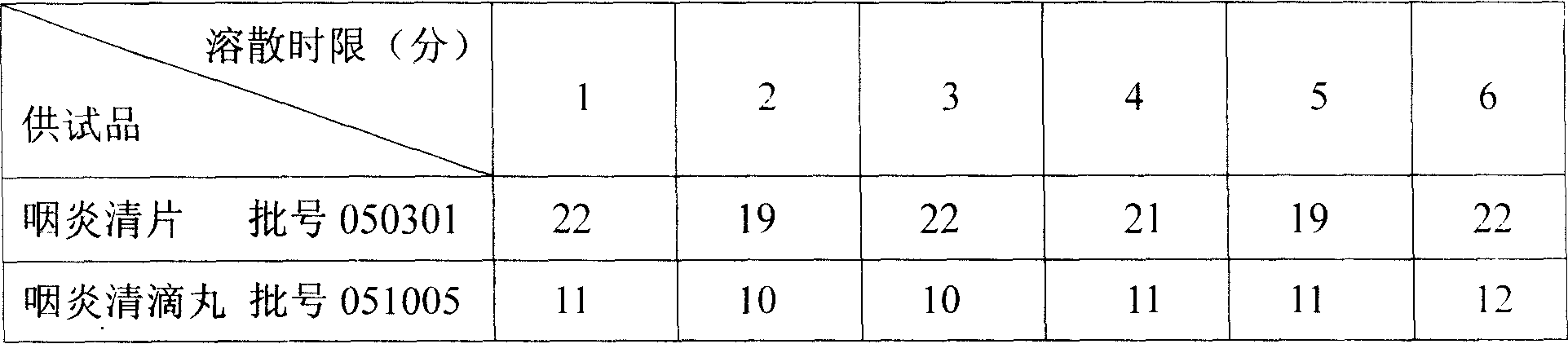

A technology for clearing dripping pills and pharyngitis, which is applied in the directions of pill delivery, pharmaceutical formulations, and medical preparations containing active ingredients, etc., and can solve the problems of many production processes of Yanyanqing tablets, slow onset of effect of Yanyanqing tablets, and large dosage of drugs. , to achieve the effect of flexible and accurate drug dosage, avoiding first-pass effect and stable drug quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Accurately weigh 15 g of sargassum, 0.025 g of natural borneol, and 0.05 g of menthol (sarcodon: natural borneol: menthol=300:0.5:1); add 3 times the amount of 70% ethanol for sarcodon, and heat and reflux for 1 hour , suction filtration while hot, combine the filtrates, reclaim ethanol to the extract with a relative density of 1.20 (20°C), spray dry it into a fine powder, crush the fine powder until all of it passes through a 60-mesh sieve; take 99 times the fine powder after the above-mentioned sieve Weight of polyethylene glycol 6000 (that is, PEG6000 content is 99% of the weight of the pill) is heated to 50 ° C to make it melt, add the above-mentioned fine powder under stirring, dissolve the natural borneol and menthol with 1ml of dehydrated alcohol and add after slight heating , stirred at 50°C for 30 minutes to make the dispersion uniform, evaporated the absolute ethanol, drained the air bubbles, and transferred the liquid medicine to the 50°C constant temperature ...

Embodiment 2

[0044] Accurately weigh 375 g of sargassum, 0.75 g of natural borneol, and 0.25 g of menthol (sarcodon: natural borneol: menthol=1500: 3: 1); add 20 times the amount of 70% ethanol for sargassum, and heat and reflux 4 times , each time for 1.5 hours, suction filtration while hot, combined filtrates, reclaimed ethanol to the extract with a relative density of 1.15 (20°C), spray-dried into fine powder, crushed the fine powder until all passed through an 80-mesh sieve; The polyethylene glycol 4000 of the same weight of the final fine powder (that is, the PEG4000 content is 50% of the pellet weight) is heated to 90°C to make it melt, and the above fine powder is added under stirring, and the natural borneol and menthol are cryogenically ground to a viscous liquid After adding, stir at 90°C for 15 minutes to disperse evenly, heat at 90°C until the air bubbles are exhausted, transfer the liquid medicine to the 90°C constant temperature storage tank of the dropping pill machine, use a...

Embodiment 3

[0046] Accurately weigh 150 g of sargassum, 0.375 g of natural borneol, and 0.25 g of menthol (sarcodon: natural borneol: menthol=600: 1.5: 1); add 8 times the amount of 70% ethanol for sargassum, and heat and reflux twice , each time for 1.5 hours, suction filtration while hot, combined filtrates, recovered ethanol to the extract with a relative density of 1.20 (20°C), and spray-dried into fine powder; take 40g polyethylene glycol 6000 and heat it to 80°C to melt it, and then Add the above fine powder under stirring, grind the natural borneol and menthol at low temperature to a viscous liquid and add it, stir at 80°C for 15 minutes to disperse evenly, keep warm at 80°C until the air bubbles are exhausted, transfer the liquid medicine to the dropping pill machine at 80°C In the constant temperature storage tank, use a dropping pill machine with a dripper diameter of 2.5 / 3.5mm and a dripper temperature of 80°C for dripping, the drop distance is adjusted to 6cm, the condensing ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com